Drainage is not just a minor detail of window systems. Without it, none of them will be able to fully function. Therefore, the business of producing window sills will always be profitable. To organize it, you need to understand the intricacies of the technological process, selecting premises and equipment, and establishing sales channels.

Metal Master LBM series sheet benders

For small-scale production, we recommend paying attention to the Metal Master LBM series sheet bending machines. This equipment is in demand in the construction industry. The presence of this equipment greatly simplifies the performance of the required bending operations, and makes the creation of a wide range of sheet metal products a simple and convenient task that does not take much time and effort.

As an additional option, you can purchase a roller knife, which allows you to cut sheet metal directly behind the sheet bending machine. Guaranteed perfect cut, without any defects.

Range

The more diverse the products, the greater the chances of making a profit from its sale. There are several types of ebb tides, each of them has its own set of qualities:

- Copper. They are sheets with a protective coating, which is obtained by oxidation. They have a long service life.

- Steel. Made from galvanized steel up to 1 mm thick. They do not corrode and can be painted any color using waterproof varnish. And if you apply a polymer coating on them, the sound of water flowing down the gutter will be as quiet as possible.

- Aluminum. They are based on sheet aluminum. They are covered with a protective layer on top and are characterized by low weight.

- Plastic. They are made from various types of polymers. Light and silent.

- Made from epoxy resin. They are expensive and have high wear resistance. They can be made to order.

Steel castings are the most popular due to the favorable combination of affordable price and ease of operation.

CNC bending machine

To produce moldings on an industrial scale, you will need to buy a CNC bending machine. This functional technique has a powerful hydraulic drive and allows you to significantly speed up work. Rear wall protection prevents unauthorized people from gaining access to the rear support area. The safety limit switch allows you to quickly turn off the power if the back wall is opened.

The design of the press is characterized by increased rigidity, which means that even significant operating loads do not have a significant impact on the accuracy of solving the assigned tasks.

Sheet bending machines for castings production

Supply of equipment for the production of castings at a price of 70,000 rubles, to all cities of Russia. Own warehouses in Moscow, Krasnoyarsk, St. Petersburg

TAPKO-M LLC supplies mobile sheet bending equipment from the world's leading manufacturers. We offer efficient and durable machines at competitive prices.

Sheet benders for the production of castings are actively used for bending and cutting thin sheet steel, including those with a protective paint coating. Equipment for this purpose has several types, which differ in operational characteristics and productivity:

- Manual sheet benders for ebb tides are small mobile devices that have relatively small dimensions and weight, but are capable of bending metal sheets up to 0.7 mm thick. The main advantages of the equipment are as follows:

- production of necessary construction parts directly at the installation site. In particular, the creation of roofing elements and decorative cladding of the facade, the production of tin boxes and other structures;

- The manual sheet bender for ebb tides can be freely moved to a convenient location at the construction site. Thanks to its compact dimensions and light weight, the equipment is easy to transport;

- the machine is reliable and durable in operation, as it is made of high-quality steel;

- Manual sheet bending machine is easy to use and maintainable.

- Electromagnetic sheet benders for the production of castings are stationary devices located in workshops. Machines of this type are designed for large-scale production. Advantages of professional equipment:

- high productivity and power, which allows you to process metal of various thicknesses, lengths and widths;

- the machines are specially designed so that during processing the protective polymer coating of the workpieces is not damaged;

- have the ability to equip with CNC;

- are as safe as possible to use.

Sheet bending machines are actively used for the production of structural elements in the field of advertising and trade exhibition business: frames, signs, stands, showcases. They are also used for the production of various types of profiles, decorative finishing of building facades, roofing, and construction parts.

You can buy a sheet bending machine for making ebb moldings of the required power and performance at a competitive price.

CONSULTATION REQUIRED

Our operators will answer any questions: 8(800)555-30-72

Or leave your phone number:

Your order is accepted!

By clicking on the “Call me back” button, I consent to the processing of personal data.

Materials

At an early stage of business development, it is enough to start manufacturing metal castings. Then as raw materials you will need:

- copper sheets;

- Cink Steel;

- rolled aluminum;

- PVC based paint.

One sheet of metal 1-1.5 mm thick costs an average of 1,700 rubles. In order not to overpay for materials, it is better to order them in bulk from the manufacturer. And paint and varnish materials are needed in small quantities, so they can be purchased at any hardware store.

Staff and premises

At the early stage of developing your business, it is not necessary to purchase real estate to set up a workshop. It's better to rent it. In the central regions, annual use of premises for production needs will cost 10-12 thousand rubles. for every sq. m., and in remote areas - 20-30% cheaper.

The main requirement for rented space is stable access to water supply and electricity. The optimal workshop size is 200-300 sq. m. It is desirable that there be a covered warehouse on its territory for storing finished products. On average, rental costs will be 2.4-3.6 million rubles. in year.

For high-quality production of products, you need a staff of qualified employees who know how to handle equipment and know the technology for making castings. The company's rating and profit margin depend on this.

At first, it is enough to involve the following specialists:

- operator of a sheet bending machine - salary 45 thousand rubles;

- product tinting specialist – 40 thousand rubles;

- product designer – 45 thousand rubles;

- handyman - 30 thousand rubles.

An accountant can be hired remotely for 15-20 thousand rubles. As a result, 175-180 thousand rubles will be spent on staff maintenance. monthly.

Ready ebb tides

Equipment and ideas for small businesses

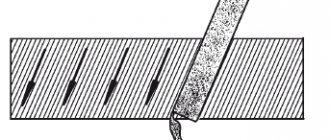

To make castings you will need: a workshop (garage, cover), galvanized steel and a sheet bending machine. On a sheet bending machine, defect-free straight-line bending and cutting of sheet metal is carried out, turning the workpiece into sills (outer window sills) for window openings.

Window tide.jpg (50.49 KB) Water and melting snow flow down the window sills. They protect window openings and walls from the formation of corrosion and fungus.

With window sills, the building takes on a refined, aesthetic appearance. This is facilitated by a variety of colors and designs produced on sheet-bending equipment.

Purchasing a sheet bending machine for making castings

To save money, equipment is purchased from manufacturers. This guarantees that you will receive a high-quality product with all the components without commercial markups.

Manual sheet bending machine is designed to work with galvanized, painted, polymer sheet steel.

Advantages of a manual sheet bending machine:

1. Compactness - can be used with the same productivity both in the workshop and on the construction site; easy to transport; 2. Multifunctionality - designed for bending and cutting sheet metal; 3. Productivity – the volume of manufactured products is limited only by production needs; 4. Durability – for the manufacture of the machine, strong, wear-resistant materials are used, painted with an anti-corrosion coating; 5. Simplicity and practicality - even novice craftsmen who know only the operating principle of the machine become operators of sheet bending devices.

Development of a business based on sheet metal bending devices

If there is a business plan based on the production of tinplate products, the state can issue a one-time subsidy for the development of the company.

The allowance is issued at business support centers.

Business centers are located in every region of the country.

If the application and business plan meet the Center’s criteria (creation of new jobs, profitability of the enterprise), then the issuance of a gratuitous benefit will be approved.

Factors that determine the quality of press brakes

The length, width, and depth of the sheet bending machine affect the configuration of the metal products produced.

The roller cutting mechanism is used to give the required size to the workpiece. Cutting accuracy is achieved up to 0.01 mm.

Window sills come in complex designs. Therefore, the bend radius of the equipment must be more than 90°.

Making castings on a sheet bending machine

1. A sheet of galvanized steel, for example, measuring 2000x1250 mm (600 rubles), is placed on the work table; 2. Using a metal ruler, the places for cutting are measured on both sides of the sheet (width from 90-450 mm); 3. Small cuts are made on the sheet with metal scissors; 4. The workpiece is inserted into the machine, into the place for fixing the sheet, and is clamped by an eccentric clamping mechanism; 5. Roller cutting mechanisms carry out cutting; 6. The clamping lever rises up, the sheet of metal is removed and placed on the work table: 6. Then markings are made on the cut workpiece for further bending; 7. The workpiece is inserted into the upper location for fixation and clamped with a clamping lever; 8. The rotary bending traverse rises upward, performing a straight bend along the markings, and falls down; 9. The clamping lever is loosened, the workpiece is released and turned over on the other side, a similar bend is carried out; droppers are also made; 10. Then the finished product is removed.

Low tide cost

1. The width of the casting is 90 mm, the length is 2500 mm: the cost for one unpainted casting is 171 rubles, painted - 198 rubles, painted with powder paint - 234 rubles; 2. Casting width 450 mm, length 2500 mm: cost per unpainted 614 rubles, painted – 700 rubles, powder coated – 837 rubles.

Results

Metal processing is becoming more and more popular every year. Using sheet-bending equipment, it is possible to produce, without special skills, the moldings necessary for the arrangement of each building. The cost of products and the demand for finished products are guarantees of stable and high earnings.