There is a misconception that it is impossible to perform [metal bluing at home], and this technical operation, in any case, should only be performed in factories.

Currently, there are several different ways in which you can effectively deal with rusty metal at home.

This type of processing is necessary in order not only to make the metal more attractive.

With its help, the protective properties against corrosion are significantly increased.

Do-it-yourself steel bluing at home is distinguished by simpler methods of metal processing, which use improvised means.

At its core, this method of dealing with rusty metal involves applying a variety of coatings to the surface being treated, which form a thin protective film on it.

At home, this can be done using citric or phosphoric acid, as well as using varnish or oil from which a certain solution is prepared.

Of course, industrial technology allows for better processing, but some methods of dealing with rusty metal at home show quite good results.

What can be achieved by bluing

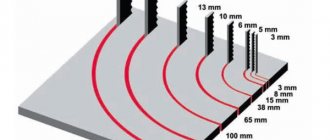

As a result of chemical or thermal treatment, a layer of iron oxide with a thickness of 1 to 10 microns appears on the surface of a steel part. The thickness of the layer is determined by the selected processing technology.

Blueing of metal allows you to achieve two main goals:

- Increasing the corrosion resistance of the product. Treated parts do not rust.

- Improved appearance. It is especially important for those parts that, due to operating conditions, cannot be painted.

Temperature conditions for bluing

The treatment does not affect other properties of the steel.

Blueing of steel is possible not only in production conditions, but also at home. There are many methods and compositions, almost all of them involve the use of chemically active substances that can cause serious harm to health. To successfully and safely use these substances at home, you must follow the following safety rules:

- Use a protective mask and gloves.

- Ensure ventilation of the room in which work is carried out.

- Use stainless steel utensils.

- Do not exceed the recommended processing temperature.

https://forum.guns.ru/forummessage/24/707827.html

— I shared with my colleagues a brief summary of the private experience of the so-called. “hot” oxidation, in which sodium nitrate and sodium hydroxide are used as the two main components. Some time has passed since then, and the situation with reagents has changed somewhat, at least in Moscow and the cities closest to it. First of all, laboratory equipment stores, out of some fright, stopped selling them to private hands. Secondly, prices for the entire line of products at Labtech have increased significantly. And besides, prices for components for bluing have naturally increased from forum sellers. There is also another point: residents of places remote from the center simply do not have the opportunity to purchase “special” analytical grade reagents, because “Labtech” or at least production facilities with stores selling such goods have never existed in their cities, and purchasing with forwarding turns out to be a matter of very expensive.

However, there are more affordable ways to obtain high-quality hot oxidation, and they have been mentioned more than once on the forums. Personally, I simply didn’t need to look for alternatives before: 1 kg. sodium nitrate cost about 140 rubles two years ago, I lived in Moscow, and Labtech sold their goods to anyone. And now it just became interesting...

In short, “it works.”

For “alternative” oxidation we need the following components.

1. Ammonium nitrate. It is sold not only in labtech stores, but also in any hardware store that has at least a small department for gardeners, because it is a fertilizer that has long been known to the world. The substance in appearance and weight looks like the usual sodium nitrate; it is yellowish-white granules with a diameter of 2-3 mm, packaged in plastic bags. The appearance of the packaging varies depending on the imagination of the manufacturing companies. The package I got from the nearest construction market weighed 2 kg and cost only 45 rubles!

2. Dry cleaning agent for sewer pipes such as the well-known “Mole”. With this, it may be a little more difficult: now gel-like and liquid products, poured into “glamorous” containers, such as “Tireta” and others like it, are more in use. The concentrate is more difficult to obtain, but it is still possible if you run around a little. I found it in the third store selling gardening supplies and household chemicals. It's called "Anti-clogging". The sachets indicate the composition: “soda ash > 30%, sodium hydroxide 5-15%, surfactant sulfanol < 5%. This product looks like granules of approximately the same diameter, but almost snow-white in color.

(Note: I once had experience using specifically dry “Mole” instead of chemically pure hydroxide, but for some reason the oxide film from the parts after such bluing was erased almost with my fingers).

I have no idea what “sulfanol surfactant” is, but soda ash is an excellent degreasing agent, and its presence in the composition of “Anti-clog” is one big benefit; Anyone who read the first article about bluing in analytical grade reagents will remember the corresponding method of hot preliminary degreasing of iron that I described, in which this is exactly what is used.

3. Actually, that’s all. Apart from clean water, ideally boiled or purchased soft drinking water, we don’t need anything else for our magic.

How do we deal with all this? Very simple, about the same as with sodium nitrate + sodium hydroxide. We place a clean stainless steel bowl on the stove that has sufficient volume to completely immerse our parts, and pour water into it. Then carefully add a tablespoon of pipe cleaner. Personally, I'm at about 0.5 liters. poured in at least 8-9 full spoons of water. During this process, the water boils violently, but the foam on its surface is quite fine and splashes do not fly in all directions. The bubbling stops approximately 3 seconds after a full spoonful of the substance is poured into the container.

Next, we saturate the resulting solution with ammonium nitrate, and here everything will be “much worse.” When ammonium nitrate granules come into contact with water saturated with hydroxide, hydrogen nitride, or more simply put, ammonia, immediately begins to be released from it. This is a colorless volatile gas with an extremely pungent odor that instantly blocks the respiratory tract: whose sense of smell has experienced the effect of ammonia will, as they say, appreciate it. Therefore, if this happens not in the open air, but in an ordinary kitchen, you need to work with the window wide open and the hood on, and try not to inhale the extremely powerful “exhausts” of the poisonous gas. At the same time, the solution also boils, but much more violently, and splashes everything around, so non-working areas of the stove must be covered with some kind of non-flammable shields, such as galvanized sheet or asbestos, especially since small splashes will fly out of the container with the solution and in the process boiling.

As for the proportions, I poured about the same 9, maybe 12 spoons of saltpeter into half a liter of Anti-clog solution. During the bluing process, both components can always be carefully added if you feel it is needed.

After some time, the process of ammonia release stops, the solution turns out to be hot due to the reaction, and it takes a minute to bring it to a boil. Having done this, reduce the gas/electricity and achieve a quiet, even boil.

Then we degrease the steel parts using any of the usual methods, and, equipped with wires, carefully immerse them in a boiling solution.

In my case, the parts being processed—the steel liner and the standard PPSh-M “mortar”—began to intensively turn black within 25-30 seconds after contact with the solution. After half an hour, both turned completely black, but I boiled for about 40 more minutes, carefully adding hot boiled water to the solution a couple of times, drop by drop.

(Note: somewhere on the forum they wrote that you need to boil parts in alkali for at least 90 minutes, they say this is an “old army postulate,” but opinions generally differ greatly on this issue).

Degreasing was carried out using the simplest method - first I wiped the parts with acetone, then with Galosh gasoline. There is hardly any need to remind once again that both solvents and rags must be clean. And as usual, before wiping with a solvent, it is better to wash them thoroughly with warm water and dishwashing detergent.

I was more than satisfied with the result of the oxidation.

“In reality” both details turned out exactly like that - pitch black, like the deadest night. I even have a feeling that the bluing turned out to be even more intense than what was obtained in solutions of analytical grade reagents: it is very possible that this is the case, since Anticlog contains a large amount of soda ash.

Then everything is as usual: the parts removed from the solution must be cooled, rinsed with running water, wiped and dipped in the solvent. After this, they can be traditionally boiled in an aqueous solution of laundry soap, and then machine oil, or simply dipped in any mineral oil and heated over a gas burner.

Good luck.

Methods for bluing metals at home and requirements for their implementation

Popular methods of bluing metal at home are:

- Boiling in self-prepared or purchased chemical compositions.

- Coating the steel with special oil and subsequent heat treatment.

- Coating the surface with the prepared composition at room temperature.

Burnishing steel at home

Chemical bluing of iron also involves preparatory operations of etching and cleaning, as well as grinding and polishing.

When carrying out blueing of steel, it is important to select a container for the solution so that it completely covers the object being treated.

Chemical oxidation treatment

Most often, metal surface treatment is carried out using chemical oxidation.

This method is quite effective and, if the technology is followed, allows you to achieve a high quality final result.

This method of bluing metal is based on the ability of the metal to oxidize.

Video:

At the preliminary stage, it is necessary to mechanically treat the surface of the workpiece, as well as completely degrease it.

After this, the appropriate solution should be properly prepared.

For these purposes, you should take a container of a certain size, which must be made of porcelain.

Next, one hundred milliliters of ordinary tap water is poured into it, after which a small amount of sodium nitrate and about one hundred grams of technical soda are added.

After this, the solution should be thoroughly mixed and ensure that all components are dissolved in it.

The resulting mixture should be heated to a temperature of about one hundred and forty degrees Celsius, and the workpiece should be immersed in it for about thirty minutes.

After the specified time has elapsed, the part is removed from the solution and thoroughly washed with distilled water.

Next, you should dry it thoroughly and generously lubricate it with machine oil using a soft brush, achieving a uniform layer.

IMPORTANT TO KNOW: Secrets of copper plating at home

The metal surface treated in this way will acquire a pronounced black tint with a blue tint.

If the bluing was done correctly and in accordance with the technology, the metal will become smooth and does not require subsequent polishing.

In the video posted in the section, you can see how a metal surface is treated at home using a chemical solution.

Popular bluing methods

The most common methods of bluing at home are:

- alkaline;

- thermal;

- acidic.

The alkaline method is well suited for self-use at home. It will require

- water;

- precision scales;

- sodium nitrate and hydroxide.

For the coating to become durable, the process must last at least an hour and a half.

Alkaline

The technology for bluing steel using the alkaline method at home is divided into the following operations

- Degrease the surface with a solvent or special degreaser.

- Pour 100 g of water into a stainless steel container with a capacity of at least a liter.

- Add 120 g of caustic soda and 30 g of sodium nitrate, stir thoroughly until completely dissolved.

- Heat the solution to 130-145 °C.

- Place the product in the dish, avoiding touching the walls.

- After 20 minutes, after the part has turned black, rinse it in distilled water.

- After drying, generously lubricate the product with machine oil and wipe thoroughly.

Steel bluing with alkali

Careful adherence to proportions and parameters will allow you to obtain a smooth and abrasion-resistant coating that does not require polishing.

Important! The product must be completely covered with the solution throughout the treatment. Otherwise, coating inhomogeneities, color transitions, etc. are possible.

Acid

This method involves the use of acidic solutions.

Before starting processing, you should carefully remove all rust from the surface of the object. To do this, use ordinary sandpaper, and in hard-to-reach places and with severe rust, use a grinder or a screwdriver with a wire brush.

Means for degreasing steel before processing

Next, chemical cleaning is carried out. It is used for

- sodium triphosphate;

- ethanol mixed with kerosene;

- or pure kerosene.

The product is placed in a container with the solution so that it completely covers it and kept for at least a quarter of an hour. After cleaning, the product is washed with plenty of water and dried.

The composition for acid bluing consists of:

- water: 1 l;

- tannic acid: 2g;

- tartaric acid: 2g.

After thorough mixing and complete dissolution, the composition is heated to 150 ° C and the workpiece is completely immersed in it. Leave for 15 minutes, then rinse with running water and briefly dip in boiling water for complete and high-quality rinsing.

Components of the solution for bluing

The last stage of the process is soaking in machine oil for an hour. After drying, the product is ready for use.

Thermal

Thermal bluing is the oldest and simplest method for home use. The whole process boils down to heating the steel in the open air. It lasts until the upper layers of steel react with oxygen in the air and result in an oxide film. The more a part is heated, the darker it becomes.

Thermal bluing

It should be remembered that heat treatment also changes the physical properties of the steel of the entire product.

Bluing with hyposulfite

The part is dipped into a saturated solution of copper sulfate, after adding 5-6 drops of sulfuric acid drop by drop. The part is aged to a red copper color. Then it is rinsed in hot water and dipped for 20-30 seconds in a filtered saturated hyposulfite solution. After which the part is kept in a solution of potassium alum 1:10 for 10-12 hours, then it is washed, dried and lubricated with drying oil. The coating turns out to be the color of black plastic and lasts a very long time.

Features of chemical bluing and recipes for some compositions

Before applying a new coating at home, you must remove the old one. This is done by combining mechanical and chemical cleaning methods.

To obtain a durable and beautiful coating, the part must be boiled for 30 to 90 minutes, during which time part of the solution boils away. The workpiece must be completely covered with the composition at all times, so the composition must be prepared with a reserve and periodically topped up during boiling.

At the end of the chemical bluing procedure, the product should be washed in a soapy solution, dried and generously lubricated with oil.

There are many options for chemical bluing. In some, the composition is made by the master himself, while others involve the use of ready-made factory-made products, such as Parisian oxide, Voron3M, Clover and others.

Means for bluing metals

Relatively simple methods of bluing, available for doing it yourself, include surface application of oil, saltpeter and the purchased composition “Clover”

Sapphire for bluing

Oil coating

This is one of the most popular home methods. The technology is divided into the following operations:

- The part is sanded and degreased with a solvent.

- Cover with oil.

- In a muffle furnace it is heated to 350-400 °C. It is permissible to use an oven.

- The cooled part takes on a black or brown tint.

- To saturate the color, the procedure is repeated.

The oil is applied with a brush or by dipping the product into a container of oil. Different types of oil are used, such as

- weapons;

- olive;

- flaxseed

Use of saltpeter

Home craftsmen achieve excellent results using saltpeter solution. You can purchase a ready-made solution, or you can make it yourself:

- water-1000 ml;

- sodium nitrate - 0.5 kg;

- caustic soda - 0.5 kg.

After boiling for an hour, a smooth surface of a deep blue-black color is obtained that does not require further processing.

Means "Clover"

The gel-like product can be purchased in 50 ml jars and is used for alloys with a chromium content of no more than 3 percent

Means "Clover"

It is designed to restore localized corrosion. To obtain a bright shade, the product will have to be applied several times. The product should first be sanded and wiped with a degreaser.

Apply clover with a brush and leave for two minutes. The white-yellow coating that appears is washed off with water and the part is wiped with a rag.

Cold bluing at home

“Clover” does not require heat treatment of the part, so this method is considered cold bluing. Cold bluing can be carried out by other means.

- "Voron-3M". The drug forms a dense film of deep black color on the surface.

- "Paris Oxide" An imported selenium-based preparation is supplied in three containers: 1- for surface preparation, 2- the main composition and 3- a fixative that gives the coating additional protection.

Liquid for cold bluing is applied to the parts with a brush, and after painting it is washed off with warm soapy water. The method is popular for processing barrels and other parts of firearms that do not require boiling.

Burnishing steel at home

If you are bluing steel at home, you need to wisely choose the components of the boiling solution. Heating hardened parts can lead to them losing their strength properties.

Alkaline solutions have a less harmful effect on steel, and experienced craftsmen advise choosing them. Treatment with acidic solutions is preferably carried out at low temperatures

So, for example, when using an acid composition for bluing steel from:

- calcium nitrate – 94%;

- orthophosphoric acid – 3%;

- manganese dioxide – 3%.

processing is carried out from half an hour to 45 minutes at 100 ° C

Cold bluing: features, advantages, disadvantages

Quite often, when asked how to burnish steel at home, some option is given specifically from the cold method of blueing. As a rule, this method is used in cases where the part does not experience strong mechanical stress. From the name it is clear that this process of bluing barrels at home occurs without thermal effects. In practice, various solutions are used.

Using a solution and a brush

There are several industrial options for ready-made mixtures for applying them to the metal surface with a brush. This is a domestically produced bluing agent “Voron 3”, as well as a well-known bluing agent, the imported mixture “Parisian oxide”.

The benefits are visible to the naked eye. This is the simplicity of the process, as well as the fact that the liquid for bluing steel does not need to be prepared independently, and the safety requirements and conditions for the process are minimal.

But this method also has disadvantages. It is very difficult to penetrate with a brush into all the “cracks” of the part given its complex configuration. To make the product “smooth”, additional polishing will be needed. Well, the worst thing about this type of bluing of barrels is that even slight mechanical damage will leave a mark and the treatment will have to be repeated.

Immersion method

The second option involves immersing the metal of the part in a solution to bluish it. The main advantage of this method is that the liquid penetrates into “all the cracks” of the part and covers it with a uniform protective layer. Secondly, the liquid does not splash, as in the first case when applied with a brush.

Recipes for cold application of protective film can be taken as follows:

- Ferric chloride (FeCl3) – 75 grams; ethanol (ethyl alcohol, medical alcohol C2H5OH) – 30 grams; copper sulfate (copper sulfate, CuSO4 (anhydrous white) or CuSO4 * 5H2O (blue)), nitric acid (HNO3) - 20 grams each.

- Ferric chloride (FeCl3) – 170 grams; nitric acid (HNO3) – 13.5 grams; hydrochloric acid (HCl) and copper sulfate, copper sulfate, CuSO4 (anhydrous white) or CuSO4 * 5H2O (blue)) - 4 grams each.

This method is not suitable for those who are trying to learn how to coat a knife, since such a coating is not resistant to mechanical stress and will quickly wear off. Quite often, it is recommended to solve the problem of how to blue a gun using rusty varnish, as one of the most effective and least costly methods. The essence of the method is to treat the part with a very active corrosive medium - “rusty varnish”. This mixture should be prepared first.

It is recommended to do everything under a hood or outside on the leeward side, so as not to inhale the very harmful gases formed during the chain of reactions. First, 12 grams of hydrochloric acid (HCl), as well as nitric acid (HNO3) in the amount of 20 grams (attention, we look not by volume, but by weight, acids have different densities) are placed in a glass container (required). Add 30 grams of iron scale (rust) and 5 grams of iron filings to this container with a mixture of acids.

The reaction must be allowed to pass. After this, add 50 grams of distilled water and ethyl alcohol (medicinal alcohol C2H5OH) to the resulting reaction products.

The solution must be left for 12 hours and after that the resulting solution must be separated from the scale and precipitated salts. Now, for bluing at home using this method, you should place the part in the solution and wait until the part turns black. After this, the part must be rinsed with water and the red marks from the solution must be removed with a brush. As a result, we get a very good result of chemical bluing.

As in the first case (with a brush), and in the second (using solutions), after all the procedures, the blued parts must be thoroughly washed using detergents. Unfortunately, this method is not suitable for those who are trying to learn how to coat a knife, since such a coating is not durable and will quickly wear off.

Metal blackening

Depending on the acidity of the environment in which the workpiece is processed, the color of the resulting coating changes, from yellow to black. Therefore, bluing and blackening of metal are not the same thing. The required shade is selected by varying the intensity and duration of heat treatment and the percentage of solution components.

Metal blackening

If you take a mixture of 7 parts copper nitrate and 3 parts alcohol denatured alcohol, apply it to the product and heat it over a fire, then as it heats up the coating begins to change its color. When the desired shade is achieved, stop heating.

It is also possible to blacken steel by coating it with oil and calcining it in an open flame. The result is a durable film of deep black color. There are other compositions for blackening.

Burnishing of minor parts / fire oxidation

Blueing of minor parts (excluding barrels, bolts and receivers) is done by heating the parts over a fire until they become tarnished (do not overexpose them) and then lowering them into any mineral oil. Or, in a metal box, the part is filled with crushed charcoal and heated over a fire. Attention: before any type of oxidation, degrease the parts in a 10% solution of soda or potash. During liquid oxidation, barrels should be tightly sealed with plugs on the chamber and muzzle sides.

Based on materials from verstak45.narod.ru

Application of rust varnish

The method using the so-called “rusty varnish” is distinguished by its cost-effectiveness against the backdrop of quite acceptable quality of the coating.

The product is immersed in a chemically active corrosive liquid based on hydrochloric acid, which forms red and black oxides on its surface.

To remove rusty deposits, you will have to use a stiff wire brush. A black oxide film will remain on the product.

Ready rusty varnish

The method is long and labor intensive, but provides excellent results at home.

Before starting processing, as with all other methods, you should thoroughly clean the object with sandpaper and degrease it with a solvent.

The active liquid is prepared in special porcelain vessels; the use of protective gloves, an apron, acid-resistant shoes and thick work clothes is mandatory. A respirator and clear face shield should also be used.

A small amount of hydrochloric acid is poured into the vessel, adding rust scraped off the iron, sawdust and nitric acid. The mixture should be stirred carefully with a porcelain stirrer until bubbles stop appearing.

Next, carefully add water and vodka in equal parts. The solution is allowed to settle and drained from the sediment.

The result of using rusty varnish

The part is placed in the solution for a time sufficient to acquire a deep black color. At the end of the process, the part should be rinsed with plenty of water.

Attention! The solution used in this method is one of the strongest solvents. Beware of even the smallest splashes - they can cause very serious injury and property damage.

If splashes get on clothes, they should be removed immediately. If, despite all precautions, drops get on the skin, the affected area should be washed generously with a soda solution and immediately seek medical help.