P18 steel is a very hard, high-quality alloy, which, in addition to iron, contains many alloying substances that improve its qualities. It is used not only to produce high-quality edged weapons, but also to make tools that must be very hard. P18 is used to make drilling or cutting tools such as saws or drill bits. Due to its high hardness, this steel can cut softer metals.

The closest domestic analogue of P18 is P12 . Among foreign ones we can cite Chinese W18Cr4V and T1 from the USA.

P18

P18 contains a large number of substances that improve the properties of steel. The main one is tungsten . The letter P in the stamp means it contains tungsten, and the number 18 indicates the percentage of tungsten . In addition to tungsten, P18 contains many other substances: 0.8% carbon , which gives high hardness, 0.4% manganese and silicon , which improve toughness, 4% chromium , which slows down rusting, 1.2% vanadium , which is responsible for overall strength and 0.5% cobalt, for due to which cutting properties are ensured. The iron content in this steel is 73% , which is not very much.

Since this type of steel is often used for tools, molybdenum is added for heat resistance and nickel for ductility.

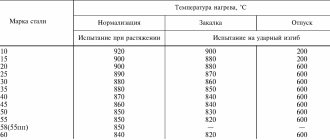

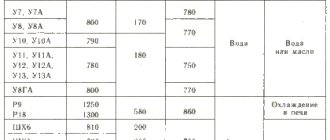

The metal is hardened up to three times - after the second hardening at a temperature of 400 degrees, it becomes stronger, and after the final third, it becomes especially hard.

All these properties classify P18 as high-speed - a tool made of this steel can work up to 4 times faster than a simple one. Let us now consider the pros and cons of this alloy for making knife blades.

Help a beginner

Since childhood, I have been indifferent to knives.

I love the cold warmth of steel and I want to make my own knife, but there’s no soul in a store-bought one. I don’t have the opportunity to forge anything, I can grind it on a sharpening stone (I don’t want to use a file) from which I can grind a feather with a blade length of 15 centimeters ; it’s easier to snatch a feather from a goose.

But seriously - why is a file bad? Well, also look at the plane blank, hacksaw blade, etc.

I tried it with a file and it broke (the metal was very brittle in half) there is a knife blade, but it’s thin and very flexible, but as for the plane blank, I’ll definitely look into that. Thank you

Saw blade for metal, quick cutter R6M5. It is also called samokal, it is truly self-hardening steel of high hardness. Disadvantage - somewhat fragile and rusts.

Electric planer blade (8x6NFT)

quote: Originally posted by genium: Saw blade for metal, quick cutter R6M5. It is also called samokal, it is truly self-hardening steel of high hardness. Disadvantage - somewhat fragile and rusts.

But it’s more difficult to let go during processing; for beginners, that’s it!

In general, as I figured out, the optimal one for me is a block from a plane. On Saturday, I’ll buy a stone for a sharpener. Well, this block itself, as I figured out, is best 2 stones, one rough, the other thin, I still need to make a special krzg for polishing with goyim

To start, either a quick cutter or a file. But it’s better to let it go before processing.

impudently, I half-heartedly realized that letting go of it would be like de-hardening by heating so that the metal would become softer? To what extent? and how to re-order

The file was released until red - it was processed perfectly. Heated it until it was white and then let it go until it was cherry red. Here the experts will give you more precise advice. There was a lot of useful information on heat treatment here, search for it. In short, tempering is heating and slow cooling, quenching is heating and rapid cooling. Working holiday – relieving unnecessary stress. The file is patient with experiments; you can always repeat the process. I didn’t have such success with the spring, and it’s hard to heat in the stoker.

Vryatli at home you may have to do this without heat treatment

Then the self-cut (or quick cutter). Only for 15 cm the wedge may be fragile. To begin with, try to carve it no longer than 9–10 cm.

I’ve already done 10 cm 2 times from a file at work, I don’t like it, it’s too short, I’d like at least 15 cm, as soon as I can I’ll do it. What is Samokal (well, how can you ask in the market, for example?)

Genium has already answered you: ————————————— Saw blade for metal, quick cutter P6M5. It is also called samokal, it is truly self-hardening steel of high hardness. Disadvantage - somewhat fragile and rusts.

Ok I got it on Saturday I’ll be at the market to pick up some Thank you very much I’ll try to post a photo when I do it

Another beginner's question. In what form is this “quick cutter” sold? Plate or. And where can you get it anyway? Iron market, shop.

This is not where your happiness is hiding, future knife makers! Turn your burning eyes to the knife for an industrial bone grinder (as a workpiece). This device works in bone meal factories. This is something.

Anyone can tell you, show me))

quote: Originally posted by petvas: Anyone can tell you, show me))

IT is in the center;

drachun Gee, what are the dimensions and most importantly, where to buy this device?

quote: Originally posted by eduardus: drachun Gee, what are the dimensions and most importantly, where to buy this device?

Maximum length – 300mm. Thickness – 5mm.

About buy. . probably find the entrances and exits to the factory mentioned above. This is a consumable item (in the sense of a replaceable part). I admit the idea that they are sometimes sharpened, but most likely they are simply replaced. This means there must be a pile somewhere to be scrapped.

It was given to me by a policeman who took this device away from a group of tall teenagers who were very successfully practicing throwing this crap in a horizontal plane. The shape of an industrial knife, as you can see, is conducive to this kind of flight.

An interesting contraption))) but I prefer classic straight shapes))) and I will make the device just a straight knife with a blade of 20-25 cm (well, or less depends on the workpiece; tomorrow I’ll go to the market and take a closer look at the blade from the plane or this same “quick cutter”)

quote: Originally posted by drachun: This is not where your happiness is hiding, future knife makers! Turn your burning eyes to the knife for an industrial bone grinder (as a workpiece). This device works in bone meal factories. This is something.

As an option, use a knife from a cutter (a healthy meat grinder, this is what you use to make minced meat for boiled sausage). I saw it in two versions: 1. Original German. Came complete with equipment. Excellent stainless steel, quite wear-resistant, holds an edge well. The knives for fishing turned out just like a fairy tale. Since on the original workpiece the hardness gradually increased from the working surface (I dare not call it RC) in the mount, some craftsmen managed to make blades with a fairly hard RC and a relatively viscous spine without any additional heat treatment at all. The price of a set of 4 knives (about 2-3 kg each) was IMHO somewhere around 2-3 thousand euros. 2. Local production. As they said, it was done almost in the same workshop with the satellites. if so, then I do not envy our companions. According to the manufacturer, the German device is identical. Only a German knife was sharpened once every 1-2 shifts, and this one 2-3 times per shift.

pros

- High quality . Products made from this steel will almost certainly be free of defects, due to the quality of the raw materials. Therefore, when buying a quick cutter from P18, you don’t have to worry.

- High hardness is very important for any cutting tool. And grade P18 has a hardness on the Rockwell scale from 65 to 64. For a knife, such hardness is considered very high, which classifies such a blade as a high-speed blade. It will very rarely have to be sharpened, because it does not become dull on ordinary materials - it can cut wood almost without hindrance.

- Good elasticity and impact strength due to additives . Usually, hard metal also turns out to be brittle - it is easy to break under lateral loads on the tool. But this alloy, as a rule, will bend, but not break, because some impurities, especially manganese and nickel, make it more flexible and ductile. Carbon and silicon not only add strength, but also protect against breakage. Therefore, saws and cutters are made from P18, which work great.

- The P18 blade has good cutting abilities , does not dull for a long time, and holds an edge well. The admixture of cobalt helps here, which is responsible for the cut. It helps the blade hold an edge, and also allows you to sharpen the blade to a razor sharpness, which it will maintain even during hard work.

- With this knife it will be possible to cut products made of softer materials . This alloy is traditionally used for metal cutting tools.

- In general, this type of steel can be considered almost perfectly balanced - it is distinguished by its hardness, is quite durable, and retains its cutting ability for a long time. Users note that of all high-speed steels, P18 is one of the best. The combination of all these properties makes it an ideal candidate for premium knife steel.

Self-hardening steel - Self-hardening steel.

⇐ PreviousPage 22 of 25Next ⇒

Self-lubricating material - Self-lubricating material. Any solid material that exhibits low friction in the absence of lubricant.

Semi-automatic plating - Semi-automatic plating. Metallization in which cathodes are mechanically transferred through metallization baths using intermediate manual transfer operations.

Semiconductor - Semiconductor. A solid crystalline material whose electrical resistivity is intermediate in value between that of a metal and an insulator, ranging from 2 × 103 ohms to 2 × 108 ohms, is usually highly temperature dependent.

Semifinisher - Semifinisher. A recess in a series of forging dies that only approximately corresponds to the final dimensions of the forging. Semi-finishers are often used to increase the life of dies or final grooves and help ensure the required allowances.

Semifinishing - Finishing. Processing prior to final finishing.

Semiguided bend - Semi-free bend. A bend obtained by applying force directly to the specimen at the part to be bent. The specimen is held at one end and twisted around a pin or rounded edge, or held at the ends and bent by a force applied to the opposite side of the specimen midway between them. In some samples, bending begins in this way and ends with free bending.

Semikilled steel - Semikilled steel. Steel that is not completely deoxidized and contains enough dissolved oxygen to react with carbon to form carbon monoxide, thereby avoiding solidification shrinkage.

Semipermanent mold - Semi-permanent form. A mold made of sand or plaster.

Semisolid metal forming - Semisolid metal forming. A two-stage casting/forming process in which the workpiece is cast in a mold equipped with a mixer that continuously mixes the melt, resulting in the formation of a fine-grained globular structure. After cooling, the burr is trimmed. The blank is then heated to a semi-solid state and formed in a die. Forming is usually done when the liquid metal content is between 30 and 40%.

Sensitization - Sensitization. In austenitic stainless steels, the precipitation of chromium carbides, usually along grain boundaries, when heated from 540 to 845 °C leads to depletion of the grain boundaries in chromium and, consequently, increased sensitivity to corrosion. Welding is the most common cause of sensitization. Sensitization of the weld caused by the precipitation of carbides in the heat-affected zone leads to intergranular corrosion.

Sensitizing heat treatment - Sensitizing heat treatment. Heat treatment is accidental, intentional, or concomitant (as in welding) that causes precipitation of components at grain boundaries, often making the alloy susceptible to intergranular corrosion or intergranular stress corrosion cracking.

Sendzimir mill - Sendzimir rolling mill. A type of 6-roll or group rolling mill with small diameter work rolls and large diameter backup rolls supported by bearings on the shaft so mounted that they can alternate to increase the pressure between the bearing and the backup rolls. Used for precision rolling of very thin sheets and strips.

Series submerged arc welding - Consistent submerged arc welding. The method is a variation of the submerged arc welding process, where an electric current is passed between two consumable electrodes that are located directly above the surface of the part. The part is not in the electrical circuit.

Series welding - Sequential welding. Resistance welding, in which two or more welding points, projection welding seams are made simultaneously by a single welding transformer with three or more electrodes forming a series circuit.

Set copper — Fire-refined copper with a high oxygen content. An intermediate containing approximately 3.5% copper oxide obtained at the end of the fire refining cycle.

Settling - Sedimentation, settling. (1) The separation of a solid from a suspension in a liquid of lower density solely by gravitational effects (2) The process of removing iron from magnesium alloys in the liquid state by keeping the melt at a low temperature after manganese has been added to it.

Shadowing - Shading. Directed application of carbon or metal film to replicas or the surface under study for further analysis by electron transmission microscopy. Often used to provide contrast and highlight features of fracture surfaces.

Shakeout - Knockout. Removing castings from sand molds. See also Knockout

—

Pressing out.

Shaker-hearth furnace - Furnace with a vibration mechanism. A continuous type oven that uses vibrators to move parts along heating elements.

Shank - Rod, shank. (1) the shank of the die, which holds it in the correct position during forging or pressing. (2) Handle for carrying a hand casting ladle. (3) Tool shank.

Shank-type cutter - Shank cutter. A cutter having a straight or pointed shank that is inserted into a spindle or adapter.

Shape memory alloys - Shape memory alloys. A group of metallic materials that exhibit the ability to return to predetermined shapes or sizes when exposed to an appropriate thermal process.

Shaving - Scraping. (1) Precision finishing operation - removing a thin layer from the surface of a part by straight-line movement of the cutter. (2) A part of the finishing of stampings, forgings, and pipes that eliminates uneven cut edges.

Shear - Shift, chip. (1) A force that is capable of causing two adjacent parts of the same part to slide relative to each other parallel to the direction of the plane of their contact. (2) A mechanism or tool for cutting metal or other material according to the movement of two sharp adjacent edges; for example, when creating a rectangular or circular offset. (3) An inclination between two cutting edges, such as between two straight knife blades or between a punch cutting edge and a die cutting edge, resulting in cutting. This reduces the required force, but increases the required stroke length. This method is also called bevel cut.

Shear angle — Shear angle. Angle that Shear plane

—

The shear plane

when cutting metal is equal to the working surface.

Shear bands - Shear bands. (1) Areas of very high shear strain that appear as stripes during rolling. They appear when rolling at approximately 35° to the transverse direction. They are independent of grain orientation and, at high voltage, cross the entire thickness of the sheet. (2) Zones of localized deformation in metals that occur at very high loading rates (100 to 3600 m/s or 330 to 11,800 ft/s).

Shear fracture - Viscous fracture. A type of fracture in crystalline materials that runs along the slip plane, oriented in the direction of the shear stress.

Shear lip - Side bevels. An inclined edge along the edge of a fracture surface. The term sometimes also refers to a narrow, crescent-shaped, fibrous area at the edge of a fracture, even if this fibrous area is in the same plane as the rest of the surface.

Shear modulus - Shear modulus (G). The ratio of shear stress to the corresponding shear strain for shear stresses less than the proportionality limit of the material. Shear modulus values are usually determined by torsion testing.

Shear plane — Shear plane. A limited area from the cutting edge to the working surface along which shear occurs when cutting metal.

Shear strain - Shear strain. The tangent of the angular change between two lines initially perpendicular to each other. Also called tangential stress.

Shear stress - Shear stress. (1) The stress component tangential to the plane on which the forces act. (2) The stress produced when parallel planes in metal crystals slide across each other.

Sheet - Sheet. A flat product of a certain maximum thickness and minimum width, arbitrarily depending on the type of metal. It has a width to thickness ratio greater than 50. Typically, such flat products with a thickness of less than 6.3 mm (1/4 inch) are called sheets, and those with a thickness of more than 6.5 mm (1/4 inch) are called slabs or thick sheet. Another steel sheet thickness limitation given in the "No 10 Manufacturer's standard Gage" for sheet steel is 3.42 mm (0.1345 in.).

Sheet forming - Forming a sheet. Plastic deformation of a section of a sheet by tensile forces into a three-dimensional shape, often without significant changes in sheet thickness and surface characteristics. Compare with Bulk forming

—

Volumetric formation.

Shelf roughness - Surface roughness. Roughness on surfaces after metallization.

Shell - Shell, body, shell. (1) Hollow structure or container. (2) Product after deep drawing. (3) The metal sleeve remaining after extruding the blank with a block of slightly smaller diameter. (4) In shell casting, a rigid layer of sand and thermosetting plastic or resin is formed by a pattern and used as a casting mold. (5) Tubular casting used to make a seamless pipe.

Shell core - Shell core. In shell casting there is a sand core.

Shell hardening - Surface hardening. A surface hardening process in which the surface of a steel workpiece, when heated and quenched, forms a martensitic layer, maintaining the contours of the part and surrounding a core with a pearlite structure.

Shell molding - Casting into shell molds. A foundry process in which a casting mold is formed from a thermoset resin mixed with sand and heated (150 to 260 °C or 300 to 500 °F), resulting in a hardened shell to conform to the contour of the model. Also called Craning process

—

Croning process.

Shielded metal arc welding (SMAW) - Welding in a protective atmosphere. Electric arc welding, in which an arc is created between the electrode and the workpiece. The electrode tip, weld pool, arc and adjacent areas of the workpiece are protected from atmospheric contamination by a gaseous screen obtained from decomposition during combustion of the electrode coating. The filler metal is provided by the consumable electrode core or metal powder mixed with the electrode coating. Shielded metal arc welding is often called stick arc welding, manual arc welding, or stick welding.

Shielding - Shielding. (1) A material barrier that prevents radiation or leakage of liquid or gas from a part or part thereof. (2) Placing an object in an electrolytic bath to change the distribution of electricity at the cathode. The insulator is a shield.

Shielding gas - Gas protection. (1) Gas shield used to protect the weld pool. (2) A stream of inert gas directed onto the substrate during thermal atomization to surround the plasma flame and substrate; Designed to provide protection from the atmosphere while minimizing oxidation.

Shift - Shift. A casting defect caused by misalignment of parts of the casting mold.

Shim - Wedge, washer. A thin piece of material used as a spacer between two surfaces to ensure proper alignment.

Shock load - Shock load. The sudden application of an external force that causes stress to occur very quickly - such as piston loading in internal combustion engines.

Shoe - Shoe, last. (1) A metal block used in a variety of bending operations to form or support the workpiece. (2) Upper part of the anvil.

Shore hardness - Shore hardness. A criterion for the resistance of a material to an applied and spring-loaded indenter when determining hardness with a scleroscope. The higher the number, the greater the opposition. Typically used for rubber materials.

Shortness - Fragility. To indicate the temperature ranges of its manifestation, it can be called cold brittleness or red brittleness.

Shot - Fraction. (1) Small spherical particles of metal. (2) Injection of molten metal into the injection mold. The metal is pumped so quickly that it can be compared to shooting from a gun.

Shotblasting - Shot blasting. Surface treatment with a high-velocity stream of metal shot to remove defects and mill scale. It is carried out more efficiently and quickly than sandblasting.

Shot peening - Strengthening shot peening. A method of cold metal working in which compressive stresses are created on the surface by shot peening.

Shotting - Granulation of metal. Production of shot by casting molten metal from a height into a tank of water.

Shrinkage - Shrinkage. (1) Reduction in metal volume upon cooling after hot forging. The die dies are made to non-standard sizes according to a precise shrinkage scale to allow for shrinkage of the forging and compliance with dimensions and allowances. (2) Dimensional change during the crystallization of the casting in the mold.

Shrinkage cavity - Shrinkage cavity. A cavity left in cast metal due to shrinkage during solidification.

Shrinkage cracks - Shrinkage cracks. Cracks that form in metal as a result of stress formation at the intergranular level due to shrinkage during solidification and cooling.

Shrinkage rule - Shrinkage ruler. A measuring ruler with graduations marked to compensate for changes in the dimensions of the solidified casting as it cools in the mold.

Shroud - Shroud. A protective, fire-resistant metal distribution system that prevents oxidation of molten steel as it pours from the ladle into the mold during the casting process.

Side milling - Side crushing. Fine crushing by cutting elements having peripheral and lateral teeth, usually with a sharp profile.

Side rake - Lateral angle of inclination. In a single-point turning tool, the angle between the rake face of the cutter and the reference plane. It is located in a plane perpendicular to the base of the tool and parallel to the axis of rotation.

Sieve - Sieve. A normal wired glass or screen used in graduated sets to determine the size of screen openings or the particle size distribution of granular solids.

Sieve analysis - A method of obtaining powders with particles of a certain size or particles consisting of a well-established percentage of various fractions by number or weight.

Sieve classification - Separation of factions. This is done using a sieve or other devices.

Sieve fraction - Sieve fraction. That part of the powder that passes through a sieve with a precisely set number and is retained by a finer sieve.

Sigma phase - Sigma phase. A hard, brittle, non-magnetic intermediate phase with a tetragonal crystal lattice containing 30 atoms per unit cell, found in many binary and ternary transition element alloys. The compositions of this phase in different systems are not the same and the phase usually exhibits homogeneity. Fusion with a third transition element usually expands the homogeneity region.

Sigma-phase embrittlement - Sigma-phase embrittlement. The brittleness of iron-chromium alloys (especially austenitic stainless steels) caused by the deposition of a brittle intermetallic sigma phase at grain boundaries when subjected to prolonged exposure to temperatures ranging from 560 to 980 °C (1050 and 1800 °F). The brittleness of the sigma phase results in a decrease in the stiffness and ductility of the material and can make it more brittle and susceptible to intergranular corrosion.

Siliconizing - Siliconizing. The saturation of silicon into the surface of a metal (usually mild steel) at high temperature to improve corrosion and wear resistance.

Silky fracture - Silky fracture. A fracture of metal in which the metal surface has a fine-grained structure, usually smooth in appearance. Characteristics of hard and durable metals.

Silver soldering - Soldering with silver solder. A non-technical term used to refer to the brazing of silver-based filler metal.

Single-action press - Single-action press. A press that only applies pressure on one side.

Single-bevel groove weld - A weld with a one-sided groove. A groove weld in which the edge of the joint of one element is beveled on one side.

Weld seam with one-sided edge preparation

Single-impulse welding - Single-pulse welding. Single-pulse spot, projection or butt welding. When alternating current is used, the pulse can be any number of cycles.

Single-J groove weld - A weld with a one-sided J-shaped edge groove. A single-sided groove weld in which the edge of one joining element is prepared in a J shape on one side.

Single-sided J-groove weld

Single-stand mill - Single-stand mill. A metal rolling mill designed so that the product comes into contact with only two rolls at a time. Antonym: Tandem mill

-

Stand tandem.

Single-U groove weld - A weld with a one-sided U-shaped edge groove. A groove weld in which each edge of the joint is prepared in a J or half-U shape on one side. See fig.

Single-sided U-groove weld

Single-V groove weld - A weld with a one-sided V-shaped edge groove. A groove weld in which each element is beveled on the same side. See fig.

Single-sided V-groove weld

Single welded joint - one-sided welded connection. In arc and gas welding, any joint welded on one side only.

Sintered density — Density after sintering. The ratio of mass to volume of the sintered material, expressed in grams per cubic centimeter.

Sintering - Sintering. Cohesion of adjacent surfaces of particles in a mass of powder when heated. Sintering increases the mass of the powder and usually produces densification and recrystallization of the powder metals.

Size effect — Scale factor. The influence of the dimensions of a metal fragment on mechanical and other properties and on production processes such as forging, cutting and heat treatment. Strength properties decrease with increasing dimensions of the part.

Size of weld — Size of the weld. (1) Joint penetration in a weld with cut edges. (2) Nominal fillet weld side lengths. (3) The thickness of the metal being welded, measured at the root of the flange. See fig.

Sizing - Calibration. (1) Secondary shaping necessary to level, smooth, or otherwise correct a surface to produce precisely specified dimensions and allowances. See also restriking

—

Edit.

(2) Polishing, broaching, broaching or shaving. (3) Finishing operation to correct ovality in pipe joints. (4) Final pressing in powder metallurgy to obtain the desired dimensions.

Skelp - Strip iron for rolling welded pipes. Iron strip for producing welded pipe or pipe joint; most often this is a tape of suitable width, thickness and edge configuration.

Skim gate - Slag barrier. In casting, a barrier device designed to prevent slag and other unwanted materials from entering the casting.

Skimming - Raking up slag. The removal or retention of slag from the surface of molten metal before or during casting.

Skin - Shell. A thin outer metal covering, formed by a non-rigid bond, as in plating or plating, that differs in composition, structure, or other characteristics from the bulk of the metal.

Skiving - Shaped tangential finish. (1) Removal of material in thin layers or chips with a high degree of shear or slip of the cutting tool. (2) A machining operation in which cutting is performed with a shaped cutter having such an inclined surface that the cutting edge moves from one end of the workpiece to the other while the machine feeds the tool tangentially to the rotating workpiece.

Skull - Garnissage. (1) A layer of solidified metal or slag on the walls of a crucible remaining after the metal has been poured. (2) The unmelted residue of consumable welding filler metal.

Slab - Slab. A flat ingot of metal for rolling, with a width of not less than 250 mm (10 in.) and a cross-sectional area of not less than 105 cm2 (16 sq. in.).

Slabbing mill - Slabbing. Rolling mill for slabs.

Slack quenching - Incomplete quenching. Incomplete hardening of a steel due to slower than critical cooling from the austenitizing temperature for a particular steel, resulting in the formation of one or more hardening products in addition to martensite.

Slag - Slag. A non-metallic product formed by the mutual dissolution of non-metallic impurities during melting, cleaning and certain welding operations (see, for example, Electroslag welding

—

Electroslag welding).

In steelmaking processes, slag serves to protect the molten metal from air and remove some impurities.

Slag inclusions - Slag inclusions. (1) Slag or inclusions absorbed by the metal. (2) Non-metallic solid materials trapped in the metal being welded or between the metal being welded and the weld metal.

Slant fracture - Inclined fracture. A type of fracture in metals in which the plane of separation is inclined (usually approximately 45 degrees) to the axis of the applied force.

Slime - Sludge. (1) In ore processing, a material with extremely large particles. (2) A mixture of metals and some insoluble compounds that forms at the anode during electrolysis.

Slip - Sliding. Irreversible plastic deformation by displacement of one part of the crystal relative to another in a certain crystallographic direction and usually on a specific plane.

Slip band - Slip band. A group of parallel glide lines so closely spaced that they appear to be one line when observed with the naked eye.

Slip direction — Slip direction. The crystallographic direction in which sliding occurs.

Slip line - Slip line. Visible traces of sliding planes on metal surfaces; marks can only be observed if the surface was polished before deformation.

Slip plane - Slip plane. The crystallographic plane along which sliding occurs in a crystal.

Slitting - Cutting in narrow strips. Cutting or shearing along a single line to cut strips of sheet metal or trim along lines of a given length or contour in a sheet or workpiece.

Sliver - Burr. A defect consisting of a very thin, elongated piece of metal attached at only one end to the parent metal.

Slot furnace - Slot furnace. A conventional furnace for heat treating metals in which material is introduced through a slot or hole.

Slotting - Slotting. Cutting a narrow aperture or groove and finishing it on a vertical cross-planer with a cutter, auger, or grinding wheel.

Slot weld - Slot welding. A weld made in an elongated hole in one element of a lap or corner joint connecting one element to the surface block of another element that is exposed through the hole. The hole may be open at one end and may be partially or completely filled with the metal to be welded. The welding groove is not included in this definition.

Slow strain rate technique - Technique for slow crack development. Experimental procedure for assessing susceptibility to stress corrosion cracking. It involves loading a sample under a controlled, slow change in stress while the sample is exposed to a corrosive test environment.

Slug - Cutting down. (1) A short piece of metal placed in a die to be forged or pressed. (2) A small piece of material made by punching a hole in a sheet of metal.

Slugging - Clogging. The unhealthy practice of adding a separate piece of material to a weld joint before or during weld production, resulting in a weld joint in which the weld is not entirely created by the molten filler metal or base metal and which therefore does not meet design requirements.

Slush casting - Hollow casting. A hollow casting, usually made of an alloy with a low melting point but a wide range between liquidus and solidus. After the desired thickness of metal has been established on the walls of the mold, the remaining liquid metal is poured out. This practice is outdated.

Smelting - Smelting. Thermal process for producing liquid metal from enriched ore.

Smut - Soot. The result of the reaction sometimes remaining on the surface of the metal after etching or electroplating.

Snagging - Stripping. (1) Finish the workpiece rough using a portable grinder equipped with an abrasive wheel. (2) Removal of excess metal from castings and forgings with an abrasive wheel: sprues, profits and burrs.

Snake - Snake. (1) A product produced by twisting and bending a hot metal rod. (2) Any warping defect on the surface of the plate having a serpentine shape. (3) A flexible spindle placed inside the tube to prevent flattening or buckling during bending.

Snap flask - Crimping flask. Casting flask with one corner hinge allowing the template to be opened and removed for reuse before metal is poured.

Snap temper - Vacation. An intermediate stress-relieving treatment applied to steels immediately after hardening to prevent cracking.

S— N

curve -

S

-

N

curve.

Diagram of stress ( S

) versus number of cycles to failure (

N

).

The voltage can be maximum ( S

max) or with variable amplitude (

S

a).

The nominal voltage is usually given, i.e., without any adjustment with respect to stress concentration. N

is almost always on a logarithmic scale.

For S,

the most commonly used scale is linear, but sometimes a logarithmic scale is also used.

Also known as S

-

N

diagram.

Soaking - Exposure, languor. When heat treating a metal, holding it for a long time at a selected temperature to homogenize the structure or composition.

Soft magnetic material - Soft magnetic material. A ferromagnetic alloy that becomes readily magnetized when a field is applied and returns to a virtually non-magnetic state when that field is removed; an alloy with the properties of high magnetic permeability, low coercivity and low magnetic hysteresis losses.

Solder - Solder. A filler metal used in brazing whose melting point does not exceed 450 °C (840 °F). The most commonly used solders are alloys of lead and tin. Other solder alloys include antimony-tin, silver-tin, zinc-tin, cadmium-silver, cadmium-zinc, zinc-aluminum, indium-based alloys, bismuth-based alloys (fusible alloys), and gold-based solders.

Solderability - Solderability. The relative ease and speed with which the surface of a metal is wetted by molten solder.

Solderembrittlement - Embrittlement caused by soldering. Embrittlement at the soldering site as a result of local penetration of solder along the grain boundaries of the base metal.

Soldering - Soldering. A series of processes that combine metals by heating below the solidus temperature to complete melting of the filler metal, at temperatures not exceeding 450 °C (840 °F). The molten filler metal is distributed between the closely fitting joint surfaces by capillary action.

Solid cutters - Solid cutting tools. Cutting tools made from a single piece of material.

Solidification - Solidification. A change in state from liquid to solid upon cooling and passing through the melting point or melting temperature range.

Solidification range — Solidification interval. Temperature interval between liquidus and solidus.

Solidification shrinkage - Shrinkage. Reduction in metal volume during solidification.

Solidification shrinkage crack - Shrinkage crack. A crack that forms, usually at elevated temperatures due to internal stresses during shrinkage, and develops during the solidification of a metal casting. Also called hot crack.

Solid lubricant - Solid lubricant. Any solid material in the form of a powder or thin film on the surface of rubbing parts that provides protection from damage during relative movement and reduces friction and wear. For example, molybdenum disulfide, graphite, polytetrafluoroethylene (PTFE), mica.

Solid-metal embrittlement - The fragility of solid metal. A type of brittle state in a material below its melting point. See also Liquid-metal embrittlement

—

The fragility of liquid metal.

Solid solution - Solid solution. A solid, homogeneous crystalline phase containing two or more chemical components.

Solid-state sintering - Solid-state sintering. The technological process of sintering compressed or uncompressed powder aggregates, during which none of the components melts. In contrast to liquid phase sintering.

Solid-state welding - Welding in a solid state. A series of welding processes at temperatures well below the melting point of the base metal, without the addition of filler metal or brazing. Pressure may or may not be applied to the connection. For example, cold welding, diffusion welding, forge welding, hot pressure welding and rolling welding.

Solidus - Solidus. (1) The highest temperature at which a metal or alloy is completely solid. (2) In a phase diagram, the positions of the points on the solidus line represent the temperatures at which compounds with different chemical compositions complete crystallization when cooled or begin to melt when heated.

Solute - Dissolved substance. A component of a liquid or solid solution that is present in lesser or negligible quantities; component dissolves in Solvent

-

Solvent.

Solution heat treatment - Hardening of a solid solution without polymorphic transformation. Heating an alloy to a suitable temperature, holding it at that temperature long enough to cause one or more components to go into solid solution, and then cooling it quickly enough to keep those components in solution.

Solution potential — Solution potential. Electrode potential of the reaction between a metal electrode and ions.

Solvent - Solvent. A component of a liquid or solid solution that is present in greater or significant quantity; the component dissolves the solute.

Solvus - Solvus. In a phase diagram, the position of points representing the temperature at which solid phases with variable chemical composition coexist with other solid phases, that is, showing the limits of solubility in the solid state.

Sorbite - Sorbitol. A dispersed mixture of ferrite and cementite obtained at elevated cooling rates of steel from austenitization temperatures or during tempering of steel after hardening. The first type is lamellar, the second is globular (after martensite tempering).

Sour gas - High sulfur gas. Gas environment containing hydrogen sulfide and carbon dioxide. Prolonged exposure to acid gas can lead to hydrogen embrittlement, sulfide stress cracking and/or stress corrosion cracking in ferrous alloys.

Sow block - Under-die plate. A slab of heat-treated steel placed between the anvil and the hammer to prevent excessive wear of the anvil.

Space lattice - Spatial (three-dimensional) lattice. A regular, periodic arrangement of points in space that represents the arrangement of atoms in a perfect crystal.

Spacer strip - Spacer pad. A metal strip or rod inserted into the apex of a joint prepared for slot welding serves as a backer and keeps the apex open during the entire welding process.

Spalling - Cracking. (1) Separation of particles from the surface. Cracking is usually associated with the rotary bearings and gear teeth. Cracking is usually the result of subsurface fatigue and is more extensive than pitting. (2) Direct spalling or separation of protective coating from the surface. (3) Chipping or flaking of the surface due to improper heat treatment or decomposition of the material.

Spangle - Sparkle. The characteristic crystallite form that is obtained on a steel surface as a result of hot-dip galvanizing.

Spark testing - Spark test. A method used to classify iron alloys according to their chemical composition. The spark or stream of sparks that is thrown off when the sample is processed with an emery wheel is monitored visually.

Spatter - Splash. Metal particles removed during arc or gas welding that do not participate in the formation of the weld.

Spatter loss - Spatter loss. Metal Lost Thanks to Spatter

-

Splashing.

Specific energy - Specific energy. In cutting or grinding, the energy expended to remove a unit volume of material.

Specimen - Sample. The test item is usually of standard dimensions and/or configuration and is used for destructive or non-destructive testing. One or more Samples

-

Samples.

Speed of travel - Welding speed. In welding, the speed at which a weld is formed along its longitudinal axis; usually measured in meters per second or inches per minute.

Speiss - Speyza. Metal arsenides and antimonides resulting from the fusion of metal ores of cobalt or lead.

Spelter - Technical zinc. Unrefined zinc in pigs or tiles obtained from the smelting of zinc ores.

⇐ Previous22Next ⇒

Recommended pages:

Use the site search:

Minuses

- It is very difficult to forge this steel yourself , because even to melt it you will need a temperature of up to 1280 degrees . After such heating it will have to be processed for a long time, which is also difficult. The finished blade can only be hardened in oil preheated to 200 degrees, after which the blade continues to cool in the open air. Also, after cooling, it has to be released three times at a temperature of 400 degrees, for an hour each time.

- Price : this alloy belongs to the highest class in terms of price. Even a small blade made from it will cost around four thousand. And instruments made from it are produced only by expensive brands.

- P18, despite the chromium content, is easily corroded , so the knife requires care. Protect it from water and other aggressive substances. Knives made of such steel are usually coated with a protective substance at the factory, or undergo protective oxidation. Over time, the coating comes off, especially if the instrument is used frequently, and therefore regular maintenance becomes necessary.

- When using a knife to carry out lateral loads, there is a high risk of breaking it . This happens with all knives made of very hard steel, because with hardness comes brittleness. But for knives made from P18, this risk is noticeably less, because special attention was paid to strength - manganese and silicon were added.

- Sharpening the blade will become very difficult because the alloy has high hardness. The only sharpener that is suitable for such knives is corundum, because corundum is harder than this alloy. The turning process itself will be long and complex. But if you have an electric saw with a rotating whetstone, the process becomes much easier and faster. The knife keeps sharpening for about a year if you do not subject it to extreme loads.

From Samokal

Sagamore 08/29/2010 20:17

Interesting director, but I didn’t understand the lanyard. This is skin?

Ilya Glebov 08/29/2010 20:21

horror dreams

mexican69 08/29/2010 20:22quote:Originally posted by Sagamore:Is this leather?Yes. Raw pork meat.mexican69 08/29/2010 20:24 quote:Originally posted by Ilya Glebov: terrible And I’m not arguing by the way, I gave it to a friend today, he liked it Zebra2 08/29/2010 20:29

Removing the metal behind the horns is problematic... It seems clear... Work on the shapes of the wedge and slopes for now... The approaches of the horn to the blade (sides) - remove more...

Ilya Glebov 08/29/2010 20:33quote:Originally posted by mexican69:And I don’t argue by the way, I gave it to a friend today and he liked it. God willing, I apologize for saying it :-)mexican69 08/29/2010 20:37quote:Originally posted by Ilya Glebov: God willing, I apologize for saying it :-) I don’t begrudge the truth mexican69 08/29/2010 20:41 quote: Originally posted by Zebra2: Taking the metal out by the horns is problematic... It seems clear.. Above the shapes of the wedge and slopes work until you finish it... Approaches of the horn to the blade (sides) - remove more... I also wanted to remove it from the bottom, or glue in inserts. I twirled it in my hand - it doesn’t seem to interfere... But in terms of shape and slopes - there were no special requirements, although if necessary, I can: taliban-alex 08/29/2010 20:47 quote: An acquaintance asked in exchange for a batch of substandard horns for a simple knife that fully corresponds the customer's requirements and it's not a bad working knife, not a shelf-sitter, so work and work, remove the metal stools on the belly and throw away the terrible lanyard and put a simple one made of leather cord or, at worst, paracord and a piece of horn on the knot Mexican69 29-08 -2010 20:56quote:Originally posted by taliban-alex:remove the metal stool on the belly and throw away the terrible lanyard and put a simple one made of leather cord or, at worst, paracord and a piece of horn on the knot. Actually, I told him myself - use it Completely, if you don’t like it, we’ll redo it without arguing, and I also agree about the lace. It’s just that the hunting season has opened, I wanted to quickly get into it Mikha_A 08/29/2010 21:57

This is your other one - I really liked it! Beautiful and complex work! And the first one... why do it carelessly if you can do it well? The iron belly sticking out from under the linings... I don’t understand!!! I want to ask about the one-way descent - is there any advantage? I've never tried it myself, so I'm curious.

Grad 29-08-2010 22:12

As I understand it, the terrible thing was made specifically to “use it to the fullest” so that it wouldn’t be a pity... Mich A - the iron belly in such designs should, in theory, stick out both from the bottom and from the top, that is, the pad in the middle.. but he should have made a new sheath for it... Is the descent concave???

Burchitai 30-08-2010 07:18

Even if you preserve these shapes and the outline of the knife, you can make a treat for the eyes of a feast. From the jambs - a crooked mechanic. EVERYWHERE. triggers, sharpening, butt line, handle. The sheath is a babaykin’s attribute, and you can use it to scare children on your own, without a babayk. Throw it away. The descent, as I understand it from the view from above, is one-sided. With a one-sided release, you shouldn’t make a concave lens, just a wedge, but this is IMHO. RK will be led away through this lens. But I just liked the lanyard because it’s wild.

samsam83 08/30/2010 09:36

Eh, I would joke about SamoKAL, but I won’t... The second one is not very good, the first one is not very good. By the way, is a mechanical saw really self-tempering steel? It’s like p6m6 and not 40X13.

skippi 08/30/2010 09:51quote:Originally posted by mexican69:impregnated with cosmoplastExcuse the teapot, but what kind of animal is this?Burchitai 08/30/2010 10:28quote:Originally posted by samsam83:By the way, is the mechanical saw a self-melting steel? (self-hardening) is a not very competent, slang term for any steel that can be hardened in air. These are almost all modern high-alloy tool steels. mexican69 08/30/2010 17:29quote:Originally posted by skippi:Excuse the teapot, but what kind of animal is this? Glue. Used in the production of plastic windows. At least we have a workshop at our company, it’s going great! Basically, the same cyanoacrylate IMHO. quote:Originally posted by Grad:they threw stools at me, that’s normal..that’s a work process

So that's good! So people are not indifferent

silence is much worse quote:Originally posted by Grad:

[QUOTE]Originally posted by Grad: I meant that in terms of style it could easily fall into this category of knives if, of course, we try harder next time...

It very well could. But mine will actually work in the forest, according to the beast. Therefore, I did not make a protrusion on top. Although…. maybe it should have been positioned somehow in the center, the protrusions would have been smaller... Thanks for the hint, we’ll take into account quote:Originally posted by Burchitai:One of the jambs is a crooked fitter. EVERYWHERE. triggers, sharpening, butt line, handle. The sheath is a babaykin’s attribute, and you can use it to scare children on your own, without a babayk. Throw it away. The descent, as I understand from the view from above, is one-sided. With a one-sided release, you shouldn’t make a concave lens, just a wedge, but this is IMHO. RK will be led away through this lens. But I just liked the lanyard because it’s wild. I'll keep this in mind for the future Thank you all for your advice and opinions mexican69 08/30/2010 05:34 PM quote: Originally posted by skippi: Excuse the teapot, but what kind of animal is this? Glue. Used in the production of plastic windows. At least we have a workshop at our company, it’s going great! Basically, the same cyanoacrylate IMHO.quote:Originally posted by Grad:and they threw stools at me, that’s normal..that’s a work process

So that's good! So people are not indifferent, silence is much worse

quote:Originally posted by Grad:

[QUOTE]Originally posted by Grad: I meant that in terms of style it could easily fall into this category of knives if, of course, we try harder next time...

It very well could. But mine will actually work in the forest, according to the beast. Therefore, I did not make a protrusion on top. Although…. maybe it should have been positioned somehow in the center, the protrusions would have been smaller... Thanks for the hint, we’ll take into account quote:Originally posted by Burchitai:One of the jambs is a crooked fitter. EVERYWHERE. triggers, sharpening, butt line, handle. The sheath is a babaykin’s attribute, and you can use it to scare children on your own, without a babayk. Throw it away. The descent, as I understand from the view from above, is one-sided. With a one-sided release, you shouldn’t make a concave lens, just a wedge, but this is IMHO. RK will be led away through this lens. But I just liked the lanyard because it’s wild. I’ll keep it in mind for the future. Thank you all for your advice and opinions

guns.allzip.org