GOST 30242-97

GOST 30242-97

Group B05

INTERSTATE STANDARD

DEFECTS IN JOINTS WHEN FUNCTION WELDING OF METALS

Classification, designation and definitions

Imperfections in metallic fusion welds. Classification, designation and definitions

MKS 25.160.40 OKSTU 0072

Date of introduction 2003-01-01

Preface

1 DEVELOPED by the Institute of Electric Welding named after. E.O. Paton of the National Academy of Sciences of Ukraine; Interstate Technical Committee for Standardization MTK 72 “Welding and Related Processes” INTRODUCED by the State Committee of Ukraine for Standardization, Metrology and Certification

2 ADOPTED by the Interstate Council for Standardization, Metrology and Certification (Minutes No. 11 of April 23, 1997) The following voted for adoption:

| State name | Name of the national standardization body |

| The Republic of Azerbaijan | Azgosstandart |

| Republic of Armenia | Armgosstandard |

| Republic of Belarus | State Standard of the Republic of Belarus |

| Republic of Kyrgyzstan | Kyrgyzstandard |

| The Republic of Moldova | Moldovastandard |

| Russian Federation | Gosstandart of Russia |

| The Republic of Tajikistan | Tajikgosstandart |

| Turkmenistan | Main State Inspectorate "Turkmenstandartlary" |

| The Republic of Uzbekistan | Uzgosstandart |

| Ukraine | State Standard of Ukraine |

3 This standard fully complies with ISO 6520-82 “Classification of weld defects in fusion welding of metals (with explanations)”

4 By Decree of the State Committee of the Russian Federation for Standardization and Metrology dated March 2, 2001 N 115-st, the interstate standard GOST 30242-97 was put into effect directly as the state standard of the Russian Federation from January 1, 2003.

5 INTRODUCED FOR THE FIRST TIME

Group 1. Cracks

100 E Cracksen cracks

fr fissures Discontinuity caused by local rupture of a weld, which may occur as a result of cooling or stress 1001 Microcrack

en microfissure (microcrack)

fr microfissure A crack having microscopic dimensions, which is detected by physical methods at no less than fifty times magnification 101 Ea Longitudinal crack

en longitudinal crack

fr fissure longitudinale A crack oriented parallel to the axis of the weld.

It can be located: 1011 in the weld metal; 1012 at the fusion boundary; 1013 in the heat affected zone; 1014 in base metal 102 Eb Transverse crack

en transverse crack

fr fissure transversale A crack oriented transverse to the axis of the weld. It can be located: 1021 in the weld metal; 1023 in the heat affected zone; 1024 in base metal 103 E Radial cracks

en radiation cracks

fr fissures rayonnantes Cracks radiating out from one point. They can be: 1031 in the weld metal; 1033 in the heat affected zone; 1034 in base metal

Note—Cracks of this type, diverging in different directions, are known as star-shaped cracks 104 Ec Crater crack

en crater cracks

fr fissure de cratere A crack in the crater of a weld, which can be: 1045 longitudinal; 1046 transverse; 1047 star-shaped 105 E Separate cracks

en group of disconnected cracks

fr reseau de fissures marbrees A group of cracks that can be located: 1051 in the weld metal; 1053 in the heat affected zone; 1054 in the base metal 106 E Branched cracks

en branching cracks

fr fissure ramifiees A group of fissures arising from a single fissure.

They can be located: 1061 in the weld metal; 1063 in the heat affected zone; 1064 in base metal

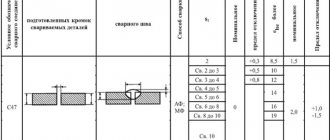

3 Name, definition and designation of defects

The name, definition and designation of defects are given in Table 1.

The table shows:

- in column 1 - a three-digit digital designation of each defect or a four-digit digital designation of its varieties;

- in column 2 - the letter designation of the defect used in the collections of reference radiograms of the International Institute of Welding (IWI);

— in column 3 — the name of the defect in Russian, English and French;

— in column 4 — definition and/or explanatory text;

- in column 5 - drawings that supplement the definition if necessary.

Table 1

| Defect designation | Name of defect | Definition and/or explanation of the defect | Drawings of welds and joints with defects | |||

| digital | used MIS | |||||

Group 2. Pores

200 A Gas cavityen gas cavity

fr soufflure A cavity of arbitrary shape formed by gases trapped in molten metal, which has no corners 2011 Aa Gas pore

en gas pore

fr soufflure spheroidale Gas cavity usually spherical in shape 2012 Uniformly distributed porosity

en uniformly distributed porosity

fr souflures spheroidales A group of gas pores distributed uniformly in the weld metal. Should be distinguished from chain of pores (2014) 2013 Cluster of pores

en localized (clustered)

fr nid de soufflures A group of gas cavities (three or more), arranged in a cluster with a distance between them of less than three maximum sizes of the largest of the cavities 2014 Chain of pores

en linear porosity

fr soufflures allignees

(ou en chapelet) A series of gas pores arranged in a line, usually parallel to the axis of the weld, with a distance between them of less than three maximum dimensions of the largest of the pores 2015 A b Oblong cavity

en elongated cavity

fr soufflure allongee A discontinuity extended along the axis of the weld. The length of the discontinuity is at least twice the height 2016 Ab Fistula

en worm-hole

fr soufflure vermiculaire A tubular cavity in the weld metal caused by the release of gas. The shape and position of the fistula are determined by the hardening mode and the gas source. Typically, fistulas are grouped into clusters and distributed in a herringbone pattern 2017 Superficial pore

en surface pore

fr piqure Gas pore that breaks the continuity of the surface of the weld 202 R Shrinkage cavity

en shrinkage

fr retassure Cavity formed due to shrinkage during solidification 2024 K Crater

en crater pipe

fr retassure de cratere Shrinkage cavity at the end of the weld bead, not welded before or during subsequent passes

Other GOSTs

GOST 17038.0-79 Scintillation ionizing radiation detectors. General provisions on methods for measuring scintillation parameters GOST 23077-78 Scintillation detectors of ionizing radiation. Terms, definitions and letter designations GOST 14105-76 Detectors of ionizing radiation. Terms and definitions GOST R 55232-2012 Photometric detectors with fixed wavelengths for liquid chromatography and flow injection analysis. General technical requirements and test methods GOST R 54792-2011 Defects in welded joints of thermoplastics. Description and evaluation GOST 28833-90 Defects in refractory products. Terms and definitions GOST 28833-2016 Defects in refractory products. Terms and definitions GOST R ISO 24510-2009 Activities related to drinking water supply and wastewater disposal services. Guidelines for assessing and improving the service provided to consumers GOST R ISO 24512-2009 Activities related to drinking water supply and wastewater disposal services. Guidelines for the management of drinking water supply systems and the assessment of drinking water supply services GOST R ISO 24511-2009 Activities related to drinking water supply and wastewater services. Guidelines for the management of utility companies and the assessment of wastewater disposal services GOST R 57725-2017 Activities of assistants to deputies of legislative (representative) bodies of the constituent entities of the Russian Federation. General requirements GOST 32608-2014 Exhibition and fair activities. Terms and definitions GOST R 53103-2008 Exhibition and fair activities. Terms and definitions GOST R 56765-2015 Exhibition and fair activities. Basic provisions

Group 3. Solid inclusions

300 Hard inclusionen solid inclusion

fr inclusion solide Solid foreign substances of metallic or non-metallic origin in the weld metal. Inclusions that have at least one acute angle are called acute-angled inclusions 301 Va Slag inclusion

en slag inclusion

fr inclusion de laitier Slag trapped in the weld metal. Depending on the conditions of formation, such inclusions can be: 3011 linear; 3012 disconnected; 3013 other 302 G Flux inclusion

en flux inclusion

fr inclusion de dlux Flux that has entered the weld metal. Depending on the conditions of formation, such inclusions can be: See 3011-3013 3021 linear; 3022 disconnected; 3023 other 303 J Oxide inclusion

en oxide inclusion

fr inclusion d'oxyde Metal oxide introduced into the weld metal during solidification 304 N Metal inclusion

en metallic inclusion

fr inclusion metallique A foreign metal particle embedded in the weld metal. Particles are distinguished from: 3041 tungsten; 3042 copper; 3043 other metal

Group 4. Lack of fusion and lack of penetration

401 Non-fusionen lack of fusion (incomplete fusion)

fr manque de fusion (collage)

Note - In some countries, the terms “colage noir” and “colage blanc” are used depending on whether oxide inclusions are present or absent in places of non-fusion. Lack of connection between the weld metal and the base metal or between individual weld beads. There are non-fusions: 4011 on the side; 4012 between rollers; 4013 at the root of the weld 402 D Lack of penetration (incomplete penetration)

en lack of penetration

(incomplete penetration)

fr manque de penetration Failure of fusion of the base metal along the entire length of the weld or in a section, resulting from the inability of the molten metal to penetrate the root of the joint

2 Classification of defects

2.1 Defects in fusion welding of metals are formed due to violation of the requirements of regulatory documents for welding materials, preparation, assembly and welding of joined elements, thermal and mechanical treatment of welded joints and the structure as a whole.

2.2 In this standard, defects are classified into the following six groups:

1 - cracks;

2 - cavities, pores;

3 - solid inclusions;

4 - lack of fusion and lack of penetration;

5 - violation of the shape of the seam;

6 - other defects not included in the above groups.

Group 5. Violation of the seam shape

500 Violation of formen imperfect shape

fr forme defectueuse Deviation of the shape of the external surfaces of the weld or the geometry of the joint from the specified value 5011 F Undercut continuous

en continuous undercut

fr caniveau continu Longitudinal depression on the outer surface of the weld bead formed during welding 5012 F Continuous undercut

en intermittent undercut

fr morsure: caniveau discontinuation 5013 Shrinkage groove

en shrinkage groove

fr caniveau a la racine Undercut on the root side of a single-sided weld caused by shrinkage along the fusion boundary (see also 512) 502 Excessive convexity of a butt weld

en excess weld metal

fr surepaisseur excessive Excess of deposited metal on the face of the butt weld in excess of the specified value 503 Excess of fillet weld convexity

en excessive convexity

fr convexite excessive Excess of deposited metal on the front side of a fillet weld (over the entire length or in a section) in excess of the established value 504 Excess penetration

en excessive penetration

fr exes de penetration Excess of deposited metal on the back side of the butt weld in excess of the established value 5041 Local excess penetration

en local excess penetration

fr exces local de penetration Local excess penetration in excess of the set value 505 Incorrect weld profile

en incorrect weld profile

fr default de raccordement Angle α between the surface of the base metal and the plane tangent to the surface of the weld, less than the established value 506 Overlay

en overlap

fr debordement Excess weld deposit metal that has flowed onto the surface of the base metal but is not fused to it 507 Linear displacement

en linear misalignment

fr defaut d'alignement Displacement between two welded elements in which their surfaces are parallel, but not at the required level 508 Angular displacement

en angular misalignment

fr deformation angulaire Mixing between two elements to be welded, in which their surfaces are located at an angle different from the required 509 Natek

en sagging

fr effondrement Weld metal that has settled due to gravity and lacks fusion with the surface being joined. Depending on the conditions, this may be: 5091 leakage in a horizontal welding position; 5092 leakage in the lower or overhead welding position; 5093 leakage in fillet weld; 5094 leakage in the seam of the lap joint 510 Burn-through

en burn through

fr trou Flow of weld pool metal resulting in a through hole in the weld 511 Incompletely filled edge groove

en incompletely filled groove

fr manque d'epaisseur Longitudinal continuous or discontinuous groove on the weld surface due to insufficient filler metal in welding 512 Excessive fillet weld asymmetry

en excessive asymmetry of fillet weld

fr defaut de symetrie de soudure d'angle Excessive excess of the dimensions of one leg over the other 513 Uneven seam width

en irregular width

fr largeur irreguliere Deviation of width from the set value along the weld seam 514 Uneven surface

en irregular surface

fr surface irreguliere Rough unevenness in the shape of the surface of the weld reinforcement along the length 515 Concavity of the root of the seam

en root concavity

fr retassure a la racine Shallow groove on the root side of a single-sided weld resulting from shrinkage (see also 5013) 516 Porosity at the root of the weld

en root porosity

fr rochage Presence of pores at the root of the weld due to the formation of bubbles during metal solidification 517 Renewal

en poor restart

fr mauvaise reprise Local surface roughness at the point where welding is resumed