Level

The level is a fairly common tool. It is also called “level”. It performs a number of important tasks. It is used in many areas.

The level is used by topographers, designers, builders and surveyors. It is also actively used by professional and home craftsmen when carrying out repair work. In terms of construction, the “level” is very simple. It is a device for measuring height differences.

Not everyone knows how to work with a level correctly. Some home craftsmen decide to determine the height difference by eye. But this is inaccurate and can lead to serious problems during the construction or renovation process. Professional craftsmen often use laser types. They are more modern and have high accuracy. But they are more expensive than optical analogues. It is important to be able to use different tools, understand their operating principles and features.

Types of levels

Currently, you can find various types of levels on sale, which differ in their characteristics. Depending on the accuracy of such devices, they are usually divided into three categories:

- Technical, the error of which can reach 10 millimeters.

- Accurate - with an error of no more than 2 millimeters.

- Highly accurate - with a permissible error of 0.5 millimeters.

Until the recent past, optical levels were in demand, but today the most popular are measuring instruments that are built on electronic and laser technology.

Laser levels are compact in size, and using such a device does not require any professional skills. Today, such devices are most popular in construction , where they can be used to calculate the horizontality of even small-sized surfaces. Laser models are capable of drawing a luminous, clear line, the presence of which makes it possible to visually establish existing deviations from the horizontal, which greatly simplifies the necessary calculations.

Optical instruments use a special design of numerous lenses, which allows you to build the most accurate image, obtaining data on the horizontal surface. This measuring device is simple in design and easy to use. It consists of the following elements:

- Telescope.

- Stands.

- Round level.

- Tripod or tripod.

Let's look at an example of setting out the height at one of the points.

You, standing behind the device, aim at a staff standing on a benchmark with a known altitude mark. Let's say +148.900. The count on the staff at this point was 1.100, respectively, adding up, we get +150.000 - our Tool Horizon (do not forget that the device must be properly initially leveled and motionless during the work process). Let's say we want to set the elevation H=149.600. By simple calculations, we find the reading that should be on the staff: 150.000–149.600 = 0.400. We inform the assistant about this information and he moves the staff vertically until the reading of 0.400 is in the crosshairs of the level’s grid of threads. We stop the assistant with a confident shout and watch as he fixes the height of the point. When working on the ground, in a field, or at a summer cottage, it is most convenient to use cut reinforcement of a small cross-section as a beacon/benchmark. On it, for example, our elevation mark will be marked with multi-colored tape. It would also be useful to designate our fixed point by wrapping a signal tape around it, or by building something like a pyramid from scrap materials.

With these simple operations we mastered the level! :)

Operating rules

Working with the level is not particularly difficult. We offer you the simplest algorithm for using these measuring instruments, which will allow you, even without any special experience, to obtain the most accurate data and determine even the slightest deviations from the horizontal.

- It is necessary to correctly install the tripod, for which you loosen the fastening screws located on the legs, install the level horizontally on a stationary plane, and the measuring device should be located at chest level. Fasten the screws and fix the legs.

- A telescope is installed on a tripod and secured with a mounting screw.

- The level is brought to a horizontal position, for which three adjustment screws are rotated and the air bubble is placed in the central position on the round screen in the viewfinder.

- The optics are being focused and adjusted. The eyepiece should be adjusted to the operator's vision. To do this, the device is pointed at a large illuminated object, after which, by rotating the ring on the eyepiece, a clear image is achieved.

- To work, you will need two geodetic slats, which can be 3 or 5 meters long. The slats are marked in millimeters on one side and in centimeters on the other. They can be made telescopic from plastic or aluminum and folding from wood.

- Height alignment. The surveying rod is installed as close as possible to the point that needs to be measured and leveled. In the eyepiece it will be possible to observe the center line of the reticle, the data from which is recorded on paper or electronic media. Next, similar measurements are taken with other points, the area along which the alignment will be determined is determined, and based on the calculations obtained, it will be possible to ensure the most accurate and perfectly straight line.

- Centerline alignment will give you the most accurate data possible. It is necessary to choose a place where all the points are visible, through which you need to build a perfectly straight horizontal line. The level is installed in such a way that the nearest point is at least 5 meters away. The measuring rod is placed at the front of the device, and the second measuring rod is installed at the rear. The rear staff will be needed for marking, and the main staff at the front will allow you to calculate the height. The instrument is initially aimed at the rear staff, the values are recorded along the lines, after which the main staff is focused and data is recorded on the red side.

Modern laser and electronic devices can significantly simplify calculations. All information and all data are calculated automatically and then provided to the user in a readable form. Each of us can handle the use of such electronic and laser devices, even if he does not have the relevant work experience.

Levels are fairly easy- to-use devices that allow you to obtain geodetic data and determine the ideal geometry and horizontal plane. The use of such devices is not difficult, especially when used for measuring laser and electronic levels.

So let's assume we have:

- You, with a phone, a calculator, or at worst with a notepad and pencil.

- Optical level (preferably with a compensator, which will greatly facilitate the work process).

- Tripod.

- One or two leveling rods (the pattern on them can be either checkered (black and red stripes) or in the form of a ruler; if the distance to the standing points is short, this is not critical for us).

- An assistant who understands your commands (you can use walkie-talkies to save your vocal cords).

What we need:

In a general sense, any action with a level is a transfer of elevation marks. Using a point with a known height, we determine the instrument horizon (HI) - the height of the instrument’s sighting beam (the horizontal line along which our gaze goes when we look into the instrument) above the conditional “zero”.

GI = the ground mark known to you in advance at a certain point (benchmark, finished floor mark, etc.) + counting on the leveling rod (if anything, both black strokes and red strokes, and the spaces between them on the leveling rod have the same height 1 cm)

If we want to determine a mark at any other point with an unknown height, we place a staff on it (of course, maintaining its vertical position), and subtract the reading on the staff from the horizon value of the instrument. Voila! The altitude is now known to us.

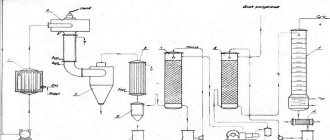

The principle of geodesy on a construction site

The correct organization of geodetic work on a construction site begins with a clearly defined goal of the work. According to the task, the necessary measuring instrument, production technology, and permissible error in measurements are selected.

The principles of geodesy are designed to reduce the accumulation of measurement inaccuracies.

“From general to specific” is a system in which they move from large geodetic reference networks to lower-class networks. Geodetic work at a construction site begins with reference to the state support network . Then the breakdown of the building axes is determined and only then the position of the structural elements in the building outline is identified.

The second principle is to control previous measurements . New measurements are made after careful checking of the previous ones.

Following these rules, they ensure high accuracy of geodetic work in construction.

List of leveling tools

In addition to the device itself you will need:

- tripod;

- measuring rod;

- plumb line with thread;

- a tablet with a piece of paper or a journal for recording measurements.

Description of the technique

Electronic levels are popular because they allow you to automate the measurement process. Today, only foreign manufacturers produce them. Modern models are divided into the following types:

- Digital electronic goniometer. This is a device that has a built-in LCD display. On it you can see measurements of surface inclination angles. The data is displayed on the screen without additional settings.

- Digital electronic level. Such devices are also equipped with a display. Additionally, the level can have a laser beam or a built-in water level.

- Combined digital device. This device combines the functions of a protractor and a digital level. The level provides more efficient and faster measurements.

The operating principle of the levels is based on recording readings using slats that are installed at different heights. Accordingly, the difference in readings shows the excess between the points.

The devices themselves, according to GOST 10528-90, are divided into technical, precision and high-precision.

Investigation of the correct operation of the cylindrical level

If a cylindrical type level is used on the telescope on the model of the device, then it must satisfy the following conditions - its axis must be strictly parallel to the line of sight of the telescope. This check must be done in two stages:

- the plumb plane passing through the main axis of the cylindrical level must be parallel to a similar surface passing through the line of sight of the telescope;

- the projection onto the vertical plane of the angle between the axis of the level and the pipe should not exceed the limit established in the passport.

The first condition is checked using a rod installed 45-55 meters from the tripod, the lifting screw of which is directed in its direction. Carefully check the horizontal position of the device, use the lifting screw to align the ends of the level bubble, and use the fixing mechanism to obtain a clear image. They count down. Then the axis of the device is tilted using lifting screws so that the readings do not change, and the position of the ends of the cylindrical level is fixed. The same is done when tilting in the opposite direction. If the bubble remains in place in both cases or its ends move in the same direction, then the level setting is considered correct. If this is not the case, then adjustment is made with horizontal and vertical screws of the cylindrical level itself.

The second condition is checked using methods such as:

- leveling in a straight forward direction;

- the same, but in combination with measurements from the middle;

- application of the method using different arms.

With each method, and they are described in the specialized literature, at least 3 measurements of the angle between the level axis and the projection onto a vertical plane must be carried out. Then the arithmetic mean of these measurements is calculated and compared with the passport data. If the resulting figure does not exceed the permissible limits specified in the document, then the level is configured correctly.

Installing a leveling tripod

When installing the level, it is important to follow a number of rules. Setting up a tripod is of utmost importance. The tripod must stand firmly on the ground. Otherwise, measurements may have unacceptable errors. Also, if the tripod is in an unstable position, there is a risk of it falling along with the device. If the soil is soft, then the ends of the tripod legs need to be pressed into the soil. On slippery surfaces and when there are gusts of wind, it is advisable to use a metal base (in the shape of a triangle). This base has special holes for tripod legs.

When installing a tripod, you should strive to ensure that the position of the platform on which the level will be installed is horizontal. This will allow you to easily install the device in the desired position for operation. The sighting axis of the device must be strictly in the horizontal plane. In this case, you can count on high-quality measurements of excesses and obtaining the required result.

Overview of the TOPCON device

Topcon is a Japanese leader in the production of surveying equipment. All devices can be divided into optical and digital levels.

Digital options provide bright images and accurate measurements. The devices are resistant to vibrations and shocks. They are equipped with a magnetic compensator, which allows measurements to be taken on site where heavy equipment is operating.

Reviews of electronic levels are presented in the table below.

| Parameter | DL-102С.N | DL-101С | DL-502 | DL-503 |

| Accuracy, mm | 0,4 | 0.6 | 1.0 | |

| Lens diameter, mm | 45 | 36 | ||

| Min. sighting distance, m | 1 | 1 | 1,5 | 1,5 |

| Telescope magnification | 30x | 32x | 32x | 28x |

| Weight of assembled device, kg | 2,8 | 2,8 | 2.4 | 2.4 |

| Operating temperatures | -20°C … +50°C | |||

| Working time in hours | 10 | 10 | 16 | 16 |

By whom and how is the adjustment carried out?

If careful reading of the instructions and attempts to independently configure the device did not lead to the desired results, you should contact specialized metrological service centers that have certificates and licenses to perform metrological procedures such as verification and adjustment.

Licenses and state-issued certificates of admission to a certain type of work in geodetic activities confirm the quality of the work performed and services provided, as well as compliance with the requirements and state standards of the material base used and the qualifications of specialists required to carry out the work.

Upon completion of the work, a standard certificate is issued on the results of verification and adjustment of the level.

Adjustment result

The result of adjusting device characteristics may not always be positive. If the device at any stage of the settings does not give the desired results or it is impossible to achieve them for various reasons, the level is considered unusable and is taken out of service with a corresponding mark in the technical passport.

The cost of adjustment, as a rule, ranges from 800-1000 rubles. and higher, but the work is usually carried out as a complex, since high-quality adjustment cannot be performed without checking the device.

How to use a laser level

Taking measurements with a laser level is easy. But before using it, you need to study the instructions. It is supplied with each device by the manufacturer.

How to measure distance

Distance

Most models of levels of this type are equipped with rangefinders. This allows you to build a plane and calculate the distance automatically. If you don't have a rangefinder, you'll have to use a tape measure.

Use for flooring

A laser level is used when installing floor joists. It is enough to start the device. A zero level will appear around the perimeter.

Application when working with walls

A laser level can be used to control the process of laying a brick wall, installing a shelf, or a lighting fixture. It is also used to level railings on stairs. The list of works for which the level will be useful is wide. The device allows you to accurately determine the position of an object relative to a plane.

Error of laser levels

High precision laser tool. But it is better to check its accuracy before use. There are different methods for this. The easiest way to do this is in a small room that you can measure yourself by hand. This will allow us to correlate both results and clarify the calculations.

Error check

The laser level is placed in the center of two walls and turned on. The location of the laser cross is marked on the wall. Next, the device is rotated 180 degrees. Make a note on the wall. Then you need to move the level to any of the walls and install it at a distance of 70 cm. Make the same marks. Measure the distance between the marked points. Subtract one distance from another. Compare the obtained result with the specified accuracy. If the data does not exceed the accuracy specified in the manual, then the laser device is working correctly.

Video instructions for working with a laser level

Level Bosch GLL 3-80 Professional and other popular models

Today there are many devices that are designed to take measurements on the ground or indoors. Some of them are more effective, which is achieved due to the quality of the ingredients. Let's consider which devices of this type are worth purchasing.

The most functional device is considered to be the laser level GLL 3-80 Professional, produced by the famous German company Bosch. A similar device is used indoors. The error of the device is extremely small. Deviations are practically not observed even at a distance of up to 10 m. It is worth saying that there are special receivers with which you can increase the range of the instrument to 60 m.

Laser level GLL 3-80 Professional is the most functional device

The device is powered by batteries. If you use the device without interruptions, the charge will last only 4 hours. Therefore, it is worthwhile to provide additional sets of batteries in advance. This tool is equipped with a holder, thanks to which its location can be adjusted.

The GLL 3-80 Professional level can be used for economic and professional purposes. There are special magnetic type holders on the tool body. Among other things, the device has an automatic adjustment function, which allows for its alignment.

Among the optical levels, it is worth highlighting the H-05 level, which belongs to the high-precision category. This device is professional; it is intended for calculating the difference between points when performing various engineering and geodetic works. When using such a device, you should understand that it requires certain knowledge and skills from the operator. To operate the device, you need a special staff equipped with a half-centimeter scale.

It is worth highlighting several companies that produce reliable and durable equipment. For example, on the modern market you can often find various models of levels manufactured by DeWALT. Stabila also sells high-quality devices.

Devices manufactured by DeWALT are of excellent quality.

What to look for when purchasing?

When choosing a level, they are guided by the scope of its application, that is, they look at why it is needed in a particular situation. Selection criteria - range, measurement accuracy, additional functions.

For a home craftsman, when choosing a laser level, the following characteristics are sufficient :

- measurement accuracy ±0.3 mm/m and higher;

- operating range with the receiver is 40-60 m;

- projection of horizontal, vertical planes, right angles;

- average sweep angle;

- battery operation;

- reasonable price.

For home use, you do not need a long measuring range and high-precision optics, and the self-leveling mode of the laser device will not be superfluous. The green beam is better visible under artificial lighting.

A professional laser level must meet higher requirements:

- measurement accuracy ±0.1 mm/m and higher. Large distances on the ground increase the error;

- work with a receiver to increase beam visibility, operating range from 300 meters;

- high class of protection against dust and moisture;

- remote control device;

- laser plumb.

The rotary device provides 360 degree coverage. Accordingly, professional devices also have a higher cost.

Review of Trimble devices

Levels from the American company Trimble are designed to accurately determine the level of elevation and height differences on the ground. The devices have a reinforced body, which allows them to be used in almost any weather.

They are also equipped with many additional functions and spacious internal memory. The display backlight allows you to work even in low light.

The devices are distinguished by long-term operation without recharging, maximum productivity and high accuracy. Measurements are taken automatically using powerful software.

Detailed characteristics of Trimble electronic levels are presented in the table below.

| Parameter | DiNi 03 | DiNi 07 | DiNi 22 | DiNi12T |

| Increase | 32x | 26x | 26x | 32x |

| Accuracy, mm | 0,3 — 1,5 | 0,7 | 0,7 | 0,3 |

| Min. focal length, m | 1,3 | |||

| Lens diameter, mm | 40 | |||

| Weight of assembled device, kg | 3,5 | 3,5 | 3,2 | 3,7 |

| Operating temperatures | -20°C … +50°C | |||

| Working time in hours | 72 | |||

Review of Sokkia devices

Sokkia electronic levels are professional devices for effectively determining elevations. They are distinguished by proprietary coated optics and high operating speed. All measurements are made automatically and saved in the device memory.

They also use a special Wave-and-Read device stabilization technology. The following features are available in the levels:

- carrying out single measurements;

- carrying out repeated measurements;

- using the rack tracking mode;

- turning on the stabilization mode;

- Calculation of the average value.

Detailed characteristics of the devices are shown in the table below.

| Parameter | SDL50 | SDL30 | SDL1X |

| Increase | 28x | 32x | 32x |

| Accuracy, mm | 1,5 | 1,0 | 0,3 |

| Min. focal length, m | 1,6 | ||

| Operating temperatures | -20°C … +50°C | ||

| Weight of assembled device, kg | 2,4 | 2,4 | 3,7 |

| Measurement time, sec | 3 | 3 | 2,5 |

| Working time in hours | 16 | 8,5 | 9-12 |