The quality of water from a well or borehole often does not satisfy the owners of dachas, private houses and cottages. This water can be used for irrigation, but not for drinking. The question arises - how to purify water? For this purpose, modern water treatment and water purification systems are used. The aeration column is the first element of the system with a cylinder.

The aeration column is one of the important components of water purification systems. Thanks to it, the water is saturated with air, which leads to the removal of gases dissolved in the water (mainly hydrogen sulfide H2S) and the oxidation of iron before the water is supplied to the deferr filter.

Let's consider the types of aeration, as well as the composition, purpose and principle of operation of the aeration column. How to select and assemble equipment and when should it be serviced?

- Types of water aeration Pressure

- Non-stop

- Ejection

Types of water aeration

There are the following types of water aeration:

- pressure;

- non-pressure;

- ejection

Pressure aeration

Pressure aeration involves forced saturation of water with air using a compressor. This type of aeration is used in systems with consistently high water pressure. When a source of water consumption (for example, a tap) is running, the air compressor is turned on (the water flow sensor is activated), which forcibly supplies air to the aeration column.

An air separating valve is used to remove excess air.

Air enters the water with the help of dispersants, which separate the air into small air bubbles to better saturate the water with air.

Dispersant at the end of the tube

Modern dispersants provide optimal air flow speed for the fastest saturation of water with air oxygen.

Thanks to the compressor, this aeration method is the most productive, but also the most expensive, since a good compressor is not cheap.

Compressor as part of a water purification system in a cottage

At the time of writing, pressure aeration is the most common method of water aeration in water purification systems for private homes and cottages.

Gravity aeration

Gravity aeration is used in water treatment systems with low water pressure or if it is necessary to increase the water pressure in the system. This method allows you to regulate the pressure in the water supply system.

The water is saturated with oxygen in the storage tank. It is in the storage tank that mixing of water and oxygen occurs. Air is supplied to the tank using a silent air compressor.

At the same time, over time, a layer of iron accumulates in the tank, which must be removed during timely maintenance.

After removing the iron, it is advisable to treat the tank (storage container) with a special disinfectant. The fact is that over time, bacteria and microorganisms can appear there.

They cannot exist under pressure, so if the system uses gravity aeration, an ultraviolet lamp is always placed at the end of the system for disinfection.

Ejection aeration

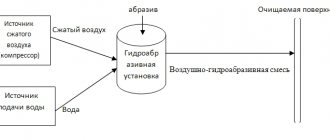

An aeration column without a compressor operates on the principle of ejection. With ejection aeration, water is saturated with air using an ejector. The ejector operates on the Venturi principle. When water passes through the ejector, a vacuum is formed inside the pipe, which sucks in air, resulting in a mixture of water and air being supplied to the aeration column.

Ejection aeration does not require high water pressure in the system. At the same time, the ejection method of aeration is not expensive, but also less productive.

Ejector for water aeration

When using an ejector in a water treatment system, keep in mind the conditions that will provide the best performance:

- There should be no filters in front of the ejector.

- The well pump should only work on the filtration system.

- A storage tank or container (or a hydraulic accumulator) is installed after the ejector.

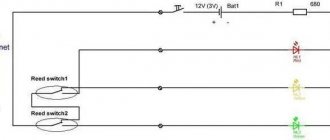

In cases where gravity or ejection aeration is used, a float switch-water level regulator is inserted into the storage tank (container).

When the water reaches a predetermined level in the tank, it opens the electrical circuit of the pump and water stops flowing into the tank.

The regulator itself is not expensive, the average price for it is 3,000 rubles.

High-tech material polyacetal

has particular strength and dimensional stability, which provides a high level of resistance to wear , cracking, shock and dynamic loads, as well as to high and low temperatures, organic substances, oils, fuel compounds, weak alkalis and acids.

Due to its physical characteristics, polyacetal is used as a substitute for metal alloys for the manufacture of gears, bearing shells, gear wheels, automobile parts, household appliance housings, sports equipment, electrical parts, fittings, etc.

At the same time, polyacetal is absolutely non-toxic to living organisms, is physiologically inert and resistant to disinfectants. Therefore, the material has found wide application in medicine, the production of food and water treatment equipment.

voda.kr-company.ru

Aeration column - purpose of water aeration unit

The aeration unit (aeration column assembly) in the system is necessary to saturate the water with air oxygen. This is done with the aim of oxidizing iron dissolved in water, as well as removing dissolved gases.

Essentially, during oxidation, iron changes from a divalent (soluble) form to a trivalent (soluble) form and precipitates, which is subsequently removed in a deferrization filter.

In addition to iron, other impurities contained in water are oxidized. Hydrogen sulfide H2S is also removed from the water, which has a characteristic odor (reminiscent of the smell of a rotten egg).

Composition and principle of operation of the aeration column

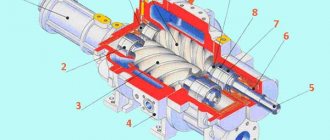

Structurally, the pressure aerator consists of the following elements:

- Frame.

- Compressor.

- The head of the aeration column.

- Dispersant.

- Air release valve.

- Drainage pipe.

Construction of an aeration column

Operating principle of the aeration column

Water passes through the tube and fills the aerator body. When the source of water consumption (tap) is opened, the air compressor starts working. The compressor pumps air into the aeration column and, with the help of a dispersant, the water is saturated with small air bubbles. Excess air is released through the air separating valve.

When water comes into contact with oxygen, iron and other metals oxidize and pass from the divalent form to the trivalent form, and are subsequently removed in a deferrization filter.

Aeration column dimensions

The most common sizes of cylinder bodies are 0844, 1054, 1252 and 1354; aeration column sizes 1044, 1465 and 1665 are also found.

The standard size of the cylinder, for example 1054, is the diameter of the cylinder and its height in inches, i.e. 10″x54″.

Table of standard sizes of cylinders for aeration columns.

| Standard size | Height, cm. | Case diameter, cm. | Case volume, l. | Weight, kg. |

| 0844 | 113,2 | 20,7 | 32,1 | 4,8 |

| 1054 | 137,4 | 25,8 | 61 | 6,2 |

| 1252 | 133,8 | 31 | 87.3 | 9 |

| 1354 | 137,4 | 33,4 | 103 | 9,2 |

| 1044 | 112,2 | 25,7 | 48 | 6,6 |

| 1465 | 166 | 36,9 | 140 | 19 |

| 1665 | 167,1 | 41,3 | 194 | 18,7 |

Popular cylinder manufacturers:

- Aquatek.

- Canature.

- Wave Cyber.

- WiseWater.

Ejector aeration

A fairly common method for cleaning iron. The principle of operation of the system is the same as that of other technologies - it is based on contact of liquid with air. However, in this case, a compact installation made according to the Venturi principle is used.

As liquid passes through it, air is sucked into the device, which comes into contact with water. Next, the liquid passes through filters on which the oxidized iron settles.

Pros:

This technology has one drawback - low productivity. In addition, in case of severe contamination, the use of ejectors will be inappropriate.

Equipment selection

The standard size of the cylinder is usually chosen to be one smaller than the standard size of the deferrization filter. The head is actually a piece of plastic, so you can safely buy any one that fits the selected case.

Aeration column in front of the deferrization filter - the cylinder is one size smaller

Stores often offer to buy an assembled aeration column (along with a compressor) taking into account the required performance. Prices for such columns vary from 25 to 80 thousand rubles, I do not take into account the prices for industrial aerators.

Compressor for pressure aeration

A compressor for water aeration consists of a housing and an electric motor, connected to a 220 V network. The motor rotates a shaft which compresses the air in it, using a valve system, it is pumped into a plastic tube connected at the other end to a head and a dispersant.

Compressors for aeration column

The choice of compressor depends mainly on the budget and required performance. Typically, at a flow rate of up to 10 m3/hour, an AP2 compressor is used, the average price of which at the time of writing is 30,000 rubles. For flow rates greater than 10 m3/hour, AP200 is suitable. You can also choose analogues based on your budget.

In my experience, these compressors work without problems if there are no manufacturing defects.

The following compressors are popular among installers:

- Air Pump AP-2.

- Hailea HAP-60.

- Hailea Aco-500.

- LP-12.

- Hiblow HP-60.

Task

The presence of two cleaning processes in the upper part of the installation allows us to consider this unit either as a trickling biofilter or as a mechanical aerator. Therefore, the discussion “what is it - a biofilter or an aerator” has not subsided on the Internet for a long time.

In our opinion, this unit performs both functions. However, due to the fact that the design has only one pump, with a fixed performance, the parameters of both functions of the unit are not in the optimal zone, namely:

- The efficiency of the unit as a biofilter is limited by the hydraulic load, which is greatly overestimated compared to the calculated values applicable for classical biofilters;

- The effectiveness of the unit as an aerator is limited by the physical solubility of oxygen in water, which is underestimated when compared with the estimated amount of oxygen required for the purification process in aeration structures.

To increase the efficiency of each of the processes occurring in Eurolos Bio systems, it is necessary to perform diametrically opposed actions:

- To increase the efficiency of the biofilter, it is necessary to reduce the hydraulic load on it, i.e., reduce the pump performance;

- To increase the amount of oxygen entering the treated water, an increase in the amount of water supplied to the mechanical aerator is required, i.e., an increase in pump performance.

Connecting the aeration column

Installation (installation) of the aeration column does not require special skills. To introduce an aeration unit into a water purification system, in addition to equipment, you will need:

- Combined collapsible couplings (MKR, American) with external thread - 2 pcs., usually the connecting size to the head is 1/2″.

- Fum tape.

- Tools: gas adjustable wrench (2 pieces are enough for me), hammer drill and screwdriver (attach the stand for the compressor to the wall).

If you can’t find American ones for 1/2″, you can take 3/4″ and an adapter for 1/2″, as well as elastic bands for them. In practice, the rubber bands calmly hold pressure up to 6 atmospheres (I haven’t tried it at higher pressures).

We choose a place, attach the stand for the compressor to the wall, and the compressor itself to it. We assemble the column, carefully wrap the fum tape on the American ones (with a cone - the closer to the base, the thicker).

Next, we assemble the aeration column according to the diagram.

Aeration column connection diagram

Aeration columns can be supplied assembled, then all that remains is to screw on the American ones and connect the compressor and the head with a tube.

Otherwise (if you want to assemble it yourself), to install it you need to follow these steps:

- Insert the water-lifting tube into the head and tighten it until it stops. When doing this, do not miss the rubber gasket.

- The air supply tube with dispersants at the end must be secured to the water-lifting tube using plastic ties or tape.

- Screw the air separating valve with a tube into the head (wrap fum tape around the threaded connections).

- Screw the tap into the head to connect the pressure gauge.

- Screw the head to the cylinder.

- Screw the pressure gauge to the tap.

- Wrap the fum tape around the American ones (water inlet and outlet) and tighten them.

- Insert the air supply pipe from the compressor.

- Solder the pipes.

- If necessary, tighten connections.

The assembly of the aeration column is complete.

Do not overtighten plastic threaded connections with a wrench. It is better to hold them out after water supply than to tear them off.

If you have tightened the connection, but water is still coming out of it, you need to disassemble it and “pack” it again - most likely you have not wound enough fum tape.

Types of aeration systems

There are three types of purification plants:

They differ in efficiency and technical implementation.

Gravity system

Gravity aeration of water from a well is based on the spraying of water, due to which it is saturated with oxygen. In this technology, a sealed container is used, in its upper part there is an inlet of water that comes from a well.

It is fed through a fine sprayer, and while the water drops fly down, they have time to oxidize. Those. divalent iron is converted to ferric iron. In addition, saturation with oxygen and removal of hydrogen sulfide occurs.

Additional air is also supplied to the container. This is done with a special compressor, the output of which is installed approximately in the middle of the tank. This also improves the efficiency of water purification.

Due to the specifics of the technology, in the water supply system there is a break in the water supply at the point of its spraying. Therefore, the initial pressure created by the deep-well pump drops. To compensate for this phenomenon, an additional pump is connected to the aeration tank, which pumps water further through the system.

Advantages:

Flaws:

Due to its simplicity and high productivity, free-flow aeration of water from a well is a very popular method for purification.

Equipment

The filtration system includes the following equipment:

Also, the system can be equipped with a hydraulic accumulator, designed to equalize the pressure in the water supply system and protect it from water hammer.

Maintenance

Maintenance of the aeration column should be carried out every 6 months. In practice, cleaning the aeration column is carried out when the following problems appear:

- drop in water pressure;

- the appearance of iron in water;

- water leaking from the head.

As a rule, when such problems occur, maintenance of the entire water treatment system is usually carried out.

Maintenance schedules may vary depending on the aerator manufacturer. Usually the deadlines are specified in the equipment passport.

Do you want to carry out maintenance yourself? Then you need to buy citric or oxalic acid and make a solution in a small bucket. It is advisable to add hot water to the acid. I won’t tell you how to concentrate, I always do it “by eye”.

You disassemble the aerator, wash the body, the head with everything on it except the tube, put it in acid for 15 minutes, then rinse it in cold water and reassemble the aerator in the reverse order.

Please note that before dipping your hands into acid, be sure to wear rubber gloves.

It's quite simple. And if it doesn’t leak anywhere, it means that the installation and dismantling of the aeration column was completed successfully.

Making an aerator

Considering the high cost of aeration equipment, many homeowners want to make a system for purifying water from a well with their own hands. And this is quite real.

For self-production, it is better to choose a non-pressure installation, because it:

Required Equipment

Before manufacturing, you need to correctly calculate the volume of water consumption. The volume of the aeration tank depends on this. It must be taken into account that consumption should be less than 50% of its volume. If this condition is not met, the water will not just have time to settle.

To make your own cleaning system, you will need the following equipment:

In addition, you will need a float switch. It is needed to turn off the deep-well pump in a timely manner.

Instructions for creation

Making such an installation yourself is not too complicated and consists of the following steps:

In addition to the float switch, it is necessary to provide protection for the system against overflow. To do this, at the input level, another output is cut in and connected to the sewer. If the switch does not work, the water will go down the drain.

With this, the installation is complete. As can be seen from the instructions, the scheme for its implementation is quite simple and does not require the use of specific equipment. And the big advantage of such an installation is that in addition to the oxidation of iron, it provides effective removal of hydrogen sulfide.

kanalizaciyasam.ru

Our objects:

| Modernization of water purification systems from iron. High iron content in water. With a high iron content, water is best helped by dosing sodium hypochlorite followed by installing an activated carbon filter to destroy residual chlorine. Despite the cheapness of hypochlorite, as well as the high efficiency of such a system for purifying water from iron, many people are afraid to use active chlorine as an oxidizing agent - completely in vain - chlorine is completely retained by activated carbon and the output is absolutely potable water purified from iron and bacteria. This is exactly the case at this facility - instead of installing an additional hypochlorite dosing system, they had to install two oxidizer systems in a row, because the resident women were disturbed by the noise of the compressor, and they completely abandoned the hypochlorite dosing system. It's a pity… | Silent aeration system oxidizer. Purification of water from iron and aeration of water in one cylinder We have been using the oxidizer water purification system from iron relatively recently, but it has already proven its high efficiency in cases where the water does not contain traces of hydrogen sulfide - in this case, compressor aeration is urgently needed for stripping and partial oxidation of hydrogen sulfide. The oxidizer effectively purifies water from iron even in high concentrations and significantly saves space and, most importantly, the customer’s money, since it allows you to do without a compressor. On the other hand, an oxidizer-type water purification system increases the load on the septic tank, because needs more frequent washing. To load iron-removing oxidizer filters, it is better to use catalytic materials such as Burm or Pirolox with a high degree of water purification from dissolved iron. |

| Iron removal filter in the caisson. Iron 7 mg/l. 75,000 turnkey Is it possible to place a water purification system in a caisson? The answer is presented in the video. The system has not only been working perfectly for more than two years, but also does not cause any inconvenience to the owners - such as compressor noise, noise made by the filter when washing, etc. The caisson must be insulated. Installation of iron remover in a caisson. Despite the very small installation space, a very decent system for purifying water from dissolved iron was installed. | Iron removal system. VZU of the village. Hypochlorite dosage Sodium hypochlorite dosage. Deferrization. Water treatment and water supply in Moscow and the region. Purification of water from iron at the water treatment plant in the village of Semenkovo, Odintsovo district. The system is designed for 30-40 houses with the possibility of expansion to 100 houses. To expand, you need to add iron removers to the cascade. Sodium hypochlorite is a modern, safe for human health, scheme of chemical oxidation of water for its purification. |

Positive results

By using a recirculation unit of a new design, in which the recirculating flow is divided into two parts, the following was achieved:

- A new source of air supply has appeared with characteristics equivalent to the use of a membrane compressor and a fine-bubble aerator, with an air capacity of up to 40 liters per minute;

- The hydraulic load on the biofilter was reduced as much as possible, which had a positive effect on its operation and allows us to consider this unit a biofilter with additional aeration of the recirculating flow, and not a mechanical aerator.

The implemented technical solution for additional aeration of the liquid being purified makes it possible to increase the stability of the cleaning technology as a whole and can be used on both newly produced and already in use Eurolos Bio models.

| 40 liters per minute |

The need to replace a standard unit with a modified one may be due to the specific use of Eurolos Bio installations, for example, a short-term increase in the number of users above the permissible limit, accelerated startup of the station, or any other factors requiring an increase in the oxidative power of structures.

Briefly

Ejector Eurolos Bio

, pdf file ~142.79Kb

What is dissolved iron and how to remove it. Methods for deferrization of water.

The presence of dissolved iron in water is one of the most common water quality problems encountered when installing water treatment systems. In some cases, in addition to the presence of both dissolved and undissolved iron, manganese and hydrogen sulfide are also present in the source water. As a result, the turbidity and color of the water increases, and the use of this water for domestic or drinking needs becomes almost impossible. Such water has an unpleasant taste and odor due to the influence of special iron bacteria - iron bacteria are typical representatives of microflora that are carried from the water supply source into the water supply network, after which they become attached to the walls of the pipeline. Having attached themselves to the wall of a pipeline, boiler or boiler, iron bacteria multiply, forming a biofilm. As a result of such biofouling, the internal surfaces of pipelines become covered with deposits and lose capacity by 20-60% in some cases during the first 4-6 years of operation. There are various methods for purifying water from dissolved iron, described in detail in our article On choosing a method for deferrizing water. The most popular and frequently used method for deferrizing water is oxidation followed by filtration. To remove iron or manganese, in this case, their initial oxidation is carried out by introducing various oxidizing agents into the water, such as oxygen, ozone, sodium hypochlorite, potassium permanganate, hydrogen peroxide, etc. In this case, iron, manganese and hydrogen sulfide are oxidized to a water-insoluble form in the form of a fine suspension, which then completely settles on the filter media of the deferrization filter. Depending on the degree of water contamination, the following filter media can be used as loading:

| Name | Price | |

| Loading of iron removal EcoFerox (20l, 13kg) | RUB 1,500.00 | Add to Basket |

| Loading of deferrization PinkFerox (20l, 25kg) | RUB 750.00 | Add to Basket |

| Catalytic iron-removing filter material ORE Filter B | RUB 2,500.00 | Add to Basket |

| Catalytic deferrization material Baufilter B (28 l/20 kg) | RUB 2,000.00 | Add to Basket |

| Catalytic material for water deferrization Greensand Plus (14.15 l bag) | RUB 3,500.00 | Add to Basket |

| Catalytic material from dissolved iron MFO 47 | RUB 3,000.00 | Add to Basket |

| Multifunctional sorbent for water deferrization EcoMix A (25l) | RUB 9,500.00 | Add to Basket |

| Multifunctional sorbent for water purification from dissolved iron EcoMix P (25l) | RUB 7,800.00 | Add to Basket |

| Complex loading for water purification systems from iron EcoMix C (EcoMix C) | RUB 12,200.00 | Add to Basket |

| AC sorbent for iron removal and water clarification systems | RUB 1,920.00 | Add to Basket |

| MS sorbent for clarification and iron removal systems | RUB 2,500.00 | Add to Basket |

| Iron removal sorbent ODM-2F 0.7-1.5 mm (40 l bag) | RUB 1,800.00 | Add to Basket |

| Iron removal filter material Birm (pack of 28.3 liters) | RUB 4,000.00 | Add to Basket |

| Filter material for removing iron from water iron, manganese and hydrogen sulfide Pyrolox (pack of 14 liters) | RUB 10,000.00 | Add to Basket |