Oil separators are recommended for systems:

- working at low temperatures;

- with immiscible refrigerants;

- with evaporators that do not return oil - flooded evaporators;

- with oil bypass lines;

- with variable performance;

- with a long vertical suction or discharge pipeline.

Although properly installed oil separators are usually very good at separating oil from refrigerant vapor, they are not 100% effective. Therefore, it is necessary to provide some additional means of removing the small amounts of oil that pass through the separator to other parts of the system.

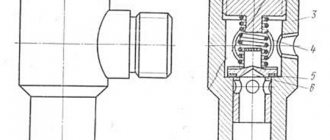

The design of oil separators in the discharge pipeline is shown in Figure 24.1. The large diameter pipe is equipped with parallel screens and perforated partitions. Refrigerant vapor with lubricant flows from the smaller diameter discharge pipe into the oil separator, as a result of which the vapor velocity decreases. The oil droplets have more kinetic energy and therefore continue to move towards the partition at a higher speed. Since heavy drops cannot quickly change direction and pass through the separator, they settle on the surface of the partitions, and steam passes through the holes. The droplets collect and flow into the base of the oil separator and then back into the compressor through the float control and pipe. Other oil separator designs use centrifugal force, reducing the velocity of steam, and changing the direction of steam to separate the oil. Each device is also based on the difference in kinetic energy between oil and steam.

When using an oil separator in the system, it is important to limit liquid refrigerant from entering the crankcase when the compressor is off. Refrigerant may condense in the oil separator if it is colder there than in the compressor or connecting piping. The liquid level in the separator will rise and open the float control, allowing the mixture of oil and liquid refrigerant to enter the compressor crankcase. To minimize condensation of refrigerant vapor in the separator when the compressor is turned off, it must be installed near the compressor in a warm place. The separator must be well insulated to reduce heat transfer to the environment when the compressor is turned off. To further reduce the possibility of liquid refrigerant from the separator entering the crankcase, the oil return line should be connected to the compressor inlet rather than the crankcase. Thanks to the passages in the compressor, the liquid refrigerant will evaporate rather than mix with the oil in the crankcase.

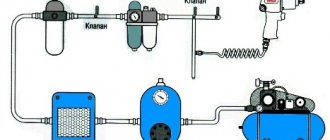

The oil return line must be equipped with a solenoid valve, sight glass, manual control valve and manual stop valve as shown in Fig. 23.15 in the previous chapter. Determining the oil level through the sight glass, the manual control valve is turned so that the liquid mixture from the oil separator slowly flows into the inlet while the compressor is running. The solenoid valve is connected to the compressor motor starter so that the valve is open only when the compressor is running. This prevents liquid from flowing from the separator into the compressor when the compressor is off, but allows the flow and evaporation of refrigerant into the inlet to be controlled when the compressor is on.

Oil separator functions

The main function of an oil separator is to remove oil from the high pressure refrigerant vapor stream in the discharge line and return it to the compressor. The oil separator prevents increased oil carryover from the compressor crankcase and increases system efficiency by reducing the rate of oil circulation in the refrigeration circuit.

Oil can be returned to the compressor directly (single-compressor units) or through an oil sump-oil level regulator system (multi-compressor units).

Oil separators of different manufacturers and series can differ significantly from each other in internal design and have different oil separation efficiency. In addition, oil separators are produced both sealed and collapsible.

Compressor oil separator - general information on equipment

The compressor is seen as a system operating on the principles of mechanical movements. Therefore, the use of lubricant for the moving parts of the compressor unit is a matter of course.

Screw compressor: 1 - electric motor; 2, 7, 8 — bearings; 3 - driven rotor; 4 — compressor housing; 5 - shaft; 6 — oil seal; 9, 11 — balance piston; 10 - driving rotor

Compressor oil is traditionally used as a lubricant. Supplied to mechanical components and moving parts, compressor oil provides lubrication to the rubbing parts of the machine.

This maintains long-term operation of the compressor and significantly increases the service life of the mechanical parts of the system. However, the compressor oil used inevitably mixes with the working gaseous medium. Moreover, the oil content in the same compressed air is noted at a high level.

The working gas medium compressed by the compressor actually becomes unusable. In addition, a mixture of air and oil in certain concentrations is explosive.

In practice, a variety of designs of systems designed to purify a compressed gas mixture are used. Each design differs in technical parameters and efficiency

This is why most air compressor designs are equipped with oil separators by default. And those of them that do not have such equipment must be equipped with an oil separator.

Standard oil separators

Operating principle. When entering the oil separator, refrigerant vapors with oil droplets enter the oil separator housing, where the flow rate drops significantly. Due to the reduction in flow rate, a significant part of the oil droplets and vapors settles in the lower part of the apparatus. The gas then passes through the outlet strainer where the final separation of the oil from the refrigerant occurs. At the bottom of the oil separator is a float mechanism with a needle valve that returns oil back to the compressor.

Oil separators for freon and ammonia plants

The refrigerant pumped into the system by the compressor captures vapors and oil particles, which must be separated; oil separation usually occurs mechanically, by reducing the speed of the mixture to 0.5 - 0.8 m/s and its direction. The oil separator is a container, the supply and intake of refrigerant occurs in the upper zone, but the supply is lowered down the container, to change the movement of the flow, large drops of oil immediately fall out of the mixture, and small ones pass back up through a series of special metal gratings that prevent movement, thanks to which is why the rest of the oil falls on them. It flows down the walls into the float chamber, and from there it returns to the refrigeration compressors . Unfortunately, this method only catches 65% of the oil, since even at low speeds, the droplets are so small that they are still drawn further. To increase the efficiency of the oil separation process, the mixture is pre-cooled with water.

In ammonia refrigeration units, the refrigerant (for more efficient oil separation) is passed through a small layer of liquid ammonia, this method is called bubbling; vapors of a mixture of ammonia and oil are bubbled through the liquid layer, while the oil condenses more effectively, even small drops are effectively retained. The compressor constantly supplies liquid ammonia to the receiver, thereby maintaining the entire cycle. Thus, oil recovery increases to 87%. Ammonia evaporators are more susceptible to oil film formation, so the use of oil separators is often a critical solution.

The two-stage installation uses an intermediate vessel design, which allows for more efficient separation and collection of oil, as well as even distribution between the compressors.

Freon refrigeration units are less susceptible to film formation in the evaporator, but the oil increases the viscosity of freon, which increases heat transfer resistance. In two-stage systems, an oil separator is installed after each compressor stage; if the compressor is located below the evaporator, the oil naturally returns back. If the compressor is located higher, then hydraulic valves are used in which the oil accumulates until it completely blocks the section, then due to the vacuum created by the compressor, the oil will begin to rise. One valve can raise oil to a height of up to 3 meters; if the compressor is located higher, then such valves must be installed every 3 meters to the required height.

Cyclonic oil separators

Operating principle. When entering the oil separator, refrigerant vapors with oil droplets enter the spiral part of the device. The flow moves in a spiral and, due to centrifugal force, oil droplets are deposited on the inner surface of the walls of the oil separator. The oil flows down the walls into the lower part of the apparatus, separated from the main part by a special oil separator, which prevents re-absorption of oil. At the bottom of the oil separator is a float mechanism with a needle valve that returns oil back to the compressor.

Read also: Motor connections 380 to 220 without capacitor

The oil separator and sump design prevents oil from escaping when the refrigeration compressor starts.

To separate oil from refrigerant, various types of oil separators , the efficiency of which depends on the conditions of their use. For example, the degree of oil separation in devices increases with decreasing temperature of the steam entering the oil separator. Oil separators with a filter attachment provide a greater degree of separation with a smaller proportion of oil in the refrigerant vapor entering the device. Bubble oil separators operate with a nominal separation degree if the height of the bubble layer in the apparatus is at least 0.12 m, and the separated oil is continuously removed from the apparatus.

Painting work in a garage or outdoors is simplified if you use a spray gun powered by a compressor. The method has one significant drawback: the air pumped by the compressor has quite high humidity, which will negatively affect the quality of painting. A special moisture separator for the compressor is responsible for removing moisture from the air flow. Is it worth buying it or can you make it yourself? Let's figure it out!

What is the device and what is it used for?

Water separators differ in their design and operating principle. The cost of the factory model is considerable, it depends on the power of the device and its performance. There are also several homemade schemes that will help you make a reliable and effective dehumidifier at home.

To remove moisture from the compressor, you can use low temperature, centrifugal force or special filters. The main task is to remove excess moisture before the air mixture enters the compressor. To create such a device, it is necessary to strictly follow the instructions of experienced mechanics and assemble the parts in accordance with the instructions.

The design of the filter-moisture separator and the principle of its operation

Water separators operate according to one of three principles:

- Using centrifugal forces.

- Using substances that adsorb moisture.

- Removing condensate during cooling.

The action of the dehumidifier is to reduce the humidity of the air entering the compressor to optimal values. The easiest way to do this is to use the principle of a conventional cyclone, when the air flow, when rotating around the central axis, is thrown towards the walls of the working tank. More humid air has an increased density, and therefore, condensing on the walls of the tank, flows in the form of drops to the bottom of the tank, from where it is periodically removed with a conventional condensate drain. The task is to create such a speed of air flow that it has a pronounced turbulent character, and the laws of physics will do the rest.

To reduce air humidity, you can also use substances that have active moisture absorption properties. The most common of them is silica gel. It consists of granules of dried silicic acid gels, to which various dyes and stabilizers are added. Silica gel is produced in accordance with the technical requirements of GOST 3956, and differs in the size of the granules, the percentage of water, the size of the working surface and the diameter of the pores in the granules, where moisture is adsorbed. The activity of silica gel extends to a temperature range from 20 to 250ºС. A compressor dehumidifier using silica gel can be found in scuba filters and imported heavy trucks. The device has a block system: when replacing the adsorbent, it is necessary to remove the used granules from the filter and fill the space with fresh silica gel.

The third method is least functional, when the air flow enters the compressor through the refrigerating chamber. The main problem is reliable sealing of the refrigeration chamber, which must be equipped with a condensate drain. When soldering/welding, the maximum air pressure that will enter the refrigeration chamber should be taken into account. Of all types of filter drier for a compressor, the permissible pressure here will be the lowest, which will accordingly affect the painting performance.

A dehumidifier for an industrial compressor is not cheap. For example, the price of a compact filter-moisture separator of the Caliber brand (designed for excess air pressure up to 8...10 atm) is 1600...1800 rubles. And for the multifunctional station Hans (Germany) with a pressure regulator and lubricator (nominal pressure - up to 10 atm) the price is already 7,500 rubles.

There are also combined designs. For example, a moisture separator can be easily obtained from coarse filters from SATA (Germany) or WALCOM (Italy). To do this, a deflector is built into the existing circuit diagram of the unit (regular, automobile, has too large dimensions), and in the lower part of the device it is necessary to replace the solid bottom with an annular one, into which a float or nozzle type condensate drain must be welded.

DIY compressor dehumidifier

Homemade cyclone type moisture separator

If it is not possible to get a coarse filter from DAF or Iveco trucks (such filters are the easiest to adapt), then there is nothing impossible in making the device in question with your own hands.

For a cyclone dehumidifier you will need an old liquefied gas cylinder (or fire extinguisher body), an adapter fitting and two metal tubes. First, a hole is made at the bottom of the cylinder for a condensate drain (but you can do without this if you weld a regular tap into the bottom of the lower part of the cylinder or body). The outlet fitting is welded into the top of the cylinder.

Three legs are welded along the perimeter of the body at an angle of 120º. The legs are equipped with heels for a stable position of the dehumidifier. After this, the body can be painted. The inlet pipe is welded in such a way that there is a distance of at least 120...150 mm between it and the condensate drain valve.

A steel mesh filter can be attached to the upper fitting. To do this, the upper fitting is made as a composite: first, a thick-walled washer with a mesh is welded between it and the body, and then the upper fitting is welded to it. However, such reinsurance is only needed if the air in the room where painting is performed is contaminated with fine dust.

Read also: Power supply for cordless screwdriver

Homemade adsorption type dehumidifier

In order to make this type of dehumidifier for a compressor, you need to use an oil or water filter from any car. The housing and placement of fittings, as well as the location of the condensate drain, do not change. A steel tube (preferably with a built-in filter) is installed in the inlet hole of the filter, and the second hole is plugged using a threaded plug, which is seated on the sealant.

The annular space between the inner wall of the housing and the outer diameter of the filter is filled with adsorbent. In order for moisture absorption to occur gradually, rubber sealing rings are used, with the help of which the entire space of the housing can be divided into 3 zones. You will need two o-rings. But, if the compressor dehumidifier is not used often for its intended purpose, you can fill the entire annular gap with silica gel.

All that remains is to assemble the device and attach it to the body. Calculation of the amount of silica gel is carried out from the practical ratio of 1 kg of adsorbent per 800...850 l/min of air. Silica gel is a regenerable substance: to do this, just leave it in the oven for several hours. Silica gel with a color indicator is more convenient: when all the pores in the substance are clogged with moisture, its color changes, which is the basis for replacing it.

This is not a flaw or design flaw. A compressor of this type has found its wide application in various work processes that do not require high-quality preliminary preparation of the air mass. Models without an oil tank are equipped with a filtration system. To do this, use a compress moisture separator , which helps separate the oil components and the incoming air flow.

Device Description

By dehumidifier we mean a high quality filtration agent. It ensures optimal operating characteristics of the equipment, and also cleans the composition of the air environment that is released by the pneumatic system. Modern compressor models are often supplemented with a panel or oil filter, which thoroughly prepares the working mixture.

This is an important filtration stage for a pneumatic system that maintains oversized tools. Standard models of compressor dehumidifiers are more often used in automotive workshops, as well as on production lines where workers perform a large volume of paint and varnish operations.

As a result of thorough cleaning and reprocessing, the pneumatic system releases air that is free of moisture particles. Due to their properties, moisture separators are used for the proper operation and operation of sandblasting construction equipment.

Principle of operation

The dehumidifier begins to process the compressed air before supplying it to the pneumatic equipment. It is important to remember that spray guns cannot be used without this device, so that it does not fail prematurely, as well as to ensure high quality paint application to the surface. During the filtration process, the jet goes through a cleaning stage , so fine liquid particles, as well as small solid elements, are removed from the air.

Depending on the type and design of the device, the operating principle of the dehumidifier may vary slightly. Today, among a large and varied selection, the following options are presented:

The most commonly used are vortex and cyclone dehumidifier devices for compressor equipment. The device helps to effectively retain water particles thanks to the artificially created turbulence of the air flow.

The liquid settles on the surface of the walls, so clean compressed air enters the pneumatic system. To ensure maximum efficiency of the dehumidifier, the internal space is supplemented with blades. When they are set in motion, they carefully collect water and oil particles. They are discharged into a special condensate drain. Liquid fractions are retained and blocked using membranes.

Types of ammonia receivers for refrigeration units

Ammonia receivers , being containers for collecting liquid refrigerant, depending on the purpose, are divided into the following types:

- Linear receivers in the form of horizontal welded vessels perform the following functions:

- unloading the condenser from liquid ammonia;

- compensation for uneven supply of refrigerant to the evaporation system;

- container for ammonia when creating a reserve that ensures uniform supply to the control station in the event of possible leaks from the system;

- a hydraulic seal that prevents steam from flowing from the high pressure side to the low pressure side.

- The drainage receiver is a container covered with thermal insulation (horizontal or vertical), which is used for the following purposes:

- receiving liquid refrigerant when defrosting cooling devices;

- freeing equipment from liquid before repair;

- as a line receiver when connected to the condenser drain pipe.

- The circulation receiver is used to accumulate liquid ammonia before it is supplied to cooling devices in pump-circulation cooling systems. It can be horizontal or vertical; the latter also functions as a liquid separator.

- Protective receivers, installed on the suction pipeline between the evaporator and the condenser in pumpless systems, are used to protect the compressor from water hammer.

- A spare receiver is included in the refrigeration system to create a supply of refrigerant.

Since the day someone invented the refrigerator , refrigeration systems have become more complex and improved. Now it is a multicomponent system, the operation of which is carried out using specialized devices and is clearly regulated by certain rules.

Source

Specifications

The size of the fraction affects the quality of air mass purification. Devices for industrial use are used for fine water treatment. They cut off small particles, the size of which is about 5 microns. Most often, standard models of moisture separators are equipped with filters , the fraction of which is about 15 microns.

When choosing, special attention should be paid to the level of pressure maintained. In most cases, the mid-compressor filter operates at 7 bar. This parameter does not affect the quality of the final work. But users should consider the filter matching plan to the compressors. It is necessary to compare the level of power and load that arise during the circulation of compressed air under pressure within the system.

Filter-oil-moisture separator WIEDERKRAFT WDK-7840

To organize the efficient operation of pneumatic tools in the painting business, the WIEDERKRAFT WDK-7840 device is used. A chamber with dimensions of 213x87x81 mm and weighing 610 g purifies the surrounding air from dust, moisture, oil compounds, and other impurities.

Filter-oil-moisture separator WIEDERKRAFT WDK-7840

The WIEDERKRAFT WDK-7840 filter is used in piston and rotary (screw) compressors. In these systems, when compressing air, it is necessary to supply oil and mix it with air, so the installation is equipped with a lubricator. If at this moment the air is not cleared of moisture (the main enemy of paint):

- an emulsion is formed that will clog the pneumatic channels;

- at sub-zero temperatures, condensation will turn into ice and damage the lines;

- The air ducts will begin to rust.

Atmospheric moisture not captured by the WIEDERKRAFT WDK-7840 filter will mix with the car paint, causing bubbles to form and further peeling of the coating. The oil and moisture separator has a replaceable filter element, which can be easily replaced by disassembling the simple structure.

The device operates at -5 °C on the thermometer and at high positive temperatures, up to 60 °C, maintaining a stable pressure of 10 atm. The device is capable of passing 3000 liters of air in one minute.

Main technical characteristics:

| Replacement filter | 5 µm |

| Operating ambient temperature | From -5 °C to +60 °C |

| Maximum performance | 3000 liters of air per minute |

| Threaded connection, dimensions | 1/2 inch, 1/2 inch |

| Line pressure | 10 atm |

The cost of the goods is from 2500 rubles.

Types of dehumidifiers

There are several types of dehumidifiers that are used for domestic and industrial purposes. Before purchasing, you need to identify the tasks and compare them with the technical characteristics in order to select the optimal type of dehumidifier. Among the large and varied selection you can find:

- vortex filters;

- modular systems for compressed air purification;

- moisture-oil separator for compressor.

The peculiarity of the latter type of device is its effective removal of water, solids and oil. They are installed on oil compressors, which can intensively process parts using a lubricant. Large manufacturing enterprises with a large volume of work often use modular filtration systems.

Read also: Drawing of a wooden candlestick

In this design, the dehumidifier is a functional and important component, but it does not serve as an independent working filter.

The modular system is controlled by a controller, which issues various commands not only to the filter, but also to other nodes in the unit.

Criterias of choice

Depending on the application, the cleaning requirements also change. If you need to paint the surface using a pneumatic gun, but you need to pay attention to the small filter capacity. It is better to give preference to fine cleaning.

There may be minimum filtration quality requirements during the manufacturing process. But in this case, special attention is paid to production volumes. Experts recommend looking at the list of foreign particles that the filter collects. The optimal solution is a moisture-oil separator for a compressor, which processes water and oil particles from an air stream.

If your work requires a filter to collect excess moisture, then you can also purchase dehumidifiers. But they do not guarantee high-quality removal of various fractions, particles and foreign bodies.

Filter Wester 816-002 10 atm, 1/4F, 1/4F

To spray paint well with a gun, you need a lot of clean air - at least 200-400 liters per minute. Modern compressors are able to create the required pressure to satisfy such needs. But microparticles of atmospheric dirt and moisture will not allow high-quality painting of metal parts of machines.

Filter Wester 816-002 10 atm, 1/4F, 1/4F

An excellent embodiment of engineering comes to the rescue - a filter for a compressor for painting cars Wester 816-002. The device effectively cleans compressed air from mineral oils, water droplets, and suspended particles. At the same time, it not only shows the working pressure, but also allows adjustment to be made according to the needs of the master.

In addition to the air filter and gearbox with a built-in pressure gauge, the package includes a separator and equipment for supplying liquid lubricant - a lubricator.

Specifications:

| Brand | Wester |

| Product type | Filter, reducer, lubricator |

| Material of manufacture | Metal |

| Compound | 1/4 inch-1/4 inch |

| Maximum working pressure | 10 atm |

Filter price – from 2500 rub.

DIY making

A homemade dehumidifier consists of an old or used propane tank, fitting and pipes. The blank for the body is installed in a vertical position. A fitting for air inlet must be welded to the top part. Experts recommend moving it closer to the edges of the cylinder. Next, you need to make an inlet pipe for which you can use a pipe.

To remove moisture, make a hole equipped with a valve. It should be located at the bottom of the structure. At this stage, during the manufacture of the moisture separator, it is necessary to think through, perform calculations and make the filler. Wood shavings are used as a sorbent material, which can be filled into the inner niche of the cylinder. It is important to remember not to pack the container tightly. Air must circulate freely inside the system.

Adsorption type moisture separators

To make such a moisture separator with your own hands for use in compressors, you need to use oil and water filters from a car. There is no need to change the original arrangement of the housing, fittings and drainage device for collecting condensate.

The filter inlet needs to be changed. To do this, install a tube made of durable steel. To ensure stable operation of the device, it is best to use the built-in filter. The second hole is tightly closed with a screw plug. To make it stick better, it needs to be placed on a sealant.

There is an annular space between the inner wall of the housing and the outer diameter of the filter. It must be filled with adsorbent. A person who makes a dehumidifier on his own must remember that moisture absorption must occur gradually. Rubber O-rings are used for this purpose.

They can be used to divide the internal space of the case into three zones. If the dehumidifier will be used infrequently, the internal space and annular gap can be filled with silicate gel. After this, you can assemble the device and process the connecting elements. If you follow these rules, you can make a dehumidifier for a compressor with your own hands at minimal cost.

To calculate the required amount of silicate gel, you must use the following formula: take 1 kg of adsorbent for 830 l/min of compressed air. Silicate gel is a regenerable substance. To restore its original properties, you need to place the substance in the oven for 2-3 hours. Experts recommend using silicate gel, which has a color indicator. When the pores are filled with moisture, the color will change and you can dry it.

Installation Requirements

When operating a dehumidifier, several basic rules and requirements must be taken into account:

- The device can be installed strictly in a vertical position and securely fixed inside the case.

- During connection, you need to check the direction of air movement.

- If you buy a ready-made design, the direction is indicated on the body in the form of arrows.

If these rules are followed, the dehumidifier will function correctly and provide high quality.

Licota PAP-C207B Fine filter-moisture-oil separator 3/8″ 3-level, 0.01 micron

The design of the moisture-oil separator filter consists of 3 series-connected metal modules with a volume of 80 cm3 and a 3/8-inch internal thread. The highest level of air purification before entering the pneumatic lines occurs in products - 99.9%.

Licota PAP-C207B Fine filter-moisture-oil separator 3/8″ 3-level, 0.01 micron

Compressed air passes through the adsorbent substances of all three modules, hence the high degree of purification, inaccessible to standard filters:

- first chamber – 5 µm;

- second compartment – 0.3 µm;

- third flask – 0.01 microns.

The device operates in a pressure range from 1 to 9 atm. But an accurate pressure gauge also has a second scale with an international unit of pressure measurement - PSI.

The device weighs 2.6 kg and includes an automatic pressure regulator. Moisture falling from the air is released automatically: a breather is provided for this.

The compressor filter for car painting is protected from damage by contaminants. The threat will be signaled by the pink-colored granules of the 3rd flask. In this case, the central indicator scale will turn red.

Specifications:

| Internal thread size | 3/8 inch |

| Operating pressure | Up to 9 kg/cm2 |

| MAX pressure | 17 kg/cm2 |

| Performance | 300 l/min |

| Device weight | 2.605 kg |

The product costs from 2500 rubles.

Advantages of cyclone type filters

Water separators greatly simplify the operation of an air gun and compressor. They ensure stable operation of the equipment. The following advantages of cyclone type filters can be highlighted:

- simple design;

- reasonable cost;

- maximum efficiency;

- retention of large condensate particles;

- simple maintenance;

- regeneration and complete restoration of original properties;

- providing preliminary rough cleaning.

Dehumidifiers for compressors and air guns are an effective tool, without which it is impossible to imagine the operation of this equipment. They qualitatively prepare compressed air for further use. Filters separate primary moisture, oil particles, as well as contaminants of various fractions and other solid particles. Any pneumatic network must be equipped with a moisture separator that will clean the air for further use.

“>