What can be forged from a profile blank?

Profile pipes include products whose cross-section is not round. It can be oval, rectangular or square. The difficulty of processing lies in maintaining the maximum load on the walls of the workpiece. If this is not provided for, a rupture may occur and the integrity of the structure may be compromised.

Using cold forging, you can make the following elements from a profile pipe:

- Arcs. The most common type of processing. Greenhouses and frames of complex structures are made from the blanks.

- Spirals and curls. Unlike rods, they have a large bending radius, which is due to the likelihood of rupture. Used for fences, gates and decorative grilles.

- Volumetric spirals. They can become the basis for decorative decorations.

- End flattening, forming clamps to connect parts of the pattern.

Unlike stamping, during cold forging the metal of the profile pipe practically does not flow. This allows you to maintain its original dimensions and strength parameters.

Design options

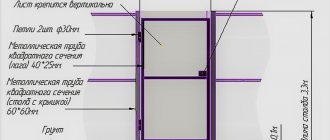

There are a lot of design ideas for designing a gate made of corrugated sheets. Forging makes it possible to add originality to any product.

Forged door with polycarbonate

Classic way

Lattice structures made from corrugated sheets are the simplest and most popular. Despite their apparent simplicity, they look very beautiful.

After installing the sash with your own hands

A popular way of decoration is forged gates with a wicket built inside. Every craftsman can make and install such a product. In this case, you do not need to have much blacksmithing experience.

Sometimes this design is not entirely successful, since it is difficult to add artistic forging.

Structurally, the product already contains a large number of forged elements. But often there is a rather beautiful and original version.

Wrought iron gate at the dacha

Its secret is that the gate is, as it were, disguised. Forged decorations and decoration add originality to this design.

Forging tools and accessories

To manufacture forged products from profile pipes, it is necessary to use special tools and devices. You can make them yourself from scrap materials, order them from an experienced craftsman, or purchase factory models. You should also arrange a work area - a functional table, and provide space for forging long pipes.

To process small workpieces, you can use a tabletop with dimensions of 2000*1500 mm. It houses the main tools and devices for the production of products from profile pipes.

Gnutik

Designed for making arcs of various diameters. The machine consists of a T-shaped base on which support rollers are located in pairs. On the vertical stand there is a support roller, the height of which is adjusted using a threaded mechanism.

- Possibility of replacing rollers for bending pipes of various sections;

- Changing the distance between support elements to vary the radius;

- When making it yourself, it is recommended to use a U-shaped metal profile with a thickness of at least 2 mm.

The design of the bend for profile pipes differs from the traditional one. It is impossible to make a high-quality bend without evenly distributing the load over the entire surface. The average cost of a homemade model is 9,600 rubles.

Twister

Used for twisting profile pipes for artistic purposes. For processing, it is recommended to use models with a plowshare, which facilitates the manufacturing process, reduces the time of controlled deformation, and improves its quality.

The machine consists of a base on which a movable block for fixing the workpiece and a mechanism with a plowshare for twisting are mounted. Main equipment parameters:

- Maximum and minimum length of processed products.

- Section of the workpiece, its dimensions. They depend on the shape of the fastening mechanism;

- Drive type – manual or mechanical. To produce forged products from profile pipes at home, budget models with manual drive are most often used.

The price of a complete set is from 16,800 rubles.

Snail

It is used to make spiral-shaped components. The device consists of a square or rectangular platform. There are holes on it for installing supporting arc elements. A pipe end is used to secure the pipe. The bend is formed by the action of a lever mechanism with a support roller.

Snail characteristics:

- maximum and minimum bend radius;

- workpiece size;

- permissible degree of mechanical impact.

The average cost of a household snail for bending profile pipes is 12,000 rubles.

Types of cold forging

In the manufacture of metal products, 7 types of cold forging can be distinguished. These are a kind of stages of creating elements that need to be performed when working with blanks.

All work must be carried out in accordance with the requirements and rules, otherwise you should not hope to receive a beautiful forged product.

The most important stage is forging metal blanks. This is the largest, most responsible, complex and serious process, so you need to treat it very carefully. Cold forging can be of several types:

- Upsetting - it is performed under high pressure. This is necessary in order to increase the workpiece on the sides by reducing its height.

- Broaching - this stage is performed by heating a metal part and then hammering it. This is necessary in order to reduce the cross-sectional area by increasing the length of the metal rod.

- Firmware - this stage involves making holes inside the workpiece. When doing this work, you can get holes of different diameters and lengths. It can be open or closed.

Upsetting and broaching makes the structure of the metal workpiece more fragile, so further work must be carried out very carefully to prevent breakage of one or another part of the structure.

- Stamping - at this stage, plastic deformation of the metal occurs, which leads to a change in the shape or size of the workpiece. Stamping can be volumetric or sheet. In the first option, work is performed under pressure. In this case, the part is heated and pressed to the desired size. This method is more suitable for production scale, when you need to make a large batch of identical elements. Sheet stamping differs from the first option in that the parts are made from sheet iron. This method is suitable for the manufacture of small or medium-sized parts, and they will be of high quality and durability.

- Pressing - at this stage, the density of the metal workpiece increases and its shape changes due to high pressure. Pressing can be direct or reverse. With the direct method, metal blanks are extruded through various holes, which leads to the production of various rods, pipes and profiles. In reverse pressing, metal products are placed in a special mold, while pressure is applied in the opposite direction.

- Drawing is the process of drawing metal, only already pressed, through a special matrix. With this processing method, various shaped profiles, wires or thin pipes can be obtained.

- Rolling is the final stage of processing, which involves the law of friction. When special rollers rub against a metal surface, the workpiece becomes deformed. Rolling can be of several types, depending on the method of rotation of the rollers:

- longitudinal - in which the rollers rotate in different directions. This leads to a gradual compression and elongation of the metal part. In this way, sheet and strip iron is produced;

- transverse - in which the movement of the rollers occurs in one direction. This leads to deformation of the workpiece in the transverse direction. This method is used to produce cylindrical gears with knurled teeth;

- screw - in which the arrangement of the rollers is made at an angle to each other. In this case, the workpiece passes simultaneously through two rollers with translational and rotational motion, which makes it possible to obtain a small gap into which the metal falls. In this way, pipe blanks, “sleeves,” are obtained.

Machine tools as an alternative to tools

If you plan to organize home production, and not perform one-time work, it is best to purchase a combined machine for cold forging. It will take up significantly less space than the equipment separately.

Most models have an electric drive, which speeds up the production process. Contents and functionality depend on requirements. The average cost of such equipment is from 60,000 rubles.

Recommendations

Special requirements are placed on the alignment of the rollers: they must be located in the same vertical plane and be strictly parallel. Any misalignment will lead to uneven compression of the profile, which will significantly reduce the quality of the rolled product.

A machine made at home specifically for strengthening profile pipes should not pose a danger to humans during operation. During assembly you should:

- Fix all moving parts as reliably as possible. Prevent them from bouncing during operation.

- Provide protective flaps.

Properly assembled home-made installations are not inferior to professional models in terms of the quality of their products.

Home page » machines for cold forging of profile pipes

On this page you will find information on the topic “cold forging machines for profile pipes”, as well as links to other pages of our website that are related to this topic. Read the detailed information below, to find out more, please follow the links that interest you; at the end of the page there is a list of pages with this label.

Machine "BLACKSMITH UNV-3-220".

In various metal structures, profile pipes - rolled metal, the blanks of which have a cross-section different from round (square, rectangular, oval). to increase the number of products manufactured using profile pipes. This section is dedicated to this list of equipment.

In addition, the following equipment is in use in cold forging technology for bending workpieces of different sections:

- universal machines;

- special machines (manual, hydraulic, electromechanical), among which devices (snails) for making workpieces in the form of curls and spirals, as well as benders for producing arc-shaped elements are in particular demand; with the help of conductors of different configurations it is possible to obtain elements of different shapes;

- tools.

Brands, brands, manufacturers

From the rich variety of foreign and Russian manufacturers, the following companies can be distinguished, based on customer reviews:

- Manual pipe benders:"Stalex" (the main production is in Europe), "Smart&sol >

- Electromechanical pipe benders: “Blacksmith” (a popular Chinese manufacturer of equipment for cold forging in Russia).

Hydraulic pipe bender Stalex HB-60 Premium. Photo VseInstruments.ru

Making a machine yourself

It doesn't always make sense to purchase a professional machine. For one-time work, simple DIY installations are more suitable. The main thing is to have drawings, carefully study the design principle and operation of the machine, select high-quality materials for the workpieces and the necessary tools for assembly.

Scheme

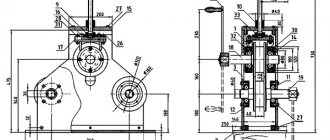

Schematic diagram of a machine for rolling 2 types of profile sections in section. Based on it, you can get an idea of the design and interconnection of the main components and the principle of pipe processing. In this case, the upper shaft is the driving one.

Machine diagram

Accessories

Rolling roller components must not have chips or gouges, have a decent margin of safety, and be made from certain grades of steel.

Shafts and axles are turned on a lathe. Some components can be bought in a store or removed from other mechanisms, for example:

- self-aligning rolling bearings (4 pcs.);

- stars (4 pcs.);

- chain from a bicycle, moped.

To assemble the frame (base), you will need rolled metal (channels, pipes), sheets 5-10 mm thick. The base ensures stability of the installation during operation.

Frame assembly

To strengthen the profile, it is better to make rollers (2 pieces of each type) from alloy steel; for a small amount of work, St3, St10 are also suitable. Roll blanks are subjected to hardening.

Rollers and axles must be many times harder than the pipes being processed. Otherwise, the rollers will have to be replaced frequently with new ones. The hardness of rollers on professional installations is at least 52 HRC.

Tools

When assembling the machine, you will need the following skills (as well as appropriate equipment):

Fastening by welding in some places can be replaced with threaded connections.

- drill, with a set of drills;

- wrenches of different sizes;

- level for setting the horizon line;

- caliper, tape measure.

Design of incoming parts

Special rollers are machined along the edges of the rollers, which reliably fix the position of the pipe during rolling.

Rollers

You can get the dimensions of the rollers for profile drawing from a kit from professional installations. It is not difficult to develop drawings of rollers and axles according to the obtained dimensions yourself. Below is an example drawing.

Roller drawing

Rolling of each profile size is carried out using rollers of appropriate sizes. Making a model with removable elements is not easy; for this reason, it is recommended to make multi-stage rollers for reinforcing the profile pipe when assembling the machine yourself. This will allow processing of pipes of different sizes without reinstalling the rollers.

Both axes have the same dimensions, but different lengths. The movement handle is attached to the longer axis (driving). Below is a drawing of an axle with a seat for the handle.

Drawing of an axle with a seat for the handle

Assembly work

The frame is created gradually as the remaining parts are assembled. The individual elements of the base are connected to each other by welding or large bolts.

The distance between the upper and lower axle depends on the diameters of the rollers. In the absence of precise assembly drawings, the dimensions between the axes are determined experimentally:

- install the rollers on the axle;

- measure the distance between the axes;

- drill holes on the side walls of the frame for installing bearings;

- then the axles are put aside and the bearings are installed.

The connection between the axle and the rollers is carried out in several ways:

- using a key, about 8x8 mm in size;

- welding through pre-drilled countersunk blind holes made with a large-diameter drill.

The second method is available if you have a machine for manual electric arc or semi-automatic welding.

Next, the axle is inserted into the bearing, which is pre-fixed in the axle box, which is pre-welded to the wall of the frame from the inside. Reliability of fastening is maximum. First of all, the axles with rollers are installed in the side wall of the frame where the chain drive is supposed to be located. Then the axles are inserted into bearings mounted on the 2nd side wall of the frame.

After installing the main elements, the frame is strengthened:

- welding seams;

- threaded connections.

The assembly of the chain mechanism in practice also occurs with the determination of dimensions on site:

- install the 1st sprocket on the lower axle;

- on the upper axis - 2nd sprocket;

- try on the chain, mark the location of 2 more sprockets.

Assembling the chain mechanism

The rollers should rotate without difficulty when the chain is tensioned. The handle is welded to the drive axle last.

Chain mechanism

For the motion feed mechanism in the form of a worm gear, it is necessary to stock up on gears of the required size.

Motion feed mechanism

Making a simple part on a machine

The strip steel workpiece is cut to the required size. This size is usually clarified by drawing the finished product and its component elements.

The free end is placed in the center of the spiral. The workpiece is secured using an internal screw.

The “Snail” rotation is performed. The workpiece is pressed tightly against the guides. This requires some effort to obtain the desired product profile.

By turning the device further, a curl is made. If necessary, insert the other end of the workpiece and make a closed or open curl.

Usually the other end does not stay straight. It is also bent. Therefore, a distinction is made between internal and external reverse curls. Marks are made on the device itself using a marker or chalk. They are used as a guide when making curls with the required parameters.

Step-by-step manufacturing of a small-sized manual machine for making curls

A small machine is designed for the production of curls from rolled strip with a width of 20...30 mm. It's easy to make it yourself.

Center

First the center is made. To do this, a small fragment of round timber is sawed off. The workpiece is fixed in a vice and the cutting line is marked. Using a cutting disc and an angle grinder, the workpiece is sawed off.

It has a diameter of 38 mm. The side surface is not further processed.

The center length is 28 mm. A little more is possible, but this is enough to bend a strip 30 mm wide.

A hole Ø 8 mm is drilled on a drilling machine. It is placed eccentrically. This situation is due to the fact that it is necessary to make a clamp for the end of the workpiece.

Examples of products with curls

Original canopy over the entrance to the building:

When decorating a French balcony, original curls give an openwork look to the entire product.

On a flight of stairs, the curls look very original.

Using only curls, they make supports for the bench, and also create a grate for the fireplace in the same style.

The hand of an excellent craftsman is visible on the spiral staircase. Not everyone will be able to make such a product.

The gate leaf contains elements made on the “Snail” machine. The heavy product acquired a special lightness.

Light staircase in high-tech style. It can decorate not only a country house. Modern palaces with minimalist design can have an excellent appearance.

The scope for creativity is unlimited. Many blacksmiths are true artists. They decorate the world around them.

Video: “Snail” – do-it-yourself cold forging.