No welding takes place without the main element - the electrode. It is worth choosing a certain optimally suitable electrode for a specific welding machine. But there are types that are suitable for almost any brand of welding unit and have a number of advantages. Such convenient and easy-to-use electrodes include rutile ones, the main thing is that the welding seams after their operation are distinguished by accuracy and subtlety. What are rutile electrodes and when should they be used - in the text.

Rutile electrodes: what are they and what are they for?

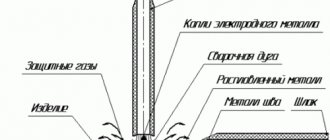

All electrodes are made according to the same principle: a special coating is applied to a metal rod made of a special alloy. As a rule, the type of coating determines where the electrodes of this type will be used.

Rutile coated electrodes are designed for manual arc welding.

The coating is made primarily from titanium dioxide. This allows you to achieve high quality welding seams and also has a beneficial effect on the entire welding process. REFERENCE: This type of coating is one of the safest, as it does not emit harmful substances during combustion that can be inhaled by the welder.

Why so popular

Rutile electrodes are considered one of the best. They have a number of advantages, thanks to which a welder with any experience can obtain an even and high-quality seam.

- Can be used with both AC and DC current . The welding arc in any case maintains combustion stability.

- You can weld metal joints coated with a light layer of primer .

- Ideal for use when welding short seams or in awkward places. The arc is easy to ignite and just as easy to re .

- Allows you to form a seam with a high impact strength . This is achieved due to the increased alkalinity of the slag.

- The rutile welded seam has excellent durability and fatigue strength . Even under prolonged exposure to alternating loads, it retains its qualities.

- a low spatter coefficient is characteristic . This makes the welding process more convenient for the welder.

- Convenient to reuse the electrode. After welding is completed, carbon residue remains on the tip of the rod, which does not need to be cleaned off (unlike other types of coatings). The carbon deposits of rutile electrodes are a semiconductor, so you can continue working without additional problems.

- Less harm to health . During the combustion of rutile coating, no hazardous substances are released. Therefore, there is less negative impact on the welder’s respiratory system.

IMPORTANT: Low requirements for the hob. Even with strong surface moisture, the seam does not lose its properties. Welding is also allowed in the presence of a corrosion layer (up to 30%).

How to choose electrodes for inverter welding

First of all, the composition of the core is selected: it must be similar to the type of metal being welded. Structural steel is the most commonly used material in households. The electrodes should be made from the same wire. Sometimes you still have to cook stainless steel. Then the core should also be made of stainless steel, and for highly alloyed and heat-resistant ones it is made of metal with the same characteristics.

You can perform all the work around the house or at a construction site using just a few brands of electrodes:

- MR-3

- SSSI 13/55

- ANO 21

- OK 63.34

They are recognized by many as the best electrodes for beginners who work with inverter welding machines: they are easier to work with, at the same time, they allow you to weld high-quality seams even without significant experience. Below are the characteristics and general application of those consumables that many experts consider good electrodes for an inverter. In any case, they are often recommended for beginning welders to gain experience.

Electrodes with rutile coating MP 3

MP-3 is perhaps the most popular welding electrodes for inverters among beginners.

Most often, beginners are advised to start mastering welds with MP-3 electrodes. They light up easily, even with a not very good current-voltage characteristic of the welding machine, provide good protection for the weld pool, and make it quite easy to control its position. If the electrode does not ignite, calcine it at a temperature of 150-180° for 40 minutes.

They are used in devices with alternating current (welding transformers) and direct current (welding rectifiers and inverters). Inverters are usually connected with reverse polarity (+ on the electrode). Suitable for any type of seam, except vertical from top to bottom.

Read about the types of welding machines here.

MP 3 electrodes are not picky about the quality of the surfaces being welded. They can be used even on untreated, rusty and wet parts. Welding is carried out with a medium (2-3 mm) or short arc.

The MP 3 feature is very important for novice welders: they “hold” the arc well and are easy to work with. This is why not all professionals love this brand: they call them sparklers. They cook too softly: slow movements are necessary for good heating. What the pros don't like, is just what beginners need. Try to start learning welding with MP3. Everything should work out for you.

| Electrode diameter LEZ MR-3, mm | Length, mm | Recommended welding current, A | Pack weight, kg | Price, rub |

| 2,0 | 250 | 40-60 A | 1,0 | 146 |

| 2,5 | 300 | 60-100 A | 1,0 | 120 |

| 3 | 350 | 70-100 A | 1,0 | 95 |

| 4 | 450 | 80-170 A | 1,0 | 91 |

| 5 | 450 | 130-210 A | 1,0 | 91 |

UONI 13/55 with basic coating

Electrodes preferred by professionals for the UONI 13/55 inverter (click on the picture to enlarge the size)

These are, perhaps, the most widespread and popular electrodes with a basic coating. They are recommended for welding carbon and low-alloy steels. Suitable for connections of critical structures. The seams are resistant to shock loads and ductile, and withstand low temperatures well.

The disadvantage of these electrodes is that they ignite well only when the idle value of the inverter is sufficiently high (above 70 V). The second significant drawback: high requirements for stripping and processing of welded metals. If rust, dust, oil or other contaminants remain on the edge, the seam will be porous.

You can work with UONI 13/55 only on DC welding machines, including those with inverters, with reverse polarity (+ applied to the electrode), and with a short arc (keep the tip of the electrode closer to the surface to be welded). Minimum open circuit voltage 65 V.

| Electrode diameter UONI 13/55 (manufacturer: Mezhgosmetiz) | Electrode length, mm | Recommended welding current, A | Retail price of a pack, rub |

| 2,0 | 250 | 30-60 A | |

| 2,5 | 300 | 40-70 A | 127 RUR |

| 3 | 350 | 80-100 A | 116 RUR |

| 4 | 450 | 130-160 A | 111 rub. |

| 5 | 450 | 180-210 A | 110 rub. |

ANO 21

This type of rutile-coated electrode is designed to work with thin carbon steels. (Read about welding thin metals here.) When using them, the arc is easily ignited (including when re-igniting), the weld is fine-scaled (made up of small waves), and the slag is easily separated. ANO 21 electrodes can be used for welding water or gas pipes.

Try ANO 21 electrodes to work on the inverter

They work with both alternating and direct current of any polarity. Before welding, heat treatment is required: they are calcined at a temperature of 120°C for 40 minutes.

| Diameter, mm | Low electrode position | Vertical electrode position | Ceiling electrode position |

| 2 | current 50-90 A | current 50-70 A | current 70-90 A |

| 2,5 | current 60-110 A | current 60-90 A | current 80100 A |

| 3 | current 90-140 A | current 80-100 A | current 100-130 A |

Stainless steel electrodes OK 63.34

If you need to weld stainless steel, try OK 63.34. They can also cook structural steel. This produces a seam with a small wave with a smooth transition to the main surface of the metal. The amount of slag is small and can be easily removed.

This electrode is good for welding vertical seams in metal 6-8 mm, passing from top to bottom. Suitable for multi-pass welding of butt and overlap joints. Works with direct and alternating current of any polarity, minimum open circuit voltage is 60 V.

Welding electrodes OK 63.34

For welding you will also need a mask. To make your work easier, take a chameleon welding mask.

Rutile electrode coating - characteristics

Electrodes with this type of coating can most often be of two main types: E42 and E46 (according to the state standard). The type must be indicated on the packaging label. Weld metal welded with E42 type electrodes has the following technical characteristics:

- Tensile strength - 410 MPa;

- Relative elongation - 22%;

- Impact strength - 80 J/cm2.

A seam welded with E46 electrodes has more durable characteristics:

- Tensile strength - 450 MPa;

- Relative elongation - 20%;

- Impact strength - 147 J/cm2.

In the manufacture of rutile electrodes, low-carbon welding wire (SV-08 or SV-08A) is used. A rutile coating is applied to it. The marking of such electrodes contains the letter “P”, which indicates the type of coating. As a rule, the letter “P” is always followed by two numbers:

- The first indicates in what spatial positions welding can be performed. Most rutile electrodes can be welded in any position.

- The second indicates the type of welding current: alternating or direct, its polarity and open circuit voltage.

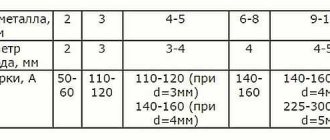

What electrode diameter to choose

This is another question you may encounter. Everything here is quite simple: the diameter will be selected according to the thickness of your welded metal.

Moreover, if the metal is very thin (less than one and a half millimeters), then manual welding (RMW) is most often unacceptable (here we use tungsten electrode welding, semi-automatic or automatic).

In other situations, you can select an electrode. You can see the ratio in the following table:

Marking

Depending on the manufacturer and the specific type of product, package markings may differ slightly. However, most rutile electrodes are labeled almost the same. Let's take a closer look at the example of marking MP-3 electrodes.

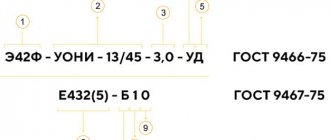

On their packaging you can see the following markings: E 46 – MR-3 – UD E 430 (3) - P26.

Let's look at everything in order:

- E46 - indicates the type according to GOST. This means that this model is designed for welding low-alloy and carbon steels. Tensile strength - 46 kgf/mm2.

- MP-3 is a brand from the manufacturer.

- U - indicates the purpose of the electrode. For welding carbon steels, tensile strength is 60 kgf/mm2.

- D is the coating thickness coefficient (thick).

- E - international marking. Indicates the type of electrode with a consumable coating.

- 43 - tensile strength (430 MPa).

- 0—relative elongation index (20%).

- (3) - temperature indicator -20°C. This is the minimum temperature at which the weld metal retains an impact strength of at least 34 J/cm2.

- P - type of coating. In our case - rutile.

- 2 - shows in what positions welding work can be carried out. This indicator means that you can cook in any direction except vertical “top to bottom”.

- 6 - for high-quality work you need to use a current of reverse polarity, constant. The open circuit voltage should be approximately 70V.

[ads-pc-2][ads-mob-2]

Coverage type

E42A-UONI-13/45-3.0-UD ———————————— E

432(5)-

B

1 0

The letter E at the beginning of the second line of marking indicates a consumable electrode, the coating of which burns out from the temperature of the electric arc. But the type of coating is indicated by the letter B. There are four main options, as well as their mixing with each other:

- A - this is the designation for acidic coating. Electrodes with this marking are manufactured for work in all spatial positions on direct and alternating current. But they cook poorly from top to bottom. Not suitable for joining metals with a high carbon and sulfur content; they promote splashing of droplets and may cause cracks in the seam.

- B is the main coating designed for welding with direct current of reverse polarity. Suitable for joining thick workpieces.

- P - designation for rutile coating. Electrodes can work on alternating or direct current in any spatial position, but verticals from top to bottom are difficult.

- C - cellulose coating. Consumables are used for the installation of metal structures; they are excellent for welding in all positions in space on direct and alternating current. But there are increased losses due to splashing.

- RB, AC - mixed coating options. Optimal for welding in the lower and vertical positions of pipelines. Provide low consumption.

In order for the electrode to correspond to the markings, its coating must contain chemicals in certain proportions. These can be: quartz sand, kaolin, marble, manganese ore, titanium concentrate, chalk, etc. It is the gas from the molten coating that reacts with the weld pool and gives the seam certain characteristics. This process occurs during the burning of the arc and after its extinction, while a new crystal lattice is formed.

Physico-chemical composition

Depending on the manufacturers and various modifications, the composition of the rutile coating may differ slightly. However, in most cases the composition is as follows:

- Rutile concentrate (titanium dioxide) - 48%.

- Feldspar - 20%.

- Ferromanganese - 15%.

- Magnesite - 15%.

- Dextrin - 2%.

Some types of electrodes may also contain additional elements: for example, cellulose. Such coatings are marked with the letters “RC”, which stands for “rutile-cellulose coating”.

Rutile electrodes: application

Due to its excellent qualities, rutile coatings are widely used in various conditions and are considered one of the most practical types. We list the main applications in which electrodes of this type do an excellent job:

- Welding of low carbon steel structures . The chemical composition of the coating allows you to effectively work with ferrous and low-alloy metals. In such cases, the seam is smooth and without cracks.

Welding of pipelines. Excellent for repairing pipes that carry liquids. In this case, it is difficult to completely dry the working surface of the metal. However, the welding arc of rutile electrodes burns stably even when drops of water enter the combustion zone.- Widely used for repairing parts or tools that wear out over time . Rutile electrodes make it possible to deposit welds of considerable thickness as efficiently as possible. Due to small splashing, material savings are achieved.

Rutile coated electrodes: pros and cons

Compared to other types of coatings, rutile has a number of advantages:

- Seam durability . Welded metal is not susceptible to cold or hot cracks.

- In contrast to the acid coating, the rutile welding arc burns with alternating current as intensely as with direct current.

- Easy to process areas where short seams are needed . If the main coating requires continuous welding, since the welding arc is difficult to re-ignite, then with rutile it is easier. The arc ignites easily, and there is no need to clean carbon deposits from the tip of the rod.

- It is not necessary to prepare the work surface . Other types of electrodes are susceptible to oxidation and rust, resulting in a weak weld. Rutile electrodes allow you to form a stable and durable seam, regardless of the quality of the surface.

- After welding, the slag is easily separated , and the surface of the weld practically does not require grinding.

There are also disadvantages:

- Not suitable for all designs. The small range of metals with which this type of coating can be used imposes certain restrictions on their operation. Such electrodes cannot be used for welding high-carbon steel .

- The properties deteriorate sharply with increasing voltage. Therefore, you will have to monitor compliance with the nominal indicator.

- It is necessary to carry out preparatory work - drying and calcination .

[ads-pc-4][ads-mob-4]

What is the purpose of electrodes?

Differences in the coating and core material of the electrodes are determined by their purpose. Some are used for welding carbon, low-carbon, and low-alloy steels whose tensile strength does not exceed 600 MPa. This group is conventionally designated by the letter – U.

The second group are materials used for medium-alloy steels whose tensile strength exceeds 600 MPa. Symbol – L.

The third group includes welding materials used for welding work with high-alloy steels. The properties of which are aimed at solving certain problems. They are designated V.

The next group is used when welding heat-resistant alloy steels. Denoted by T.

And the group closes, which also includes highly specialized welding materials, namely those used for surfacing metal products with special characteristics. Designated - N.

The last designation is “D”.

The thickness of the coating is indicated here. They come in 4 types:

- “M” – with thin.

- "C" - with average.

- "D" - with thick.

- “G” – especially thick.

Each type includes electrodes in which the ratio of the diameters of the rod and coating corresponds to the following conditions:

- For thin – D/d ≤1.2

- For medium D/d ≤1.45

- For thick D/d ≤1.8

- For particularly thick D/d ≥1.8

Now let's go down. We see “E 43 2(5)” - this is the index of the weld metal (welded metal). Most often it is taken from GOST 9467, 10051 or 10052. According to the index in GOST, you can see what minimum properties the seam will have. Next we see the letter “B”. It indicates the type of electrode coating.

Types of coverage: how to determine which one to choose?

Coating of electrodes is possible in the following options:

- Acid coating - A

- Basic coating - B

- Rutile coating - R

- Cellulose coating - C

In this regard, it is impossible to say which one is better and which one is worse: they are all designed for different types of work, as well as conditions of use. Therefore, it is impossible to unambiguously answer the question which electrodes for welding will be better. As a rule, it is necessary to use them to form a strong weld seam in critical structures.

Next we see the number “1”.

This is a designation for the positions in which you can cook.

“1” – for any provisions;

“2” - for any, except top-down;

“3” - vertical from top to bottom, horizontal, bottom;

“4” - lower position and boat position.

And the number “0” ends.

This is the type of current and polarity. This figure is taken from the table below. Indicates “0” that welding must be performed on direct current with reverse polarity connected. Having analyzed the transcript, we will dwell in more detail on each point.

What are welding electrodes coated with and what is this coating?

Coating is a special coating that is designed to protect molten metal from the negative effects of oxygen. It creates a gas shell while the core melts.

Coatings are divided according to the functions they perform: gas-forming and slag-forming functions.

Gaseous components create protective gases and an ionizing atmosphere.

Slag-forming agents include elements that promote deoxidation, refining, alloying of the seam and the base metal, increasing the bonding and plastic properties of the seam. During welding, a layer of slag is formed in the weld pool for protection.

Types of coverage: how to determine which one to choose

There are 4 main types of electrode coatings used in manual arc welding. Let's deal with each of them one by one.

Let's talk about the main component. Rutile is a natural mineral that, forming a protective gas shell, creates a weld pool. Welding with materials such as rutile is characterized by high stability.

Ignition of the arc occurs without problems even for beginners. That is why they are often used in installation. The seam is obtained with small scales, with a uniform casting structure over the cross-section.

The following advantages of working with this coating can be highlighted:

- It is permissible to use both alternating current (AC) and direct current (DC);

- Easy to ignite using both new and secondary arc ignition;

- Not demanding on the cleanliness of the product surface. Can be used on rust, undried edges of the product, scale and even paint;

- The metal practically does not splash.

The disadvantages include:

- There is not a large range of materials that can be used with;

- In the weld pool there is active mixing of slag and metal, which makes it difficult to distinguish where the slag is and where the metal is. This leads to slag inclusions;

- The presence of moisture in the coating leads to a defect in the form of pores. This is an important point that is worth paying attention to. Proper storage and calcination before welding is necessary.

Acid coating: application features

Good to use, but in an open space, otherwise it will not be safe for the welder. The advantage is definitely that the slag is easily separated.

Acid coating requires low idle voltage. Currently they are rarely used.

Basic coating

They have become very widespread, one might even say ubiquitous, due to their versatility. Their coating contains fluorine and calcium. During welding, the coating elements evaporate, protecting the molten metal. The bath's gas shield actually consists of carbon dioxide.

They are used when using direct current; as a rule, the polarity is reversed.

When melted, the coating removes harmful impurities from the weld such as sulfur (S), phosphorus (P) into the slag. This helps to increase strength, increase ductility, and reduce fragility. As a result, there are no cracks.

Arc ignition is worse than that of rutile ones, but their range of application is wider. The arc burns less stably compared to rutile. This is due to the content of fluoride compounds that reduce ionization.

Welding should be carried out only on a well-prepared surface. There should be no moisture or dirt. Otherwise, we will get a large number of pores in the weld metal. Another reason for pores is an increase in the length of the arc. The protection dissipates and gas from the atmosphere enters the weld pool.

Cellulose coated electrodes

The use of welding materials with this type of protection is less and less. This is due to the fact that welding with them hydrogenates the weld seam. The strength of the connection decreases and pores appear.

More than half of the coating consists of organic substances and during welding provides strong gas formation. They cook in all positions; it is even possible to carry out the process from top to bottom.

The surfaces may not be well prepared; this will not actually affect the quality of welding. This has something in common with rutile coating.

The best brands of rutile coated electrodes

ESAB-SVEL OK 46.00

Produced in Russia by the Swedish concern ESAB. This model is one of the best in its category and has the following advantages:

- Low requirements for preliminary preparation. Even damp products can be calcined at a temperature of 70-90°C.

- They are not afraid of moisture. The arc burns stably upon contact with a moistened surface.

- The minimum threshold of the required current, which is needed for reliable combustion, is significantly lower than that of other types of electrodes.

- Forms a strong and impact-resistant seam.

Lincoln Electric Omnia 46

They are produced by the American company Lincoln Electric, which has been producing electric welding products since 1927. Electrodes are affordable and are an excellent choice for beginners. The welding arc does not require precise control; if it is slightly extended, combustion stability is not lost.

When operating the Omnia 46, a relatively small amount of sparks are generated. A strong seam allows them to be used for welding critical structures (for example, pipelines operating under high pressure).

OZS-12

Electrodes of this brand have a NAKS certificate, which allows them to be used for welding work at critical and hazardous facilities. Among the advantages of the brand:

- The seam is made easily and smoothly, even without special welding skills.

- After cooling, a thin slag crust remains on the surface, which is easily separated.

But there is also a drawback . Despite the fact that rutile coatings are usually not susceptible to moisture, electrodes of this brand are sensitive to dampness . This entails additional requirements for storage, calcination (at a temperature of 150 ° C before each use), as well as cleaning the weld pool from large contaminants.

MR-3

MP-3 type electrodes are one of the most common. The Resanta brand managed to preserve all the advantages of rutile coating and avoid the disadvantages that are found in other manufacturers of products of this type.

MP-3 are easy to ignite, form a strong and even seam, and work effectively with different currents. The disadvantage is increased sensitivity to moisture. Before use, they must be calcined for at least an hour at a temperature of 150-170°C.

What is alternating current in welding

Is it good or bad, which current is better? Variable or constant? No one will give you a definite answer.

Welding classification.

To begin with, it is better to understand the features of processes with alternating current, they are as follows:

- The behavior of the arc leaves much to be desired: with alternating voltage it is the most unstable.

- The welding seam is not of the highest quality due to deviation from the axis of the welding arc.

- If the arc goes out, its combustion can only be resumed when the voltage increases.

- The metal is splattered to a large extent.

Despite all these complexities, the equipment required for AC welding is simple and inexpensive. These are, first of all, transformers - devices that are still very popular among welding masters.

It would seem that electrodes for alternating current should gradually lose their relevance: after all, many rectifiers have appeared on the market - inexpensive and with small dimensions convenient for use. However, these consumables are still in demand in many industries and handicraft workshops.

Most of the brands are universal, which is also extremely suitable for older generation domestic welders.

If you look at it, the best consumables for “change” have and show very serious production advantages. First of all, this concerns the resulting electric arc: its durability and easy ignition. Another feature of such electrodes is the low level of metal spattering during welding.

Welding transformer

Electrode diameter and steel thickness.

To carry out welding using a transformer, the following mandatory structural elements are required:

- Windings primary and secondary. The primary is made of a special insulated wire; there is no insulation on the secondary winding.

- Magnetic wire.

- Screw for controlling the position of two windings and changing the distance between them.

- Protective housing for the entire unit.

- Screw handle, running nut.

- Fan and other elements depending on the transformer model.

Despite the fact that many welding professionals regard transformers as equipment of the “outgoing generation,” they are presented on the market in the form of a wide range of models of very different values and for wallets of any thickness.

Transformers differ according to the following criteria:

- dimensions and weight;

- output current strength;

- output voltage level at idle;

- volume of electricity consumed;

Welding generator

It is assessed as an independent device, necessary for operation if there is no full-fledged network electricity.

Electrode markings.

The generator design includes the required structural elements:

- The most important part - the converter consists of an electric generating element with an alternating voltage motor. They provide changes in current indicators.

- Drive internal combustion engine.

- Indicator for monitoring and recording current strength.

- Mode switches.

- Special circuit breaker.

- Regulators for current and arc behavior.

- Terminals for connecting cables and 230V outlets.

These types of generators are available in two versions:

- Collector generators.

- Valve generators.

The main advantages of a gas generator in comparison with other welding machines are:

- Compact and therefore highly mobile.

- Convenience, relative cheapness, noiselessness.

- Wide functionality and high reliability.

- Quite high technical characteristics.

Welding with rutile coated electrodes

Several nuances that must be taken into account when carrying out welding work:

- Check what material the electrode is made of. And now we are not talking about the coating, but about the rod itself. To achieve the highest quality weld, the metal of the rod must match the metal of the structure that is being welded.

- It is also important to consider the thickness of the electrodes. It must correspond to the thickness of the metal of the structure, although it may be thicker or thinner, which is compensated by the current strength and the skill of the welder.

Video

Watch a couple of videos where a craftsman shares his experience of working with rutile electrodes.

Calcination of electrodes with rutile coating

Electrodes of this type require pre-calcination before use. Common requirements for calcination: at least an hour in an oven at temperatures up to 350°C.

These are general requirements, and exact guidelines vary by brand. Some models are slightly sensitive to moisture and can be calcined at relatively low temperatures (up to 90°C), or do not require calcination at all. Although there are brands that can become damp and lose their properties. The exact calcination mode is indicated by the manufacturer .