Just 150 years ago, blacksmithing was at the peak of its popularity. Almost every village had a workshop where various things were made and repaired. For example, in Moscow in the mid-19th century there were about 300 forges. And in centers such as Kyiv or Donetsk there were schools of metal forging, where entire trends in blacksmithing were developed.

With the advent and development of machine metalworking, the development of such a craft began to decline. However, in industry, many components and workpieces are still processed by forging. In the 21st century, small-scale forgings are most often of an artistic nature.

How has blacksmithing developed throughout human history and how much has technology changed?

The evolution of blacksmithing

The first metals that man began to process were gold, silver and copper. Later, a more durable alloy appeared - bronze. However, for a long time, casting remained the main method of metalworking. This was due to the properties of the materials; it was easier to cast the desired object in a mold. And it was impossible to harden such a metal, since when heated and quickly cooled, a lowering process occurred. The product became too soft. The only techniques similar in technology to forging were used after casting. When, to make the product homogeneous, the product was forged, thus removing voids and cavities in the metal.

The first attempts to forge bronze swords were made in Ancient China. To do this, the rod was initially made from a softer material, and the cutting parts were forged along the edges from a stronger, but brittle metal. However, this technology did not receive further development due to its complexity.

But, along with this, such a technique as cold forging also appeared. When a piece of native copper was shaped without preheating.

A striking example of cold forging is a dagger found in the tomb of the Egyptian pharaoh Tutankhamun. Long before its spread, it was made from meteorite iron. The blade is cold forged without heating the workpiece.

A real breakthrough in blacksmithing was the appearance of iron. It became clear that such a material requires different processing methods than bronze and copper.

Initially, they used the so-called meteorite iron, then they began to smelt it from ore. Like the first metals, iron was initially used to make knives and weapons. However, even here attempts to forge such metal were not particularly successful.

The real impetus for the development of blacksmithing was the invention of steel and its adaptation for the manufacture of weapons and agricultural implements. Various objects began to be forged from steel and iron: chains, rings, armor and others.

Steel forging began in various parts of the world. For example, Celtic craftsmen are often credited with the invention of “harloug” steel. When several rods of steel of varying carbon composition were twisted and forged, getting quite strong swords. The same method of layer-by-layer welding and forging was used by Japanese gunsmiths.

During the Middle Ages, iron deposits were discovered on the European continent in Gaul (modern France), which led to the invention of phosphate steel as a cheaper analogue of imported crucible steel. Blacksmithing centers began to appear, where weapons and armor were primarily produced.

In ancient times and the Early Middle Ages, a forge was a simple hut or even a dugout, usually built on the shore of a reservoir. All work was carried out manually with hammers and anvils.

Interior of an ancient forge

In the 16th century, the medieval forge received the first mechanisms to simplify work - lever hammers driven by water power.

During the late Middle Ages, blacksmiths made almost all products from steel, from complex closed armor to ordinary horse shoes. The concept of a blacksmith shop appeared, when many apprentices took part in the manufacturing process. Production has become more massive.

Blacksmithing reached the peak of its development in the 18th century; many examples of products made by craftsmen of that time have survived to this day. The blacksmith shop began to turn into a factory.

In the 19th century, with the advent of steam engines, the forge structure became even more complex. Equipment powered by steam, hydraulic hammers, and rolling mills appeared. The production of things and weapons was put on a massive scale.

At the beginning of the 20th century, welding and machine production technologies appeared and hand forging faded into the background. However, blacksmithing techniques have found wide application in industry and modern metallurgy.

Wards of the Great God

Blacksmiths were respected and even feared, and over time, the image of a blacksmith became the embodiment of courage and strength. The patron of this craft was one of the greatest Slavic gods, Svarog. It was believed that the blacksmith to whom God gave his “spark” would master the skill in all its nuances and would even be able to influence people with its help. How?

There were popular beliefs that an experienced blacksmith could “forge” two destinies together. Perhaps this is some kind of hint of wedding rings or forged family amulets. Anyone who saw the blacksmith’s work could not remain indifferent. Just imagine: under his skillful hands, the iron became liquid, taking on the shape that the master gave it. Perhaps the blacksmith could control destinies in the same way?

Andrey Shishkin “Svarog - the god of blacksmithing”, 2014

Russian blacksmithing

In Rus', as in Western Europe, blacksmithing occupied a place of honor.

Moreover, the art of blacksmithing received its own directions and styles, distinguishable from foreign examples. Due to the peculiarities of iron mining, metallurgy was separated from metalworking in the early Middle Ages. Earlier than in Europe, Russian blacksmiths began to process carbon steel. All cutting edges of tools and weapons were made using this material.

The blacksmithing skills of artisans produced all household items, from sickles and scythes to needles and fishhooks. A separate isolated group in Rus' was occupied by gunsmiths producing high-quality weapons.

Old Russian sword

A huge impetus to the development of blacksmithing was given by the reforms of Peter the Great, who quickly began to develop industry in the country. Workshops turned into entire factories using metal forging technologies. Forges switched from ordinary crafts to mass production.

At the beginning of the 20th century in the Russian Empire there was a forge in almost every locality. The centers became Moscow, St. Petersburg, Kyiv and others.

Industrialization in the USSR practically destroyed individual blacksmith shops, but forging received a new round of development.

Blacksmith or sorcerer?

The skill of the blacksmiths was impressive and even aroused some superstitious fears among people. Some beliefs have been preserved according to which a blacksmith could be successful only when he appeased evil spirits. It turns out that he himself supported evil spirits. Archaeologists often note that the blacksmiths' workshops are located far from the settlement.

Why? It seems to me that this was a desire to maintain safety. After all, think about it: as soon as one spark falls on the wooden wall of the building, the entire workshop will be engulfed in flames, and from it the fire will spread to other buildings.

It would seem that everything is logical, but our ancestors did not always support this version. The blacksmith sometimes seemed to be the master of the forces of fire and water. Some explained this by the great art that Svarog himself patronized, while others believed that such a gift could only be received from evil forces. In the “Izbornik of Svyatoslav”, dating back to 1073, the blacksmith is even called “khytrets”. True, there can be two meanings here - “cunning person” and “skillful master”. However, I think that one is not a hindrance to the other.

The forge was often located far from the settlement

Forging in modern production

Forging at metalworking enterprises and in mechanical engineering today remains one of the main processes in the technological chain.

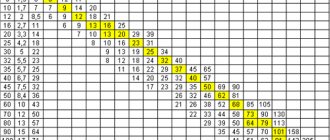

It is with the help of powerful forging equipment that multi-ton parts and their elements are processed. Also, one of the types of forging (stamping) made it possible to make the production of many things mass-produced and cheap. Modern forging production uses the following technologies.

- Hot and cold stamping.

- Pressing and crimping.

- Drawing.

- Rolling.

Hot and cold stamping

This is the process of shaping blanks according to a ready-made standard sample. That is, all those operations that a blacksmith used to perform to give the desired configuration and volume to a part are now performed at enterprises by stamping machines.

The following types of industrial stamping are distinguished: sheet and volumetric stamping.

In the first case, for example, holes are punched in sheets of metal, resulting in perforated surfaces.

The second option involves the production of any volumetric parts and elements using both cold and hot methods.

The use of this technology made it possible to reduce material costs and production time.

Pressing and crimping

Pressing also comes from forging technology, although today it is completely separated from this process.

Previously, before the advent of mechanization, the blacksmith carried out compaction and reshaping of the part manually through the so-called crimping technique. When the entire surface of the metal was forged.

An example of how a hydraulic press works can be seen in the video:

Today, at metalworking enterprises, this is done by multi-ton presses, which are capable of molding and compacting a multi-ton element in a short period of time.

Small forge shops also use pressing technology using mechanical or hydraulic equipment.

Drawing

Drawing example

A technology that also originated from forging metalworking methods. It allows, by pulling round parts through a hole, to make its diameter smaller.

Round elements are also formed using the forging method. For this, various machines (rotary) are used, where the process is practically automated.

Using this technique, various pipes and rolled products of round or shaped shapes are produced. As well as blanks for further production of shafts.

Rolling

This method makes it possible to produce so-called rolled metal, the list of items of which is quite large, ranging from fittings to steel pipes.

What was once done by a blacksmith is now done by a rolling mill, producing standardized products that go into further processing and construction.

Technologically, this is done by pulling heated metal blanks through the shafts of rolling equipment.

As with forging, this metalworking method allows you to obtain the required shape and the desired structure of the material.

Forging

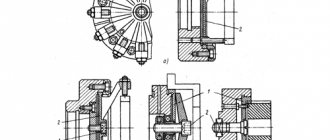

Forging in industry occurs using various equipment and forging machines.

At the same time, the dimensions of the processed parts sometimes reach significant sizes and weight.

Investments and income

Financial investments in opening a business producing forged products will amount to about 3 million rubles. The main expense items are as follows:

- Payment of rent for the blacksmith shop premises.

- Purchase of equipment and raw materials.

- Salaries for shop workers.

- Fare.

- Business advertising.

- Unforeseen expenses.

Naturally, the lion's share of the funds will go to the purchase of equipment - all other expenses will amount to no more than 10% of the total amount.

As for the profit from the manufacture of forged products, it directly depends on the complexity and exclusivity of incoming orders. It may also turn out like this: the income from completing ten orders in August will be lower than the income from completing two orders in September. It’s just that in August you were ordered to make ordinary household consumer goods (pokers, nails, iron wedges), and in September – an exclusive forged gate and a gift dagger.

To summarize the above, I would like to note that you will begin to receive tangible profits only after you have gained a decent base of regular customers. The average payback period for this business idea will be from six to twelve months.