Home / Articles / Bent channel

A bent channel is a steel profile similar to the letter P or U and is manufactured using special profile bending equipment.

Bent steel channel is easily weldable and can be used in various fields of activity, which gives you a reduction in the overall weight of the structure and material savings of approximately 30%, compared to other options for similar metal products.

Channel bending (rolling)

At first glance, this detail seems symmetrical.

In fact, its symmetry is very conditional and is associated only with the horizontal plane. This makes the process much more difficult. It can be performed as accurately as possible, without Herculean efforts and the risk of defects, only using special equipment. Bent channel is used to produce parts such as rings, arches and products of non-standard shapes. Deformed profiles are in demand in leading areas of production:

- in construction (for example, for installation of frames);

- in repair and finishing (production of frames for cladding, construction of partitions);

- in the installation of street advertising objects;

- in the production of frames for specialized equipment, including trucks, asphalt pavers, etc.

How to bend a metal strip into a ring?

In the process of building a house or cottage, there is often a need to equip drains, sewers, and metal frames.

When manufacturing such products, it is necessary to give the flat workpiece the necessary spatial shape. Advice from experienced craftsmen on how to bend a sheet of metal at home will allow you to produce good quality structures that will last a long time.

Bending technology - basic information

Metal bending is performed without welding seams, which avoids corrosion in the future and produces a product of increased strength. Deformation does not require significant effort and is usually performed in a cold state.

The exception is hard materials such as duralumin or carbon steels. Sheet metal bending technology is developed according to the assigned tasks in such options as:

- radius,

- multi-angle,

- single-angle,

- U-shaped.

A special case is flexion with stretching. This technology is used in the manufacture of parts with large bending radii and small diameters. When making parts with your own hands, the process is combined with operations such as cutting or punching.

Soft types of metals and alloys, such as brass, copper, and aluminum, are well suited for home processing. The production of products by bending is carried out on rolling or rolling machines, or manually.

The last procedure is quite labor-intensive. Bending is done using pliers and a rubber hammer. If the sheet is thin, use a mallet.

How to bend at right angles

To bend a bracket from a metal sheet, you will need a set of tools and accessories, consisting of:

- vice,

- hammer,

- power saws,

- bar,

- frames

The length of the strip is made according to the scheme, with the calculation that there should be a margin of 0.5 mm for each bend, plus another millimeter for folds on both sides. The workpiece is placed in a vice with squares. Clamping it along the fold line, process it with a hammer.

After this, the future bracket is unfolded in a vice, clamped with a frame and a block, and the other side is formed. The workpiece is pulled out, the required length of the sides is measured, making bends along the bottom.

Use a triangle to check the correctness of the angle, correcting inaccuracies with a hammer. When performing both operations, the workpiece is pressed with a block and a frame. The finished staple is filed to the desired size.

:

How to make a sheet bending machine yourself

To give the metal the desired configuration, tinsmiths use a sheet bending machine. But what should a master do if he doesn’t have special equipment at hand?

In fact, the question of how to bend sheet metal at home is easily resolved. It is enough to use your own ingenuity and basic equipment to make a simple machine.

To make a bender for a metal profile, you will need:

- I-beam 80 mm,

- fasteners (bolts),

- loops,

- corner 80 mm,

- clamps,

- a pair of handles.

You will also need a welding machine and a stable table on which the finished machine is mounted.

The basis of the device is an I-beam, to which a corner is screwed with two bolts, holding the workpiece during the bending process. Three door hinges are attached under it by welding. Their second part is welded directly to the corner.

In order for the machine to easily turn while bending sheet metal, handles are attached to it on both sides. The finished machine is secured to the table with clamps. Before laying the workpiece, the corner is unscrewed or lifted. The sheet is pressed, aligned along the edge and folded, turning the machine by the handles. The homemade device is only suitable for processing workpieces of small thickness.

:

Bending a metal sheet with a hammer

In order to bend a sheet up to 1.2 mm thick at a right angle, use the simplest tools - pliers (clamps) and a rubber hammer.

The processing is carried out on a flat wooden block. The fold line is drawn using a pencil and ruler. Then the sheet is clamped with pliers so that their ends fall exactly on the marking line.

The edge is gradually bent upward, moving along the fold. Once the angle approaches 90 degrees, the sheet is placed on the block and finally leveled using a hammer.

Narrow parts, such as tin edges, are made in this way.

Tip: Use a rubber or wooden hammer to prevent dents from forming on the metal. If bending is performed with a conventional tool, you need to take a textolite plate as a gasket.

It is convenient to bend sheets up to 2 mm thick on a desktop. The metal is positioned so that the marking line falls on the edge. A steel corner is placed under the material being processed.

The sheet is clamped in a vice using two wooden blocks. Bending is done using a hammer, tapping the metal from one end to the other. At the same time, the edge of the sheet is directed downward so that it ultimately lies completely on the corner fixed along the edge of the table. This method can be used to make products of any width, including boxes or barbecues.

:

Making pipes without using a machine

Home craftsmen have invented a lot of ways to bend a metal sheet into a pipe without using a machine.

We propose to consider the simplest option using a blank of suitable size. It is made from an old pipe of suitable diameter.

A sheet of metal is laid out on the floor and a piece of the required length is cut from it. To determine the required size, the required pipe diameter is multiplied by 3.14 and added 30 mm for the seam.

A pair of tubes are welded to the blank on both sides, perpendicular to one another. The crowbar should be freely inserted into their holes.

Master's recommendation: by bending a metal sheet using a blank, it is convenient to make pipes no more than a meter in length.

To use the device, the effort of three people is required. The blank is placed on the edge of the sheet. One person stands on top, two others screw the metal onto the blank, turning the crowbar 90 degrees.

The entire length of the sheet is rolled in this way, the remaining edge is hammered. The seam is secured by welding.

:

It must be taken into account that the bend radius of sheet metal depends on its thickness and manufacturing method. Hot rolled steel is more suitable for pipes; profile products are made from cold rolled steel. (

15,00

Channel bending along the radius

On thematic websites and in specialized literature you can find the term “radius channel bending”, or “radius bending”.

It differs from the usual one in that it is carried out strictly for a given amount. Such precision can only be achieved with the help of a profile bender, and before working with a batch of products, be sure to bend one or two prototypes and evaluate the result. Taking into account the characteristics and capabilities of the material helps to produce accurate plastic deformation and avoid consequences such as kinks and violations of the channel geometry.

Our advantages

Need to order sheet metal rolling? We know how to solve your problem. Our company’s specialists are true masters of their craft who:

- have extensive work experience;

- familiar with various modern metal processing techniques;

- We carry out orders of any complexity.

We guarantee high-quality metal rolling and other related services, without which no construction project can be completed. Our quality and affordable prices in Moscow are not a luxury, but a necessity.

Metal has an irresistible charm. It combines beauty, durability and the ability to be used in thousands of different ways. Metal processing is as exciting a process as the material itself, which has amazed humanity for centuries. All modern machines and devices of the most technologically advanced industries that require metal elements. Their production process is still being improved. Thanks to digital control devices, we are able to offer customers the highest quality and precision at low prices.

Basic methods of bending beams and channels

The channel, like its closest relative - the I-beam, can be bent in three directions: along the flanges, that is, in the horizontal plane, and along the walls (vertically).

In the latter case, bending can be carried out with the shelves inward or outward. According to the characteristics of the deformation that the workpiece acquires, smooth bending and local bending are distinguished. The result of a smooth part is a curved part with one or more radii. With a simpler, local one, a profile is formed with straight ends joined at the desired angle (usually by welding). The advantage of smooth channel bending is that it does not violate the integrity of the workpiece and does not have welds, which, despite their strength, become “vulnerable zones.”

And finally, according to the technology used, bending can be manual or automatic. Manual is performed according to a pre-drawn radius template. When working with hard materials such as steel, an acetylene torch is used to heat the bending zone. This operation can be carried out even in a garage, but a high-quality result is not guaranteed.

In contrast to this semi-handicraft method, automatic bending of the channel on profile benders helps to avoid heating the workpiece, and due to the system of rollers that the profile passes through, the radius can be maintained as accurately as possible. This method is also distinguished by its versatility, efficiency and the possibility of mass processing of workpieces.

How to bend a strip of metal into a circle? — Machine tools, welding, metalworking

page » Metalworking - metal bending

A series of articles devoted to metal processing continues on our website. We talked about how sheets and rolls from the delivery state are unraveled into strips (strips) in the article “Metal slitting lines.”

Metal bending is done using specialized equipment or manually. We described how this happens with imported equipment using the example of products from the Italian machine tool concern WARCOM. We talked about the use of domestic sheet bending machines for these purposes in an article about the Lipetsk sheet bending plant.

Today we will talk about manual bending of strip metal.

Manual bending of strip metal

Manual processing of metal strips is a labor-intensive operation, in most cases requiring special training of the worker and the appropriate tools. This operation is performed by a mechanic at a specially equipped workplace:

- a mechanic's workbench equipped with an appropriate vice;

- set of locksmith tools.

Let's look at a few simple operations with strip metal.

Right angle bending

We will bend the strip steel in a bench vice. Place the workpiece (clamp it) in a vice.

Bending in a vice.

We do this in such a way that the side with the bending point faces the stationary jaw of the vice (away from the worker). In this case, the mark should be approximately 0.5 mm higher than the jaw of the vice.

Hammer blows should be applied in the direction of the stationary jaw of the vice.

To avoid injury (if the workpiece springs back), the mechanic, when performing this operation, should not be positioned in the path of the hammer.

Bending at an acute angle

In this case, a mandrel having the required angle is used. It is installed in a vice along with the workpiece, as shown in the figure (with the high side facing the workpiece). The workpiece is deformed by hammer blows until it touches the bevel of the mandrel.

Manufacturing of staples and clamps

To make a bracket, you should use a frame block, the thickness of which will be equal to the opening of the bracket. Next, you should fasten the strip with the mandrel in a vice, as indicated in the figure, and bend first one side, and then the other.

Manufacturing of staples and clamps.

To make a clamp, fix the frame in a vice and bend a strip on it (see figure). Then, bend the ends of the clamp, release the equipment from the vice and use a hammer to give the part its final shape on the workbench table.

Hammer blows should not be applied to the clamp itself, so as not to leave scratches, nicks and dents on it. They should be carried out through a copper plate of small thickness, since it will well redistribute the impact force.

Bending connection

Strip bending is widely used for bending joints of parts. The connection can be completely bendable, as shown in the figure. Here, the fastening force is created by bending one part (often all connected parts are deformed).

In a number of cases, strip bending plays a supporting role. It can, for example, strengthen a threaded connection.

Examples of bending connections.

The figure shows examples of strip bending and strengthening of a nut-bolt threaded connection: a cotter pin and a lock washer.

Edge bending

The operation is performed on the roller machine shown in the figure.

Bending steel strip “on edge”.

There are two features of this machine to consider:

- the upper guide of the base bar must have a groove that exactly matches the size of the deformed metal strip;

- The working roller and the top of the strip must be lubricated with grease.

These are the basic simple techniques for manually bending strip metal.

At the addresses indicated here you can select and purchase a metal bending machine.

Metal landing. Angle bending along the radius. Malkovanie

Metal landing. Angle bending along the radius. Malkovanie. 5.00/5 (100.00%) lost 7

Metal landing.

Sheet metal bending, called upsetting, is used in cases where one sheet must overlap the edge of another sheet (Fig. 1).

Types of metal bending. Three-roll rollers. Four-roll rollers.

Calculation of metal bending. Bending thick metal. Minimum metal bending radii.

Upsetting is carried out in a cold or hot state of the metal manually or on upsetting machines (roller, eccentric) or on presses. On eccentric machines and presses, the sheet is planted simultaneously along its entire length or gradually in separate sections. When upsetting on roller machines, the sheet is passed between the rollers.

Fig.1. Planting the edges of sheets.

.

Profile bending. Angle bending along the radius.

Profile metal is bent by hand or on rollers. Profile metal (angle) with small radii of curvature is bent in a heated state to avoid distortion of the profile.

The profile metal in a heated state is bent by hand on frame plates. Frame slabs are straightened (straightened) slabs with holes into which rods are inserted according to a template. The metal is bent along the rods (Fig. 2). Angle metal can be bent with a shelf outward or inward.

Rice. 2. Bending according to a template on a frame plate.

In the first case, the horizontal shelf is subjected to tension, in the second - compression with the formation of folds. To eliminate distortions in both cases, it is necessary to correct the vertical and horizontal flanges, followed by checking with a square.

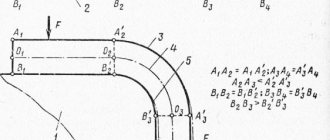

Rice. 3. Ring bending device:

1 — disk with recess; 2 - strip; 3 — fastening the end of the strip; 4 - roller; 5—handle; 6 - wing nut.

Rings made of profile metal are bent on a special device shown in Fig. 3.

Rice. 4. Position of the rollers for bending the corner.

Angle bending machine

A further step in improving devices for bending profile metal is a driven bending machine with four rollers for bending corners (Fig. 4). Bending of angles of various profiles is performed on composite rollers.

Rice. 5. Cutting the corner flanges for bending at an angle:

a - cutting down the shelf; b - bent position.

In the latest machines, the rollers are given shapes that match the contours of the metal profile.

Bending machines for profile metal are used mainly for parts with large bending radii; For small radii, it is more advisable to bend manually in a heated state.

In order to bend profile metal at an angle, the shelf is cut, bent and welded by electric welding, as shown in Fig. 5.

Planting of profile metal (corners) at the ends and in the middle part of the strips is done manually (Fig. 6) or on machines in a heated state.

Fig.6. Planting a corner.

Removal of profile metal.

An operation close to disembarkation is metal stripping. When the dihedral angle decreases, the profile angle changes to acute or obtuse (Fig. 7).

Fig.7. Removal of profile metal.

a - formation of an obtuse angle; b - formation of an acute angle; c - change in the position of the box-shaped metal flange (channel).

Steel channel bending

The technology and quality of steel channel bending largely depend on the type of material.

Carbon steels that are simpler in composition are more susceptible to deformation. The effectiveness of the same operation on alloyed ones depends on the inclusions of other elements: some of them reduce the ductility of the material and can negatively affect the process. The method of manufacturing the channel also makes its contribution: it is known that a profile produced by the cold method tolerates deformation better than a heat-treated - hot-rolled one. Some types of steel (for example, especially strong structural steel) can only be bent after preheating.

Features of channel bending

In order for radial bending of a channel to be easy for the performer and harmless for the profile, the process cannot be approached “on the fly, with a turn.” Preparation is no less important than the technical implementation itself. To avoid problems, you must:

- study the properties of the workpiece in detail;

- determine the force that will be needed to bend it;

- calculate deformation values;

- configure the equipment.

And, as we have already mentioned, “practice” on a signal sample, take into account negative experience, if any, and only then proceed to serial production.

Manufacturing of bent channel

20 Jul 2013 Category: Mechanics | 2

The production of a double sequential “V”-shaped flexible bent channel on sheet bending machines (press brakes) from rectangular sheet blanks is one of the most widespread technologies for single and small-scale production...

...formed profiles in mechanical engineering and construction.

In this short article we will briefly look at the technological process of manufacturing a bent channel and perform calculations in Excel of some important, in my opinion, technological dimensions.

The manufacturing technology of a bent channel is shown in four figures below.

1.

Place the workpiece by pressing it against the working surface of stop No. 1.

2.

Press the pedal of the sheet bender and make the first bend.

3.

Let's reinstall the semi-finished product by pressing it against the working surface of stop No. 2.

4.

Let's press the pedal of the sheet bender - make the second bend - the channel is ready!

To perform the above operations, it is necessary to calculate several technological dimensions in Excel

Initial data: we need a bent sheet of thickness S

with internal bending radii

R

, height

H

and flange width

B.

Algorithm of actions:

1.

Let's determine the dimensions of the workpiece - calculate the length of the profile development

- L.

2.

Let's determine the distance from the edge of the workpiece to the axis of the fold line -

a

.

3.

Let's calculate the coordinates for installing stop No. 1 -

U 1

.

4.

Let's calculate the coordinates for installing stop No. 2 -

U 2

.

5.

To determine the technological feasibility of manufacturing a bent channel with given dimensions, we calculate the size from the edge of the free flange of the channel to the axis of the matrix -

c

and check whether the channel at the end of the punch stroke does not rest on its side surface.

If you do not have MS Excel on your computer, you can perform the calculation in Calc from the free Open Office package.

The initial data is in cells with a light turquoise fill, the calculation results are in cells with a light yellow fill.

Fill the cells with the original data:

1.

the height of the channel

H in millimeters

in cell D3: 200

2. the width of the channel flanges B in millimeters

to cell D4: 80

3. the thickness of the wall and shelves S in millimeters

to cell D5: 4

4. the internal bend radius R in millimeters

to cell D6: 6

Excel will perform the subsequent calculation based on this data and produce the five required technological dimensions.

Calculation in Excel is performed using the formulas:

5. the development length of the channel section L in millimeters

in cell D8: =2*(D4-D5-D6)+D3-2*(D5+D6)+PI()*(D5/LN (1+D5/D6))=344,600

L =2*( B - R - S )+ H -2*( R + S )+3.14*( S /ln (1+ S / R ))

6. the distance to the fold line from the edge of the workpiece a in millimeters

in cell D9: =D4-D6-D5+PI()/4*(D5/LN (1+D5/D6))=76.150

a = B - R - S +3.14/4*( S /ln (1+ S / R ))

7. Distance for installing stop No. 1 from the axis of the matrix U 1

We calculate in millimeters

in cell D10: =D8-D9=268.450

U 1 = L -a

8. Distance for installing stop No. 2 from the axis of the matrix U 2

We calculate in millimeters

in cell D11: =D3-D5-D6+PI()/4*(D5/LN (1+D5/D6))=196,150

U2 = H - S -R+3.14/4*(S/ln (1+S/R))

9. the distance from the edge of the free flange of the channel to the axis of the matrix c in millimeters

in cell D12: =(D3-D4-D5)*(20.5)/2=82.024

c =( H - B - S )*(20.5)/2

The side surface of the punch should not be at a distance greater than

c .

Otherwise, during the bending process, the channel will rest against the punch! In our example, this does not threaten to happen, since the value of c is very large - 82.024 mm! It is unlikely that for any reason the punch will be made with a total thickness of about 160 mm (two sizes c)! I recommend looking at the related articles “Calculating the force of a sheet bender”, “Calculating the length of the development”, “All about the bent channel” and “All about the bent angle”.

Dear readers, to receive announcements of my blog articles, please subscribe in the “Subscribe to news” window located at the top of the page. Enter your email address and click on the “Receive article announcements” button.

Occasionally, you will receive a small notification in your inbox about the appearance of a new article on my blog, its title and a brief description.

If you don’t like something or just get tired of the author or topic, you can always unsubscribe right in the mail.

I look forward to your comments!

Link to download the file: izgotovlenie-gnutogo-shvellera (xls 31.5KB).

Other articles by the blog author