Steel 35 structural carbon quality

A variety of materials can be used to create various parts and mechanisms. Among the metals, steel 35 should be noted. It belongs to the class of high-quality carbon structural steels and is considered the most affordable offer. Steel 35 (GOST 1050-88 previously determined the basic qualities and chemical composition, now it has been replaced by GOST 1050-2013) is used to produce industrial fasteners of various types.

Types of delivery

Steel 35 is supplied in the form of sheets, long and shaped rolled products, ground wheels, rods, silver bars, wire, strips and strips, sheet steel, forgings, pipes. The exact data is given in the table.

Types of material supply 35

| B03 - Metal forming. Forgings | GOST 8479-70; |

| B22 – Long and shaped rolled products | GOST 2591-2006; GOST 9234-74; GOST 1133-71; GOST 11474-76; GOST 2879-2006; GOST 2590-2006; |

| B23 - Sheets and strips | GOST 82-70; GOST 14918-80; GOST 19903-74; GOST 16523-97; GOST 103-2006; |

| B24 - Tapes | GOST 3560-73; |

| B32 – Long and shaped rolled products | GOST 8559-75; GOST 1051-73; GOST 14955-77; GOST 7417-75; GOST 8560-78; GOST 1050-88; GOST 10702-78; |

| B33 - Sheets and strips | GOST 4041-71; GOST 1577-93; GOST 4405-75; |

| B34 - Tapes | GOST 2284-79; |

| B62 — Steel pipes and connecting parts for them | GOST 12132-66; GOST 8638-57; GOST 8645-68; GOST 24950-81; GOST 8646-68; GOST 53383-2009; GOST 8642-68; GOST 20295-85; GOST 6856-54; GOST 8644-68; GOST 23270-89; GOST 13663-86; GOST 3262-75; GOST 8639-82; GOST 8731-87; GOST 8732-78; GOST 8733-74; GOST 8734-75; GOST 9567-75; |

| B71 – Low carbon steel wire | GOST 792-67; GOST 1526-81; GOST 5663-79; |

| B72 – Medium and high carbon steel wire | GOST 9389-75; GOST 17305-91; GOST 26366-84; GOST 3110-74; GOST 3920-70; GOST 7372-79; GOST 9850-72; |

Main characteristics

The main characteristics largely determine the scope of application of the metal. Steel 35 is characterized by the following qualities:

- The density of Steel 35 is 7826 kg/m 3 at a temperature of 20 degrees Celsius. It is worth considering that the indicator decreases with increasing temperature. A serious increase in temperature leads to a restructuring of the structure, it becomes more plastic. The density indicator is taken into account when carrying out various calculations. For example, it is necessary to calculate the pressure exerted on supporting structures.

- When choosing a metal, attention is paid to the hardness indicator. In the case under consideration, the hardness is 163 MPa. M35 steel can be subjected to various heat treatments, which are aimed at increasing the hardness of the surface layer. Normalization technology is often used as a heat treatment, which makes the structure more uniform and resistant to high loads.

- The degree of weldability is limited. That is why it is recommended to preheat the workpiece. By heating the structure, it became possible to use various welding technologies. To improve the quality of the resulting seam, additional heat treatment is carried out after welding.

- The structure is not prone to temper brittleness. During heat treatment, tempering is performed, which reduces internal stresses. Too high fragility means that structural cracks may appear during impact or other dynamic loads.

- The material is being cut. This property determines that the material is often supplied to machine-building plants where a large amount of turning and milling equipment is installed. The supplied workpieces can be processed using conventional cutters. The quality and speed of processing can be significantly improved by using cutters with carbide inserts.

Mechanical properties st 35

The metal in question can be forged at a temperature of 1280 degrees Celsius. Cooling can be carried out using oil or in the open air, the choice is made depending on the size of the workpiece.

Tempering of high-speed tool steels

The main alloying elements of high-speed steels (P18, P6M5, etc.) are tungsten, molybdenum, cobalt and vanadium - elements that provide heat resistance and wear resistance during operation. High-speed steels belong to the carbide (ledeburite) class. For hardening, these steels are heated to a temperature above 1200°C (P18 to a temperature of 1270°C, P6M5 to a temperature of 1220°C). High quenching temperatures are necessary for more complete dissolution of secondary carbides and obtaining austenite highly alloyed with chromium, molybdenum, tungsten, and vanadium. This ensures that heat-resistant martensite is obtained after quenching. Even at very high heat, only part of the carbides dissolves. These steels are characterized by the preservation of fine grains at high heating temperatures.

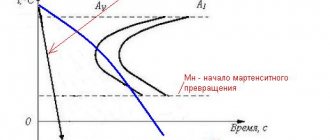

Iron and “quick-cut” alloying elements have very different thermal conductivity properties, therefore, when heating, temperature stops should be made to avoid cracks. Typically at 800 and 1050°C. When heating a large instrument, the first exposure is made at 600°C. The holding time is 5-20 minutes. Holding at the quenching temperature should ensure the dissolution of carbides within the limit of their possible solubility. Cooling of the instrument is most often done in oil. To reduce deformation, stepwise hardening is used in molten salts at a temperature of 400-500°C. The structure of “quick cuts” after quenching consists of highly alloyed martensite containing 0.3-0.4% C, undissolved excess carbides and retained austenite. The higher the quenching temperature, the lower the position of points Mn, Mk and the more retained austenite. In R18 steel there is approximately 25-30% retained austenite, in R6M5 steel - 28-34%. To reduce austenite, cold treatment can be done, but as a rule this is not required.

After quenching, tempering follows at 550 - 570°C, causing the transformation of retained austenite into martensite and dispersion hardening due to the partial decomposition of martensite and the release of dispersed carbides of alloying elements. This is accompanied by an increase in hardness (secondary hardness). During the holding process during tempering, carbides are released from the retained austenite, which reduces its alloying, and therefore, upon subsequent cooling, it undergoes a martensitic transformation (Mn ~ 150°C). During a single tempering process, only part of the retained austenite is transformed into martensite. In order for all the austenite to transform into martensite, two and three times tempering is used. The holding time is usually 60 minutes. When assigning a regime, it is necessary to take into account the chemical properties of the elements and the frequency of carbide release depending on temperature. For example, the maximum hardness of R6M5 steel is obtained through 3-stage tempering. The first tempering is at a temperature of 350°C, the next two at a temperature of 560-570°C. At a temperature of 350°C, cementite particles are released, evenly distributed in the steel. This contributes to the uniform release and distribution of special M6C carbides at a temperature of 560-570°C.

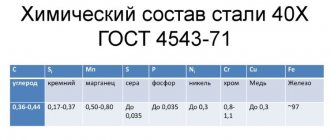

Chemical composition

Various chemical elements can change the performance characteristics of the resulting materials. Steel grade 35 is characterized by the following ratio of chemical elements:

- The main composition is iron. It is included in the composition of almost all alloys, in this case the concentration is about 97%.

- Hardness and other qualities are associated with carbon. In the case under consideration, the concentration of this chemical element ranges from 0.32 to 0.4%.

- The composition includes silicon, manganese and nickel. They determine the main operational characteristics. Nickel concentration is no more than 0.25%, manganese in the range from 0.5 to 0.8%. Silicon accounts for only 0.17-0.37% of the composition.

Steel sheet 140x500 mm steel 35

Harmful components are kept within a certain range, which allows for higher performance. Modern production technologies make it possible to improve the quality of the material.

Interpretation of steel: index 35 shows that the alloy contains 0.35% carbon, and the remaining elements make up an insignificant amount.

Application in various industries

Due to its resistance to impact loads, grade 35 steel can be used for the manufacture of fasteners: bolts, studs, nuts.

Since weldability is limited, this does not allow the grade to be widely used.

In mechanical engineering, metal is used only to create elements that do not suffer from wear.

In construction, grade 35 is used in the construction of water pipelines and the installation of reinforced concrete slabs. Plumbing products cannot do without 35 steel. Many factories use this steel and its analogues to produce enameled bathtubs and sinks, which are later used in construction.

Most of this steel grade is used for the production of rolled metal elements. Various steel mesh, sheets, corners and more. Often the 35th grade is used for the production of pipes of different diameters. This is due to the fact that steel “grabs” well when welded to any other pipe. Rods are often made from 35, which are then often used to create reinforced concrete slabs. Often the simplest metal parts are used for domestic purposes.

Steel 35 may not be the standard of quality and reliability, but it can be used in absolutely any industry. The popularity of this alloy is explained by its price; the metal is suitable for many purposes and does not have a high price.

Source

Application of steel 35

As previously noted, the metal in question is widely used. This is due to the low production cost and fairly high performance characteristics. The alloy is often used to produce the following parts:

- Characterized by low strength and experiencing low stress. This group includes crankshafts, axles, cylinders, rims, traverses and others.

- Various fasteners: bolts, nuts and studs. They are cheap, but cannot be used in the manufacture of wear-resistant parts.

When choosing this alloy, it should be taken into account that due to the fairly high carbon concentration, the degree of weldability is significantly reduced. Therefore, in most cases, workpieces are supplied for machining. Corrosion resistance is average; the resulting parts can be used in moderately aggressive environments. The resulting bolts are often used when constructing foundations or creating other load-bearing structures.

Download GOST 1050-2013

Analogs of steel 35 have similar chemical composition and properties, and are marked when applying GOST standards. Other countries have their own standards. For example, in the USA, analogues are called 1034, 1035; alloys ML35 and ZG270-500 are supplied from China. A more affordable offer is metals produced by domestic companies.

Advantages and disadvantages

The advantages and disadvantages of steel are determined by its mechanical and technological characteristics, price, and complexity of production. The main advantages of steel 35 include:

- ability to withstand high impact loads, which allows the use of steel 35 in the production of fasteners;

- the combination of low ductility with hardness may be a disadvantage in some areas of application of steel parts, but in construction this quality is successfully used in rigid load-bearing structures;

- no tendency to form cracks;

- affordable price due to the simplicity of the production process and the absence of expensive alloying additives in the composition;

- fairly wide temperature range of application from -40 to +425C.

The disadvantages of steel 35 are the following:

- the scope of application of the alloy is limited by weldability;

- steel 35 is not resistant to corrosion and requires the application of a protective coating for use in aggressive environments;

- With prolonged mechanical loads, a tendency to fatigue appears.

Welding medium and high carbon steels

Medium carbon steel structures can be welded well if the welding rules and the following additional guidelines are strictly observed. In butt, corner and T-joints, when assembling the elements being connected, the gaps provided by GOST should be maintained between the edges so that welding transverse shrinkage occurs more freely and does not cause crystallization cracks. In addition, starting from a steel thickness of 5 mm or more, edges are cut in butt joints, and welding is carried out in several layers. The welding current is reduced.

Welding high carbon steel

Welding high-carbon steels of grades VSt6, 45, 50 and 60 and cast carbon steels with a carbon content of up to 0.7% is even more difficult. These steels are mainly used in castings and tool making. Their welding is possible only with preliminary and concomitant heating to a temperature of 350-400 ° C and subsequent heat treatment in heating furnaces. When welding, the rules for medium carbon steel must be followed; we will discuss this process below.

Welding technologies for high carbon steels

Good results are achieved when welding narrow beads and small areas with cooling of each layer. After welding is completed, heat treatment is required.

Welding medium carbon steel

Welding medium-carbon steel grades VSt5, 30, 35 and 40, containing carbon 0.28-0.37% and 0.27-0.45%, is more difficult, since the weldability of steel deteriorates with increasing carbon content.

Foreign analogues of material 35

Attention! Both exact and closest analogues are indicated. USAGermanyJapanFranceEnglandEuropean UnionItalyBelgiumSpainChina—DIN,WNrJISAFNORBSENUNINBNUNEGB103410351038G10340G10350G10380G1040001.01.01| 31.12.80 |

| 31.12.82 |

| C35 |

| C35E |

| C35R |

| C38D |

| Cf35 |

| Ck35 |

| Cm35 |

| Cq35 |

| S35C |

| S38C |

| SWRCH35K |

| SWRCH38K |

| 2C35 |

| AF55 |

| C30E |

| C35 |

| C35E |

| C35RR |

| CC35 |

| RF36 |

| XC32 |

| XC35 |

| XC38 |

| XC38H1 |

| XC38H1TS |

| XC38H2FF |

| XC38TS |

| 080A32 |

| 080A35 |

| 080A5 |

| 080M36 |

| 1449-40CS |

| 40HS |

| C35 |

| C35E |

| C35 |

| C35E |

| C35EC |

| C36 |

| 1CD35 |

| C35 |

| C35E |

| C35R |

| C36 |

| C38 |

| C35-1 |

| C35-2 |

| C36 |

| C35E |

| C35k |

| F.113 |

| F.1130 |

| ML35 |

| ZG270-500 |

| Sweden | Bulgaria | Hungary | Poland | Romania | Czech | Austria | Australia | Switzerland | South Korea |

| SS | BDS | MSZ | PN | STAS | CSN | ONORM | AS | SNV | KS |

| 1550 | |||||||||

| 1572 |

| C35 |

| C35E |

| M.C. |

| D35 |

| OLC35AS |

| OLC35q |

| OLC35X |

| C35SW |

| Ck35S |

| Ck35 |

| SM38C |

Chemical composition

GOST 1050-88, which previously regulated the composition and characteristics of steel 35, has been replaced by another standard. The features of its production and processing today are determined by GOST 1050-2013. The decoding of the marking indicates the content of the main element - carbon - in the metal - 0.35%. The share of other additives is also small:

- nickel – 0.25%;

- manganese – 0.5-0.8%;

- silicon – 0.17-0.37%;

- copper and chromium – up to 0.25%;

- sulfur and phosphorus – no more than 0.3-0.35%;

- arsenic – 0.08%.

Substitutes for steel 35 differ mainly in the mass fraction of carbon:

Despite these differences, the properties of the analogues are almost identical. The alloy has many analogues abroad:

- 1034, 1038 – in the United States;

- 1.0501, С35, Сk35 – Germany;

- 1С35, RF36 – France;

- 080A32, 080A35 – Great Britain;

- C35 – Italy;

- C36 – Belgium;

- 1572 – Sweden;

- 1.1181, C35E – European Union;

- S35C, SWRCH35K – Japan;

- ML35 - China.

The range of manufactured products is regulated by many standards and is supplied to the market in the form of:

- long products;

- calibrated and ground rod;

- thick and thin sheet steel;

- silverfish;

- ribbons and stripes;

- wires;

- forgings;

- various pipes.

Explanation and characteristics of steel steel 35

The number 35 indicates the carbon content, which is 0.35% of the alloy. The state of the steel in terms of the degree of deoxidation is calm. The amount of additives is insignificant (not reflected in the labeling). In terms of carbon content, steel 35 belongs to medium-carbon alloys, which characterizes it as medium-strength, fluid and ductile. An increase in carbon content in steel leads to a change in structure, an increase in hardness and strength, but is accompanied by a decrease in ductility and fluidity.

Calm steel is an alloy with the lowest concentration of gases (oxygen, carbon dioxide and nitrogen) at the time of solidification. The deoxidation procedure is carried out at the final stages of steel production using nickel and manganese deoxidizers. Deoxidizers react and remove dissolved gases, so that small bubbles and gas pockets do not form, and the metal turns out to be homogeneous and durable. Undeoxidized steel is called boiling steel, in the marking kp. Partially deoxidized steel is called semi-quiet steel, marked ps.

If there are no additional symbols in the marking, it means that the steel is classified as calm in terms of the degree of deoxidation.

Physical properties

The main characteristics and application of steel 35 depend on the chemical composition.

The density of the metal decreases with increasing temperature. In the range from 20 to 800 degrees it changes from 7826 to 7600 kg/m3. At the same time, the ductility of steel increases. The density indicator is necessary when calculating the load on load-bearing structural elements.

With increasing temperature, other physical properties of the material also change:

- electrical resistivity – from 251 to 1156*109 Ohm*m at 900 degrees;

- specific heat capacity – 469-699 J/kg*deg;

- linear expansion coefficient – from 12 to 13.9 1/deg;

- the thermal conductivity coefficient decreases from 49 to 28 W/m*deg;

- The modulus of elasticity also decreases in the range of 20-400 degrees from 2.06*10-5 to 1.68*10-5 MPa.

Mechanical parameters

The hardness of the alloy is 163 MPa. The indicator can be increased using heat treatment. Most often, the normalization mode is used for this purpose, which normalizes the metal structure and increases surface hardness.

Mechanical properties at T=20oC of material 35

| Assortment | Size | Eg. | sв | sT | d5 | y | KCU | Thermal change |

| — | mm | — | MPa | MPa | % | % | kJ/m2 | — |

| Forgings | up to 100 | 470 | 245 | 22 | 48 | 490 | Normalization | |

| Forgings | 100 — 300 | 470 | 245 | 19 | 42 | 390 | Normalization | |

| Forgings | 300 — 500 | 470 | 245 | 17 | 35 | 340 | Normalization |

| The hardness of the material is 35 hot-rolled annealed, | HB 10 -1 = 163 MPa |

| Material hardness 35 after annealing, | HB 10 -1 = 207 MPa |

Technology and features of steel welding

In modern industry, a wide variety of steel is used for welded structures. It can be stainless or ordinary, high or low carbon, heat resistant and so on. Various technologies are used for welding them, but the simplest is welding with a semi-automatic machine or inverter. In this article we will talk about the features of popular types of steel and how to weld them.

Welding tool steel

Tool steel is a type of steel containing less than 1% carbon. This steel is hard and durable, but not wear-resistant, so it is used only in the manufacture of tools. In addition, it has a low purchase price, which makes production profitable.

It is recommended to weld tool steel with a special electrode and using an inverter. Electrodes must be designed specifically to work with this type of steel. We recommend UONI-13/NZh/20X13 rods and a mid-price welding inverter. Be prepared for the fact that welding tool steel will require a lot of effort and patience from you. This is due to the low carbon content.

Welding structural steel

Structural steel is used much more often than tool steel. Everything is made from it: from small parts to factory machines. It is this category that includes welding of 40x steel, 30xgsa steel, 35xgsa steel and other other grades.

What is structural steel? This is a very interesting metal in composition. It consists of various impurities, in particular phosphorus and sulfur. The more of these components there are in the composition, the more unreliable the steel will be, so you need to monitor this indicator. Structural steel can be ordinary, high-quality, high-quality and especially high-quality.

As you understand, the latter type of structural steel contains a minimum of impurities, due to which it is possible to obtain truly high-quality and durable metal. Well, ordinary structural steel contains the most impurities; it is considered the most short-lived. By the way, this classification also has separate subgroups (they differ in the presence of some additional chemical components). But we will not describe the classification in detail so as not to confuse you.

Alloy steel welding

Alloy steels are one of the most popular. Their main feature is their composition. Various alloying components are added to it, thanks to which the steel can be given the desired properties and characteristics. Simply put, due to alloying additives, it becomes possible to adjust the composition to your needs.

If necessary, such steel can be made stronger, more durable and better. You can literally change its physical and chemical properties by simply adding alloying elements to the composition.

A few more advantages of alloy steel: increased heat resistance, corrosion resistance (not at the level of stainless steel, of course, but still high resistance). To weld this type of steel, you can use arc welding and electrodes that contain fluorine and calcium. But we recommend gas welding. It is more complicated, but at the same time allows you to get better connection quality.

Gas welding technology, of course, differs from classic semi-automatic or inverter welding. Here the heat is generated not by the electric arc, but by the welding flame. It is formed when a flammable gas mixes with oxygen and burns. The technology of welding carbon steels using gas requires skill and experience. But that doesn't mean you can't experiment. Practice on a scrap piece of metal before doing the main work.

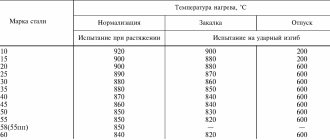

How to release steel yourself

In order to temper steel at home in order to relieve internal stress, it is not necessary to know its grade - it is enough to heat it to a temperature no higher than 200 ºC and hold it in these conditions for at least an hour. If you plan to temper a steel product to reduce hardness and increase toughness, then knowledge of the steel grade is necessary to determine the tempering temperature conditions. This is actually not as difficult a task as it might seem. In textbooks on heat treatment and on Internet sites there are enough tables with lists of products and the grades of steel from which they are made, and often even with the temperature conditions for their quenching and tempering (see table above).

To heat your part, you can use almost any heat source: from the oven to a gas burner or a homemade forge. An important point is the heating temperature. In principle, it can be determined by color tables of tarnish appearing on hot metal, which are also easy to find on the Internet.

This is an old proven method, known since ancient times, but it requires some experience, since its main disadvantages are the subjectivity of color perception and its dependence on external lighting. For a beginner, the best solution would be to use a stove thermostat or a regular multimeter with a thermocouple.

Has anyone ever used a multimeter with a thermocouple to measure the tempering temperature? How accurate is this device and how do its readings correspond to the color of the tarnish? If anyone has such experience, please write your opinion in the comments.

Welding low alloy steel

Low-alloy (they are also often low-carbon) steels are metals containing an extremely small amount of alloying elements (usually no more than 2-3%). They consist largely of iron, a small amount of carbon and various impurities.

Low-alloy steels usually include silicon, nickel, tungsten, aluminum, copper and many other metals. By the way, on our website we devoted several articles to aluminum welding and the specifics of the work. We also talked about copper welding. Read these articles to get up to speed.

Low alloy steel can withstand operating temperatures of up to 200 degrees Celsius and is used to make surgical instruments, jewelers' and engravers' tools, as well as razors and blades. And if you add a little chromium to the composition of such steel, you can get a very strong and durable metal. You will have the opportunity to produce any product.

Also, beginners will probably be surprised that low-alloy steel is classified as ferrous metals and bulky welded metal structures are often made from it. And despite the small amount of alloying substances in the composition, it is possible to obtain a truly durable metal. This is possible due to the positive properties of chromium, nickel and molybdenum, which significantly improve the characteristics of low-alloy steel. Also, chromium and nickel improve the anti-corrosion properties of low-alloy steels.

In addition, if the technology is followed, low-alloy steel cooks very well. But here you still need to take into account some features, and this type has a lot of them. Without preparation and a theoretical basis, you are unlikely to be able to weld low-alloy steel. The most common problem is overheating of the welding zone. This feature is observed with many grades of low alloy steels. Also, when welding such steels, very rapid cooling of the weld joint and the metal as a whole is observed, which leads to the formation of mertensite. Mertensite is a hard carbon structure that forms on a weld when it cools too quickly. This is not always to your advantage.

Welding of low-carbon steels is performed using electrodes containing fluorine and calcium. Recommends rods with a basic coating (for example, E42A or E50A coating). The best proven brands of electrodes are UONI 13/45, MR-3, ANO-8, SM-11. You can also use other rods with similar characteristics.

You can also choose semi-automatic or automatic submerged arc welding using a semi-automatic welding machine and filler wire. Instead of flux, you can use carbon dioxide or its mixture with argon. In this case, the quality of the seam will be noticeably better than when using an inverter and electrodes.

Is it possible to temper steel in a home workshop?

Home use of this technology becomes possible when it is necessary to relieve the internal stress of the metal. In this case, the steel grade does not matter - heating must be done to 200°C (no higher), and maintained in such conditions for up to 1 hour. If you need to reduce hardness and increase viscosity, then it is important to know the grade of steel (to determine tempering temperature conditions). Information of this kind can be found on the Internet or in textbooks on heat treatment, which present tables with steel grades, products and temperature conditions for quenching and tempering steel.

A homemade forge, kitchen stove or gas burner can serve as a heat source for heating the part. In this case, the heating temperature is determined using tarnish color tables - the disadvantage of this ancient method is the subjectivity of color perception and its dependence on external light sources. Beginners are recommended to use stove thermostats or a multimeter with a thermocouple.

Typically, home tempering of steel is used for knives, forks, metal cups, automobile parts, etc. In this case, you may encounter some fairly common problems:

- Most home ovens cannot reach high temperatures. Therefore, at home you can only make a low or medium vacation. Theoretically, you can try to re-equip or “strengthen” your stove to increase the heating temperature, but this will be difficult for a person without experience.

- To carry out heat treatment, it is necessary to use a protective medium (oil, alkali, saltpeter). But each substance has its own temperature characteristics. A simple example: saltpeter-based compounds can explode when heated to high temperatures, which can be dangerous to the life and health of the home metallurgist.

- Tempering without the use of a protective environment can be fatal to the metal itself. The fact is that without the use of a protective environment, the metal will cool quickly, which can affect the quality of the steel (increased brittleness, bending, plastic deformation, rust).

- Also, do not forget about low-temperature brittleness of the first type (from 250 to 300 degrees). If the temperature is incorrect, the quality of the metal can be seriously affected, up to the complete destruction of the alloy.