Features of application in the furniture industry

Conductors and templates are needed when assembling furniture. These things will prevent you from having a common problem that occurs during drilling—the drill hitting the part at the wrong angle. Correcting such an error will take an extremely long time, in some cases it will even be impossible.

A jig for making holes will not only allow you to correctly orient the working tool, but will also prevent it from straying from the desired trajectory.

In the furniture industry, jigs and templates are used in the following cases:

- in mass production;

- when assembling structures, when it is necessary to make holes for fasteners in the parts being connected. In this case, a jig for drilling holes for dowels or confirmat is suitable;

- a jig for drilling holes at an angle is used both in such cases and when working with thin boards, for example, MDF or chipboard.

When using such a device, the assembly process will be much easier and faster; you will be able to make the necessary holes regardless of how far they should be located from the edge of the part and how wide it is.

When assembling furniture yourself, you often have to connect parts end-to-end using dowels. Holes for dowels are best made using a special jig. The peculiarity of dowels is that despite the fact that such fasteners, although outdated, are still relevant in furniture production.

The difficulty in their use lies in the fact that the axes of the holes that are made in the parts when connecting must have a right angle with each other. Accordingly, they must be placed strictly perpendicular to each other. It is difficult to do this without a special device. Therefore, if you want to achieve high quality performance, it is recommended to buy a dowel jig.

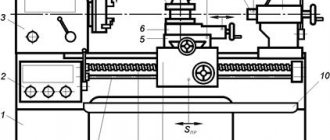

Drill stand DIOLD SMS-43

The device consists of three main units - a base, a column and a traverse for attaching an electric drill. The base and traverse are made of silumin. The table surface and legs are sanded in one setting, meaning they are parallel, which ensures perpendicularity when drilling. The base has milled grooves for attaching a vice. Column height - 50 cm, diameter - 25 mm. The diameter of the hole for the drill is 43 mm. There is a locking ring to limit the drilling depth. Factory-made drill guides combine:

- type of construction;

- aesthetic appearance;

- assembly inaccuracy;

- different suppliers;

- one manufacturer is China.

Other uses

Hole jigs are used not only in furniture production. Quite often they are used when you need to make a hole in a pipe or other cylindrical part. Thanks to them, you can make a high-quality hole even in a pipe with a small diameter.

Such devices are universal and easy to use, so they are also used in the following industries:

- mechanical engineering - drilling holes in different-sized workpieces based on different materials;

- construction - drilling holes in building structures;

- home communications - as already mentioned, pipe drilling and more.

Modern drilling jigs can be of different sizes and have different operating principles. Some of them are complex, so they are easier to buy. And some modifications can be made independently, especially since some serial furniture models, especially those with universal purposes, are expensive.

What is it used for?

When manufacturing and assembling elements of furniture structures, specialists have to carry out many similar actions related to both marking locations and drilling future holes. The furniture jig allows you to optimize both of these processes.

According to their functional purpose, furniture jigs can be marking and drilling. The first, as their name implies, are intended to simplify the marking of the locations of future holes. Drilling jigs used in the production of furniture structures exclude the use of marking devices.

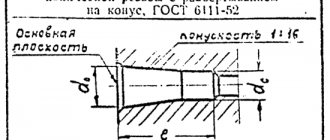

Drilling jig for confirmations

Many people purchase a furniture template, designed for preliminary marking of the locations of future holes, in a factory-made version. However, you can make a jig for assembling furniture with your own hands. The easiest way is to make a furniture jig from a metal ruler, to which the crossbar is screwed strictly perpendicularly. This furniture template is a multi-purpose marking device that is easy to make and use. The holes through which the drilling sites will be marked are made in a metal ruler at a certain distance. So, if holes are drilled for a minifix, then the distance between them will correspond to 32 mm, and for shelf holders - 100, 200 or 300 mm.

You can make a simple furniture marking template using a regular carpenter's square as a base, in which holes are also drilled at the required distance. Such a marking device, although more functional, is less stable on the surface of the workpiece. This is its most significant drawback.

The simplest furniture template for handles is a plate with calibrated holes, on the reverse side of which a stop strip is fixed

Using a similar principle, using available materials, you can make highly specialized marking devices (for example, a jig for furniture hinges or for marking holes intended for fixing furniture handles or any other furniture fittings).

Of course, if you have your own serious furniture production and the volume of assembly operations performed is quite large, you should pay attention to professional equipment for furniture assembly. However, the cost of such furniture jigs and templates, especially if they are produced under well-known brands, is quite high.

Benefits of use

Essentially, such a jig acts as a template for making holes so that they are made as accurately as possible. They can be used for those holes whose axis is perpendicular to the surface of the workpiece, as well as for working at an angle.

This tool is an excellent alternative to sketches and manual measurements. You can place the drill strictly at the desired angle in relation to the workpiece and will not allow any deviation. The result will be especially noticeable when it comes to making deep holes.

If you use such a high-quality device for working with chipboard, then it should have the following characteristics:

- facilitate quick assembly of furniture without the need to use complex tools;

- make it possible to make several holes simultaneously without manual marking;

- significantly improve the quality of work with the drill.

Conductors are made from different materials; there are models based on plastic or organic glass. However, the best option is considered to be made of steel , which has such advantages as:

- minimal likelihood of deformation;

- the drill is directed as clearly as possible;

- no heating during operation.

Very often, overhead models based on lightweight materials that are easy to manipulate are used as furniture jigs. Many people use factory or homemade tools.

And the most qualified and experienced craftsmen no longer use a jig, since they can easily make a hole in structures on their own as accurately as possible. But not everyone can do this.

The key advantage of such a device is that the work can be performed as accurately and efficiently as possible, even by a person who does not have the proper experience. You don't have to do markings and complex preliminary calculations. You will save a lot of time and produce furniture much faster.

Furniture jigs for marking fasteners for guides for drawers

The fastening of any guides and pull-out systems also obeys the furniture “law”: the distance from the edge for fastening the first screw is 37 mm, and then the installation holes are located in increments of 32 mm at distances of 64, 128, etc.

Most manufacturers of components for drawers offer their own furniture jigs to facilitate marking for fasteners. However, you can also choose universal templates. Most often they consist of a set - left and right conductors.

Classification of tools

Before you buy a ready-made conductor or make it yourself, you need to decide what problems you will solve with its help and only then you need to select the appropriate option in terms of design and functions.

There are a number of categories of devices that differ in their design and functional features. Here are some of them:

- overhead - such devices are applied to a part that can be processed, then it is attached to it or simply fixed manually. With their help, holes are made in various flat parts, MDF boards or chipboard;

- rotary - these templates are used when processing cylindrical parts. They are equipped with horizontal and vertical axes of rotation, so holes can be made at different angles;

- universal - such devices are suitable for small serial furniture manufacturers, where sometimes quick readjustment of the equipment used is required, they have all the functions necessary for this;

- tiltable - used when the technological procedure is carried out in several planes at once;

- sliding - such conductors do not need to be attached. Simply attach them to the surface area of the workpiece where you want to make a hole;

- fixed - they are more convenient to use, but they limit freedom of action, which is very critical when working with machines where there is only one spindle.

How to make a conductor with your own hands

Since there are many varieties of conductors, we will therefore consider an unusual design and an analog based on this. And so we begin.

Jig for perpendicular drilling

Its main purpose is to make holes in thick workpieces at an angle of 90. Essentially, it is a set of bushings connected in one body. In most cases, these are overhead conductors, which are widely used in furniture assembly.

Just attach the device to the surface and start drilling right away, without punching. There is one drawback: the device must be held firmly, and even more so at the beginning of work. Because vibration may cause the device to move.

This type of conductor can be made by hand.

- As a base, you can use a block of wood, a piece of textolite, or reinforcement with a square section of 10 x ten millimeters.

- We finish the surface perfectly, clean it and begin marking.

- It is necessary to take into account that the center of the holes should be 8 mm. from the edge of the workpiece. This is due to the fact that 8 mm. this is half the thickness of a chipboard sheet.

- According to the standards, there should be exactly 32 mm between the centers of the holes.

- Then we make holes with a diameter of 5 mm in these centers.

Handmade conductor

can be used, however, for more comfortable use, you should build a stop; to do this, use metal with a width of 23-25 mm. and 1 mm thick, after which the sheet is bent at an angle of 90 and attached to the jig. Also, bushings of different diameters can be inserted into the base of the conductor.

Conductor for pipes and cylindrical blanks

Everyone knows that making a hole in a sloping surface is problematic; the end of the drill regularly jumps off. This type of jig is mounted in a given position and makes it possible to work very accurately.

This type of conductors can be done quickly and on your own.

- For this we need a block of hardwood, running along the diagonal. And we attach a piece of plywood to the edge of the block using screws.

- Then we make holes of the required diameter in a block of wood.

Now we can say everything conductor

ready for work. To make the holes less likely to break, they can be improved with iron sleeves, which are made from round pipes of various diameters.

Jig for drilling holes at an angle

This type of drilling is rarely used.

Suitable when it is usually impossible to hold a drill or screwdriver at the required angle.

Here it must be said that in metal products this type of hole is made only with a milling cutter. As for wood products, there are ready-made solutions in the form of kits.

It’s easy to use these jigs; we press the workpiece tightly to the base, set the specified height and, as a result, we get smooth and beautiful oblique holes at an angle. Yes, if we need a non-through hole, then don’t forget to put a stop ring on the drill itself.

Making this type of device on your own is difficult and problematic. There are quite simple methods and options, but they are not particularly accurate. So, for example, a drill is placed on a prepared inclined surface and our workpiece is drilled at the resulting angle; as we understand, the accuracy suffers too much.

Jig for drilling holes for dowels

Their main purpose is to ensure the alignment of the holes into which dowels will be installed in the future. In other words, when you apply, the conductor

to both sides of the product, you get a wonderful joint.

As you understand, this type of conductors can be made with your own hands. If you have a flow of workpieces with the same geometry, you will be comfortable using an overlay template. It is best to use hardboard or other light-transmitting material (plastic) as a template.

We mark and drill holes. It would be better to hammer brass or copper tubes into the holes so that the drill does not break the calibration hole.

Universal device

When you use workpieces of different sizes and shapes, you will need a universal device. The most interesting thing is that this device can be made from materials that are always at hand.

- For this we need plywood approximately 15 mm thick.

- We make three equal blanks.

- We make holes along the edges into which dowels are installed as legs.

- We make one hole in the middle, which we reinforce with an iron tube.

- We make three metal slats with symmetrically placed holes; they will act as a shoulder. These shoulders are responsible for the linearity of the holes of the future conductor.

- We make cuts in the plywood blanks and install iron shoulders, fastening everything. Our multifunctional self-centering jig is ready.