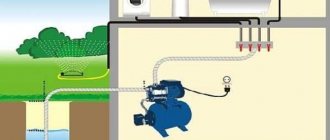

When the supply of water from a well becomes difficult due to its depth, an ejector for a pumping station comes to the rescue. Adaptation can be internal or external. Read to the end and you will understand how they differ from each other and what service they provide to the surface pump. And also what is the difference between an ejector and an injector.

External ejector in the pump Source ytimg.com

Device Features

When arranging an individual water supply in a house, they often encounter a problem when the drinking water pool is located far from ground level. The surface pump is already starting to work intermittently, pumping it from a depth of 8-9 meters. But if you equip the pumping station with a simple ejector, water is drawn in more efficiently.

The device becomes necessary in several cases:

- If you need to lift water from great depths.

- When the source silts up. This happens during dry periods and the water level drops.

- In cases where water intake occurs intensively. For example, when watering a garden.

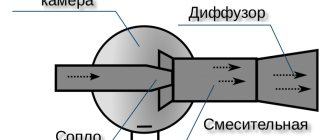

Let's look at how an ejector for a pump works. The movement of fluid in a system obeys Bernoulli's law. When there is a certain flow, its speed can be increased. To do this, it is enough to direct the flow of water through the nozzle. The passage of a bottleneck entails the formation of a field around the flow. The pressure in this zone decreases and is accompanied by a vacuum effect.

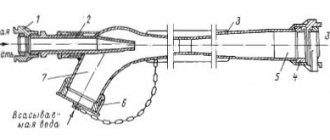

Water jet ejector Source ytimg.com

A chamber is assembled with a suction pipe attached to one side, directed towards the water source. On its other side, a diffuser is installed in the form of a Venturi tube, which ends with a pipeline connected to a surface pump. A pipe with a fixed nozzle at the end cuts into the side of the chamber.

When a stream of water released along a side branch creates a vacuum in the chamber, it sucks in a fresh portion of liquid from the source. And the accelerated jet from the nozzle directs it into the diffuser, in which the low pressure returns to normal.

The water rushes upward and is picked up by a surface pump at a depth at which there are no difficulties with suction. But some of the liquid on the surface is immediately redirected to a second pipeline, which is called the recirculation line. It ends with a nozzle in the chamber. By gravity, the water reaches the last one, and the process is repeated again. And while the pump remains in active mode, it continues indefinitely.

Ejector drawing Source truboproduct.ru

The recirculation line contains a valve that regulates the amount of liquid returned. This allows you to configure the entire system to operate more efficiently. And the productivity of an ejector pumping station is determined by the excess water reaching the consumer.

The mechanism makes it easier to start the pump. A small amount of water passed through the system is sufficient to make the first intake. Therefore, the pump does not run idle for a second. And for work you can use a much lower power engine. All this significantly saves energy.

Surface ejector pump Source prom.st

See also: Catalog of companies that specialize in the design and installation of sewerage and water supply

DIY air ejector - Metalist's Handbook

Hello, dear readers of “San Samych”.

Today, at your request, I will tell you how to assemble a simple ejector for a pumping station on your own in order to provide additional meters of water lifting from the well and to protect the operation of the pumping station from possible dry running in the event that the water level in the well suddenly drops.

I wrote earlier about the connection diagram for such an ejector. The same article shows a sketch of this ejector. But how exactly to do it turned out to be unclear to many.

Let me make a reservation right away that in the process of writing this article I did not make this ejector. I don’t need it at the moment, but I can do it at any time, spending an hour and a half on it.

And yet I will start a little from afar so that there are as few questions as possible.

Names and symbols.

Having visited my wife’s parents in the Ulyanovsk region, I was surprised to find that salespeople in plumbing stores do not always understand what I am asking them for, although I did not experience such problems in St. Petersburg. Therefore, I would really like you and I to speak the same language and understand each other, especially in terms of names and designations related to plumbing.

In plumbing, it is customary to designate parts and threads on them with symbols, which, however, are understandable to anyone who speaks and writes in Russian.

The size or diameter of the thread is most often indicated in inches: ½, ¾, 1½. This also indicates that the threads on the parts are not metric, but conical - pipe.

The letters next to the thread designation indicate which thread it is: internal (

B ) or external ( H ).

For example, the short designation: ¾ H x ½ H angle means an adapter angle (or corner adapter), one end of which has a ¾ inch or 20 mm diameter male pipe thread and the other end has a ½ inch or 15 mm diameter internal pipe thread. Let me clarify once again, the letter “ B ” in this designation does not mean external thread ( external thread, there is external thread ), but only and only internal thread .

In some previous articles I have already mentioned symbols, abbreviations, and plastic pipes.

Let me remind you: MP - metal-plastic, PP - polypropylene, PVC - polyvinyl chloride, HDPE - low-density polyethylene.

So, if in the part designation there is a certain number with the abbreviation of the pipe material in place of the thread size, this means that this “tail” of the part is intended for connection with the specified type of pipe of the same diameter.

For example, an angle ½ N x 16MP is an angle at one end of which there is an external pipe thread with a diameter of ½ inch or 15 mm, while the other has a fitting and thread (in the case of threaded crimping) intended for connection to the angle of a metal-plastic pipe with a diameter of 16 mm.

If there are no markings, this means that this side of the part is intended for a non-threaded connection with, say, a garden hose of the specified diameter and this is most likely an ordinary fitting. For example, adapter ¾ N x 12 .

Within the framework of this article, I would not like to go further into the jungle of conventions, because what I have told is already quite enough for our understanding, and we, I hope, will not be distracted by further explanations. However, I will try to express my thoughts clearly, while still explaining the bottlenecks in detail.

Parts and tools.

Actually, the ejector itself consists of only two, maximum three, parts. This is a tee (let it be ¾) and a fitting that needs to be somehow pushed inside the tee.

If the fitting is short, then a third part will be needed - a small vinyl chloride tube that matches the diameter of the fitting. If it is long, then it will have to be sharpened or cut.

I'll explain later why this is important.

But the ejector needs to be attached to the pipes, so the corresponding parts will need to be added to the ejector design. As an example, I will consider connecting to MP pipes, as the most common and easiest to install. If you use any others, you will need to make appropriate changes to the design.

So, from the details we will need:

- Tee ¾ V;

- Fitting ¾ N x 12 or less (¾ N x10, ¾ N x 8);

- Vinyl chloride tube, resp. diameter;

- Adapter ¾ N x 26MP;

- Angle ¾ N x 26 MP;

- Angle ¾ N x ½ B;

- Angle ½ N x 16 MP.

The last two corners can, in principle, be replaced with something else, the main thing is that the result is the turn we need with a transition to the pipe we need.

The tools you will need are ordinary plumbing wrenches, emery or a grinder for grinding the fitting, and any tool or device for straightening the ¾ thread of the fitting that we knock down during the grinding process (a die, a finishing screw or just a ¾ coupling). A vice is also desirable for convenience, but this is individual.

Making an ejector.

Most of all you will have to tinker with the fitting. It is necessary to grind off its hexagonal part, almost to nothing, making it into a cone, the base of which is slightly smaller in diameter than the external thread of the fitting.

In addition, you will have to shorten the threaded part of the fitting slightly, leaving a maximum of four threads.

Using a thread-cutting tool or coupling, you will need to correct the thread damaged by turning and cut it further into the resulting cone so that the threaded part of the fitting can be freely screwed into the coupling or tee from either side.

If everything worked out, then everything is much simpler. Now you just need to assemble the ejector.

We screw the fitting into the tee with the narrow part inwards until it stops, checking how much of the internal thread of the tee remains (there should be at least 4 threads left), and how far the edge of the outlet hole of the fitting extends beyond the border of the middle hole of the tee (should be 1-2 mm).

If there are not enough threads on the tee, grind off the threads on the fitting even more. If the outlet of the fitting is not long enough, then you will have to put a small piece of vinyl chloride pipe on it, or grind it off if it is too long.

After correcting the flaws, screw in the fitting completely, sealing the threads with any sealant.

The bottom corner will protrude slightly from the tee, but the four remaining threads are enough to reliably seal the connection.

All. The ejector is assembled.

The principle of operation of the ejector.

By supplying water through the recirculation line, the lack of pressure in the suction pipeline is compensated, and the pump begins to operate normally. But if that was all, then an ordinary tee would be enough, and there would be no need to “fence the garden” with a fitting. By the way, sometimes they do this.

What does the fitting built into the tee give us? By narrowing the flow of recirculating water, its speed increases. Two regions with a pressure difference are created.

One immediately behind the outlet of the fitting - an area of high pressure is used to compensate for the lack of pressure at the pump suction.

The second - in front of the outlet of the fitting - is an area of low pressure that facilitates the suction of water into the ejector.

Overall, the system becomes more efficient and requires less energy than if the tee were empty.

Therefore, by the way, it is better to look for a fitting with a smaller outlet hole. True, this rule does not apply indefinitely. But, to be honest, I wouldn’t like to go into the jungle of hydrodynamics.

For the same reason, I don’t want to explain why this ejector is not very efficient. I will only say that the volume of the mixing chamber is insufficient and its geometry is not respected. Anyone interested can easily find out why this is so.

The main thing is that this homemade ejector is guaranteed to work, pulling water to the missing 3-5 meters, and maybe more. And it's been verified.

Good luck to you! See you again on the pages of “San Samych”.

Ejector - what is it: principle of operation of ejector pumps, device, drawings

Ejector - what is it? This question often arises among owners of country houses and dachas in the process of arranging an autonomous water supply system.

The source of water entering such a system, as a rule, is a pre-drilled well or well, the liquid from which must not only be raised to the surface, but also transported through a pipeline.

To solve such problems, a whole technical complex is used, consisting of a pump, a set of sensors, filters and a water ejector, installed if liquid from the source needs to be pumped out from a depth of more than ten meters.

Water jet ejector with flange connections

In what cases is an ejector needed?

Before dealing with the question of what an ejector is, you should find out why a pumping station equipped with it is needed.

Essentially, an ejector (or ejector pump) is a device in which the energy of motion of one medium moving at high speed is transferred to another medium.

Types of ejectors

Pumping stations are equipped with ejectors in two different ways. Usually the device acts as part of the pump itself and is then considered internal. But there are situations when it is more profitable to install the water ejector as a separate external unit. Although this is accompanied by a loss of productivity.

Built-in ejector

This design feature allows you to significantly reduce the dimensions of the installation. The pump itself creates primary pressure in the ejector mechanism and takes in liquid for recirculation. The device is not afraid of silt and sand that may be present in the stream. And if liquid is needed for irrigation, then you don’t even have to filter the water coming from the well.

Used when the depth is no more than 10 meters. But this is the maximum value and for operation you will need a very powerful motor for the pump. The location of the water at a distance of 7-8 meters allows the use of a conventional surface pump, which creates sufficient pressure for running a large household.

But the noise level created by the ejector is very high. Therefore, there is a need to leave the pump outside the house. It is best when a small technical room is installed above the well, in which a surface pump with an ejector is located.

Internal ejector Source oboiman.ru

Ejector for the pumping station yourself

To supply water from wells, centrifugal surface pumps are most often used; less often they are used to supply water from a well.

The use of this type of pump has a limitation, which is the inability to lift water from a depth of more than eight meters; if the water surface in the well is below 8 m, then a simple pump will not be able to lift water.

In order for the pump to lift water from a greater depth into the system, it is necessary to include an additional device called an ejector.

It is not always possible to find it on sale, and the prices are high, but making an ejector for a pumping station with your own hands from scrap materials is completely possible. It will not, of course, be as effective as an industrial ejector, but it is guaranteed to add about five meters to the missing depth.

How does an ejector work?

The principle of operation of the ejector is based on the movement of water in a pipe, which, when entering the smoothly tapering part of the ejector, increases its speed, due to which an area with reduced pressure is formed, into which water is sucked in from the outside.

The remote ejector of the pumping station operates by supplying water through a recirculation pipeline; the flow, entering the tapering part, increases speed, forming an area with low pressure, where water from the outside begins to be sucked in to compensate for the low pressure.

In other words, the ejector pushes the water to a height from which the pump can independently suck it up.

The efficiency of the ejector is characterized by the ejection coefficient, which shows the amount of sucked water per unit amount of recirculated water. In our case, the water ejection coefficient is 0.12, in other words, with a water flow rate in the ejector of 1000 l/hour, the ejector will suck in about 120 l/hour.

Ejector design (option 1)

The simplest ejector can be assembled on the basis of a fitting and a tee - these details will be used to make the function of a Venturi tube in a very simplified version. Shaped elements for the ejector can be used from different materials (metal, plastic). In this case, the ejector structure is assembled from collet fittings and a brass tee for metal-plastic pipes.

The diameter of the shaped elements for the ejector design is taken depending on the performance of the pumping station and the diameter of the suction and recirculation pipeline; the diameter of the suction pipeline cannot be less than 25 mm. In our design, a tee with a diameter of 20 mm will be used with a 26 mm suction pipeline and a 12.5 mm recirculation pipeline connected to it.

- Tee? mm.

- Union ?" mm and with a 12 mm outlet.

- Adapter 20?25 mm.

- Angle 90? (external/internal) for metal-plastic pipe ?? 16 mm.

- Angle 90? (external/internal) for metal-plastic pipe ?? 26 mm.

- Angle 90? (external/internal) ???.

The difficulty in this design can be the fitting; it will have to be slightly modified, in particular, the hexagon must be turned to a cone-shaped state.

The lower base of the cone that appears should have a diameter a couple of millimeters smaller than the outer diameter of the fitting thread, in addition, it is necessary to shorten its thread so that a maximum of four turns remain. Using a die, you need to drive the thread and cut a couple more turns on the taken cone.

Now it is possible to assemble the ejector.

To do this, we screw the fitting (2) with its narrow part inside the tee (1) so that the fitting extends 1–2 mm beyond the upper edge of the side outlet of the tee, and so that at least a few turns remain on the internal thread of the tee so that it is possible to screw in the outlet (6 ).

If the remaining free thread of the tee is not enough, it will be necessary to grind off the threads of the fitting; if the length of the fitting is short, it is possible to put a piece of tube on it.

It is imperative to attach a check valve to the outlet (5) through which water will be suctioned, so that when the system starts, water does not flow out of the suction and recirculation water supply, otherwise the system will not start. In addition, it is necessary to seal all threaded connections using any sealant.

Such an ejector will not have a high ejection coefficient due to the imperfect design of the Venturi tube; therefore, it can be used to lift water from a depth of no more than ten meters.

Option 2

There is also an option to make an ejector, this design is more effective due to the more ideal Venturi tube, it is more complex to manufacture, but the ejection coefficient will be higher than in the previous model.

- Tee? 40 mm.

- Branch 90? 1/2″ mm.

- Squeeze 1/2″ mm.

- Squeeze 3/4″ mm.

- Lock nut 1/2″ mm.

- Lock nut 3/4″ mm.

- Stub.

- Check valve.

- 1/2″ mm fitting.

- 3/4″ mm fitting.

- Nozzle 10 mm.

- Threaded bend 1/2″ mm.

Such an ejector is made from metal shaped parts. It is possible to use a bronze tube as a nozzle (11), make longitudinal cuts in it, compress it, and solder the seams. In the plugs (7), it is necessary to make holes of a suitable diameter and cut a thread in order to screw in the bends (3 and 4) and secure them with locknuts. The nozzle will need to be fixed in the drive by soldering.

operation and installation features

The operation of the ejector will only be effective on excellent pumps, at least 1 kW with high productivity, and the installation depth of the ejector is no more than twenty meters; installation deeper quickly reduces the efficiency of the ejector. To ensure that there are no malfunctions when operating a pump with a remote ejector, the supply pipes to the ejector must be placed strictly vertically.

It is imperative that there is a crude filter in front of the pump, since such pumps are very vulnerable to the action of abrasive particles, which can damage the pump.

In front of the pump, on the recirculation pipeline, it is imperative to install a tap so that it is possible to regulate the amount of return water, thereby regulating the suction efficiency of the ejector.

Photo

Models for different states of the transported medium

There are ejectors for specific purposes:

- The name of steam jets speaks for itself. In this case, a stream of steam enters the mixing chamber from the nozzle. It is created at the beginning of the recirculation line on the surface. The hot jet carries a portion of liquid upward. Most often used for pumping water from the bilge of a ship.

- The gas industry uses an ejector to pump out gas that accumulates in a confined space.

- There is an air ejector that uses the Venturi effect. The air passing through the nozzle increases the dynamic pressure, but at the same time reduces the static pressure. A vacuum is created, which supplies the pumped air out.

Steam jet ejector Source bullion.ru

How to make an ejector with your own hands

The operating principle of the ejector is quite simple

Very often in suburban areas there is no centralized water supply. Therefore, owners of private houses have to drill wells and organize a water supply system themselves.

However, pressure waters are often located at great depths. In this case, water extraction is complicated by the fact that a conventional pump for transporting water becomes insufficient. Therefore, very often an ejector is installed in such systems.

Operating principle of the ejector

The deeper the well, the more difficult it is to draw water from it. Therefore, a pump is used to move fluid through the pipeline.

However, with a well depth of more than 7 meters, a conventional such device will not be enough.

In this case, you can purchase a more powerful submersible device or supplement the system with an ejector, which will completely solve this problem.

The principle of operation of the ejector can be understood by studying the illustration presented.

An ejector pump is a device that moves the energy of one medium to another. Its operating principle is based on increasing the water pressure in the pipeline due to the rapid movement of liquid along a special branch.

This operating principle allows you to increase the capacity of an existing surface pumping station.

Thanks to this, it is possible to extract water from a well up to 40 meters deep.

To better understand how this device works, it is necessary to monitor its operation.

Operating principle of the ejector pump:

- Water flows through the nozzle into the ejector. In this case, the cross-sectional diameter of the nozzle is less than the diameter of the entrance to the ejector system.

- By passing through a narrow nozzle into a chamber with a larger diameter, the liquid is significantly accelerated. Thus, its pressure increases. An area of lower pressure is formed in the mixer chamber.

- Thanks to the rarefied atmosphere, liquid, which is under higher pressure, begins to be sucked into the chamber at tremendous speed.

This device is very useful for deep wells. After all, it allows you to quickly pump out water from the deepest holes.

Types of ejector pumps

An ejection pump is a useful thing on the farm, especially if there are deep wells on the site. To make it convenient to use them, you need to choose the pumping equipment option that suits you.

Ejectors have a fairly simple design. That is why they are easy to make with your own hands.

There are several types of ejector pumps, they are divided according to their operating principle and design:

- A steam ejector pump pumps out gaseous media from confined spaces. Thanks to this, a rarefied environment is maintained. Such ejectors are used quite often.

- A jet steam ejector sucks gases or water out of a confined space using the energy of steam jets. In this case, jets of steam exit the nozzle and force water to move, which exits the annular channel through the nozzle.

- A gas (or air) ejector compresses gases that are already in a rarefied environment using highly directed gases. This process occurs in a mixer, from which water flows into a diffuser, where it is slowed down and the voltage increases.

Ejector pumps have excellent performance properties

Ejectors also differ in their installation location:

- The built-in water ejector is installed inside or next to the pump. Thanks to this arrangement, the device takes up minimal space and is not afraid of dirt. In addition, such devices do not require the installation of additional filters. They are used for wells whose depth is no more than 10 meters. In addition, built-in ejectors make a lot of noise during operation and require a powerful pump.

- The device, which is called remote (or external), can be installed at a certain distance from the pump, but not more than 5 meters. They are often placed in the well itself.

All types of ejectors are suitable for use in a private home. They help to quickly pump water out of a well, despite its depth.

DIY making

It is quite possible to make ejectors with your own hands. Of course, such work requires a certain responsibility and care, but it is still quite doable.

The vacuum pump is especially popular. The drawings and diagram of such a device are extremely clear.

The ejector, of course, can be easily purchased ready-made. However, if you want to save a lot, it is better to do it yourself.

Making an ejector with your own hands:

- It is necessary to take the tee and attach the fitting to it so that the fitting pipe fits inside the tee and does not protrude from it. If the pipe is too long or short, this can be corrected. In the first case, it can be ground off, and in the second, a polymer tube can be extended.

- Now you need to work with the part that will be connected to the pump. To do this, an adapter is screwed at the top of the tee.

- At the bottom of the tee, in the part where the fitting is located, a bend in the shape of an angle is screwed on. It will connect to the recirculation part of the ejector.

- An angle-type adapter is also screwed into the side of the tee. It is attached to the pipe using a collet clamp.

All connections must be sealed with special tape.

Installation rules and first launch

After you assemble the ejector, it must be installed correctly. If you follow the instructions, it will be easy to do.

After all, the product itself has a very simple design. There are three outputs on the ejector.

Each of these outputs must have its own pipe connected.

First of all, the pipe is attached to the outlet that will draw water from the well. It is located on the side of the device.

A filter and check valve are mounted at the end of such a pipe.

The pipe used for sampling should be long, but it does not need to reach the very bottom of the well.

Before installing the pump, you should watch the training video

A pipe with a narrowed fitting is connected to the bottom of the ejector. This is the main line for water circulation.

The second end of the pipe is connected to the container. Water will be drawn from it to create a reverse flow. A third pipe is connected to the top of the ejector.

The other end is mounted on the pump.

How to start the station for the first time:

- Pour water into the ejector hole and turn off the valve that allows water to move from the pump through the water supply.

- Next, you need to turn off the pump for half a minute and then turn it on. Open the tap and release some of the air from the system.

- Repeat these steps until the water line fills the pipes with water.

- Turn on the pump, wait until the system is filled with water, and the pump will automatically turn off. Open the tap and wait until the pipes are empty and the pump turns on again.

If water does not flow, the system is not assembled correctly. In this case, you will have to find the problem and fix it. That is why the first launch must be carried out in the described way.

An ejector is needed for those who live in a private house and have a very deep well. Such a system will allow you to use a not very powerful pump as efficiently as possible.

Ejector for a pumping station: principle of operation, types, installation

An ejector is a device capable of transferring kinetic energy from one medium to another.

An ejector for a pumping station helps lift water from sources more than ten meters deep and is used to protect the engine during a sharp drop in water level.

You can buy the device in a store or make an ejector for a pumping station with your own hands.

Principle of operation

The ejector works on a fairly simple principle.

The water is recirculated at the bottom of the pipeline, thereby filling the lack of pressure in the suction pipeline.

The ejector pushes the water to the height from which the engine can draw it.

The water coming out of the tapering T-shaped pipe is poured into the mixer at high speed from the suction chamber. In the diffuser, the normal flow of water is mixed with the accelerated one and enters the pipeline.

The ejector solves the problem of low pressure

An ejector is installed in the part of the pipeline located between the well and the pump.

Part of the water flow that rises returns back to the well, and forms a constant recirculation on the way to the ejector.

Additional vacuum occurs in the pipeline, and less pump energy is spent on lifting the liquid.

The operation of the system is adjusted using a valve. Part of the water is supplied to the house, the rest continues to be recirculated in the ejector.

The pumping station starts up faster, energy consumption is reduced, and the installation of lower power equipment is required.

Difference from injector

Although both devices work in a jet manner, their operating principle is strikingly different. The purpose of the mechanisms is the same. Pour liquid or gas to the top.

But a pump with an ejector for sucking water from the source supplies it with an active recirculation flow with enormous energy. Mixing liquids rush upward, simultaneously creating a self-suction effect.

The injector for the pumping station operates differently. It compresses gases or liquids. And the upward flow occurs simply due to pressure.

Briefly about the main thing

When planning to set up a pumping station on the site to supply household water, you need to check at what depth the water lies. After all, if it is located further from the surface than 10 meters, you will have to drill a large diameter well. This is necessary to immerse the remote ejector into it. Otherwise, the surface pump simply won’t cope.

But if the water depth is within 7 meters, then you can use a pumping station with a built-in ejector. In this case, the cost of system equipment will be significantly reduced. And the productivity of the system will allow uninterrupted provision of water to the entire household.

Ejector for a pumping station: principle of operation, types, installation

An ejector is a device capable of transferring kinetic energy from one medium to another. An ejector for a pumping station helps lift water from sources more than ten meters deep and is used to protect the engine during a sharp drop in water level.

You can buy the device in a store or make an ejector for a pumping station with your own hands.

Types of ejectors

Water supply pumping stations for a private house or cottage are manufactured with an ejector built-in or separately mounted into the pipeline.

Stations with a built-in ejector are used for pumping water from shallow wells, storage tanks and other water sources. They are distinguished by their ability to capture water located below the pipe.

The built-in ejector is installed inside the pump. This solution makes it possible to significantly reduce the size of the station.

In this case, installation of a filter is not required; the pump with a built-in ejector is not sensitive to sand particles suspended in the water.

Such stations are primarily used for irrigation systems and with wells up to ten meters deep; it is not recommended to install them for water supply to residential buildings - they operate very noisily.

Pumping station with built-in ejector

When installing the ejector as a separate unit, an additional water tank is required to remove the load from the engine. The ejector is connected between the well and the engine to the part of the pipeline located in the water.

For trouble-free operation of the device, two pipes are laid, as well as a pipe with a coarse filter and a check valve.

To prevent airing of the system, pipes are installed strictly in a vertical position.

A station of this type operates almost silently and supplies water from wells up to fifty meters deep (optimal depth is from 15 to 20 meters). Pumping stations require the installation of filters to protect against the ingress of sand, silt, and clay impurities in the water.

The efficiency of stations with a remote ejector is low compared to a built-in one, but this disadvantage is compensated by the ability to supply water from considerable depths. Stations can be located several tens of meters from the source.

Self-production of an ejector

The cost of the ejector is quite high, and they are not always on sale. It is not difficult to make an ejector for a pumping station with your own hands.

Let's look at step-by-step instructions for self-manufacturing a conventional ejector, which can facilitate the lifting of water from wells up to 10 m deep, and is used for drawing water from greater depths.

Making an ejector is not a difficult task!

The following materials and tools will be required:

- A half-inch tee with internal thread is the main part;

- A half-inch fitting with a 12 mm or three-quarters 8-10 mm outlet, we will insert it inside the tee.

Serves as a conductor of water under high pressure. To extend the fitting, you can use a vinyl chloride tube of the same diameter as the fitting; - Adapter 20x25 mm with the necessary angles for further fastening to a pipe or three-quarters with an external thread at one end, and at the other end with a thread for a metal-plastic pipe with a diameter of 16 mm;

- Fitting;

- 90 degree corners for metal-plastic pipes:

- ¾ with external thread x ½ with internal thread;

- ¾ with external thread x 26 mm with internal thread for a metal-plastic pipe;

- ½ with external thread x 16 mm with internal thread for a metal-plastic pipe;

- Grinder, plumbing wrenches, adjustable wrench, sandpaper;

- A coupling with a three-quarter diameter (or clamp, screw) for straightening the threads on the fitting;

- A vice, but you can do without them.

If the well depth exceeds 10 m, it will be necessary to install an ejector of a more complex design, used in pumps with a power of more than 1 kW.

Diagram of elements of a homemade ejector

To manufacture such an ejector you will need the following parts:

- threaded pipe with a diameter of half an inch;

- ten-millimeter nozzle;

- tee E40;

- half-inch and three-quarter locknuts;

- check valve with coarse filter;

- plugs with holes and threads for fittings;

- half inch and three quarters cut;

- 90 degree bend half inch;

- nozzle or compressed copper tube with longitudinal holes and sealed seams.

First of all, it is necessary to grind off the hexagon of the fitting until it is shaped like a cone. The outer diameter of the fitting thread should be 2-3 mm larger than the lower base of the resulting cone. The length of the thread should be four turns. We cut off the excess length.

Then you need to align the threads, which will be disrupted when turning the part. We cut the thread longer so that it fits onto the cone and you can later screw it from any edge into the coupling or tee.

Screw the fitting into the tee until it stops. It should fit 2 mm upward into the tee outlet from the side.

There should be four or more turns left on the internal thread of the tee for attaching the outlet to them. If there are fewer turns left, grind the threads on the fitting until the required parameters are achieved. If the thread is short, you can add it to the required size using a vinyl chloride tube. The fitting should not protrude from the tee by more than 3 mm.

Ejector installation

If the device is installed in close proximity to the pump, then a pumping station with a built-in ejector is obtained.

In order for the system to work on the principle of a water supply pumping station for a private house with a remote ejector, you need to place it directly into a well or other source of water supply.

In this case, several pipes will be needed for installation:

- a pipe with an installed coarse filter is connected to the tee on the side and lowered to the very bottom;

- a pipe connected from below through which the emerging high-speed flow of water passes;

- a third pipe that connects to the tee from above and is discharged into the water supply system, through which an accelerated flow of water passes under high pressure.

Ejector connection diagram

We screw an adapter with an external thread onto the tee from above. It should be located above the fitting. The second edge will serve as a connection to the pipe supplying water to the water supply. It will be secured with a fitting.

From below, we screw the corner elbow to the tee (into which the fitting was previously inserted) for further connection with the recirculation pipe. Fastening is done with a crimp nut.

We screw a corner into the tee on the side to connect it to the water supply pipe. We secure the pipe with a collet clamp.

We check the quality of fastenings and waterproofing.

All joints are sealed with tow or sealant.

We must install a check valve at the outlet. It will prevent liquid from flowing out of the suction pipe. If the water leaves, the system will not be able to work.

How to extend the service life of the ejector?

To extend their service life, pumping stations with an ejector must be operated in compliance with the following rules:

- When installing a station, it is important to correctly calculate the ratio of the power of the device and the depth of the source from which water is extracted.

- Constantly monitor the pressure in the pipeline.

To measure the pressure in the system, you can use a pressure gauge used for car tires or purchase a station with a special built-in sensor; - for sources with great depth, it is necessary to purchase a powerful pump, which must be installed as close as possible to the water intake;

- the use of a built-in ejector is justified only at high-power stations;

- when the source depth is from 15 to 40 meters, it is necessary to use a remote ejector installed inside the well and located in the water.

- When using a surface-type pump, it is important to correctly install the pipes coming from the surface of the ejector - strictly vertically. If the pipes are positioned incorrectly, air will enter the system and air pockets will form, which will negatively affect the operation of the system and reduce its service life.

If all operating rules are followed, ejector pumping stations operate uninterruptedly and provide tap water to the home, irrigation and other equally important household needs.