Angle grinders are available in almost every home workshop today. This is justified by the fact that with its help you can solve many problems in construction and repair work. Let's consider which side to place the disc on the grinder so that you can use the tools for a long time and safely. Let's get acquainted with the methods of removing the equipment using a special wrench and alternative devices, if the attachment is serviceable or damaged and in case of jamming of the mechanism.

Replacing a disk on an angle grinder Source ad-cd.net

To install a new disk, after cleaning the casing, you must perform the following steps:

- We install the lower flange in its place;

- We place a special gasket on top of it (if gaskets are not provided, you can cut them yourself. The optimal material is cardboard or tin).

- Install the disk;

- Place the second gasket;

- We install the upper flange on top;

- We turn the upper flange by hand in the opposite direction from the rotation of the grinder circle, while holding the disk itself;

- Next, press the lock button again and turn the flange by hand until you feel resistance;

- At the final stage, we perform final fixation using the same open-end wrench. To do this, insert the key into the holes and scroll a little more.

After all the actions have been completed, you can safely continue to perform work.

One of the most frequently asked questions about installing/dismantling angle grinder equipment is: “Which side should you put the disc on the angle grinder?”

Usually, inexperienced masters ask this question. Is it possible to install the circle with the wrong side - yes. Firstly, if the disk is not flat, but, for example, petal-shaped, then you will not be able to install it incorrectly; if the petals are positioned incorrectly, you just need to twist the casing and handle on the grinder. That is, the question disappears by itself.

If the circle is still flat, then you should focus on its label, the so-called “shirt”.

If the angle grinder rotates towards itself, the disc should be installed with its face outward, but if the disc rotates away from itself, then, accordingly, it must be installed with its face inward.

If you do not adhere to this algorithm, there is a high probability that the disk will fail very quickly or immediately become deformed.

Why is it better to point the label and ferrule outward?

Let's consider the advantages of placing the ring and pattern on the outside, when there are no other instructions on which side to install the disk on the grinder. The first point significantly simplifies the process of replacing the nozzle. The metal part offers less resistance than the abrasive surface. It also ensures that the circle is secured evenly.

If you place the picture outside, then the main advantage of this solution is the availability of information about the physical parameters of the disk, its purpose and operating conditions (for example, permissible metal thickness or rotation speed). Often the name of the specific sample and the manufacturer are also important.

An example of decrypting information from the labeled side of a disk Source yandex.net

Saw blades for angle grinders

Wood saw blades for angle grinders were developed by various manufacturers and, accordingly, have several varieties. The simplest and definitely the most budget-friendly option is to install a disk for a circular saw of appropriate sizes on the grinder - both the outer diameter and the diameter of the internal mounting hole. For an angle grinder, which according to its size characteristics is classified as small, a circle measuring 125x22 mm is suitable.

Technically, you can install a disk with a diameter of 230 mm on a small grinder, but to do this you will have to remove the protective cover, which is absolutely unacceptable. The angle grinder user's hands are in close proximity to rotating working surfaces and any emergency situation can cause serious injury. Using such a wheel on an angle grinder can cause serious safety violations and is strictly not recommended for beginners.

Any distortion, including those associated with the unevenness of the wood structure, can cause jamming of the disk and, as a result, a sharp jump in the entire unit, to the point where it can break out of your hands and make a dangerous, unpredictable flight. The circular saw blade is not designed for such fast speeds as the angle grinder spindle produces; this causes it to heat up excessively, which affects the strength of the steel. As a result, if the saw wheel is misaligned, it may collapse with fragments scattering at high speed in unpredictable directions.

Special attachments for sawing wood, developed for UMS, have significant differences from the circular saw blade. Let's look at the most common options for sawing wood. On sale you can find saw blades similar to circular saws, which have an increased tooth spread, which significantly reduces the likelihood of them jamming. In addition, the difference in the manufacture of such a disk is that other alloys are used, this reduces the risk of destruction of the disk when it is heated.

Further attempts to protect the blade from jamming led to the combination of a circular saw and a chain saw in one product. A chain similar to a chainsaw chain moves freely along the working surface of the disk, which absolutely eliminates jamming. There are quite a few modifications of this hybrid. Craftsmen using such a combination saw successfully cut branches and can even cut not very thick trees.

A completely new direction in the evolution of circular discs was marked by the invention of a special attachment that is suitable for working on various materials. This universal disc is made from a special composition - tungsten carbide. There are no teeth on such a saw blade at all. This type of disc allows you to cut a wide variety of materials well; it can be considered the safest disc for sawing wood of all those used on angle grinders.

Roughing

It’s worth mentioning right away that roughing and grinding discs go hand in hand, and in many stores in the “type” parameter of the attachment it may be written: “roughing grinding disc.” In our article we will divide this “couple” into two types. Peelers in this context are an attachment for freeing the structure being processed from the outer layer, for example, from rust. There are the following peeling attachments:

Roughing discs. Sanding discs, like cord brushes, can be flat or cup-shaped. They are intended for cleaning welds and preparing metal surfaces for grinding.

For metal, concrete, wood and other materials

To effectively process any material, it is important to choose the right power so that it matches the diameter of the tool and its thickness. In addition, the consumable must be suitable for processing a specific type of workpiece material

The main difference between discs for steel, cast iron, and non-ferrous metals is in the composition of the fillers. To process alloy steels, a very strong additive is added to the disc material that can overcome the resistance of alloy steel. When processing non-ferrous metals, on the contrary, a soft filler is added, which works effectively when processing viscous materials.

Disc for aluminum

To process concrete (tiles, paving slabs), diamond discs are used (actually, these are metal circles coated with diamond).

Tile disc

It is not recommended to process wood with an angle grinder due to the high risk of injury. If such a need nevertheless arises, then the best option would be a grinder with a disk with a diameter of 125 mm. As a working tool, special angle grinder discs for wood should be used.

Wood disc

Typical disk sizes

When choosing a disc for an angle grinder, you need to make sure that the outer diameter of the attachment does not exceed the maximum permissible values allowed for your angle grinder. For example, if a grinder is designed to use a circle with a maximum diameter of 125 mm, then a 230 mm circle cannot be installed on it. And there are several explanations for this:

- the linear speed of the cutting edge will be exceeded, which can lead to destruction of the abrasive wheel and injury to the user;

- a small grinder does not have enough power to work with a large tool;

- installing a nozzle that exceeds the permissible dimensions requires removing the protective casing, and this is a violation of safety rules.

Discs for angle grinders have standard sizes: 115, 125, 150, 180 and 230 mm. In modern angle grinders, the mounting diameter (the diameter of the shaft on which the tool is installed) is almost the same and equals 22.2 mm. If you have an outdated model of an angle grinder lying around, you will need to use adapters - rings of different diameters.

All abrasive wheels of any size have special markings, from which you can find out the following information: the diameter of the disc and its thickness, the diameter of the seat, the maximum rotation speed, as well as what materials it is intended for processing.

How to change a disc on an angle grinder without a key?

Method 1. Use a gas wrench

Use an adjustable pipe wrench to grasp the nut and carefully unscrew it without applying much force. Disadvantage: you can crush the nut and break the rotation lock

Method 2. Make a homemade key for the grinder. To do this you will need a long nail (at least 100 mm). You need to cut off the head, the point and give the nail a U-shape. It should be bent in such a way that the “tool” posts fit into the holes in the flange. If the nut is tightened tightly, insert any metal rod between the posts of the nail and, holding it with both hands, rotate the structure in the direction of movement of the circle. At this time, you need to press and hold the spindle lock button. The method is safe, but it requires time and additional tools - a hacksaw, a vice, a hammer.

Method 3. Tapping with a chisel. Before changing the disk, you can treat the spindle shaft with WD-40 and wait at least 15 minutes. Then place the tip of a thin chisel at an angle to the hole of the flange nut and gently tap over the entire surface of the hole with a plumber's hammer. Sooner or later, thanks to gentle tapping, the nut will move, and it will be possible to unscrew it manually. The disadvantage of this method is that the holes can be damaged and the flange can be damaged.

Method 4: Heat the nut. If it is difficult to unscrew the angle grinder nut by hand, you can heat it a little with a gas burner or autogen. You need to wear gloves when unscrewing the flange to avoid getting burned. This is the riskiest of the proposed methods. It is possible to overheat the bearings and oil in the gearbox of an angle grinder.

Finally, I would like to mention a few important points regarding replacing a disc on an angle grinder.

- You need to install wheels of the appropriate size on your angle grinder. It is necessary to strictly observe safety precautions and under no circumstances remove the protective casing to install a disc of a larger diameter. When choosing a disk, you need to take into account the model of the power tool, its power, and spindle speed.

- Due to the disk rotating at high speed, hardening forms on the protective casing of the angle grinder. Therefore, when changing a disk, remove and clean the casing.

- Some models of angle grinders are equipped with washers to prevent the disc from getting stuck between the flanges. At the very least, the support flange can be equipped with a rubber washer. Instead of factory fasteners, you can cut gaskets from cardboard, rubber or plastic. It is necessary to use 2 gaskets: between the support flange and the disk, between the disk and the nut.

- Do not forget: if the circle rotates clockwise, then the nut is also unscrewed clockwise and tightened counterclockwise.

- If you don’t want to buy a new key, install a Bosch quick-release nut on the angle grinder - you can easily unscrew it by hand.

The main thing is that when changing a disc on an angle grinder, do not violate safety precautions and perform all manipulations with the tool unplugged.

How to remove and change the disc of an angle grinder, what types of angle grinder cutting wheels are there + video instructions

spare part for an angle grinder (angle grinder) - a replaceable cutting tool. An abrasive disc rotating at high speed cuts, grinds or polishes materials.

For metal processing, circles are made from abrasive chips; for wood, steel cutters are used; for stone, metal discs coated with diamond are used. Special attachments - brushes, flap sanding wheels - further expand the capabilities of your grinder.

Next, we will find out what types of disks there are, how to properly remove the old one and install a new one, and also consider possible problems that arise during the replacement process and ways to solve them.

Types of discs for grinders: how to choose the right one

The industry produces grinders and wheels for them in standard sizes: 115, 125, 150, 180 and 230 mm. Angle grinders from 180 mm are used for cutting stone. The most common size of machines for home and garden use is 125 mm; they produce the most discs and attachments for them.

Attention! Always select a disc that matches the size of your angle grinder. A disc of a smaller diameter can be installed in an angle grinder. But removing the casing and installing a disk with a larger diameter is extremely dangerous!

We suggest dividing the discs according to their purpose: cutting, grinding, sharpening and roughing. Let's look at each type in detail.

Cutting through metal

Inexpensive steel disc from Luga plant

Cutting materials is the most common task during repairs and construction; a simple abrasive wheel for metal can easily cut through steel bars, roofing iron or plastic. These wheels are made of corundum (crystalline alumina) or electrocorundum (synthetic corundum).

When purchasing, we recommend that you carefully read the labels on the disc or packaging. A circle for cutting metal is indistinguishable in appearance from a disc for stone.

Sawing stone

The budget stone disc is produced by the Luga plant

To cut stone, we recommend taking a special disc - they use a different abrasive - silicon carbide. It can handle white sand-lime brick and slate. But red brick, tiles and especially concrete will not succumb to it - you need to take a diamond blade.

For work at home and in the country, we recommend wheels from the Luga plant. They quickly wear out and get dusty, but cost only 15–20 rubles apiece.

Letting go of the tree

These are also available for grinders

The blades that cut wood are very similar to the blade of a circular saw. Actually, this is a disk for a circular saw, only the mounting diameter of 22.2 mm is suitable for the grinder spindle.

Attention! We do not recommend that home craftsmen cut wood with a manual grinder. A tool thrown by recoil will cause serious injury.

Diamond

As you know, diamond is a very hard mineral, so diamond discs can easily cope with red brick, porcelain stoneware, and tiles. The main material that is cut with diamond blades is concrete.

Diamonds must be handled with care - the disc should not be used to cut steel, and it should not be overheated. After just two minutes of sawing concrete, the disc will become very hot - take a break. Slots are made around the circumference of the dry cutting disc for cooling.

They produce discs for wet cutting of ceramic tiles and porcelain stoneware. The water cools the disc and washes away dangerous dust.

How to choose the thickness of cutting discs

Every master knows that the thinner the tool, the better. Less material goes into chips, it’s easier to saw, and the cut comes out cleaner.

Discs for grinders 115 and 125 mm are produced with a thickness of 1.0–2.5 mm. Discs 150 and 200 mm - thickness 1.8–4.0 mm. Pressed corundum powder is reinforced with synthetic mesh.

Attention! The thinnest disk (1.0 mm) “walks” when sawing and breaks easily, its pieces fly at high speed in all directions. Don't forget to protect your eyes and hands.

The recommended cutting disc thickness is 1.6 mm.

Grinding

The next most important job that craftsmen entrust to an angle grinder is grinding and polishing. Similar processing is applied to metal, wood, plastic and other materials.

Flap wheel for wood: dozens of sanding flaps quickly cut off chips

The choice of grinding discs is very wide. If you are restoring a sideboard, a flap wheel is suitable for removing layers of shellac. It covers large surfaces and cuts a lot of material in one pass.

The sanding attachment is a plastic circle to which sandpaper is attached with Velcro

Another attachment is screwed onto the grinder spindle. Sandpaper is attached to it with Velcro. For coarse processing - P60 or P80, for finer processing - P120 or P180. As the grain size decreases, grinding smoothly turns into polishing.

Polishing disc made from alpaca wool

Especially for polishing, there are attachments in the form of pads, felt or fabric discs. Before work, polishing paste, for example, GOI, is applied to them.

Grinding wheels

In fact, there are special machines for sharpening tools - sharpeners. Nevertheless, the rotating disk of the grinder is capable of correcting a dull ax or cleaver, knife or scythe. Taking into account the wishes of the craftsmen, the industry produces 115 and 125 mm sharpening discs for grinders.

Sharpening discs turn the grinder into a sharpener

The discs are made of coarse abrasive, compressed into a thick plate (more than 5 mm) with a bulge in the center. If you install such a disk on a spindle, the flange is hidden in the recess and does not protrude above the plane of the disk. Coarse grinding wheels are also used for cleaning welds.

Sanding brushes and discs

Craftsmen renovating mid-century homes are faced with removing oil paint from walls. Wire brushes are suitable for this type of work.

Not a single paint can resist such a steel cup.

The brush is a cup with steel or brass strands around its circumference. They differ in the thickness and rigidity of the wire - for coarse and fine stripping. The brush is screwed onto the spindle using an M14 thread.

Stone grinding disc cuts old cement evenly

After removing the oil paint, the curved concrete wall must be sanded. Only a grinder can cope with such a task. The working surface of the diamond grinding disc is perpendicular to the axis of rotation. Synthetic diamonds cut and smooth concrete like sandpapering wood.

How to make a replacement

It’s already inconvenient to cut with such a disk

Grinder discs are a consumable material; when cutting, they wear out quite quickly. A worn out disk must be replaced. Let's see how to do this using our Interskol-115 angle grinder as an example.

Attention! Before work, make sure that the machine is disconnected from the electrical network!

Step-by-step instruction

The disc is mounted on the angle grinder spindle with a clamping flange with an M14 thread. To unscrew the flange, the grinder kit includes an open-end wrench. Its pins cling to the flange holes.

An open-end wrench will unscrew the flange

To unscrew the flange, the spindle must be locked. To do this, a clamp is made on the side of the case opposite to the disk. When you press the button, the cotter pin enters the hole in the driven disk of the gearbox and prevents the spindle from rotating.

The button locks the spindle

Insert the open-end wrench into the flange holes. With our right hand we press the lock button, at the same time with our left hand we turn the key counterclockwise and remove the flange from its place.

An open-end wrench is inserted into the flange holes

Our grinder rotates clockwise. If you have a different direction, remember - you need to unscrew in the direction of rotation of the disk.

If the flange gives way, unscrew it by hand, remove it and put it aside.

Top flange removed

We remove the old disk. We don't need it anymore, we can throw it away.

Old disk removed

Remove the bottom flange.

Bottom flange removed

During intensive sawing, a hardening of burnt metal and abrasive particles is formed on the inside of the casing. Let's use a steel brush to clean the casing.

The brush cleans the casing

We install the lower flange on the spindle, making sure that the flats on the flange coincide with the grooves on the spindle. Place a gasket on top.

Bottom flange and gasket installed

If your grinder does not come with gaskets, such a washer can be cut out of cardboard or tin.

We put the disk in place and cover it with the second gasket.

New disk installed

Thanks to the gaskets, if the disc gets stuck in the material and breaks, you can still easily unscrew the flange.

We tighten the upper flange by hand against the direction of rotation of the wheel (in our case, clockwise), holding the abrasive disc. With your right hand, press the lock button and twist it by hand until you feel resistance. Insert the open-end wrench and tighten it a little more, no more than a quarter turn. There is no need to tighten the flange too much; the disc will warp.

The disk has been replaced, the angle grinder is ready for work

At this point, the replacement of the disk is completed, you can continue sawing. Sometimes when changing a disk, obstacles stand in the way of the master. We will consider what to do in such situations further.

What to do if there is no key

The open-end wrench is not attached to the grinder and may well get lost. How to unscrew the flange in this case?

- We make an open-end wrench from a nail. We take a weaving nail and bend it in the shape of the letter “P” so that the distance between the vertical posts is equal to the distance between the holes in the flange. Cut off the tip and head with a hacksaw. We stick the resulting “key” into the holes of the flange and unscrew the mount, not forgetting to fix the spindle. If the nut is tightly tightened and your fingers are not strong enough, insert another nail between the vertical sections - the lever will be greater.

- We use the gas key. We take a large pipe wrench, it is also called a “gas wrench”. Plumbers use this tool to twist steel pipes. We spread the key so that it covers the entire flange. We try to move the nut from its place, securing the spindle. The gas key has a huge leverage. If you apply force, the spindle lock will break.

- Tapping the nut. Take a metal rod or thin chisel. Lock the spindle. Tap the edge of the hole in the flange in the direction of rotation of the disc. This way you can move the nut out of place. This method is not the safest: the tool damages the flange and breaks the key holes.

The disk is broken, the flange is jammed

Let’s imagine that a craftsman is making an anvil from a steel rail and cutting out the tip with a grinder. The disk became distorted in the material and jammed. The motor continues to run and tightens the flange tightly. All work stopped. How to change the disk if now it does not unscrew?

- Let's disassemble the gearbox. Unscrew the fastening and remove the gearbox housing. We hold the spindle shaft with a gas wrench or pliers, and twist the flange with a horn or another gas wrench. This method does not affect the disc; a normal, good disc can be removed. The method works even if the spindle lock is broken.

- We use two gas keys. The method does not require disassembling the grinder. Carefully break out the remains of the disk to get to the bottom flange. We clamp the upper flange with the first gas wrench, and engage the lower flange with the second key. We twist in opposite directions.

- Heat the nut with a torch. We heat the stuck nut with a portable gas burner. The nut will expand as it heats up and can be easily unscrewed.

- Cut the flange with a hacksaw. Some craftsmen prefer to cut through a stuck flange with a hacksaw. The method is barbaric - you will have to buy a new nut.

- Lubricate the threads with penetrating lubricant. Spray the stuck nut with WD-40. It penetrates into narrow crevices and threaded connections. After a five-minute break, try to move the nut with a wrench.

- Cut out the remaining disk with a hacksaw. We break the disk with pliers while it is possible. We remove the protective casing, insert a hacksaw into the gap and cut out the remains of the abrasive wheel. Delicate and reliable method. Does not require disassembling the grinder and harsh influences on the tool. The master must have patience, as the method will take up to an hour. The abrasive quickly wears out hacksaw blades; you will need several of them. The advantage is that the angle grinder maintains the warranty, there is no risk of breakdown.

What are cardboard spacers used for?

It's very simple and very important. To ensure that the flange can always be easily unscrewed, a gasket must be placed between the abrasive disc and the flange. Or two - on each side of the disk.

These circles ensure that the flange does not get stuck

Such discs can come complete with an angle grinder, or you can cut them yourself.

For spindles of angle grinders, factories produce thin and thick abrasive discs, metal cutting wheels, and nylon brushes.

All these spare parts turn the angle grinder into a universal tool and reveal its capabilities in unexpected ways. For example, a grinder turns into a sharpener.

Changing the disk is not difficult, but the technician must know about some features of the process so as not to get into a difficult situation.

Source: https://tehznatok.com/kak-vyibrat/kak-vyibrat-i-zamenit-disk-na-bolgarke.html

Peculiarities

Let's look at what a cutting wheel for an angle grinder is. In fact, this is the main device in the process of cutting or processing material. The engine in the grinder spins a diamond disk, which has a certain number of cutting crystals. It is these strong crystals that cut the surface.

A cutter can be designed for different types of work depending on the material that needs to be worked with and its functional purpose. There are cutting wheels for metal, wood, plastic and even stone. Over time, the circle gradually wears off and becomes smaller.

What kind of discs can be used on an angle grinder? 1

spare part for an angle grinder (angle grinder) - a replaceable cutting tool. An abrasive disc rotating at high speed cuts, grinds or polishes materials.

For metal processing, circles are made from abrasive chips; for wood, steel cutters are used; for stone, metal discs coated with diamond are used. Special attachments - brushes, flap sanding wheels - further expand the capabilities of your grinder.

Next, we will find out what types of disks there are, how to properly remove the old one and install a new one, and also consider possible problems that arise during the replacement process and ways to solve them.

Recommendations from specialists for certain types of work

Next, we will tell you how to use an angle grinder with various metal products.

Sharpening a chainsaw chain

Photo No. 12: sharpening a chainsaw chain with a grinder

The chain is sharpened on the boom of a chainsaw. For work, use a sharpening disc with a thickness of 2.5 mm. It is necessary to mark the first tooth that you will treat. With proper actions, you can update the chain 4-7 times before it completely fails.

Pipe cutting

Photo No. 13: cutting pipes with a grinder

It is better to start cutting thick metal with a grinder from the edges. If you start from the middle part, the disc may jam and bend. During processing, apply force to the lower part of the cutting tool, which ensures efficient cutting.

Cutting moldings

Photo No. 14: cutting corners with a grinder

To cut metal corners, you can use worn discs or a small diameter tool.

It is important to remember that the work is gradual: first, one part of the molding is cut, then the second.

Sharpening a circular saw blade

Photo No. 15: sharpening a circular saw blade with a grinder

Start by securing the angle grinder with clamps, leaving access to the rotating part of the tool. Then bring the saw blade to the grinding wheel without applying much force. The circle should pass tangentially across the product. When working, ensure that the sharpening plane is maintained.

Cutting wheels for grinders, in turn, have their own subtypes, such as:

- Cutting wheels for metal work;

- Abrasive wheels for working with stone;

- Circles for woodworking;

- Diamond blades (mentioned above).

The purpose of each type of disk usually corresponds to its name.

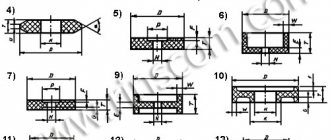

Among grinding discs, there are four main subtypes - flap, wire, diamond and bakelite-based grinding discs (straight, T41 profile and disc, T27 profile).

- The flap disc is made of sandpaper. Its main purpose is to remove existing coating, such as old paint, primer or a layer of paintwork. Also, discs of this type are used for polishing wooden products.

- Wire discs are used by craftsmen to remove rust. They can also remove other types of stubborn stains.

- Diamond discs are used for polishing stone.

- Disc discs are made of plastic or rubber and are used for polishing metal surfaces.

What are the differences between the sides of an abrasive wheel?

The two sides are different: one has a label with the characteristics of the circle, and the other has a solid color coating. Separately, it is worth mentioning the metal ring, which directly affects safety during operation.

Metal ring

The main purpose of this element is to protect against the tightening of abrasives, which can be damaged if tightened tightly during installation. In addition, it increases the supporting surface area and simplifies the process of removing the wheel, preventing it from sticking.

Cutting discs

Cutting discs are most often used when working with an angle grinder. The following nozzles are distinguished by purpose:

For metal. Such cutting wheels are made from electrocorundum or crystalline corundum. In this case, a bakelite bond is often used inside the product. Depending on the thickness and size, the disc can cut metal profiles, stainless steel, heating pipes, etc. GRAFF GADM 115 10 is one of the representatives of inexpensive metal discs.

For stone and concrete. Circles for cutting stone and concrete are made of silicon carbide

Please note that the disc is intended for relatively “soft” materials, such as white brick and slate (harder ones will require a diamond wheel)

For ceramic tiles and concrete. This attachment is designed for cutting paving stones, ceramic tiles, red bricks, cutting strips for gating, etc. The disc itself is made of metal with diamond chips applied to the cutting edge. There are solid all-metal and segmented discs. The first ones are intended for wet cutting (cooling with water), as they become very hot during the process. Segmented ones are convenient for dry cutting, and they are the most popular among diamond blades. Here, for example, is a high-quality, durable segmented disk Makita B-28086 for cutting concrete and stone products.

For the tree. Discs for processing wooden structures are made of tungsten carbide or metal with abrasive coating. The first ones are designed for cutting hard and soft wood, plasterboard, gas silicate and MDF. The second one can also cut metal and even wood with nails (but this needs to be checked experimentally). Bison Professional 36859-125 is just such a representative of the “nail saw”.

Universal. These attachments can cut almost all types of materials (for wood, it is better to take a direct-use attachment). In particular, they are convenient to use when you have to cut different materials in one working day, and you don’t want to waste time changing the nozzle. Universal models even cut reinforced concrete. However, they are often quite expensive, and sometimes it is more profitable to buy two disks for different types of materials being processed. Of the good universal circles, we can recommend Wolverine 100125, which is suitable for both wet and dry cutting.

About diamond tools

" Back

Most specialists in repair and construction work today are well acquainted with an angle grinder or, as it is popularly called, an angle grinder. It is used to process a variety of materials, including stone, reinforced concrete, concrete, marble and many others. At first, beginners may have a number of questions, among which the most common are: how to properly install the disc on the grinder, how to secure the disc on the grinder, which side to put the disc on the grinder and in which direction the disc on the grinder should spin. Let us now try to briefly answer all these questions.

What is required to install the disk?

Installing a disc on an angle grinder is usually a fairly simple process in which you need to follow a few rules. In order to do this, you need to equip yourself with the appropriate tool - a wrench, which will be necessary to unscrew the nut. The next step after unwinding it will be replacing the grinder disk or its initial installation. If something happens that jams the disk in the grinder, to remove it you will have to crumble it and remove the remains from the gap between the support flange and the nut using a flat screwdriver or chisel.

Which side should you put the disc on the grinder?

Which side to place the cutting disc on may depend on several factors. Firstly, if the disk is not flat, then there is only one way to place it and the question disappears by itself. Secondly, if the circle is still flat, you can focus on the label - if the grinder rotates away from itself, then it is installed with the label inward, if towards itself, then, accordingly, outward. If this principle is not followed, then you can expect undesirable results - breakage of the disk during the sawing process or simply its rapid wear.

As for which direction the disc on the angle grinder rotates, this is primarily a safety issue. It is believed that it is necessary to cut concrete in the direction of rotation of the disk or towards itself. In an ideal position, sparks should fly to the side to the left of the person working with the tool. If this cannot be done, then you can use another position when the sheaf of sparks is directed downwards. In any case, a situation should not be allowed where sparks fly from the user, since in the event of a sudden jamming of the disk, the angle grinder will be directed towards him.

In other words, cutting materials against the direction of rotation of the disk or away from yourself is extremely unsafe, since in the case of a wedge, there is a sharp ejection of the angle grinder in the direction of the person working. By the way, if additional questions arise regarding how to install a disk on an angle grinder, you can also watch training videos, of which there are more than enough on the Internet today.

If you have any questions or need advice on changing and installing disks, just leave a request on the website or call the specified contact phone number, and our specialists will tell you how to proceed correctly. The entire range of our diamond blade products is presented in the diamond blades section.

Types of discs for grinders

Angle grinders are widely used in construction and repair technological operations. Grinder discs differ from each other:

- dimensions of outer diameter and thickness;

- material and manufacturing method;

- purpose and maximum rotation speed.

Choosing wheels for an angle grinder requires knowledge and consideration of the features of not only the workpieces being processed, but also the capabilities of the tool itself.

Cut-off

The most used wheels for angle grinders are also called abrasive wheels. They are classified according to different criteria. There are discs for working with metal, stone, and wood. There is also a diamond disc, which is used to work with the most durable and hard materials (reinforced concrete, porcelain stoneware, tiles, marble, granite and other natural and artificial stones).

Let's give a brief description of each type.

A common feature for all cutting discs is classification by outer diameter and thickness. The outer diameter is:

- 115 mm for small household grinders;

- 125 and 150 mm for average power and weight angle grinders;

- 180 and 230 mm for powerful professional tools.

The thickness of the discs varies from 1 to 3.2 mm. It depends on the size of the nozzle: discs with a large diameter have greater thickness; medium and small disks - any. The choice of disk thickness is influenced by:

- speed of rotation of the working body of the grinder;

- expected load.

Cutting (abrasive) wheels for metal

These wheels are used to work with body sheet steel (disc thickness from 1 to 1.6 mm) and long rolled steel: reinforcement, round timber, channel, angle and other types (disc thickness from 2.5 to 3.6 mm). There are special attachments for working with stainless steel, aluminum, cast iron and other metals.

Metal cutting disc for grinder

Data about this is available on the surface of the disk in the form of markings and a colored stripe. Abrasive discs consist of several layers of fiberglass mesh onto which bakelite abrasive material (silicon carbide, corundum, electrocorundum) is pressed on both sides under high pressure. The reinforced abrasive discs are then placed in a heat treatment oven to gain strength. The set heating temperature is 200 degrees. There the mass is sintered and becomes strong and resistant to fragmentation.

They are absolutely identical to metal discs and differ only in the abrasives used.

Circle for stone

For wood

They are made of high-strength steel and equipped with sharp teeth along the outer diameter. These nozzles work on the circular principle and are quite dangerous to operate. It is recommended to permanently fix the angle grinder using a special device.

Wood cutting disc for grinder

Diamond

They are used for cutting high-strength materials from natural and artificial stone.

Diamond blade for stone grinder

There are different types of diamond blades for concrete, reinforced concrete, and stone. They differ from each other in the fractionation of diamond coating and the type of cutting edge - solid, with large or small slots, notches

It is important to know that the diamond blade is not used for working with metal workpieces. It is difficult to understand the purpose of diamond discs by appearance

The best option is to consult a sales consultant before purchasing or carefully study the package supplement.

Some manufacturers of diamond blades paint the front side, depending on the material for which they are intended:

- green - for granite;

- yellow - for plaster and tiles;

- blue - for marble and concrete;

- gray - for granite ceramics and tiles;

- orange - for brick.

A diamond blade with a segmented cutting blade is used for dry cutting of stones. Wheels with a continuous cutting edge require water cooling. Turbo discs with slots in the body of the wheel operate at a higher rotation speed than discs with a segmented blade.

Grinding and roughing

Grinding wheels are divided into four types:

Using flap (emery) attachments, remove old paint, primer or varnish, and sand wooden products.

This is what a petal disk looks like

Special wire wheels eliminate rust and remove stubborn dirt.

Diamond modifications in the form of a bowl are used to polish stone products.

Metal surfaces are polished with plastic or rubber discs. You can attach replaceable discs with sandpaper, felt, sponge, or cloth to the plates.

Most grinding discs work with special pastes or liquids that include fine abrasives. These attachments are used to grind the surfaces of any materials, including car body parts in car repair shops.

Is there a significant difference depending on the direction of rotation?

The direction of rotation of the cutting wheel can be either “pull” or “pull”. Each of them has its own advantages and disadvantages. So, when the disk rotates “pull”, dust and sparks fly at the operator, which creates additional difficulties in work and is associated with possible burns to the eyes, skin, and clothing catching fire. Rotating the disk towards itself does not have this drawback. But in this case there is also a higher risk of injury. After all, if the disk becomes jammed, the tool will fly forcefully into the operator’s face. There is no single rule for which direction the cutting wheel should rotate.

If this is important, then the information must be indicated on the instrument. In all other cases, the direction of rotation is selected by the operator, taking into account the type of surface being processed, convenience and work experience

What is the difference between the sides of the disk

The first side does not have any designations, markings or images. On the second side of the disc there is a company logo of the tool manufacturer. Its parameters and a metal crimp ring may also be indicated.

The presence of a crimp ring helps to increase the area of support and the crimp nut. This not only distributes the load on the disc evenly, but also ensures the integrity of the disc when the ferrule nut is tightened. It is also important that the locking ring protects the clamping nut and abrasive surface from boiling.

The nut is stuck - how to unscrew it?

Removing a disc on an angle grinder if it is bitten is not so easy, especially without damaging the cutting element or tool. We will also consider several options for action.

Replacing a counter-rotating disc

This method has several advantages - it can be done without a key and with a broken spindle lock. Beginners in working with angle grinders mistakenly believe that if the stopper breaks, it is almost impossible to unscrew the nut. However, this is not the case. You don't even need keys.

The point is that the abrasive wheel needs to be rotated in different directions. Wearing thick gloves, you need to hit the cutting edge of the circle several times. This is what will ensure variable movement in different directions. As a rule, a couple of sharp blows are enough so that the nut can be easily unscrewed.

Open-end wrench and socket head

In this case, you will have to slightly modify the existing standard tools - a 17 mm open-end wrench and a 24 mm socket. The thickness of the key is ground down to 4 mm. 4 protrusions are machined on the head and fit into the holes of the retaining nut.

After preparation, the key is placed in the space under the disk, and the head is put on the flange of the angle grinder and rotated in the direction opposite to the rotation of the wheel. After this, you can easily remove it and install a new one.

Heat

This is one way to remove a disc from an angle grinder without a key. The fixing nut is heated with an industrial hair dryer or a gas burner. After this, the flange will unscrew much easier. However, there is a risk of damage to the plastic parts of the angle grinder or gearbox.

With a nail

For these purposes, a 100 mm nail is best suited. It should be bent into a U-shape so that the ends fit freely into the holes of the clamping flange. The tip and cap are removed. By inserting a nail into the holes, the latch is unscrewed. If the manual effort is not enough, then add a nail or screwdriver in the form of a lever.

Using a gas wrench

The use of this tool is justified by an increase in the applied moment of force due to the increased arm. Using a gas wrench will make it much easier to unscrew a jammed connection.

However, when eliminating snagging, it is important to remember that by applying excessive force, there is a risk of damaging the spindle lock or clamping nut

Using a rotary hammer or drill in chiselling mode

You can unscrew the disc on an angle grinder without a key using a drill or hammer drill, having first switched it to jackhammer mode. A suitable drill, most often 6 millimeters, is used as a working attachment. Place the drill against the edge of the hole in the clamping nut, fix the movement of the spindle and briefly turn it on to move it from place. This method allows you to turn away even very complex snacks.

Tapping the nut

This method is similar to the previous one, only you can use a suitable metal rod or chisel. Having fixed the spindle head, tap along the edges of the clamp holes in the direction of movement of the wheel. By slightly moving the lock from its dead point, you can unscrew it by hand. However, the method is not the most harmless for the tool - the mounting holes for a standard key are damaged.

Cutting wheel destruction

You can unscrew a jammed nut by completely destroying the disk. If there is already damage, you can break it off with your hands, but most often this will not be possible. It’s better to take a hacksaw or metal blade and cut it. This will leave you with a center ring and hard-to-reach pieces. Having found a suitable plate, holding it in a vice, grind off the remaining abrasive on it to a metal ring. After this, it will be easily unscrewed with a standard key.

The most radical way to unscrew a jammed clamp nut is to cut it. It is advisable to resort to it only in extreme cases. Of course, you can find a new one, but you will have to spend your time and money. It is not uncommon for spare clamping elements to be included in the delivery set of an angle grinder.

How to properly and safely remove (install) a disc from an angle grinder?

An angle grinder (popularly called “grinder”) is the most common tool for home craftsmen after an electric drill.

Despite the ease of use, “hobbyists” often have questions about servicing the tool, especially when emergency situations arise. As a rule, breakdowns occur due to improper use of the tool.

Main uses of angle grinders

- Cleaning surfaces, stripping off old paint. It is performed with brushes with steel rods or sandpaper petals. There are no difficulties in operation, except that brushes with sandpaper require compliance with the direction of rotation.

- Sanding with sandpaper.

A concentric attachment with Velcro is screwed onto the grinder, onto which the abrasive in turn is attached. Before use, check that the direction of the threaded fastening and the rotation of the tool shaft are consistent. - Grinding with abrasive wheels.

These attachments require careful handling, as under high load, the abrasive may break. You cannot cut material with such discs; shock loads are unacceptable. - Cutting metals, stone, gating concrete. Performed using cutting discs.

It is with such attachments that emergency situations most often occur.

Let’s take a closer look at cutting wheels

The question of which side to place the disc on the grinder does not have a correct answer. Abrasive wheels do not have a programmed direction of rotation, so it doesn't matter how you set it.

The direction of rotation (from yourself or towards you) is determined by the position of the protective casing. The choice depends on the position of the tool that is convenient for the operator.

In addition, the direction of the flow of sparks (or stone dust) depends on the position of the casing.

It is advisable to place the disc with the front side (with the marking) facing up. In this case, you will not forget which nozzle is installed: for stone or metal. They are not interchangeable.

To install the disk on the shaft, the kit includes a dismountable flange. The lower part is rigidly fixed with chamfers, the upper part is a regular self-tightening nut. It is she who determines in which direction the disc on the grinder should rotate.

During operation, the threaded connection is tightened, preventing the nozzle from coming off.

Sometimes the kit includes spacer washers designed to dampen transverse vibrations. You can make them yourself from thick electrical cardboard or paronite. To secure the flange, a special open-end wrench is included with the tool. The shaft is fixed with a clamping button to create the necessary tightening force.

Popular: How to choose an angle grinder knowing its main characteristics?

Ignorance of a simple question: how to install a disk correctly for inexperienced users can lead to equipment damage or injury. First of all, when changing a disk, it is necessary to clean the shaft and the inner surface of the protective casing with a steel brush.

A layer of metal particles is riveted onto these elements (when cutting the material). The thickness can reach several millimeters, as a result of which the disk loses alignment or jams.

Large attachments do not simply overload the electric motor. Installation requires removal of the protective cover. If an angle grinder disc shatters and the protection is not installed, the fragments can seriously injure the operator.

Another controversial issue is whether it is possible to put a wood disc on an angle grinder. If you hold the instrument with your hands, the clear answer is no. The circular saw can easily get stuck in the fibrous structure of the tree. A tool that escapes from your hands will cause a lot of trouble, including fatal injuries.

What to do if you have lost your open-end wrench?

More precisely, how to unscrew a disc on an angle grinder without a key? There are three ways:

- Make a bracket from a rod of suitable diameter (a nail will do). With this device you can loosen the flange using manual force. If the tightening is too strong, insert a lever into the bracket.

- Use a gas wrench. Having grasped the outer radius of the threaded flange, it is enough to touch the nut, and then it will unscrew by hand.

- Stroke the thread with precise tangential blows. To do this, you can take a core or punch, install it in the hole for the open-end wrench, and lightly hit the hammer to rotate the flange.

All manipulations to change the nozzle are carried out after disconnecting the power cord.

Removing a split disk

There are times when the cutting wheel jams during operation. Not only have you lost the nozzle, in such a situation the flange (its threaded part) is clamped with repeated force. How to remove a disc from an angle grinder in such a situation?

Popular: Do-it-yourself stand for an angle grinder: manufacturing examples

First of all, the tool should be securely fastened. Use clamps and a sturdy workbench. Then you need to lock the shaft lock key. If the force of your hands is not enough, lengthen the handle of the open-end wrench: for example, with a piece of steel pipe.

There are cases when the flange is jammed tightly. Then there is a possibility of damage to the locking key. To save the tool, disassemble the gearbox and clamp the output shaft in a vice.

Then we continue disassembling using the above methods: a reinforced open-end wrench or a gas wrench. The disadvantage of this method is that the shaft can be damaged and nicks will remain on it.

If the shaft is completely removed from the gearbox, the bottom of the flange can be chamfered using a traditional wrench.

Then the risk of damage is minimal. For any method, it is recommended to use a penetrating lubricant: WD-40 or regular kerosene. Waiting a few minutes after application will significantly reduce the force.

Bottom line: It is easier to prevent any problem than to deal with the consequences. By following the operating rules and tools, you will minimize the possibility of emergency situations.

Source: https://obinstrumente.ru/elektroinstrument/bolgarka/kak-snyat-disk-s-bolgarki.html

To summarize: how to choose a disc for an angle grinder?

To properly buy a disc for an angle grinder, you need to:

- Know the maximum size of disks that your angle grinder can handle. You cannot take disks larger than the device allows.

- Know the maximum speed of the grinder. The higher the rotation speed of the angle grinder, the smaller the disk size it can work with.

- Processed material. There are discs for wood, metal and stone. There are universal ones that can cut almost anything.

- Socket size. The size of the wheel seat must correspond to the same parameter in the angle grinder.

- Manufacturer. Do not buy frankly cheap discs or unknown products like hot cakes in the school cafeteria, and the savings will be minimal.

- 6 dangerous mistakes when working with an angle grinder that you should not make.

- Installing wiring in the house: how to choose the right wire?