A fence that harmoniously matches the style of the house gives the completed look to the country area. Wrought iron fences and gates are an element of outdoor design. They give the site solidity, originality and emphasize the good taste of the owner. A huge selection of designs makes the fence unique. Forged fencing spans combine lacy openwork and high strength. Fences are pleasing to the eye with their appearance and reliably protect the house and the space around it from the entry of strangers. Even photos of fences with gates show their strength and inaccessibility.

Entrance group with forging elements

DIY gate made of corrugated sheets

Hot forging will require skill, as well as internship time in a forge. This is the only way to learn how to forge. Cold forging technology is available to everyone if they have experience working with metal. It makes it possible to produce decorative elements from profile pipes at home at low cost.

Option from corrugated sheet

Anyone can do forging. First, you need to look at photos of hand-forged gates. The article also presents videos on this topic.

Necessary tool

To make a gate from a profile pipe with your own hands using cold forging, you will need certain tools:

- A welding machine will be needed to create compositions. All decorative monograms made on other devices are joined into one composition by welding. Often welding experience determines how elegant a product will look from finished elements. There are professional and household devices. To attach the pattern to the corrugated sheet, you can use both. You won’t be able to create a beautiful gate with forging elements yourself without this tool.

- A grinder, with the help of which the profile is cut into the necessary parts. The kit usually contains wheels for grinding and descaling finished elements before painting. For these works, it is advisable to use a low-power device in the range of 650–850 W. Working with an angle grinder must be precise. Therefore, it is important how comfortable the device will be in your hand.

- Various elements using cold technology are made on special equipment. To bend the spirals, a machine called a snail is used. For longitudinal and transverse bends, “torsion bars” are used. Using other devices, you can twist various spirals from a strip of metal. The equipment is manufactured by industry or manufactured independently. But for cold forging you cannot do without these devices.

- A spray gun and compressor are necessary to apply primer and paint to the finished product. Naturally, you can use brushes, but this will cause drips. In addition, it is very difficult to paint uneven monograms with a brush.

Wicket and gates made of corrugated sheets

You will also need:

- roulette;

- vice;

- pliers;

- files;

- hammer.

Before installation

Manufacturing Features

Corrugated sheeting is sheet metal that is highly resistant to various atmospheric conditions. This material is initially treated with special compounds that protect the metal from corrosion. This significantly increases its service life.

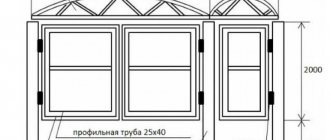

Scheme for making a gate with your own hands

Sheathing with corrugated sheets gives the structure strength. This way you can hide your garden area from prying eyes.

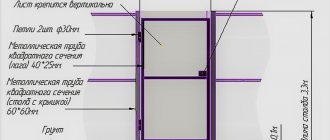

Installation of leaves for swing gates

The question of how to install a gate is an important point among all the work performed in the manufacture of gates with your own hands, since mistakes made can lead to both a short service life of the gate and the fact that they simply will not perform their functions, for example, to open well . Installation work begins with the installation of the frame. The procedure for this looks like this.

- Hinges are welded to the leaf panels using a continuous seam. This should be the part of the loop that has a blind hole at the end.

If heavy gates are installed, they should be equipped with three hinges on each side. When installing lighter structures, two hinges will be sufficient.

- For each welded loop on the frame, its second half is put on, which is immediately welded to the support.

- The gate leaves are lined:

- 1) repeated measurements of corrugated sheets are made (this will avoid errors);

- 2) using metal scissors, cut out the required sheets;

- 3) all existing edges are thoroughly cleaned;

- 4) the sheets are overlapped in one direction;

- 5) the corrugated sheet is attached to the frame with self-tapping screws. The number of self-tapping screws used to fasten the corrugated sheet is chosen arbitrarily; the distance between them should be from 10 to 15 cm.

- The finished product is painted.

Advantages of forging

The designs have many advantages. The main ones are the following:

- Original look. By using different forged elements, the gate can be given any look. But the most important thing is not to forget about combining the styles of various elements.

- Strength. During cold and hot forging, the metal increases its strength. Therefore, the structures perfectly maintain their performance characteristics for 50 years.

- Spatial rigidity. When combining various parts of forged structures, forge welding technology is used, so the possibility of deformation of the elements is excluded.

- Corrosion protection. Forging technology involves processing all elements. This can be bluing - a chemical oxidation process, due to which the structure acquires a beautiful black tint. Or patination - a chemical procedure of metallization with copper or bronze.

- Duration of operation. Forged products performed excellently in aggressive climatic conditions, when the temperature ranged from −30 to +30 °C. In addition, the structures worked normally during snowfall, constant rain, and high humidity.

- Variety of different materials. Cold forging uses different types of aluminum alloys and steels (for example, with stainless properties). Also, forged structures can be made from bulk metal (rods with a hexagon or triangle cross-section) or from sheet and strip metal.

- Wide range of design methods. Hot or cold forging technology does not have any restrictions. Any craftsman can produce original elements strictly according to an existing template or at his own discretion.

- Versatile forged metal products combine harmoniously with stylish fences and gates. You can easily install an automatic opening system or a video surveillance camera in the gates without disturbing the design.

- Huge selection of colors. The manufactured forged element can be painted in any shade.

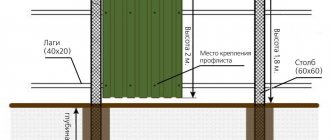

We spare nothing for the right pillars

We spare no expense, time and effort. In other words, all the resources you have.

Support pillars must be as stable, durable and strong as possible. Everything rests on them, this is half the success of the whole work, believe me.

The components are a metal pipe, mortar and facing bricks. Your task is to make sure that all this stands on the ground as stable as possible.

- To do this, we dig two holes, as deep as possible. The depth of the hole must be at least one meter. But you need to carefully monitor the width: it should be slightly wider than the metal pipe. This difference should not exceed 10 cm, otherwise the pillars may become loose in the future: after all, metal gates with a lot of weight will be hung on them, so the load will be more than serious.

- When installing pipes in holes, fill them with crushed stone and compact them at the same time. We plumbly monitor the verticality of the pipes, which is extremely important in the construction of gates: after all, at the slightest deviation, the doors will lean in one direction or another.

- Fill the filled crushed stone with a solution of cement and sand in proportions of 1:3. When pouring the solution, we again carefully check the verticality of the pipe. It is better to take M300 cement.

- Give the solution time to dry thoroughly, usually several days. Don’t rush, let the concrete dry for real, we agreed not to spare anything, including time.

- We weld special fastenings for the valves to the pipes, which are called shanks. Their width should be at least 6 - 7 cm, they should be visible from under the bricks.

- We line the pipes with alternating bricks: the next seam should overlap the next one.

And again we give our new pillars time to stand. At least for a couple of days. After all, we have something to do at this time - doors.

Disadvantages of forged products

But still, cold forging has certain limitations. When using this technology, you cannot make figurines or flowers. This can only be done by masters using the hot forging method.

Door on brick pillars

The cold forging method allows you to make only spirals, ruffles, bending, and then assemble a composition from these elements. Metal images of flowers, berries, and animals can be bought in stores. Then decorate the front door by securing the forged items in the required places.

You should also note the length of time it takes to make parts yourself. Beautiful patterns made by experienced craftsmen at home will take a lot of time. This is especially true for the implementation of intricate decorative elements.

Gate with door on the site

Traditionally, forged products are made in a common style from identical monograms. This gives sophistication, but takes a lot of time.

The photo shows a gate with forged products.

Metal door

Kinds

Forged fences and gates are divided into three types.

- Protective. The name already indicates their functional purpose. They have simple shapes, easy production, and relatively low cost. Their installation is simple and takes relatively little time, because they consist of stamped blocks.

- Decorative. These are exclusive, highly artistic fences with beautiful forging. The design is non-standard, as it is made by hand according to individual orders. Hence the high cost. Initially, the master develops sketches and demonstrates them to the customer, who chooses the option he likes. Soldering and welding are practically not used when connecting decorative parts. For this, clamps and rivets are enough.

- Combined fences. Contains elements of previous options. They combine expensive exclusive components with stamped sections. They are the most popular because they are beautiful, and installation is cheaper than purely decorative fences.

Metal structures of any kind come in different heights and designs. They are not suitable for every building and site.

Option for a wrought iron fence with lanterns on posts

Design options

There are a lot of design ideas for designing a gate made of corrugated sheets. Forging makes it possible to add originality to any product.

Forged door with polycarbonate

Classic way

Lattice structures made from corrugated sheets are the simplest and most popular. Despite their apparent simplicity, they look very beautiful.

After installing the sash with your own hands

A popular way of decoration is forged gates with a wicket built inside. Every craftsman can make and install such a product. In this case, you do not need to have much blacksmithing experience.

Sometimes this design is not entirely successful, since it is difficult to add artistic forging.

Structurally, the product already contains a large number of forged elements. But often there is a rather beautiful and original version.

Wrought iron gate at the dacha

Its secret is that the gate is, as it were, disguised. Forged decorations and decoration add originality to this design.

Gate covers, images

It is recommended to decorate forged gates:

- overlays;

- zhikovina;

- overhead loops.

Overlays for gates and doors are elements that have decorative qualities, practicality and serve as reinforcement for the structure. They give the product a strict and sophisticated appearance. The overlays are suitable for styles: country, gothic, baroque, modern.

Among the variety of overlays there are:

- specimens of trees and plants;

- compositions;

- geometric figures.

The use of overlays will give the main entrance to the courtyard an aesthetic appearance.

Wooden gates with forged gates and handles. Photos Svyatoslav

Zhikovinas give the products an antique elegance. They harmoniously combine with metal and wood, emphasizing the good taste of the owners of the estates. Forged gates can be decorative overlays, or they can carry loads if they also serve as gate hinges.

Overhead hinges for gates combine decorative and functional qualities. With sufficient thickness of the products, they cope well with their intended purpose. Curly hinges for gates will complement any exterior. And their wide range allows home garden owners to choose the best option that will be combined with a forged door handle and other fittings.

Reference. Photos of forged gates (how to send a photo) demonstrate designs made in accordance with cold processing technology, as well as other types of products.

Tips for choosing

First you need to choose the optimal type of design. It depends on the landscape of the garden area.

Sash in the fence

Then you should decide on the type of gate. First of all, they pay attention to products that can complement the landscape design.

It is not recommended to choose a forged gate that will stand out from other buildings.

It should not be forgotten that the wicket is primarily a protection.

When choosing a forged product, the style of the house and garden area is taken into account. If it’s a classic, then it’s better to choose a classic style of product. For European design, the same designs will be required.

At a private house

Dimensions of each leaf and gate

When calculating the height of the gate, it is important to take into account that at the bottom there should be a distance of 5 - 10 cm from the ground. If there are tiles or asphalt in the area where it is planned to install the gate, then this gap can be reduced to 5 cm

When talking about the size of future gates, we take into account that they must be such that a vehicle can pass through them freely. The height also depends on the height of the fence, the dimensions of the vehicle and the size of the sheet.

The dimensions of the gate should provide free and comfortable passage through it. It is believed that it is most correct to make a gate 1 meter wide and 2 meter high.

Building design

Gates are usually made swinging.

The gate consists of supports in the form of pillars and a door leaf on a frame, which is fixed to the posts using canopies. To close, locks are installed. The pillars are made of brick, steel, reinforced concrete or wood. Inside monolithic and stone supports, embedded parts made of thick metal, angles or rods are inserted in order to weld a gate frame made of corrugated pipe to them.

The door is made as a separate passage in the fence or combined with a gate. In this case, the frame of the gate is placed in one of the leaves. If there is a sidewalk in front of the yard, the opening is made inward so as not to disturb pedestrians. In this case, the size of the leaf is taken into account so that there is a distance for the sash to fully swing open.

Hinged or sliding

The first option is considered an inexpensive design that is easier to cook and install. Such a gate does not require a base to install guide beams; it does not need a counterweight or roller elements. The swing system is combined with the gate and saves space at the entrance. At the bottom, the canvas is cut to height in areas with heavy snowfall. This way, the resulting snowdrift does not affect the opening.

Sliding schemes are more complicated, since guide girders are often placed at the bottom and require a level foundation. There are options with a device for cantilever movement of the leaf, in which the beam is hung so that it does not limit the height of the span, and the rollers are placed inside the sash frame. Automation is installed on swing and sliding systems.

Tools required for work

Tools for installing a gate

For excavation work, use a bayonet shovel or crowbar. Sand, crushed stone, and cement are transported using stretchers or buckets and mixed in a concrete mixer. A small volume of the mixture can be prepared manually in a trough, stirred with shovels. To weld a gate from a profile, welding is required; consumables are purchased for it.

Other tools:

- tamper for crushed stone, sand, electric vibrator for concrete;

- grinder with a grinding and cutting wheel for metal;

- electric screwdriver and drill;

- level, square, plumb line, 5 m tape measure, core.

An angle grinder (grinder) is used to cut off the parts of the frame and diagonals, and using a grinding wheel to clean the welds from scale. In different cases, you may need other tools, such as an ax, to cut roots in the ground.

Beautiful fence

Looking at photos of forged gates, we always admire the work of the craftsmen and the beauty of their products. Such wickets and gates will help visually ennoble the area and also protect it from unwanted guests.

If desired, you can make a variety of patterns on your fence and gate. Thanks to modern technology, you can draw almost any pattern and forge it.