An excess air pressure relief valve is a simple but reliable device that ensures the safety of compressors. If the permissible pressure in the system is exceeded, it will perform an emergency release of air into the atmosphere. Safety valves must be installed and operated correctly - only then can they protect you from an accident.

Why do you need an overpressure relief valve?

The device is designed to protect the system from exceeding operating pressure. The emergency valve is activated when the threshold pressure value is exceeded, opens and releases part of the air into the atmosphere. At the same time, the pressure drops to normal, and the air pressure relief valve closes.

When the compressor stops, compressed air remains in its cylinders. The unloading valve is activated when the engine is turned off, releasing air into the atmosphere.

If this is not done, subsequent startup of the unit will be difficult or even impossible.

In addition, storing the compressor without increased pressure in the cylinders increases its service life.

Emergency air release valves must be installed on the compressor in case of failure of the pressure switch relay.

Emergency valves for car air conditioning compressors

The emergency relief valve, mounted in the compressor housing, is triggered when a critical pressure level (25-30 atmospheres) is exceeded due to clogged lines, severe overheating or other reasons. This part is not available in all cars; modern models are equipped with solenoid valves. Essentially, they are fuses that protect the climate system from serious damage due to overload.

This part is disposable and must be replaced after the cause of the operation has been eliminated. Otherwise, refrigerant will leak from the system. The fastening is threaded, sealing is ensured by a rubber O-ring. Since when the membrane ruptures, part of the refrigerant leaves the system, refilling is required after replacing the valve.

The fact that the emergency valve needs to be changed is indicated by the fact that when the system is refilled, freon immediately comes out through the valve.

The valve is sometimes replaced with a plug, but it cannot serve as a fuse.

How to buy a compressor valve or plug for a car air conditioner in the online store AutoConditioners.com

Features of choosing an emergency valve and plug:

- parts differ not only in appearance, but also in size and thread;

- inch or metric thread, with different pitches;

- The kit includes an O-ring (it is required to be installed).

If the thread parameters are precisely known:

- select a part from the catalog and add it to your cart;

- fill out the application form;

- call the manager by phone or come to the office at Moscow, st. Ugreshskaya, 12с1, office 120, to help you choose.

What does the device consist of and how does it work?

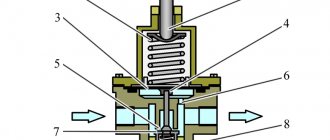

The design consists of the following main parts:

- body cast from steel alloys or brass;

- inlet and outlet pipes cast integrally with the body;

- a seat to which the locking element is pressed;

- a locking element - a disk or ball attached to the rod;

- a spring placed in the housing around the rod.

At normal or reduced air pressure, the compression force of the spring tightly presses the locking element to the seat. The air passage is closed.

As soon as the pressure begins to exceed the actuation value, it overcomes the force of the spring and begins to push the locking element away from the seat. A gap opens for air to pass through. Air is released into the atmosphere, and its pressure inside the system decreases. The spring force again overcomes the pressure force and pushes the locking element back to the seat. The shutter closes and is ready for the next air release cycle.

Types of overpressure relief valves

Based on the method of pressing the locking element to the seat, the devices are divided into the following types:

- Spring. The force of elastic deformation of the spring metal keeps the shutter closed. It is selected in such a way that a pressure exceeding a given level pushes the locking element away from the seat. Spring models are available with both constant response pressure and the ability to adjust it. To do this, an adjusting screw is added to the design, which pre-compresses or weakens the spring. During operation, the spring gradually loses its elasticity, and the response value may change.

- Lever cargo. For pressing, the force of gravity is used, acting on a load suspended at the end of the lever. Such a system has wide possibilities for adjusting the response value. To increase it, the load is moved to the end of the lever, to decrease it, closer to the body. In addition to the possibilities for precise adjustment, this design has another advantage: the stability of the release pressure over long periods of time. Lever devices are characterized by large dimensions and weight. They are used as a safety valve for high-capacity compressors installed permanently.

- Electromagnetic. These advanced devices use an electromagnetic solenoid actuator to press the locking element. Such devices operate as an executive element of a centralized automated control system. The pressure sensor can be located next to the valve, or it can be located in a completely different part of the system. Most of them are equipped with an additional working spring. If there is a loss of power or communication with the control system, the relief valve turns into a regular mechanical one.

According to the method of connection, the relief valves are divided into the following types:

- Threaded. The most common type for low pressure relief devices. Easy to install and dismantle even for untrained personnel - a wrench is enough for this. Most often used as an emergency valve for a low-power mobile compressor.

- Flanged. More difficult to install and more expensive, they provide high tightness. used in medium and high pressure systems.

- Welded. Provide maximum tightness and reliability. Difficult to install/dismantle; special equipment and trained personnel are required.

Based on the material from which the device is made, there are:

- Steel. They have high strength and long service life. Withstands great pressure.

- Brass. They are characterized by high corrosion resistance and long service life.

- Plastic. Cheap, but designed for low pressure values.

Three way boiler valves

A three-way valve is one of the main components in a heating system using a gas boiler. In the system, he regulates and distributes hot water flows.

Before you buy a three-way valve for a boiler, please note that it can be used in both gas and solid fuel boilers. This is possible due to the fact that the type of fuel that is used to generate energy does not affect the circulation of coolant in the system. This happens because the valve is not in any contact with the combustion chamber.

Installation Rules

The overpressure relief valve should be installed as close to the compressor as possible. On low-power mobile units, the installation location is provided by the manufacturer. When installing distributed stationary systems, the distance from the compressor outlet to the valve should not exceed 1.5 meters. It is unacceptable to install an emergency release device after the shut-off valve. If the valve is closed for any reason, the valve will not be able to fulfill its protective function, and the increased pressure can seriously damage the equipment or even cause an accident that threatens the life and health of people working nearby.

Before installing or replacing the valve, it is necessary to completely relieve the pressure in the system and turn off the power to the compressor motor. The threaded connection should be wrapped with FUM tape or plumbing thread. First, the threaded connection is tightened by hand, and only after making sure that the thread goes in smoothly can significant physical effort be applied to tighten it with a wrench.

Construction and details.

At a local radio market I bought an imported used fan, but this time, of course, with plain bearings. The bearings had no play and I made a new valve for this device.

The fan turned out to be conditionally non-separable (with rivets), so in order to get to the seals, I had to drill two holes for lubrication. At the same time, I already cut M1.6 threads into them.

Through these holes, I poured oil into the oil seals using a medical needle.

The valve base was made of fiberglass 4mm thick. First I marked the grille on the fan side, then I drilled out what I could, and at the very end I processed the holes with a file. All operations were done in such a way as not to damage the smooth surface of the fiberglass laminate on the side of the future valve flaps.

To seal the joint between the fan and the valve body, I used a porous rubber gasket, which I rolled into a ring and glued directly to the fan body.

I made another ring from fiberglass 0.5mm thick. It made it possible to attach a nylon filter made from women's tights to the fan housing.

A porous rubber seal and a nylon filter should protect the apartment from the penetration of small insects if they appear in the shaft.

To prevent vibration from the engine from being transmitted through the valve body to the wall, I installed the engine on rubber shock absorbers.

Recommendations for use

When operating the air pressure relief valve, follow the instructions in the manufacturer's user manual.

The valve must be kept clean and must not be exposed to dust, moisture or other contaminants. It is also unacceptable to paint the valve with a brush or spray gun. This can lead to contamination of the outlet pipe and failure of the device.

Periodically, at least once a month, the valve should be tested for maximum pressure. If for any reason the valve does not operate during testing, operation of the unit should be stopped until the problems are clarified and eliminated.

Such tests should also be carried out after any removal of the valve from the unit, even if the dismantling was not associated with its repair or replacement.

If you find an error, please select a piece of text and press Ctrl+Enter.

Source: stankiexpert.ru

Air valve for gas boiler

In domestic gas boilers, the air valve is designed to remove air from the heating system circuit. It is located in the area of the heat exchanger or circulation pump. Main parts of the gas boiler air valve:

- body with a float chamber;

- float;

- Exhaust valve;

- exhaust valve closing lever.

In different boiler models, air valves with a brass or polymer body of a collapsible or non-separable type are installed.

In our online store you can buy safety valves for gas boilers BAXI, PROTHERM, BERETTA and other models. We sell high-quality analogues of original spare parts at the best price on the Russian market with a guarantee and delivery to any region of the country. Before purchasing valves, you can consult with the experienced specialists of our store. Call +7(800) 301-55-31 and place your order!

Lada 2101 air suspension "Olive" › Logbook › Air suspension for dummies, part 2 Electrics

Greetings again, gentlemen, today we will continue our story about air suspension for dummies, namely about connecting the electrical part. But first, about some points that I missed in the previous post. No matter how hard I tried, I still missed a point related to the safety of our entire pneumatic system, namely the emergency valve. Emergency valve – valve for releasing excess pressure, i.e. when the pressure in the receiver rises above the permissible value, the valve is activated and bleeds air into the atmosphere, thereby reducing the pressure in the receiver, preventing excess pressure from rupturing the receiver or pneumatic lines.

This can happen due to a breakdown or jamming of the compressor pressure switch, i.e. the compressor will not turn off, but will pump air into the receiver until something cannot stand it, the receiver itself, the air line, the moisture separator or some other component of the system explodes, or the compressor itself simply burns out. Emergency valves can be adjustable - allowing you to adjust the response pressure, and non-adjustable - available with a certain response value. Installed directly into the receiver or from the receiver through a pneumatic line to a more aesthetically suitable location. Adjustment is very simple. Let's say the pressure switch (more on that a little later) is working properly and opens at 10 atm., we tighten the emergency valve adjusting screw and wait until the compressor pumps up the 10 atmospheres we need and turns off, now we slightly unscrew the emergency valve adjusting screw until the moment when it works, i.e. the moment came when the emergency valve itself triggered at 10 atm. and opened to relieve excess pressure. Then we tighten the valve adjusting screw again by one or two turns (depending on the type of emergency valve). The adjustment can be considered complete. We check, turn on the compressor again, and wait until it pumps up 10 atm and turns off, if the emergency valve is completely closed, no air hisses through it, the adjustment was made correctly. If the air still hisses, then press the emergency valve again a turn or two and check again, and so on until the moment when the emergency valve is closed when the pressure switch is triggered. What happens if the emergency valve is not configured correctly? If it is released too much, the compressor will work constantly because will not gain the required pressure into the receiver, and therefore the pressure switch will not work. If it is too tight, the actuation moment can be very high, some components may not withstand such pressure and fail.

A dehumidifier is a device for removing moisture from the air.

I think from the name it is clear what it is needed for. Moisture is separated from the air and accumulates in a special flask, from which it must be drained as it is filled. Moisture is the main enemy of valves and iron receivers, as it causes corrosion. It is mainly installed between the compressor and the receiver, although the most ideal option is to install two moisture separators, between the compressor and the receiver, as well as between the receiver and the valve block. When choosing a moisture separator, be sure to find out in the manual its maximum operating pressure; very often they are simply not designed for the pressure we need, and therefore the pressure causes the flask to accumulate moisture to explode. The next point when choosing is the flask itself; it is better to take a flask with a metal protective flask on top. Photo for example.

And finally, today we’ll talk about electrical connections, how the whole thing is connected and what we need for this. Everyone has their own way of connecting, I’ll tell you how I do it. Let's start with the components. Relay (regular 4-pin automotive relay).

Spare parts for piston air compressors

Home \ Spare parts \ For piston compressors

We have extensive experience in servicing compressor equipment, established spare parts supply channels and our own warehouse space. We will definitely help you find the spare parts you are interested in for piston compressors Fiac, Remeza, General Force, Comprag, Abac, Garage, Bezhetsk ASO and other well-known manufacturers.

I didn't find the part I needed

If you were unable to find the spare part you are interested in, then send a photo of the spare part and the compressor nameplate to us at [email protected] ‑compressor.ru, and we will definitely help you. You can also use WhatsApp or Viber number

+7, or leave your number and we will call you back!

Spare parts for Remeza (Aircast) piston compressors

A wide range of spare parts for Remeza (Aircast) piston compressors made in Belarus. Consumables and parts for piston blocks are available.

Spare parts for Bezhetsk piston compressors

Various spare parts for piston compressors of Bezhetsk ASO of Russian production. We have consumables and parts for piston blocks C415, C416, C412 and K24.

Spare parts for Fiac piston compressors

In our warehouse you will find spare parts for Fiac piston belt compressors. Filter elements, pistons, connecting rods, crankshafts and other parts of popular piston blocks.

Spare parts for Fiac coaxial compressors

Spare parts and consumables for Fiac direct drive piston compressors: pistons, gaskets, valve plates and other parts for household piston compressors.

Spare parts for Fubag piston compressors

Wide selection of spare parts for Fubag piston compressors. Valves, filters, piston groups, rings and other parts for piston blocks and compressors.

Spare parts for ABAC piston compressors

Here you will find sets of spare parts for ABAC piston compressors. Filter elements, repair kits, pistons, connecting rod groups, crankshafts and other compressor parts.

Spare parts for General Force piston compressors

Here you will find sets of spare parts for General Force piston compressors. Filter elements, repair kits, pistons, connecting rod groups, crankshafts and other compressor parts.

Air filters for piston compressors

Filters for piston compressors Abac, Fubag, Fiac, Remeza, General Force, Balma, Bezhetsky ASO and other models. Cartridges (replaceable elements) and assembled filters are available.

Piston blocks for compressors

In case of serious damage to the piston head, you will find replacement compressor blocks for the popular models Remeza, Abac, Fiac and Fubag.

Pulleys for piston air compressors

Pulleys for belt piston compressors Remeza, Fiac and other manufacturers. For ease of selection, the pulleys are sorted by diameter.

Impellers for air compressors

Cooling impellers (fans) for piston compressors Remeza, Fiac, ABAC and any other compressors with similar impeller dimensions.

Oil for piston compressors

High-quality and proven mineral oils for piston compressors in liter bottles or 20 liter canisters.

Check valves for air compressors

Large range of replacement check valves for piston compressors. The check valve gasket must be replaced every 1000 operating hours.

Pressure switch

Three-phase and single-phase pressure switches for piston air compressors. Chinese and German relays available.

Electric motors

Three-phase and single-phase electric motors for piston air compressors of Russian and foreign production.

Compressor fittings

Reducers and pressure regulators, lubricators and pressure gauges, check valves, fittings and other pipeline fittings for pneumatic networks and compressor equipment.

Capacitors

Capacitors for asynchronous electric motors of piston compressors. Starting and running capacitors with capacities from 25 µF to 300 µF are available.

Features of work

The check valve operates according to the following scheme:

- When compressed air enters the opening located on the valve, the spring is compressed. This causes the valve to open, which allows air to enter the pneumatic system.

- when the compressor unit turns off and the air pressure decreases, the spring returns to its normal state. As a result, the air system is blocked.

If the air pressure becomes higher than normal, the safety valve is activated and the pressure is restored. This allows you to avoid unexpected situations during compressor operation.