Her Majesty the trumpet! Of course, it makes our lives better. Like that:

The key characteristic of any cylindrical pipe is its diameter. It can be internal ( Dу ) and external ( Dn ). Pipe diameter is measured in millimeters, but the unit of pipe thread is inch.

At the junction of the metric and foreign measurement systems, the most questions usually arise.

In addition, the actual size of the internal diameter often does not coincide with Dy .

Let's take a closer look at how we can continue to live with this. A separate article is devoted to pipe threads; click here to read more.

Inch calculator

conversion from millimeters (mm) to inches (in):

conversion from inches (in) to millimeters (mm):

You can view hoses for industrial use and find those that are suitable in diameter and other characteristics in the catalog of hoses and hoses. Use the filter to select products according to the required parameters.

sewage hose for vacuum cleaner reinforced corrugated for swimming pool watering silicone rubber hose of large diameter for compressor BRS connection Camlock air duct for exhaust gases American

Table of hose diameter sizes in inches and millimeters

| metric system, in mm | British, in inches | |

| 4 | — | — |

| 5 | 3/16″ | three sixteenths of an inch |

| 6 | — | — |

| 6,3 | 1/4″ | one fourth of an inch |

| 6,4 | 1/4″ | 1 4 inches |

| 8 | 5/16″ | five sixteenths of an inch |

| 9 | — | 5 16 inches |

| 9,5 | 3/8″ | three eighths of an inch |

| 10 | 3/8″ | 3 8 inches |

| 12 | 1/2″ | one second inch |

| 12,5 | 1/2″ | 1 2 inches |

| 12,7 | 1/2″ | 1 2 |

| 13 | 1/2″ | — |

| 14 | — | — |

| 15 | 5/8″ | five eighths of an inch |

| 16 | 5/8″ | 5 8 |

| 18 | 3/4″ | three quarters inches |

| 19 | 3/4″ | 3 4 |

| 20 | 3/4″ | — |

| 22 | 7/8″ | seven eighths of an inch |

| 25 | 1″ | one inch |

| 27 | — | — |

| 28 | — | — |

| 30 | — | — |

| 32 | 1 1/4″ | inch and a quarter |

| 33 | — | — |

| 35 | — | — |

| 38 | 1 1/2″ | one and a half inches |

| 40 | 1 1/2″ | — |

| 42 | — | — |

| 43 | — | — |

| 45 | 1 3/4 | one three quarters inches |

| 48 | — | — |

| 50 | 2″ | two inches |

| 51 | 2″ | — |

| 52 | — | — |

| 53 | — | — |

| 55 | — | — |

| 60 | — | — |

| 63 | 2 1/2″ | two and a half inches |

| 65 | — | — |

| 67 | — | — |

| 70 | — | — |

| 75 | 3″ | three inches |

| 76 | 3″ | — |

| 78 | — | — |

| 80 | — | — |

| 81 | — | — |

| 84 | — | — |

| 87 | — | — |

| 89 | 3 1/2″ | three and a half inches |

| 90 | — | — |

| 100 | 4″ | four inches |

| 102 | 4″ | — |

| 104 | — | — |

| 105 | — | — |

| 107 | — | — |

| 110 | — | — |

| 120 | — | — |

| 125 | — | — |

| 127 | 5″ | five inches |

| 130 | — | — |

| 132 | — | — |

| 133 | — | — |

| 140 | — | — |

| 150 | — | — |

| 152 | 6″ | six inches |

| 153 | — | — |

| 156 | — | — |

| 160 | 6 1/2″ | six and a half inches |

| 175 | — | — |

| 178 | 7″ | — |

| 180 | — | — |

| 190 | — | — |

| 200 | — | — |

| 203 | 8″ | eight inches |

| 229 | 9″ | — |

| 250 | — | — |

| 254 | 10″ | ten inches |

| 270 | — | — |

| 280 | 11″ | eleven inches |

| 300 | — | — |

| 304 | 12″ | twelve inches |

| 312 | — | — |

| 313 | — | — |

| 350 | — | — |

| 410 | — | — |

| 460 | — | |

| 610 | — | — |

How to find out the diameter of a pipe? Measure!

For some reason this strange question often comes to e-mail and I decided to supplement the material with a paragraph about measurement.

In most cases, when purchasing, it is enough to look at the label or the seller. But it happens that you need to repair one of the communication systems by replacing pipes, and initially it is not known what diameter the already installed ones have.

There are several ways to determine the diameter, but we will list only the simplest ones:

- Arm yourself with a tape measure or a measuring tape (this is how women measure their waist). Wrap it around the pipe and record the measurement. Now, to obtain the desired characteristic, it is enough to divide the resulting figure by 3.1415 - this is the number Pi.

Example:

Let's imagine that the girth (circumference L) of your pipe is 59.2 mm . L=ΠD, resp. the diameter will be: 59.2 / 3.1415 = 18.85 mm .

- After obtaining the outer diameter, you can find out the inner one. Only for this you need to know the thickness of the walls (if there is a cut, just measure with a tape measure or other device with a millimeter scale).

Let's assume that the wall thickness is 1 mm. This figure is multiplied by 2 (if the thickness is 3 mm, then it is also multiplied by 2 in any case) and subtracted from the outer diameter (18.85- (2 x 1 mm) = 16.85 mm) .

It’s great if you have a caliper at home. The pipe is simply grabbed by the measuring teeth. We look at the required value on a double scale.

Inch and Metric Tubes

Both inch and standard steel water conduits are available, which further confuses the matter. You can visually distinguish them by the type of threads - a 1-inch pipe has rounded threads. The photo shows samples.

Thread pitch is measured in different ways. In metric products along the outer boundaries of the threads, in inch products - along the inner boundaries. The distance is different for different section sizes.

- ½ and ¾ – pitch is 1.814 mm.

- From 1 inch to 6 – 2,309.

Pipe 1 inch, which is used in the imperial system, is not equal to 2.54 cm, as it should be, but equals 3.3249, since it includes both the internal size and wall thickness. The exception is ½ inch water conduit.

Converting inch to metric sizes

The reference literature contains the corresponding tables. The same GOST, which regulates the parameters of VGP, specifies both inch and millimeter nominal diameters. Unfortunately, to assemble the system into one whole, the actual value of the internal diameter is also required. While tables often indicate external.

The most convenient table contains the nominal diameter in inches, the external size of the pipe and the equivalent diameter in mm. It indicates a throughput that corresponds to inches.

For example, a 1-inch steel conduit can be connected to a polyethylene conduit whose nominal diameter is 25 mm.

Classification of water pipes

Historically, measurements were calculated in inches. This meaning differed in each state. It was conventionally equated to:

- the width of the index finger;

- the length of three barley grains from the middle of the spikelet;

- the ratio of the distance from the tip of the nose to the thumb of the outstretched hand of King Henry 1 of England.

As a result of the development of civilization and relationships between states, people realized that it was inconvenient to use such a value for full-fledged trade. For this reason, everyone switched to a common measuring system and distances began to be measured in meters. The value of the current meter was fixed in 1983 at the XVII General Conference on Weights and Measures. At this stage it is tied to the speed of light. Despite this, diameters in water pipes continue to be measured in inches. It is officially recognized that this unit is equivalent to 0.0254 meters, or 25.4 mm.

Types of steel pipes according to their production method

- Electric welded (straight seam)

For their manufacture, strips or sheet steel are used, which are bent to the required diameter using special equipment, and then the ends are connected by welding.

The effect of electric welding guarantees a minimum seam width, which makes it possible to use them for the construction of gas or water pipelines. The metal is in most cases carbon or low alloy.

The indicators of finished products are regulated by the following documents: GOST 10704-91, GOST 10705-80 GOST 10706-76 .

Please note that a pipe manufactured in accordance with standard 10706-26 is distinguished by the maximum strength among its peers - after creating the first connecting seam, it is reinforced with four additional ones (2 inside and 2 outside).

The regulatory documentation indicates the diameters of products produced by electric welding. Their size ranges from 10 to 1420 mm.

- Spiral seam

The material for production is steel in rolls. The product is also characterized by the presence of a seam, but unlike the previous production method, it is wider, which means the ability to withstand high internal pressure is lower. Therefore, they are not used for the construction of gas pipeline systems.

A specific type of pipe is regulated by GOST number 8696-74.

- Seamless

The production of a specific type involves the deformation of specially prepared steel blanks. The deformation process can be carried out both under the influence of high temperatures and in a cold way (GOST 8732-78, 8731-74 and GOST 8734-75, respectively).

The absence of a seam has a positive effect on the strength characteristics - the internal pressure is evenly distributed over the walls (there are no “weak” places).

As for diameters, standards control their production with a value of up to 250 mm. When purchasing products with sizes exceeding those indicated, you have to rely only on the integrity of the manufacturer.

It is important to know!

If you want to buy the most durable material, buy seamless cold-formed pipes. The absence of temperature influences has a positive effect on preserving the original characteristics of the metal.

Also, if the ability to withstand internal pressure is an important indicator, then choose round products. Profile pipes cope better with mechanical loads (metal frames, etc., are well made from them).

Here are a couple more excellent slides of creative advertising for a pipe manufacturer:

Pipe dimensional parameters

Regardless of the material of manufacture - polymer, metal, ceramics and so on, the product is characterized by a number of indicators, based on which the consumer can choose the necessary product.

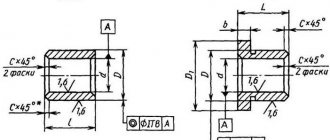

- External diameter - that is, the outer size of the pipe (we are talking only about the round cross-section).

- Internal – the size of the working section.

- Wall thickness largely determines the strength of the product.

The sum of the internal diameter and twice the wall thickness is the external diameter. The actual state of affairs corresponds to this statement. But when it comes to AIV, it is necessary to take into account this point. Most often, water conduits are connected using the threaded method. The thread is applied to the outer part; as a result, the diameter of the thread is by no means equal to the outer size. And since it is important to know the thread parameters for installation, this parameter turns out to be more important and is often indicated instead of the actual size of the product.

For example, a 1-inch conduit is not at all equal in outer diameter to 2.54 cm, since 1 inch is an indication of the thread size.

This confusion is aggravated by the use of two measuring systems on the one hand, and the variety of products available today on the other.

How to correctly convert mm to inches

Conversion table for inches to millimeters

When laying a water supply system or replacing its elements, it is necessary to be well versed in their ratio. To carry out these translations, masters use special tables. The difficulty lies in the wall thickness. An illustrative example:

- Let’s take a product with an outer thickness of 1”, which should be equal to 25.4 mm;

- the diameter of the threaded connection will be 33.249 mm.

How to calculate the diameter of a pipe for a water supply? The thread is cut on the outside of the wall. Its nominal value in relation to the internal indicator is obtained by a symbol. Therefore, to calculate it it is necessary: to 25.4 mm add double the wall thickness of the product. The result will be 33.249 mm. Common threaded connections:

- ½" - 20.4...20.7 mm;

- ¾" - 25.9...26.2 mm;

- 1" - 32.7...33.0 mm;

- 1½" - 45.8...46.2 mm.

As you can see, each case has its own discrepancies.

Conversion table for water pipe diameters from inches to millimeters

Conversion table for inches to millimeters

Conditional pass

The task of the water supply system is to uniformly supply all consumers with the required amount of water. The main calculation parameter is the throughput of the pipeline, that is, the amount of water that can pass per unit of time.

- This parameter is called conditional passage - Dn. It does not have a unit of measurement as such - it is a conditional, non-factual value, indicated in whole numbers and indicates the approximate conditional clearance of the pipe. The step between the values is calculated theoretically, with the condition that with each subsequent increase the pipeline capacity increases by 40–60%.

The convenience of the system is obvious only during practical use. It is enough to select water conduits and fittings with equal nominal bore from the table to guarantee a working water supply system.

Accordingly, a 1-inch steel pipe has a nominal bore of 1 inch, while its actual internal diameter is 25.5 mm, and the external threaded diameter is 33.25.