One of the most popular household chainsaws in Russia is the 350th saw model from Partner. This can be explained by a number of advantages of this model.

The most important qualities of such saws, which characterize them on the positive side:

- compactness and light weight with sufficient power;

- relatively affordable price;

- durability;

- excellent repair base.

Carrying out disassembly

Before you begin adjusting the carburetor of the Partner-350 gasoline saw, it is necessary to study the design of the unit in detail. Since it is used almost unchanged in many models, the recommendations below are relevant for the vast majority of them.

When removing elements, you should be as careful as possible, laying them out in the same order in which they were dismantled. This will make the subsequent assembly easier. The top cover is held in place by three bolts, they need to be removed. After this, a layer of foam rubber will become visible, serving as an air filter element. To remove the drive rod, you need to get rid of the gasoline hose. It is impossible to adjust the carburetor of the Partner-350 chain saw without removing the cable tip; this must be done at the next stage. The fuel hose located on the left side of the fitting must be removed. After completing all the above procedures, you can disconnect the carburetor and begin adjusting it. This mechanism is very complex, for this reason, during subsequent disassembly, extreme care must be taken when removing parts. Without this, they are easy to lose due to their small size.

Disassembly and cleaning

To work, we need a shaped screwdriver PH1 and a small, clean, flat surface. Unscrew the four screws to get to the membrane.

Unscrew it, remove the cover, underneath there will be a membrane, it is usually firmly glued to the intermediate gasket, carefully peel it off, the lower gasket is not always removed without deformation, so we do not touch it, lay everything out in the appropriate sequence.

Under the membrane we see a rocker arm that lifts the needle, the rocker arm sits on the rod, and the rod holds the screw and unscrew it, take everything out in place! We unfold the carburetor, and on the reverse side there will be a cover on which the idle speed adjustment screw is located, unscrew it too, and we get this picture.

On the carburetor body itself in the photo we see a large hole in the upper right corner, there is a metal mesh there, we take it out and blow it out, and also carefully insert it in place. Now we check the membrane itself, it should not be oak, when pressed it should freely return to its original state, and the central metal rod should sit dead on the membrane itself, if it rotates freely, then only replacement. But usually, if the carburetor is capricious, we immediately take a carburetor repair kit for Pratner 350-351.

We unscrew the adjusting screws L and H; before assembling them, it is not possible to confuse their different thread diameters. We blow out the carburetor under pressure and check all the mounting holes for wear, and also watch how the needle moves in its seat, it should not bite, and the end should be the same color.

If it is like in the picture, then this is wear on the intake needle due to the presence of dirt particles in the fuel. Such a needle will not provide a seal and fuel will leak, resulting in over-enrichment of the combustible mixture.

Clutch

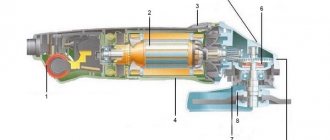

At low speeds, elements with friction linings (1), which have a degree of freedom in the radial direction, are attracted to the center of the shaft by springs (2) and do not transmit rotation to the drum (3), connected to the sprocket chain drive.

When the speed of the chainsaw reaches values at which the centrifugal force exceeds the force of the springs, the friction segments are pressed against the inner surface of the drum and begin to rotate. As a result, the drive sprocket begins to rotate, which drives the saw chain. As you can see in the photo, the sprocket is located behind the clutch.

In other chainsaws, the sprocket may be located outside the clutch.

The main advantage of this type of coupling is that when the chain jams, the clutch with the chainsaw chain does not stall the engine and does not cause destruction of the mechanisms that transmit movement from the engine to the chain.

At low speeds, elements with friction linings (1), having a degree of freedom in the circular direction, are attracted to the center of the shaft by springs (2) and do not transmit rotation to the drum (3), connected to the sprocket driving the chain. When the chainsaw engine speed reaches values at which the centrifugal force exceeds the force of the springs, the friction segments are pressed against the inner surface of the drum and begin to rotate it. As a result, the drive sprocket begins to rotate, driving the saw chain.

As you can see in the photo, the sprocket is located behind the clutch.

On other chainsaws, the sprocket may be located on the outside of the clutch.

The main advantage of this type of coupling is that when the chain jams, the chainsaw clutch slips without stopping the engine or causing damage to the devices that transmit movement from the motor to the chain.

Carburetor operation

When starting the internal combustion engine, the air damper closes. This mode produces a rich mixture. The engine gradually warms up:

- The cylinder walls heat up.

- Heat is transferred to the fuel chamber, the fuel temperature rises, which improves its evaporation during external mixture formation.

The filter elements do not allow abrasive particles contained in the surrounding air to enter the cylinder.

- After warming up, you can open the air damper. Correct idle speed control is responsible for stable operation.

- During operation in a converging diffuser, the air flow moves at high speed. Fuel is sucked into the diffuser, it evaporates, and a working mixture is formed.

- When the throttle valve is opened, the amount of charge supplied increases.

- The turnover is increasing. Power and torque are also higher.

- By closing the throttle, the flow of charge is reduced. Power is reduced.

To regulate the carburetor, there are adjusting screws; they are located on the control panel. The operating mode is set by the position of the levers associated with the damper and throttle. For ease of control, cables are attached to them.

Chainsaw Partner 350 – malfunctions and their elimination

Most owners of this Partner model encounter problems that can be considered typical for this configuration of the tool. To be able to eliminate them, you should understand the causes of breakdowns and study the most effective methods of repairing them.

Chainsaw Partner 350 starts and stalls - how to solve the problem?

The most common cause of this breakdown is a clogged air filter. Due to dust, debris and insects, it is not able to pass the amount of air that is necessary for the normal operation of the Partner 350 chainsaw. In this case, you will need to remove the filter and wash it with clean gasoline. If this does not help, then the filter element should be replaced completely.

Another common cause is a faulty spark plug. To check, you will need to unscrew the part and inspect it. If there are small light spots on the spark plug, it means the part is working properly. However, if the ceramic walls of the candle are covered with a thick layer of soot and oil, then it needs to be cleaned. To do this, you need to heat the candle with a lighter and carefully scrape off the carbon deposits. If this does not help, the spark plug will need to be replaced.

What to do if the Partner 350 chainsaw does not start?

In this case, you need to carefully check the ignition system of the tool. Most often, the saw will not start if the gap between the magneto and the ignition coil is broken. In this case, you will need to disassemble the saw and adjust the distance between these parts. If you don’t have a sample on hand, you can use a pocket calendar or a paper business card instead.

Also, the Partner 350 chainsaw may not start due to a clogged fuel filter. If a lot of debris has accumulated in it, then it will not allow the amount of fuel the engine needs to pass through. In this case, the filter will need to be replaced.

The chain on the Partner 350 chainsaw is not lubricated - troubleshooting

The main reason for this malfunction is a loss of tightness or a break in the hose through which oil circulates for the chainsaw chain. In this case, you need to remove the top and side shields of the chainsaw body, and also inspect them for stains. To solve the problem you need to replace the worn hose. When installing, sealant will need to be applied where it is attached to the pump.

If the cause of the breakdown does not lie in the hose, then you need to inspect the oil pump. It may be clogged or broken. If you cannot wash the part, then it is best to replace it with a new one.

Filling a spark plug on a Partner 350 chainsaw - troubleshooting

Often the spark plug on a chainsaw begins to flood due to prolonged use of an incorrectly prepared fuel mixture. If you mix a large amount of oil in gasoline, this will cause the fuel pump to malfunction. Oil will flow from it into the housing, including onto the spark plug of the chainsaw.

Another common problem is a broken fuel pump. To check its operation, you should remove the tool body and start the engine. Next you need to press the gas trigger several times. If oil flows out of the pump, it means it is faulty.

As a rule, chainsaw fuel pumps cannot be repaired. It's best to replace it completely. To extend the life of the new pump, in the future you need to use only high-quality fuel and motor oil to refuel the Partner 350 chainsaw.

Signs of a flooded candle

The most striking, albeit obvious, marker of excessive filling of the combustion chamber is expressed in the banal refusal of the engine to start. This problem can be identified by analyzing the actions preceding the start of the saw and the storage conditions of the tool. Perhaps, during the first start with the air valve closed, a stroke was missed and the starter made several extra jerks. If this is the first start, after a long “vacation”, before which the saw worked normally, then it is likely that the fuel was not drained from the system, which has roughened the membrane or needle.

Cleaning the air filter

An extremely simple problem with a corresponding fix. It is quite difficult to miss such an event and usually it is not taken to extremes, however, if a clogged filter takes you by surprise, it is useful to know a couple of nuances. Nylon or felt can be used as a filter material. Nylon air filters can be easily cleaned in soapy water, after which they look like new. Felt elements are almost impossible to clean due to the thick layer of material that absorbs oils.

Repairing the fuel system of a chainsaw

When the fuel supply is interrupted, it is not surprising that the chainsaw does not work. Moreover, in this case there is only one problem: no fuel enters the cylinder. And there may be several reasons for this problem, and you have to find that very reason.

First, try disconnecting the fuel hose and observing the fuel pressure. A weak, intermittent flow indicates a clogged filter. Take it out, rinse and dry it, and if possible, replace it with a new filter. Also clear the breather (valve) of any blockages.

Check the condition of the carburetor filter and, if necessary, rinse it thoroughly, dry it and reinstall it. We described in detail about setting up the carburetor above, and these actions in this case will also not be superfluous.

If the reason is not in the breather or in the carburetor, then everything may turn out to be trivial. Make sure there is enough fuel in the tank.

There may also be problems with the cylinder-piston group (abbreviated CPG) of the Partner chainsaw. This failure can be considered serious because the cylinder and piston are the basis of the engine. Therefore, the CPG is an expensive component, the cost of which reaches half the cost of the entire tool.

The power of a chainsaw directly depends on the coordinated operation of the cylinder and piston. During operation, especially if operating rules are not followed, the cylinder, piston and rings may wear out. In this case, only replacing parts will help.

CPG parts may be damaged mechanically. These defects can be diagnosed independently. Remove the muffler. You can see the CPG in the hole. Scratches and scuffs on the surface of the cylinder, located randomly, occur when debris, fragments, or solid foreign particles enter.

If the cylinder is darkened, and this defect is observed over its entire surface, then, in all likelihood, you filled the chainsaw with low-quality fuel. Bad gasoline also affects oil scraper rings. A worn surface of the cylinder on the muffler side is a sign of critical overheating of the chainsaw during operation. Minor mechanical damage can be corrected by replacing bearings, rings, etc. But in case of deep scuffing, the CPG will have to be completely replaced by contacting a partner chainsaw repair shop.

DIY chainsaw carburetor repair Partner 350

The carburetor parts of the Partner 350 chainsaw do not experience strong mechanical and thermal loads during operation, unlike, for example, a piston system. Therefore, in theory, there is nothing to break in it. In practice, after many years of operation, gaskets most often depressurize and the elastic membrane fails. Over time it can become tough.

In addition to breakdowns, the carburetor of the Partner 350 chainsaw may fail due to contamination. For repairs and cleaning, the carburetor is removed and disassembled.

It is worth noting that the accelerator pump of the Partner 350 carburetor is its weak point.

How to remove and disassemble: step-by-step algorithm

Before removing, the carburetor of the Partner 350 chainsaw and the space around it must be cleaned with a brush so that dirt does not get inside the engine. After which they remove:

- Air filter.

- Fuel hose.

- Throttle linkage.

- Then the screws securing the carburetor to the engine body are unscrewed.

After removal, place the carburetor on a clean surface and unscrew the screws securing the cover to the body. Remove the cover and gasket. Parts and fasteners are laid out sequentially. Disassembly is carried out slowly, remembering well which part was removed from where

It is extremely important not to confuse screws H and L when assembling. They are the same in shape, but different lengths

After the operations have been completed, the Partner 350 carburetor is available for cleaning.

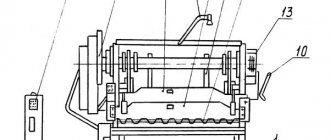

This is what a half disassembled carburetor looks like

Cleaning the carburetor: basic points, how to clean it correctly

Whether the carburetor is clean or not is usually determined immediately, visually.

First of all, the smallest holes become contaminated - in the nozzle, diffuser, channels. There may be dirty sludge in the chambers. The disassembled carburetor body and parts are washed in a bath of gasoline or kerosene. Then the channels and holes are blown out with a car pump or air compressor. It is best to use a special nozzle with a thin channel at the end. Wash again.

During assembly, if necessary, replace the gaskets and membrane with new ones from the repair kit.

When cleaning the carburetor, be sure to clean the hole in the cover under which the membrane is located. Marked in the photo with a red square

Repair kit: what is included in it and where to buy

Repair kits are sold with two sets of configurations.

The first includes gaskets and a membrane, that is, non-metallic spare parts. The second one additionally comes with a crosspiece with a needle valve.

Repair kits cost approximately from 300 to 370 rubles. and are sold in specialized stores and on many online platforms.

Chainsaw Partner 350 with Malfunctions and their elimination. Malfunctions and their elimination

Chainsaw Partner 350 malfunctions mainly due to violation of operating rules. Eliminating most problems requires experience working with gas-powered tools and knowledge of the operating principles of two-stroke engines.

But, as practice shows, repairing a chainsaw with your own hands is possible even in the field. The main thing is that before repairing, correctly diagnose the cause of the breakdown, so as not to do unnecessary work and not aggravate the situation.

Breakdowns of a new tool are most often associated with the fuel system, and a saw that has already worked for a long time, having worn parts, can make troubleshooting very difficult.

Therefore, it is important to carry out timely adjustments and preventive maintenance, so that later you do not have to carry out repairs yourself in inappropriate conditions.

Why won't it start

If the chainsaw does not start, there may be several main reasons; they are listed in order of frequency of occurrence:

- lack of fuel in the gas tank;

- the stop toggle switch is not moved to the working position;

- the safety brake is engaged;

- the carburetor is clogged or not adjusted;

- The ignition system is faulty.

The first three reasons for device failure occur among inexperienced users, and the last two require immediate intervention.

It is easy to determine if the ignition system is faulty. You need to unscrew the spark plug and, if it looks good, lean its threaded part against the metal surface of the tool, then pull the starter. A spark jumping indicates that the ignition is working properly.

Fuel system malfunctions are caused by:

- clogged carburetor jets;

- fuel filter clogged;

- violation of the integrity of fuel hoses;

- incorrect setting;

- loss of crankcase tightness (failure of crankshaft seals or crankcase gaskets).

If the saw starts and stalls, first you need to adjust the idle speed, since this adjustment most often goes wrong.

The engine stalls when you press the gas in the following cases:

- incorrect adjustment or clogged jets;

- automatic brake activation;

- excessive chain tension.

The chainsaw stalls under load, mainly only when the carburetor malfunctions. With a light load, the saw may work normally, but it does not reach maximum power and stalls.

How to adjust a chainsaw

Do-it-yourself carburetor adjustment may be required during operation of the saw and after repairing the fuel system. Adjusting the carburetor of a chainsaw is a responsible matter.

Incorrect carburetor settings will, at best, lead to increased fuel consumption, and at worst, to engine failure.

To adjust the carburetor there are 3 screws:

- T - idle speed adjustment;

- L — fuel quantity screw for adjusting power at low and medium speeds;

- H - quality screw for adjusting maximum speed.

If the carburetor has been repaired or cleaned, adjust the chainsaw using the following procedure:

- Fully tighten the quantity and quality screws and then loosen them 1/5 of a turn.

- Start the chainsaw and let it warm up for 10-15 minutes.

- Tighten the quantity screw L until the speed reaches maximum. From the found position, turn it back a quarter turn.

- Use screw T to adjust the idle speed. It is necessary to set the value when the engine runs steadily and without interruption, and the saw chain does not rotate.

- Use the quality screw H to adjust the maximum speed on the tachometer. If there is no tachometer, then adjust until the sound of the engine begins to resemble the sound of a four-stroke engine. Exceeding the permissible number of maximum revolutions is fraught with damage to the cylinder-piston group.

The ignition system, with the exception of spark plugs, rarely fails.

If the chain is not lubricated

Chain lubrication is important to reduce link friction in the guide bar grooves. To adjust the lubrication system, an oil supply screw is provided. The chain is lubricated only while it is moving. You can check the operation of the oil pump by pointing the toe of the tire towards a light-colored surface. When you press the throttle, oil splashes should appear on the surface.

Device

the Partner three hundred chainsaw is no different from similar products from other manufacturers, except for the highest quality of assembly and devices. The design is based on a high-speed, two-stroke single-cylinder engine. A special feature of two-stroke engines is that they run on the consistency of gasoline with a special oil, with the help of which the pivot-piston group is lubricated.

Motor rotation is transmitted to the driven saw sprocket through an automatic clutch, which disconnects the motor crankshaft from the drive sprocket when idling.

.

The chain is lubricated by an oil pump driven by the clutch, in other words, oil is supplied to the chain only during sawing.

The engine starts with a manual starter.

Chainsaw does not idle - repair sequence

There are actually quite a few reasons for this common problem.

These include:

- poor condition of the filters, as a result of which their throughput was impaired;

- breakdown or regular malfunctions of the ignition system;

- arbitrary deviations in the operation of the carburetor caused by shocks or other mechanical influences;

- failure of fixation or formation of a hole in the fuel hose;

- formation of carbon deposits inside the exhaust system;

- the appearance of defects on the surface of the piston, valve or working cylinder.

Before inspecting the internal structure of the chainsaw, you need to inspect the condition of its body. If a dent appears in one of its parts, then it is quite possible that you need to look for the real reason for the loss of speed precisely under the damaged housing wall.

Repairing a chainsaw whose engine randomly loses speed at idle is carried out in the following sequence:

- The first step is for the operator to remove and inspect the filter. After this, you need to install them in place, remove the fuel supply hose from the carburetor fitting and direct the tube into the container. Then you need to press the hand pump several times to pre-prime the fuel. If gasoline flows into the container evenly, without jerking, then the filter elements are working properly. If this does not happen and fuel enters the container intermittently, the filter will need to be replaced;

- Then you need to inspect the ignition system. First of all, you need to inspect the standard spark plug. If it is filled with oil and a thick layer of carbon deposits has formed on its walls, then the part will not be able to support the gradual combustion of fuel - as a result, the internal combustion engine of the chainsaw will quickly lose speed. If the spark plug is clean, then you need to check the condition of the ignition coil, namely the distance between it and the flywheel. If it exceeds 0.2 mm, then the gap will need to be adjusted. To do this, you will need to insert a special adjusting shim between the elements and bring the flywheel closer to the coil by turning the 2 upper screws;

- The third stage is checking the carburetor. In most cases, violating its factory settings leads to a loss of speed in the chainsaw engine. Re-tuning the fuel unit will help solve this problem.

All actions to repair a chainsaw must be carried out very carefully. If the operator damages small parts of the tool during troubleshooting, this will lead to even more serious damage.

Common Partner saw breakdowns: diagnostics at home

The Partner gasoline saw cannot be called unreliable. For many users it works without problems in winter and summer, for many years. But others complain about the same typical problems:

- The chainsaw won't start.

- The chainsaw starts but stalls.

- Fuel does not enter the cylinder.

All these problems have internal causes in the parts and components of the tool. This means that in order to get to the bottom of it and fix the breakdown, you will have to disassemble the electric saw. This is not as difficult as it may seem, because manufacturers always take this possibility into account.

To independently diagnose problems at home, you need to understand that common chainsaw problems in the vast majority of cases are caused by the same reasons. Therefore, just by the symptoms, you can guess where the source of the problem is.

For example, if a chainsaw does not start , then the reason most likely lies in the ignition system, namely the spark plug. If air leaks into the cylinder, then you need to look for a defect in the fuel system. A dirty filter causes the engine to stall and smoke, and so on. Let's look at these cases in detail so that you feel confident when repairing the Partner chainsaw yourself.

Main types of breakdowns and methods for eliminating them

Before starting work on diagnosing faults and eliminating them, you must prepare the necessary tools.

Due to the fact that a chainsaw is a relatively simple unit, the list of accessories includes the following items:

- a set of flat and Phillips screwdrivers;

- open-end locksmith's wrenches;

- spark plug key;

- socket set with wrench

- Stihl multi-tool.

Multifunctional tool

In order to qualitatively eliminate any breakdowns that occur and restore operational performance, it is necessary to determine as accurately as possible the malfunction that preceded the failure of the unit. Based on the fact that the chainsaw is equipped with an internal combustion engine (ICE), the main causes of breakdowns should first of all be looked for in the power unit.

The most common faults when repairing a Shtil 180 chainsaw include:

- the engine does not start;

- the engine runs intermittently, and when running for a short time, the chainsaw spontaneously stalls;

- oil leaks near the chain lubrication mechanism;

- the engine does not develop full power.

Frequent breakdowns of the transmission part of the saw include rupture of chain links. You can independently restore its integrity by riveting the links or replacing them with a new one.

Despite the relative simplicity of the design and the absence of complex mechanisms, experts recommend troubleshooting in a certain order. First of all, the presence of the mixture in the fuel tank is checked, and if everything is in order with the liquid level, you need to proceed to inspect the chainsaw starting unit. If this mechanism is also in normal condition, you need to check the functionality of the spark plug.

After performing the manipulations to diagnose the spark plug (determining the presence or absence of carbon deposits, the correct gap between the electrodes, the condition of the o-ring), we turn our attention to the carburetor. Due to small sawdust, dust and soil particles, the fuel system often becomes clogged.

If cleaning the carburetor of a stihl 180 chainsaw did not help restore the unit to its previous performance, the reason most likely lies in the cylinder-piston group (CPG). The power unit is one of the most complex mechanisms of the tool, the diagnosis of which requires almost complete disassembly.

Fuel system problems

The first stage of diagnosing the fuel supply system is checking the level of the fuel mixture in the tank.

The main components of the fuel system of the 180 Shtil chainsaw

Even if the owner is sure of the availability of gasoline, this makes it possible to eliminate the vacuum created as a result of a clogged bypass valve. It is designed to optimize pressure in the tank with fuel consumption. To make it easier to clean the chainsaw breather, use a regular medium-sized sewing needle.

When inspecting the fuel system, you should pay attention to the integrity of the pipes, the tightness of which may be compromised by mechanical damage or long-term operation of the unit. Sometimes the cause of mixture leakage and, as a result, incorrect engine operation, is wear of rubber gaskets and primer (choke button)

In this case, to repair the Shtil 180 chainsaw with your own hands, you need to purchase a repair kit for seals and replace them.

Problems with the starting and ignition mechanism

The cause of problems with a chainsaw of this model may be a malfunction of the ignition system and the engine starting unit.

General view of the 180 chainsaw ignition

If no deviations are detected when measuring the gap between the flywheel and the module, you need to pay attention to the spark plug. Shtil 180 chainsaw starter assembly

Shtil 180 chainsaw starter assembly

Having removed the spark plug from the shaft, we measure the gap of the chainsaw spark plug between the central and side electrodes. If its value is excessive (more than 0.7-1.5 mm), a spark may occur periodically, and if it is minimal (less than 0.7 mm), it may not be sufficient for optimal ignition of the fuel mixture.

If gasoline enters the combustion chamber, and no discrepancy in the ignition system has been identified, the likely cause of the breakdown may be the carburetor. This unit is designed to mix fuel with air and supply them to the cylinder. After dismantling the carburetor, we clean its channels and jets using universal products.

After diagnosing the ignition system of the Shtil 180 chainsaw and restoring it, we move on to finding problems in the power unit, namely in the cylinder-piston group of the saw.

How the mechanism works

In fact, all the tools are organized identically, both foreign (Husqvarna, Makita, Shtil, Partner 350) and Chinese chainsaws, also homemade (Druzhba, Ural). Therefore, it is very difficult to find the reason why the device starts and does not stop.

There are four elements that can trigger tasks:

- The fuel for which the carburetor is responsible;

- lubricants;

- The air that enters through the air filter;

- Spark

, the quality of which depends on the ignition unit.

They all depend on each other and interact together. If a certain element does not work correctly, the saw stops working.

To begin with, all instruments are configured differently. hot and cool. Two common mechanisms are responsible for this process.

Don't forget to check what is written in the user manual. It states that when you are exercising, it is necessary for you to ensure that the emergency brake is locked. But starting a saw with a brake is even more difficult, so it is better not to use the brake from time to time.

As can be seen from the manual, there is a fuel tank and an engine inside and outside the body. saw section (bar with chain), handle and starter.

First, we need to understand how the tool does not start. For example, a saw starts up, but immediately becomes visible or loses power, cutting quality.

Potential interruptions are caused by problems in the engine. But I would not recommend disassembling it immediately. It is better to find the problem using the most common option.

Chainsaws Partner 350: prerequisites for breakdowns, repair without the help of others

In fact, every summer resident or village resident has a chainsaw in his arsenal, the Partnera 350 model is especially popular. But from time to time this tool breaks down. If you are faced with such a problem, then do not despair, because its mechanism is so simple that you can even make repairs without the help of others. The article discusses the main causes of breakdowns and their elimination.

Checking the breather and cleaning it.

Dihalnik. This is another element, due to incorrect operation of which the chainsaw may not start and may not be delayed during the sawing process. This element is located on the fuel tank cap in the area of the air hole. This is a typical valve that prevents gasoline from leaking out and equalizes the air pressure necessary for the free flow of fuel into the carburetor.

If the blade is dirty, the working chainsaw stops, and when it starts, it refuses to start. The whole point is that air stops flowing through the hole. As a result, negative pressure (vacuum) is created inside the fuel tank, preventing gasoline from entering the carburetor.

Determining the problem is quite easy. Disconnect the fuel hose from the carburetor and see what happens to the gasoline. If it flows freely in a good stream, then everything is fine with breathing. If it is absent or it flows weakly and intermittently, then the reason appears. The dihatik is clogged with dirt. You can solve the problem by cleaning the air hole with an ordinary needle or a strong jet of compressed air.

READ Replacing the Piston on a Stihl 180 Chainsaw

Checking the spark on the spark plug and eliminating the causes.

The first step in finding the circumstances why your gas saw will not start. This is to check the spark at the spark plug. There are many reasons that affect the performance of this element. But the main ones at the initial step of eliminating inventory defects are:

- Incorrect carburetor adjustment;

- The presence of more oil in gasoline than it should be;

- The air filter is clogged.

They all contribute to the formation of carbon deposits on the spark plug electrodes. In 50 cases out of 100, saws do not start when cold due to lack of spark due to carbon deposits on the electrodes and their corrosion. As a result, the gap either decreases or increases.

Checking the spark plug with a chainsaw at idle speed

Checking for spark is fairly easy. For this you will need:

- Remove the tip of the high-voltage wire;

- Unscrew the spark plug;

- Put the tip back;

- He leaned the candle's skirt against the cylinder;

- Start with the starter.

If there is a good spark between the electrodes when starting the chainsaw engine, then everything is in order with the ignition unit. If it is not there, then you should clean the element itself and check the electrode gap. If necessary, use a special probe to adjust the distance between the contacts.

The spark plug may spark for other reasons. The main defects that affect poor starting of the chainsaw and unstable operation of the gasoline engine at idle, due to which the tool can slow down, include the following:

- Overfilling of the spark plug channel with fuel;

- Lack of contact between the high voltage cradle and the tip of the spark plug;

- Ignition unit failure.

How to start a cool chainsaw if the spark plug channel is constantly filled with gasoline? To resolve the issue when launching the tool, use the following method:

- Unscrew the spark plug with a special key;

- Wipe it with a clean and dry cloth;

- Dry for 20.30 minutes

- Remove carbon deposits with ratfil and adjust the gap between the electrodes;

- Drain the fuel remaining from the spark plug channel and dry it,

- Collect everything and try to start the mechanism.

If there is no spark due to poor contact of the high-voltage cradle with the tip of the spark plug, check the connection. The test can be done using a regular tester. If a flaw is found and removed, the chainsaw should start without problems.

If the check shows that the contact is reliable, but the saw will not start further, look for the cause in the ignition block. Usually, a faulty unit cannot be repaired or returned. A complete change is needed here.

Characteristics of the Partner 350 chainsaw

This model is in great demand among consumers, but most often it is purchased by summer residents for work on their own plots. The saw is used not only for preparing firewood, but also in construction.

In general, Partner 350 chainsaws are distinguished by their compact dimensions. They are equipped with a rather massive engine. Their main advantages are easy starting and reliable operation due to a well-made electric ignition system and fuel pump.

Using such a chainsaw is not at all dangerous. It has a built-in protective system that automatically activates the inertial brake for the chain. In the same mode, its lubrication is carried out.

There will be no problems starting the Partner chainsaw even in winter, since it has a fuel primer. The starter drum is equipped with an impeller that helps clear dirt. In addition, the manufacturers have equipped the tool with the CCS system. This design traps residual particles and is also used when using the air filter for a long time.

To increase the service life of the chainsaw, the developers made chrome-plated walls on the piston group cylinder. This model also has an ergonomically shaped handle and an anti-vibration system.

Disadvantages of the saw

On the Russian market you can find low-quality fakes of the Partner 350 chainsaw, which is not only additional evidence of its popularity, but also harms the brand as a whole. And other models of this brand are popular with summer residents and farmers.

If you are ready to consider the Partner 350 as your home tool for sawing thin trees, trimming branches and other not very voluminous work, then you should also know the disadvantages, most often mentioned by their owners:

1. The vibration damping system is not of very high quality, as a result of which the hands get tired quite quickly. But, considering that this is a household tool that requires 15–20 minutes of rest every 20–25 minutes of work, you can put up with this drawback.

2. Oil leakage from the chain lubrication system, which, however, affects most chainsaws equipped with it, including the more famous relative of Partner chainsaws - Husqvarna. (link)

3. Lack of visual control of the oil level, which is not very convenient in operation, and operating the saw without lubrication will lead to rapid stretching, overheating and wear of the chain.

Of course, you can use this saw to cut down a tree up to 30 - 35 centimeters thick, but its main purpose is to work on the site. Therefore, in conclusion, we offer you the most objective video review of this model:

Dear readers, if you have any questions, please ask them using the form below. We will be glad to communicate with you