Author of the article: Sudakov A.P.

Liquid stone is used in modern construction. In terms of its characteristics, it is not inferior to natural stone, and in some parameters of properties it even surpasses it.

An unusual material, distinguished by its practicality and beauty, has won the trust of consumers, since with its help it is possible to effectively decorate buildings, structures and their facades, providing them with surface protection and giving them a modern, respectable appearance. It is also used for interior decoration, to create durable furniture coverings, as well as for countertops and sinks. Since the material is popular and in demand, having organized a business for its production, the project manager will not be left without clients.

Appearance of liquid stone

What is liquid stone

Liquid stone is a building mixture of a special composition that, when combined with water, hardens and forms a surface that looks like real stone.

The difference can be felt when holding the material in your hands as it is warmer and smoother. After the product has completely hardened, it must be sanded to achieve a glossy, matte or mirror finish. The composite material has a dense, non-porous structure, which makes it resistant to dirt absorption and external factors such as temperature changes, high humidity and ultraviolet rays.

Choosing the color of fillers for artificial stone

Colored granules are divided into certain fractions:

Small size

Medium size

Large size

According to specially developed recipes, filler granules are mixed and form a material that has the appearance of natural origin.

Different types of fillers can contain either granules of the same size or several fractions at once. The same can be said about color: some of the litters include only single-color granules, others contain granules of several colors.

That is why we offer a wide range of decorative fillers for liquid stoneSkillStone - more than 100 colors. In addition, we are constantly expanding the collection, creating new original and unique shades.

Specifications

Nuances of technology

Artificial stone is a hardened and processed composite liquid mass of unsaturated polyester resins with a specific filler. It hardens after adding an accelerator and hardener to the prepared base solution. The liquid mixture is a semi-finished product for any products that are manufactured by spraying or casting.

Cons of agglomerated stone

Agglomerate is an artificial stone made more than 90% from crushed chips of natural stone (most often granite, quartz or marble). Quartz sand, mirror or glass particles and special organic pigments-dyes are also added to it.

Polyester resin acts as a unifying base. It is this combination of components that gives the agglomerates their exceptional strength.

Countertops made of agglomerated stone look expensive and impressive, and are much more affordable than natural stone. But agglomerate is a dense and heavy material: labor-intensive to process and difficult to install.

Some customers complain that agglomerated composite feels cooler to the touch than acrylic-based stone. However, this opinion is subjective - natural stone will seem even colder to the touch.

Agglomerate is a dense and durable stone. Unlike acrylic, it cannot be scratched by cutlery.

Some manufacturers claim that on such a countertop you can cut food without a cutting board. Theoretically, hot dishes can be placed on agglomerated marble, quartz and granite: if the material is of high quality, there should be no marks left.

But despite this, he is still afraid of abrasive detergents. Because of them, micro-scratches may also appear on the polished surface.

Over time, they can deprive the work surface of its beautiful shine. Polishing agglomerated stone is a rather complex process that requires special equipment and preparation.

However, it is possible to restore its beautiful shine.

When placing an order for a countertop, table or bar counter, carefully read the clauses in the contract about the conditions of use of the material. Knowing what weak points your specific countertop may have can help you keep it looking good longer and avoid potential manufacturer warranty issues.

Immediately after installing the stone countertop, experts advise rubbing the surface with a special protective agent. Its task is to enhance the water- and grease-repellent properties of the stone. For regular maintenance, it is recommended to use neutral detergents without abrasive particles, alcohol or acids. It is also advisable to avoid hard brushes.

Features of the material, advantages and disadvantages

All items made from composite material are durable and strong. They are valued for their spectacular appearance and rich decorative possibilities, since they are made in a varied palette and texture. The uniqueness of the material lies in the ability to create monolithic surfaces without seams or joints. The surface of the treated product is shock-resistant, moisture-resistant and hygienic. Caring for it is simple and involves cleaning with soapy water. Cracks and unevenness of the material that have arisen during the operation of the product can be easily eliminated, and the repair site will not be visible.

However, along with many advantages, liquid stone also has disadvantages that may cause a person to refuse to purchase a product made from it. The high cost forces middle-income consumers to pay attention to products made from more affordable materials, such as ceramic tiles, laminated chipboard, MDF, porcelain stoneware, stainless steel or even solid wood. Only granite, marble or natural quartz can cost more.

Another disadvantage of the composite material is the small thickness of the coating, which usually does not exceed four millimeters. Low parameters of moisture resistance and adhesion increase the likelihood of liquid stone peeling off from the base on which it was applied. However, manufacturers provide a guarantee for their products, which is valid provided that the operating requirements are met. If a business entity, in the process of fulfilling an order, complies with the norms and requirements for the technological process, then the result of its work will delight the customer for a long time with its spectacular and respectable appearance.

Sample of a liquid stone product

It is worth considering that artificial composite material is more durable than natural one. Its radioactivity parameter is normal, whereas for many natural materials, such as granite, for example, it is significantly exceeded.

Usage

The material looks like decorative stone, sometimes like brick, but at the same time it has the physical parameters of textured plaster. Due to its lightness and ability to take any shape, it has found application in both exterior and interior finishing work. In the interior, soft stone is used in the following cases:

- For decorating walls (and sometimes floors) of living rooms. The best way the material manifests itself is in creating accents in interiors of the classical style, in the style of minimalism, art deco, country, and Arabic.

Wall decoration Source i.pinimg.com

- For finishing walls in rooms with high humidity: baths, swimming pools. Flexible stone in the bathroom in the form of sandstone will create a warm and cozy atmosphere in the room. A malachite surface finish will give a luxurious look to your bathroom or pool.

In bathroom decoration Source i.nt0163.ru

- Finishing the fireplace area. A significant part of modern fireplaces are electric. To maintain style, they often build a false fireplace from plasterboard. Such a design may not support the weight of natural stone cladding, but a flexible option is ideal.

Fireplace design Source ecofloorstore.ca

Production technology

The technology for manufacturing liquid stone is not characterized by complex operations. All the necessary elements are introduced into the dry construction mixture to ensure the specific qualities of the finished product. After adding water to the container, ensure thorough mixing of the composition until a uniform plastic consistency is formed. The resulting mixture is applied to the surface of the product or poured into molds. Drying is carried out under natural conditions.

To increase production volumes when there is insufficient area for work, forced drying is possible using equipment that provides a hot air flow. To give a respectable appearance and adjust the texture, the hardened material must be sanded or polished.

Base requirements

If you are interested in this composition and want to use it to decorate the façade or interior walls of a house, then it would be useful to know that the main requirement for obtaining a high-quality result will be preliminary preparation of the walls. It is necessary, since without it the plaster will not adhere well to the surface and its consumption will be much greater.

It is very important to treat the surface with primer - the usual “Betonkontakt” will do, but it is best to buy a special primer designed specifically for working with such plaster mixtures. After application and drying, the plaster will require another treatment, which is done with a special finishing impregnation or varnish. All other aspects associated with applying and mixing compositions of this type will be identical to working with conventional plaster purchased in dry form.

Work location

Mixing the solution

Work can be carried out at our own production site or at the client’s site. When adding field services to the price list, you should consider the need to purchase or rent a cargo vehicle to deliver the raw materials of the product, as well as some elements of the finished product.

On your own premises you can manufacture products that can be easily transported to the customer: countertops, sinks, sinks and decorative elements. On-site services are provided to clients when ordering finishing of floors, facades or buildings.

Flaws

The disadvantages of using liquid stone for kitchen products are:

- Hammers for beating meat or large knives should be used with extreme caution in cooking;

- high price.

Compared to other types of countertops, liquid stone is significantly more expensive.

See alsoKitchen in the house: design for different layouts

Equipment

The technology for producing liquid stone requires the presence of specific equipment in the form of containers and molds for the material. For grinding, grinding machines are used to process the finished product. A set of equipment for opening a production line will cost an entrepreneur no more than 200,000 rubles. It includes:

- containers of various shapes and sizes;

- grinding machines;

- drill-mixers with attachments for quickly carrying out the mixing procedure;

- screwdriver;

- spray;

- electric jigsaws;

- Circular Saw;

- small construction tools;

- sandpaper;

- grinding wheels of different hardness.

To reduce the cost of delivering products to customers, it is recommended to take care of purchasing vehicles with the appropriate carrying capacity and dimensions. As an alternative, it is possible to sign a vehicle rental agreement.

Making granite at home

There are two technologies for creating liquid granite that you can practice with your own hands - casting and spraying onto the surface. Before starting work, you need to prepare the solution and all the necessary components and tools.

How to make liquid stone

The basis for the solution is polyester resin, the rate of which can vary from 18 to 21% of the total volume of the composition. About 1% of the solution is occupied by a hardener, which usually comes complete with the resin or is sold separately.

Polyester resin

As a filler (78-81%), mineral chips of the desired type and color are selected; if necessary, part of the crumbs are replaced with quartz sand and pigments are introduced. First, the resin is combined with a hardener, mixed, stone chips are added and mixed again with a construction mixer.

Working conditions

When pouring stone, the temperature in the room should be within +18…+22 degrees. The ventilation system must work properly, and the technician must use personal protective equipment.

Important! When spraying, all surrounding surfaces must be well insulated.

Casting technology

Prepare a mold for filling. For complex products (bathtubs, sinks), it is better to purchase a ready-made form in the store. You can also make it yourself from clay, gypsum, silicone, chipboard sheets.

To produce curved products, the mold must be detachable. The inner surface is covered with a film or lubricated with a special anti-adhesive compound. Without such measures, it will be impossible to separate the form from the liquid stone. After pouring, the product is left to dry for a day, then taken out, ground, and polished.

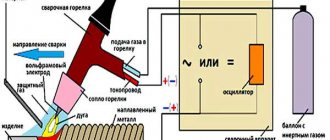

Sputtering technology

To reduce the consumption of the composite, a spraying method is used, in which the thickness of the product will be smaller. Therefore, it will be much cheaper.

Usually, tabletops, window sills, and souvenirs are made in this way. The surface prepared for spraying is cleaned, degreased, and treated with a primer. After drying, a layer of liquid granite is applied using a sprayer immediately or in parts, in sections. Then the product is ground and polished.

Room

To organize a business for the production of liquid stone, large production areas and a powerful electric line are not required.

To start production, a room of 30 m2, equipped with standard 220V electrical wiring, is sufficient. Access to cold water and sewerage is required. From a fire safety point of view, there are no special requirements for the production line.

Grinding

The specifics of production necessitate dividing the room into two compartments. In one of them the process of producing the solution and applying it to the product will be implemented, and the other compartment is necessary for grinding. To prevent dust generated during the processing of the product from getting into the solution and onto the products during the drying process, both rooms must be isolated from each other.

Important points

The manufacturing process of finishing material is relatively simple and is not controlled by strict regulations. Therefore, handicraft samples are often found on the market. Here, as a rule, a polymerizer such as butanox is added to the composition. Such liquid stone is only permissible for the facade of a house and well-ventilated rooms. The reason is that the release of styrene by the coating occurs over a period of 5-10 years. And this is a toxic substance that has a negative effect especially on liver cells.

It is not always possible to track the thickness of the coating on finished products. If it is only 2 mm, then the declared 25 years can be reduced to 3-5 with active use. Any crack becomes a source of water penetration, and fiberboard is not a water-resistant material. That is, the destruction of the same countertop will begin and continue from the inside.

Crack on a countertop coated with artificial stone Source top-acrylic.ru

As a result, before making decisions, it is necessary to carefully study all the pros and cons of finishing a particular object. When choosing a liquid stone, you need to pay attention to the composition, manufacturer and accompanying documentation. It is also worth monitoring the entire process of construction work on the manufacture of countertops, window sills, and wall cladding.

Raw materials

Liquid artificial stone consists of a polymer resin.

To give it the properties inherent in its characteristics regulated by regulatory sources, additional components are used, such as plasticine, gelcoat, hot melt adhesive, calcite, acetone, fiberglass, fillers and pastes to impart color.

A mandatory element for imparting hardness is a hardener added at the last stage of the production process. For all products in the manufacture of which liquid stone is used, identical raw materials are used. The difference lies in the color design and content of the product.

Strength

Acrylic stone or solid surface is a very durable material, stronger than natural granite. It consists of acrylic resins methyl methacrylate and polymethyl methacrylate, aluminum hydroxide, natural mineral fillers and pigment additives, which are combined in production under vacuum conditions. The more polymethyl methacrylate in the composition, the stronger, more durable and, accordingly, more expensive the stone.

It is produced in sheets from 6 to 25 mm thick, each of which has a different purpose (from light-conducting light interior elements, for example, lamps, to floor coverings of public spaces and external cladding of buildings). For the home (countertops for the kitchen, bathroom, window sills, furniture, etc.), as a rule, 12 mm sheet thickness is used, which is quite enough to provide the product with the necessary strength and resistance to impact loads. To stabilize a flat surface and to give greater thickness to the product without weighing the product down, acrylic sheets are fixed to moisture-resistant plywood.

When using liquid stone, the product is made entirely from chipboard, primed, and then the prepared composition of “liquid stone” is applied to its surface either by spraying or by casting. Accordingly, the product has all the disadvantages of chipboard - it absorbs moisture, the tabletop can “lead” or warp. In this case, a thin layer of stone can simply crack. It is almost impossible to repair such a countertop; the thin surface layer of coating cannot be sanded, so you will have to think about replacing the product.

Costs and payback

A business idea for the production of liquid stone, due to the low costs of creating production, is the best solution for beginning entrepreneurs. You will have to spend up to 200,000 rubles on a set of equipment. Renting the premises will cost 100,000 rubles. To start production, you need to purchase raw materials for 200,000 rubles. You should plan up to 30,000 rubles for advertising, and up to 20,000 rubles for general business expenses.

The most expensive expense item is the purchase of a vehicle, but at the initial stage you can rent it. The cost of services depends on the vehicle’s carrying capacity and can range from 45,000-75,000 rubles per month. Having calculated all the expenses, we can conclude that to open your own business in the field of production of composite materials you need to have up to 800,000 rubles.

When calculating the profitability of an entrepreneurial idea, it should be taken into account that a square meter of a product costs from 7,000 to 11,000 rubles. To make it, you need to purchase raw materials in the form of the base of the product for 3,000 rubles and special additives for 200 rubles. The payback of the project with such expenses is six months, while the average monthly revenue will correspond to 350,000 rubles.

Raw materials used

Since the business profitability parameter is high, it can be expanded without the need for additional investment in the project. Such a solution will be necessary when demand exceeds production capacity.

Application Features

Most often, the material is sprayed with a special gun onto the surface that needs to be given decorative and performance qualities. It is first primed, and after the liquid stone dries, which takes a day or two, it is polished with a grinding machine to a mirror shine. The result is strikingly similar to the natural source, but when you touch it, you immediately feel the difference - the coating is unique, plastic-rubber.

In addition to spraying with a layer of up to 3 mm, which can be direct or reverse, casting is used in ready-made solid or split molds - products up to 5 cm thick are obtained. This process requires factory equipment and special drying conditions, so it is rarely carried out at home, but applying liquid stone to Experienced craftsmen often decide on a countertop or bathtub on their own. The mixture is prepared using a paddle attachment on a drill.

You cannot do without the following components sold in a hardware store:

- mineral chips, usually microcalcite;

- gelcoat, that is, a polymer base;

- catalyst;

- hardener;

- hot glue;

- plasticine;

- fiberglass;

- solvent;

- pigment.

The proportions depend on the desired result and the properties of the specific substances chosen. In addition to clarifying this point, you need to carefully prepare for work. Protective clothing and a respirator are required. The room should be well ventilated and heated (18-24 degrees Celsius).

A training video will help you understand the technology in detail:

Marketing Tips

When planning to open your own business, it is recommended to choose a specialized area of activity, depending on which the sales system will be built.

When performing work at clients' homes related to the finishing of a room or building, you should consider the option of completing the order on their premises. This solution will be facilitated by small-sized equipment that is not difficult to place at the construction site.

When manufacturing products to order and performing work on the territory of a business entity, the contractor will need to go to the site to take measurements and receive an advance payment. The order is completed within a week.

To attract customers, you should use the option of promotions and discounts applied to the customer’s cost item for transporting finished products from the production workshop to the installation site. To do this, you should first highlight the delivery of the product as an additional service, and then present it as a bonus, offering the customer to receive the service at a reduced price or for free. Price parameters, as well as the level of applied discounts, should be formed taking into account the level of competition in the region.

To search for orders, you should establish relationships with construction companies, manufacturers and distributors of furniture and plumbing fixtures. Cooperation with interior designers will provide the entrepreneur with constant work based on recommendations.

Recommendations for choosing and caring for countertops

Caring for a countertop made of cast stone is not demanding. In order to remove dirt, you will need to use a microfiber cloth. This cloth should be soaked in warm tap liquid and used to clean the work surface. There is an important rule that must be followed - under no circumstances should you use abrasive preparations. These products may harm the polish.

Sharp objects on stone countertops should be used with great care.

It’s easy to give a new look to an interior item; sandpaper and polish are used for this. To remove deep damage, you need to use the services of a specialist who can spray the substance onto the defective area and then polish the uneven areas.

Manufacturers recommend using cutting boards and trivets for hot dishes. Try not to drop heavy or cutting objects, and then the tabletop made of molded material will last for many years.