Despite the fact that both galvanized and stainless steel pipes, as corrosion-resistant products, are used in similar areas of the national economy, their popularity varies mainly due to their service life, as well as the aesthetics of their appearance. These factors, among many, also influence the cost of rolled metal products. You can buy galvanized pipes at StalPro at a price lower than the cost of stainless steel by 30-40%.

Material characteristics

Zinc is a metal with a melting point of 419 C.

The composition of the zinc coating includes an alloy of zinc (99.97%), aluminum, lead and other metals. The layer thickness is standardized by GOST and ranges from 10 to 60 microns.

In air, zinc is covered with a thin film of oxide, which acts as a protection for steel from corrosion.

Galvanized steel is resistant to precipitation and temperature changes.

Convenient to process, easy to bend, roll, stamp and other mechanical loads.

Features of stainless steel pipe

The product is made from alloy steel, which contains additives such as:

- chromium;

- molybdenum;

- manganese;

- titanium;

- nickel;

- niobium;

- nitrogen.

Each of these substances increases the resistance of steel to various factors during its operation, often unfavorable. Such an alloy forms a thin film on the surface of the metal, protecting it from corrosion. An inherently strong and durable material, which is the starting material for the manufacture of stainless pipes, which can be purchased at StalPro, has a unique function of self-healing of the protective film formed during the oxidation of chromium. Depending on the composition of the additives regulated by GOST, stainless steel is produced in various grades.

Advantages of stainless pipe

Compared to galvanized products, stainless steel pipes have more significant advantages:

- Their service life reaches 50 years, which is twice as long as the period of use of galvanized pipes.

- Stainless steel products are more environmentally friendly than galvanized ones.

- High resistance to positive and negative temperatures.

- Stainless steel pipe can be processed easily with both manual and mechanized tools without losing its properties.

- Due to its high degree of ductility, stainless metal tolerates deformation well during the manufacture of various products without losing its protective layer.

- High mechanical strength allows stainless steel products to withstand significant shock loads.

- Due to the introduction of various substances into the steel composition, the resistance of stainless pipes to corrosion processes, as well as to the effects of slightly aggressive and acidic environments, is maximized.

Unlike galvanized metal products, galvanized pipes can be used in the food industry.

Can galvanized pipes be used for chimneys?

Chimneys with zinc coating are used under certain conditions.

When zinc is heated to 419°, it begins to release substances harmful to humans. Therefore, it is recommended to install outlets made of this material in smoke exhaust systems where the temperature does not exceed 350°C.

The 2009 Ministry of Emergency Situations rules prohibit the use of metal smoke removal agents for coal-fired stoves.

In addition, a single-wall galvanized outlet will burn out after one or two seasons. In practice, it is used as an outer casing in double-walled structures with insulation.

Pipe insulation

A galvanized chimney made from a single-wall pipe is susceptible to abundant condensation due to the difference in temperature of the smoke and the environment. And if the chimney itself suffers little from moisture, then condensation has a negative effect on the operation of the heating device - draft deteriorates, and drops formed on the outer surface of the pipe flow down and have a destructive effect on the roof. Insulating the smoke duct helps to cope with this problem.

For thermal insulation, fire-resistant insulating materials are used:

- basalt mineral wool, produced in the form of elastic fibrous slabs or ready-made dense cylinders;

- backfill: broken brick, slag, expanded clay.

A pipe is wrapped with rolled mineral wool, and then a brick shaft is built around the resulting structure. When using cylindrical basalt insulation, first put the cylinder on the pipe, and then build a shaft or put a steel casing on top. When using backfill materials, a smoke channel is collected, a shaft is built around it, and then insulation is poured into the shaft.

The resulting combined chimney can be painted if its outer surface is metal, or plastered if the shaft is built of brick.

Advantages and disadvantages of galvanized pipes

Users include the following advantages of a galvanized chimney pipe:

- long-term immunity to corrosion;

- rapid heating of the chimney and, as a result, ensuring good draft;

- simple assembly method;

- a smooth surface inside the channel, which does not allow soot to linger on the walls;

- Possibility of venting through the wall of the building.

Flaws:

- short service life of a single-wall outlet;

- when cutting a product, the cut lines begin to rust after a short time;

- minor damage leads to the destruction of the protective layer;

- formation of a large amount of condensate.

What is better galvanized or stainless steel?

It is recommended to make the initial section of the chimney channel from the boiler, where the temperature is especially high, from stainless steel. The inner pipe of the sandwich is made from it, which allows it to be used in any smoke removal system.

Of course, this type of steel is the most durable and rust-resistant. In these parameters it is superior to galvanization. Its main drawback is its high price.

To reduce the cost of sandwiches, galvanization is used to make the casing.

Maintenance during operation

The maintenance of a steel smoke exhaust system does not require complex manipulations.

For efficient operation of the heating system you need:

- regular cleaning of soot deposits and debris trapped in the pipe - at least once a year and when a blockage is detected;

- timely removal of condensate from the drip line (as it accumulates and during rain);

- periodic inspection of the external casing or shaft, sealing cracks and seams in case of leakage - before the start of the heating season and at its end.

Selection tips and approximate price

Manufacturers offer a large selection of both single-circuit galvanized bends and sandwich pipes with a galvanized shell. There are certain parameters by which you should select elements for the chimney:

- the diameter of the boiler outlet pipe must be equal to or less than the cross-section of the chimney outlet;

- attached chimneys can have no more than three bends along the entire length of the channel.

- Manufacturers indicate the required chimney diameter for boilers in the unit’s passport;

- The wall thickness for the outer casing must be at least 0.5 mm, usually 0.55 mm is used.

The price of single-circuit galvanized steel pipes depends on the diameter and thickness of the sheet metal. A meter bend d=110 mm costs 190 rubles, and d=250 mm costs 390 rubles.

A stainless steel + galvanized sandwich of the same diameter, 0.5 mm thick and 100 cm long will cost 1,230 rubles.

My bathhouse

Typically, fire-resistant bricks are used to construct a chimney in a bathhouse. Nowadays, as before, brick remains the most popular material. However, nowadays there are alternatives to it. These are steel chimneys in the form of a sandwich pipe. The metal used for chimneys is galvanized or stainless steel. Today we will look at steel chimneys and figure out which steel chimneys are better made of.

To many, this formulation of the question may seem a little strange. Everyone knows about the advantages of stainless steel and understands that its properties are incomparably better than those of ordinary steel, even coated with zinc. Its advantages include high resistance to corrosion, resistance to elevated temperatures, and good aesthetic appearance. All these qualities are needed in a bathhouse more than anywhere else.

Galvanized chimneys also have an increased service life, but it is still less than the service life of a stainless steel chimney. Any damage to the protective coating involves corrosion processes, which significantly reduce the service life of the pipe and render it completely unusable. A low-quality or damaged chimney is a source of increased danger, reducing the fire safety of the bathhouse.

The big disadvantage of a stainless steel chimney, which greatly limits its use, is its high cost. Not every bathhouse owner can afford to buy a stainless chimney, because their prices differ by more than 1.5 times. At least in the price lists of steel chimney manufacturers there is such a difference.

This price difference may seem significant to many. But not so much as to completely abandon the idea of installing a stainless steel chimney in the bathhouse. After all, its excellent performance qualities more than cover this difference in price.

A combined chimney allows you to reduce costs. For example, in extreme conditions of a steam room, you can install stainless steel chimney elements. This will give the steam room respectability, and the fire safety of the room will be at a high level. The section of the chimney in the attic and outside can already be made of galvanized steel. No one will see her here.

However, in this case, difficulties may arise when joining chimney elements made of different steels. Therefore, when you buy them, you should look at the installation possibilities on site. It is also advisable to buy products from the same manufacturer. This will give additional guarantees for the assembly and save you from difficulties during installation.

.

Making galvanized pipes with your own hands

The main feature of a factory-made galvanized pipe is a reliable welding seam.

If you have an argon unit at home and you are a big welder, this makes a difference. Surely what you will get is not a pipe, but a feast for the eyes.

First you need to choose a galvanized sheet for the pipe. Professionals make bends with walls 0.55 mm thick. At the same time, it must be taken into account that the thinner the material, the easier it is to bend.

Required tools and materials

You will need:

- hand scissors for metal;

- mallet with a wooden striking part;

- roulette;

- square;

- metal ruler;

- pencil, preferably a construction pencil;

- pliers.

For the convenience of bending work, a simple workbench is equipped where markings are made. A metal corner (40×40 mm or more) with a length of at least 100 cm, a steel round shape of the required diameter, is attached to the table.

Cutting out the workpiece

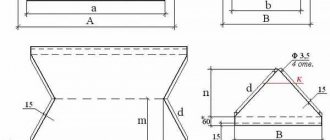

Let's look at how to make a pipe with a cross-section of 100 mm.

Calculate the width of the workpiece:

- determine the circumference as the product of the cross section and the value of pi equal to 3.14;

- 15 mm are allocated for the bends for the connecting seam.

In total, for a 100 mm bend, a workpiece with a width of 3.14 × 100 mm + 15 mm ≈ 330 mm is cut out.

Take into account that the pipes are made slightly cone-shaped for ease of installation using the socket method. Therefore, one side measures 330 mm, the other 340 mm (in the figure).

Formation of a profile

On the cut-out workpiece, mark a fold line for a fold of 5 mm on one side, twice 5 mm each on the other.

The sheet is laid on a workbench, the edge is aligned with the corner. Using a mallet, gradually bend it at a right angle. Then the workpiece is turned over and the fold is placed on the canvas.

In the same way, a 10 mm bend is made on the other edge of the sheet, and another 5 mm wide on it.

Next, the workpiece is manually bent on the forming tube, using a mallet.

Processing the butt seam

After obtaining a round shape of the workpiece, it is placed on a round form or an additional corner, the folds are connected into a lock, tapping them along the edges with a mallet. At the narrow end of the future pipe, the folds are slightly cored. Tap the entire length of the joining seam with a mallet, compacting the folds. The seam becomes almost permanent.

Is it possible to paint a galvanized chimney?

It is possible and even necessary to paint galvanized steel. Over time, rust begins to penetrate through the zinc layer and paint will be a good means of additional protection.

However, a galvanized surface does not have the same adhesion as, for example, black steel. Therefore, ordinary oil and alkyd paints, which oxidize upon contact with zinc, lose adhesion and peel off the painted surface, are not suitable here.

Special compositions have been invented:

- tsikrol, matte acrylic paint with high coverage, light resistance and adhesion;

- Nerzhalux enamel, characterized by high adhesion and wear resistance;

- aluminum enamel Serebrol, which reliably protects against rust and is suitable for outdoor use;

- a number of other compounds that can provide long-term protection from rain, exposure to sunlight, temperature changes, without causing harm to the human body.

It is better to paint no earlier than a year after installing the chimney. During this time, its surface will acquire the desired roughness and create reliable adhesion for coloring compounds.

How and with what to insulate a galvanized chimney

Among insulation materials, basalt wool is in first place - a reliable non-flammable product that is successfully used for thermal insulation and insulation of smoke removal systems. Other types of mineral wool are used as a cheap substitute, the main thing being the non-flammability of the material.

The outlet is wrapped with the selected insulation and secured with wire or other reliable and heat-resistant material. Then another pipe, larger in diameter, and usually made of galvanized steel, is placed on the insulated channel. It turns out to be a self-made sandwich. The inner pipe can be a stainless steel product.

Varieties

Galvanized pipes are produced in two types: single-circuit and double-circuit. Both varieties are available in a ready-to-assemble form, with all the necessary connecting and functional elements.

Double-circuit pipe

The easiest to install are double-circuit sandwich pipes, which you just need to buy and assemble like a construction set.

Each section consists of two pipes and a layer of thermal insulation between them. The shaped elements have a similar structure and do not require modification.

We recommend that you read: How to properly fasten and fix polypropylene pipes to the wall

This design allows you to build a chimney without much effort: the inner pipe acts as a smoke channel, and the outer pipe acts as a protective casing, and to equip a full-fledged working system, it is enough to simply assemble the sections in the right order.

The chimney can be assembled inside the house or outside. In this case, the inside of the sandwich chimney will be absolutely fireproof, since its shell does not heat up much.

A sandwich chimney located outdoors is reliably protected from the vagaries of nature, since the insulating layer prevents heat exchange between the smoke channel and the external environment, and the external galvanized pipe protects from mechanical and chemical influences.

In addition, the assembled double-circuit pipe is a completely aesthetic design that can be successfully used in any design projects.

Single-circuit pipe

For the construction of the internal part of the chimney, for arranging a smoke channel in a combined structure or for a barbecue, single-circuit pipes are used. A single-wall pipe and corresponding shaped elements are cheaper than a double-wall pipe.

However, when choosing, you should evaluate the design features, which in different situations can be both pros and cons:

- when the heating device is operating, the outer surface becomes very hot, which can be a fire hazard, but on the other hand, such a pipe can fully cope with the role of an additional source of heat in the room;

- a single-circuit smoke duct on the street cannot be installed without insulation and a protective shaft or casing, however, such a pipe is ideal for placement inside an existing brick or asbestos-cement chimney;

- the use of a single-wall pipe when constructing a combined chimney or chimney for outbuildings will significantly save effort and money.