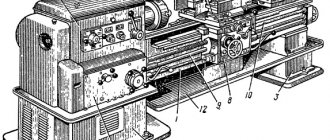

TV 16 lathes were produced in the post-war period at many machine tool factories in different republics of the Soviet Union (Kazakhstan, Ukraine, Belarus). Basically, TV 16 machines were used in various educational institutions to train children, who received invaluable experience in turning. Although in our time the TV 16 machine has already been discontinued, it can still be found in schools, colleges, private workshops, etc.

TV 16 was designed on the basis of the Czechoslovakian TOS MN80 machine, and, despite the fact that TV 16 was produced at different machine-tool enterprises, they did not have any particular differences. They could differ only in the casting forms, and all other internal mechanisms and components were identical.

The machine itself is small in size. It performs functions such as processing various types of metal, boring, drilling, threading, facing, etc.

Friends, I would like to share my story of purchasing a TV-16 lathe.

When doing aircraft modeling at home, you are faced with an acute shortage of tools and even special machines. And if in your city there are clubs and circles where you can negotiate and work at the machine, then in my case there were no such opportunities. I was looking for opportunities and found people who would hardly agree to make ordinary diffusers for little money. But as a rule, the result was not what I wanted. Either there was a big error or the price was too high.

My patience ran out when I decided to build a larger model. And he wanted to make it like Oleg Zinovkin’s Stuntress with collapsible wing consoles. Having made a simple drawing, I turned to a “turner” who agreed to do it. When a couple of parts were ready, I examined them. My mood was spoiled, not only did he demand a substantial amount of money for the work by local standards, but the part also turned out to be made inaccurately, with large errors (((To my question it couldn’t have been done better, he answered. That he suffered a lot, a duralumin blank I was constantly doing push-ups. And then buhhhh... “doesn’t the turner really know his business.” I took what was done and left.

I found out on the Internet that for such work there is a device called a lunette. By that time, I had already saved up funds to purchase a lathe, but now I set myself the topic of searching. I live in Dushanbe, there is not so much good stuff here. I started tracking virtual local flea markets and also going to real ones. He called out among his friends. One friend named Rahim had a TV-16 lathe, but when I decided to buy one for myself, he decided not to sell it, because he started the motor on it and the machine began to spin))). The fact that the machine started working made me even more excited. In addition, I could install such a machine in my apartment.

Good luck, on one local website there was an advertisement for the sale of a TV-16 “schoolboy” machine. Price $300 went to look. Unfortunately, it turned out that the machine was completely disassembled; moreover, when disassembled, it was moved and lay in different places for a long time. There was no table and engine, as well as some spare parts. The seller did not agree to reduce the price, and for such a price it’s a big risk to buy a non-complete machine, since we can’t find spare parts here. I decided not to take it.

Then I came across TV-6 and TV-4, but in other cities, in my apartment it’s unlikely that my relatives would approve of this.

At the end of the summer of 2022, when my family and I went to Russia, someone posted a TV-16 machine on the website, it seemed to be complete and the seller was asking for $350. What to do?! I contacted friends who bought and left the machine before my arrival.

When I saw the machine in real life, my happiness knew no bounds, everything seemed to be in place, but a lot of work needed to be put into it. The first thing that turned out to be a 165 mm cartridge, and such a machine is clearly too much. After a thorough inspection, it became clear that the machine was being prepared for sale. The pulley on the engine was machined from a block, the cartridge and plan washer were from another machine, the entire motor is rusty, most likely from the water pump.

After reading the forums, I realized that the bed needs at least a little scraping. On the side of the tailstock there were traces of impacts on the frame. There are traces of blows on the tailstock itself. The metal was deformed and needed to be repaired.

Operating rules

Before you start turning, you must select the number of revolutions of the workpiece according to a specially designed scheme. The specifics of the processing performed affect the installation of replaceable gears of the feed mechanism. A chuck or faceplate is fixed on the spindle. It is necessary to install and secure the cutters on the tool holder. The part being processed is fixed in a chuck or centers. When carrying out processing in centers, it is necessary to bring the tailstock. The machine is started by pressing the “start” button, and the mechanisms are stopped by pressing the “stop” button.

If there is a need to reverse the spindle, the switch handle should be turned to the “backward” position. It is important to note that only the electric motor is turned off at o, therefore, at the end of processing, for safe de-energization, the switch must be fixed at o.

Watch a video on how to build a guitar.

Excessive heating of the spindle indicates the need to change the lubricant and check the quality of its connections; it is important to monitor the condition of the bearings during operation for timely troubleshooting.

Safety precautions

Only a professional worker who understands the technical features can be entrusted with servicing the machine. To prevent accidents, important rules should be followed:

- It is prohibited to clean and lubricate machine elements during operation.

- You should not leave the machine running; you should first turn it off or wait until it stops completely.

- Good lighting in the workplace is a must.

- The occurrence of any malfunctions requires immediate cessation of work and seeking help from an adjuster.

In the event of an emergency, you must immediately disconnect the machine from the power supply.

- Provide reliable grounding.

My steps to restore the machine.

Complete disassembly of the TV-16 lathe and evaluation of the work.

The machine is important to me as a tool; I really need diffusers for my aircraft model engines, which I will install on micromotors. Therefore, I decided not to delay the process. I set myself a deadline of the end of October 2022 to do something on the machine. Every day when I came home from work, I tried to disassemble one component of the machine. Moreover, he put the parts, bolts, screws in separate containers. It’s easy to confuse or lose something without this.

Almost every component of the machine was a struggle, although the machine was well lubricated and nothing jammed. But I had to look on YouTube and also search on the Internet to see how the machine components are disassembled. I didn't want to damage anything. Each node has its own trick, do not rush to use force when disassembling.

Having finished disassembling the machine, the question arose: to make a candy out of the machine or to launch it as is without extra financial investments. I decided to launch it and then we’ll see...

PS after two years of use. The bet on launching the machine as is has borne fruit, I use the machine in the apartment. It immediately became clear that the machine was just the beginning. For successful work you need good cutters, blanks, drills, dies, taps, measuring tools and fixtures. All this was slowly sought out at local flea markets. Even now I understand that I don’t need such a powerful engine. It is necessary to place the frequency converter and the motor directly. The belt drive, together with other elements, creates vibrations. As I understand it, this is normal for this model of the TV-16 lathe.

bed

The bed of my TV-16 lathe was slightly damaged by “barbarians with hands.” From the tailstock side the machine was beaten, or something was hit with it... On the cartridge side, the caliper did not reach the end. There were traces of blows, with a file or something else.

I did not remove the headstock with the spindle because everything rotated well there, there was no play or other problems. Unless the edge of the spindle behind the thread was slightly damaged by someone. I had to correct it a little with a diamond file. Fortunately for me, the frame as a whole was not very worn. I took the measurement with a micrometer, the deviation was no more than 0.02 mm, which is normal. In places where there were “abrasions” and unevenness, there were naturally errors...

The damaged areas were carefully ground down using a file and small needle files. Ultimately, I brought the surface to condition with a homemade scraper. He did it as well as the tools allowed.

Lathe lead screw

To completely disassemble the caliper, you need to pull out the machine's lead screw. This is where I ran into some minor difficulties. The screw seemed to be caught in a bronze sleeve. I could hardly pull him out. I tried to lubricate it and put it back in place. It turned out that the edge of the lead screw was slightly deformed by the impacts. I ground off the deformed edge. The screw began to rotate better, but still with difficulty. I already started looking for a reamer, I thought the bronze bushing was damaged. Fortunately, no, the screw was jammed due to me unscrewing the “thing” where the screw is inserted on the right side. There must be exact alignment in this place, otherwise there will be a skew. After tightening the screws, the lead screw began to rotate without problems.

PS after a while I started the guitar and the lead screw. I had to sharpen the planetary gear a little. The bronze insert was badly damaged. There were also inaccuracies when the gear rotated. After careful manipulation, trial and error. The lead screw started working. By generously lubricating the guitar gears with thick lubricant (salidol), closing all the “cracks,” I achieved a significant reduction in noise.

Longitudinal and transverse feed support

Luckily for me, the caliper was in good condition and did not require any special manipulations. Although I spent a lot of time trying to completely disassemble it. There is a lot of information on the Internet showing how to do this. The main thing here is not to rush, not to put pressure or hammer.

Electric motor

It seems to me that the engine used to be on a water pump, although it was rusty and dead on the outside, everything inside was functional. The shaft on one side was lengthened by welding a piece and subsequent processing.

There were 3 wires sticking out of the engine, I tried to connect the whole thing to an alternating current network of 220 Volts, through a 10 microfarad capacitor, the engine started working. But the noise of the engine immediately became apparent, as well as the pulley that had been machined by someone was very heavy and did not stand level. All this resulted in strong vibrations, similar to the vibrations of a mobile phone... Such a machine cannot be used in an apartment. The neighbors won't stand it.

Having disassembled the engine, I checked the bearings; one of them had slight seizure. Replacing it, the noise decreased significantly. It was necessary to place strips from a beer can on the shaft under the pulley, thereby balancing the position of the pulley on the shaft.

I managed to achieve an acceptable level of noise and vibration. After playing with the belts, I achieved a slight tension on the belt, but the vibrations were minimal. For my needs of working with brass and caprolon, this was the solution.

10 microfarads of capacitor was not enough for the engine, 20 was already too much, so I chose the middle.

Scroll chuck

The photo shows that the chuck installed on the lathe is gigantic in size, 165 mm)))) for the TV-16 go. A little more and he will scratch the frame. First of all, before seeing the machine live, I began to look for a replacement for it. After reading the forums and asking around, they recommended that I take a 125 mm cartridge and preferably a Polish high-precision one. I was afraid that the cartridge might not fit my flange, but in vain, because I still had to grind the flange. Not deciding to buy a cartridge from Russia, I began to look for it in my area. At flea markets and bazaars, you can find spare parts for lathes, but very few. I found 125 cartridges, probably from a TV-6 machine, but their condition confused me. Rusty, beaten, and even the cams are not original in some places... This option was not suitable for my high-precision aircraft modeling work. I've been looking for a cartridge for several months now and couldn't decide on a size of 80-100 or 125 mm. Time was running out, by this time the engine was already spinning and I wanted to start the machine. Once again walking through the Sultoni-Kabir bazaar, one of the sellers, who already recognized me by sight, offered me an 80 mm cartridge. I began to consider wiping it from dirt. I see the inscription CT80P, I think wow, you need to take “Polish”. I began to check how the cams were moving, but there was no key in the entire market, so I had to dodge and turn with a reamer... The cams seemed to be moving, but not well. I decided there was no need to take it, but the stated price alarmed me. He began to bargain, the seller gave up a fifth of the price, but no more, saying that he himself bought it yesterday for a slightly lower price. And then I had a conversation with a flea dealer from another bazaar, who told me that yesterday someone brought several small cartridges and quickly sold them out... Our resellers live in the morning, come at 5 and go until 7 in the morning, and then go to their points at the bazaars.

The ST 80P cartridge was heavily soiled and rust appeared in places. The fists moved very, very tightly. There was a visible notch on the side of one cam, damage that slightly compressed the path of the cam. I bored out this place with a diamond file, the usual ones slipped like they were on glass. When I removed the cams, I was disappointed (((one of the cams No. 2 had damage. 2 teeth were broken but they were not there. Also, the other cam had a crack.

I washed the cartridge and all the parts in gasoline with a brush and some fine sandpaper. It turned out shining like a new cartridge. The fists still moved very tightly. It was similar to the density with which a piston moves in the cylinder of a model aircraft engine. With minimal manipulation of the diamond file I achieved a smooth glide. I assembled the chuck, fortunately it worked when clamping parts less than 9 mm, as well as more than 30 mm. I'm still looking for a replacement for the broken cam. I didn’t make any claims to the seller because the cartridge, even in this form, suited me for doing small jobs like a vice.

In search of a cam/jams for my Polish CT80P cartridge, I again searched all the bazaars and flea markets... I didn’t find anything, but I decided to buy a Soviet 80 mm cartridge, as it was good for me, and I agreed on the price. I bought several cutters, reamers and a chuck, and I asked for a good discount. The new cartridge went through the same maintenance procedure. Everything about it suited me, although it seemed to me that the Polish language was much better. Looking ahead, I will say that this cartridge copes with its role 100%, especially for a beginner, learning with it is the best thing.

I have the cartridge, all I need to do is give the flange to a “professional” turner for modification to fit my 80 mm cartridge.

Plan washer (Flange)

In search of a plan for the washer (flange), just like with other parts, I scoured the city several times, asked a lot of people, and even thought about buying a flange on the forum. But the flange is such a thing that it needs to be adjusted individually to the machine, to the chuck. So I finally decided to bore my 165mm flange to 80mm. You couldn’t do this on your own machine or in your room. Then I went to the “turners”. As luck would have it, on weekends they don’t work when I need it, and in the morning I can’t get them on site. I had to spend several days trying to find someone who would undertake to make my modifications. Moreover, I myself could not find the main “turner” and had to contact through my wife’s brother, who works in the neighboring furniture workshops. He charged him 1,500 rubles in Russian money as “his friend,” but after haggling they agreed on 700 rubles…. I had to wait a week and then a couple more days to finalize the flange. As a result, my nerves were on edge. You probably understand now why I bought myself a machine, and why turning a simple diffuser in my area is very difficult and not economically profitable. You’ll probably say that there are also turners, yes there are, but their rates are the same or higher, and often they don’t want to take on small things (((In our area, the minimum pension is 1,500 rubles, so you can understand the difference in prices.

With the installation of the puck plan we had to do the same dance. They didn’t make holes for the mounting bolts in the flange, and what they would have done was to wait and wait. In truth, I was fed up with their “tomorrow” so I decided to drill it myself. Of course, drilling with a screwdriver is rough, but you can do it right now. I drilled with small errors, so that the holes had to be expanded and adjusted. But what happiness awaited me when the machine started working)))))))

Tailstock TV-16.

The tailstock probably suffered the most in the hands of the previous owner. From the marks of the blows one could guess that it was used instead of a hammer. I smoothed out the strong bumps with files. The final processing was done with an improvised homemade scraper. The tailstock quill, like the rest of the parts, had to be cleaned of paint and rust. We must pay tribute to the previous owner, the machine was very well lubricated, so there was not a lot of rust.

Finally

In conclusion, I would like to say that the TV-16 machine pleases my eyes every day. He stands in one of the rooms and contemplation alone motivates. Apparently I, as a man, am not very indifferent to such things...

In order to be able to work successfully, I had to fight vibrations; I didn’t bring the machine to perfection, but rather launched it in a hurry. Because I could no longer invest any more money. But even so, I was able to sharpen diffusers for my aircraft model engines myself. I especially liked caprolon, this material is freely available on the market, but with duralumin everything is complicated...

If I had the opportunity to take a 125 mm cartridge now, I would not change my 80. When performing my work for aircraft model engines. (small things) the use of such a cartridge is 200% justified. Perhaps I am not experienced, but there are more possibilities for moving the caliper.

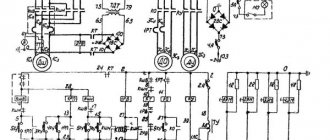

Electrical equipment

The electrical circuit of the installation is simple and does not contain elements that are difficult to master, so even beginners will be able to easily understand the principle of operation of the device. Before starting operation, the unit body must be grounded using a special block located on the side to ensure the safety of users.

The electrical equipment of the installation is designed to start and stop the unit, reverse engine starting and blocking in the event of a short circuit or change in the mains voltage. The following are responsible for performing these functions:

- Batch reversing switch.

- Magnetic type starter with two buttons.

- Fuse box.

- Contacts that block the equipment from starting if the table doors or feed boxes are not closed.

- A panel with clamps through which the unit is connected to the network.

Reviews after a while

1) The machine is worthwhile but needs some work, there is room for upgrading.

2) I started the lead screw, it’s convenient but noisy.

3) Got good incisors. Working with them on the machine is a pleasure.

4) Doesn’t take up much space, can be used occasionally.

5) For a workshop, of course, a more mature machine, at least a TV-4, is better.

6) There is not enough reverse, there is not enough speed adjustment, there is not enough adjustment of the lead screw speed (you can change the gears, but this is not serious).

7) I liked the Polish cartridge, I even use the defective one.

Epilogue

Unfortunately, or maybe fortunately, I sold the TV-16. Sold by local standards for a good price, but with all the equipment. It seemed like it was a mistake, but it didn’t seem to be. Now I am again wandering through flea markets in search of equipment, tools for a new machine...

I sold the machine on a local flea market site like Avito, for a long time and at an expensive price. They ended up buying it! The first month I was very uncomfortable, since the machine became part of the house. I really missed something somewhere in my soul, so I again started looking for a TV-4, TV-6, TV-7 machine, in general, as luck would have it. And after a while I finally found the TV-6 option. I will write about it separately. In the meantime, I want to give a parting word to those who have a TV-16 on rolling bearings. Do not sell your brainchild, it is better to invest in its modernization. The machine is very good for hobby purposes.