A metal shed today is practically a necessity in most summer cottages. In addition, such a structure serves as an indispensable place for the location of various premises on the construction site. In addition, it is easy to make a change house yourself, since it consists of blocks, which, in turn, are made of a frame, and metal plates. Of course, such a building will be difficult to use for a long stay, but it is an indispensable option for a summer residence.

Project of a modern metal shed with windows and air conditioning

Such a trailer can often be found at construction sites. Considering that most construction work can last much longer than one year, a small building for workers can temporarily replace housing.

In such cases, a metal change house may have the necessary minimum of amenities, which will allow you to relax a little after a hard day at work or even provide the opportunity to take a hot shower. Therefore, it is difficult to overestimate the need for such a structure on a site where there is clearly not enough space for certain needs. That is why there are many projects in which you can independently assemble and install such a structure.

Professional and amateur domestic buildings

Temporary amenity premises may have different names in different parts of the country. For example, beams, barracks, moving - all these are synonymous concepts. Professional builders build auxiliary cabins based on the standards GOST 22853-86, GOST 25957-83, GOST 23274-84, GOST 23345-84, as well as other State standards and SNiPs. The listed documents regulate technical conditions, terms and definitions, sanitary and technical parameters and design features of mobile (inventory) buildings.

And if standard construction cabins are mobile buildings of the container type or prefabricated type up to two floors, then the panel-type country cabin is made of wood. This is dictated by budget savings and the ability to use it for other purposes.

The practicality of a summer cottage is beyond doubt. After completing its task, it turns into a barn or moves to a new location. It is very wise to think through the functionality of a frame change house in advance and immediately lay down the possibility of future use.

Advantages and disadvantages of frame cabins

- Let's start with the pleasant cost of a frame change house. When compared with container and timber analogues, frame household premises made of wood are considered the most budget-friendly.

- The versatility of the design will appeal to the rational owner. It is better to immediately build a multifunctional building so that it will serve even after construction is completed.

- Installing the frame of the cabin will not cause any difficulties: you can build it alone or together, using a minimal set of tools.

- Dismantling, if necessary, is even faster and easier than assembly.

- Lightweight frame-panel structures when disassembled are easy to transport from place to place. But when assembled, the tree is fragile, so it requires special equipment for transportation.

about the disadvantages is that frame cabins made of wood are short-lived. They are poorly suited for permanent relocation, but they perfectly solve the problems of summer residents and amateur builders.

Types of cabins and frames

There are three types of frames for change houses:

The best quality option for a dacha cabin is considered to be a metal frame . It turns out that the wooden frame structure is built into a welded frame made of steel channels and corner posts. It is quite expensive, but strong and durable. Steel protects the wood from deformation and allows the structure to be transported in assembled form. For private construction with a small budget, a wooden-metal frame of a change house is not the most suitable option.

A classic wooden change house is good for everything except its transport potential when assembled. The frame made of 100x100 mm timber will definitely have to be disassembled for transportation, so it is better to leave it on the site as a utility room.

To do this, the country house is initially placed on a more solid foundation, equipped with internal and external decorative cladding, and additional amenities are thought out. Environmental friendliness, normal thermal insulation and low cost are the undoubted advantages of a frame cabin made of wood. And they also fit organically into the suburban landscape.

A portable cabin is the optimal choice for a construction business when temporary housing for workers needs to be transported from point to point. Mobile cabins are also made of metal and wood. The first ones are small construction trailers with a frame made of profiled pipe 40x60 with logs made of pipe 40x40.

If the frame of a portable cabin is made of wood, it must be thickened (the timber of the main beams is taken to be at least 100x150 mm). No special finishing is required inside or outside. The disadvantages of portable models are significant: heavy weight, expensive materials for walls (hydro-, thermal insulation, corrugated sheets on the outside, chipboard on the inside), a lot of welding work.

Step-by-step instructions: photo reports with explanations

It is difficult to understand some things from the description. No matter how much you read, you won’t understand until you do it, or at least watch how others do it. This is why photos of the construction of cabins are useful: you can look at how the units were made and find a solution for yourself. This is a kind of manual for those who decide to build on their own.

Construction of a wooden cabin

A cabin was built from wood at the dacha. Dimensions 3*6 m, insulated - for temporary residence during the construction of the house. The following materials were used:

- board 50*100 mm - 28 pcs;

- timber 100*150 mm - 5 pcs and 50*50 mm - 24 pcs;

- blocks 20*40*20 mm - 20 pcs;

- roof boards 25*150 mm - 10 pieces;

- tongue and groove floor board 30 mm thick - 21 pcs;

- lining class A 5 packs of 6 meters and 6 packs of 3 meters;

- roofing felt 4 rolls;

- polystyrene foam - 4 cubes;

- windows 90*90 cm - 2 pcs;

- doors;

- Senezh Ultra - 10 l;

- corners and plates to strengthen strapping connections;

- fasteners (nails, screws, finishing nails), polyurethane foam. This is what the materials on the site look like

Since prices for materials greatly depend on the region, there is no point in talking about the cost of construction. But from this list, you yourself can determine with fairly high accuracy how much a self-built shed will cost.

Please note that this list does not include roofing material (ondulin was planned) and there is no glass. Also, lining for interior decoration has not been purchased.

Before construction began, all wood, with the exception of the lining, was treated with Senezh Ultra antibacterial impregnation. Covered in two layers. So the quality of processing should be normal.

Wood processing

They marked out the area for the building. We decided to place the blocks on a sand bed. They dug holes 25-30 centimeters deep, poured sand, and compacted it. Blocks were placed. First we set up the two outermost ones, put a flat board on them, and a level on it. This is how the outer blocks were set up. Then the intermediate ones were adjusted to the height of the boards. So on all sides.

Setting up blocks

Next, the harness was laid. Beam 100*150, cut into half a tree. They folded it and secured it with pins for security.

This is how they cut half a tree. And this is how to lay a medium beam. After checking the corners and diagonals, we knocked them down with pins

The next step was to lay the floor joists. They were placed every 50 cm, and we will also install the racks every other one. They were made from a 50*100 mm board placed on a narrow part.

Floor joists installed

We decided to immediately assemble the racks with rafters on the ground, strengthen the connections with corners, and then install them ready-made. They were assembled from the same 50*100 mm board.

We knocked down the front post - it was longer, the back one and the rafters We hit it with nails, and screwed the plates with self-tapping screws. The posts were secured with temporary jibs

The posts were nailed down with long nails. Then, for reliability, all attachment points were reinforced with corners and plates. They were already mounted on self-tapping screws.

50*50 mm bars were nailed to the sides of the joists. The result was “nests” for laying polystyrene foam. It was placed on polyurethane foam: both hermetically and reliably. A floor board was nailed on top.

They nailed a block on both sides of the joists and laid polystyrene foam.

The floor was laid on top

Next, the sheathing stage began. First, we installed additional racks on the sides and reinforced them with jibs.

Additional racks and jibs give greater rigidity to the building

Now comes the actual plating. On the short side there was a lining made of packs of 3 meters, on the long side they nailed six-meter ones.

Beginning of plating

Having completed the sheathing halfway, we laid the sheathing under the roofing. A 25*150 mm board was nailed in increments of 30 cm, with increments of 20 cm at the edges (so that the overhang could withstand). Then we continued with the paneling.

In the places where the windows will be located, they installed mortgages - a board that lies across the counter. The window frame will rest on it. They were fastened with nails all the way through, but the joints were additionally reinforced with corners.

Installed mortgages in places where windows are supposed to be fastened

When the back and blank side walls were sewn up almost to the top, roofing felt was rolled out onto the roof. He will lie there until we buy ondulin.

Sheathing continues

The outer skin is almost ready. The doors were bought without finishing - only the frame covered with fiberboard

Start of door trim

While we were finishing nailing the clapboard on the outside, work was also in full swing inside - they were installing foam plastic. The width of the sheet is 100 cm, the distance between the posts is 95 cm. We have to cut thin strips.

We put foam between the posts

To prevent it from “falling”, we grab it on top with thin corners, which we attach, of course, only to the beam of the rack.

This is what a foam-lined room looks like from the inside

The corners at the top that hold the foam are visible

We started lining the inside, but the lining ran out. For now we have switched to painting the outside. It turned out well, it seems.

This is what a painted cabin looks like from the outside

We had to buy additional lining and finish the interior finishing.

The inside was also lined with clapboard

We started making the partition. It was assembled from the same boards - 50*150 mm. The joints are traditionally reinforced with corners. They covered it with clapboard.

Drains under the partition Lined on one side with clapboard

We started insulating the roof. They used the same foam and the same technology - they propped it up with corners.

Insulating the ceiling of a cabin

The joints with wall insulation were foamed with polyurethane foam.

The joint with the wall insulation is foamed

Then we started covering it with clapboard.

Start of covering the ceiling with clapboard Ceiling finishing

We started laying the roofing. We bought ondulin and laid it with overlap on one wave. They were attached to each wave with special hardware purchased along with ondulin.

Mounting ondulin on the roof of a garden shed

Then we started finishing up the interior. The partition was also insulated with polystyrene foam and lined with clapboard on the other side.

Almost sewn up partition Finishing the piece above the doorway This is how the partition looks in the final version

The inside of the lining is coated with water-based varnish. It only gives a slight tint to a slightly darker color. There seems to be no film on the wood. If you look directly, it generally seems that the tree is not covered with anything. Only when viewed from the side at a certain angle is the shine visible.

This is after painting

On the floor, the varnish is already with a film: so that the wood does not wear out. Covered in two layers.

Then we started finishing the overhangs. They were sewn up with the same clapboard. In general, working with the clapboard took the most time.

We are sealing the roof overhangs. The front is almost finished. Side view.

Metal frame for a change house

Metal was chosen as the basis as it is more reliable and durable. The thought that the change house might have to be moved also played a role. If the frame is made of metal, she will not be in any danger.

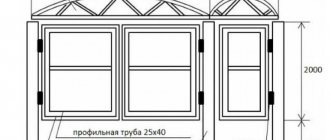

We are going to build something like this type of cabin

The dimensions were determined based on the length of the angle rods: 11.7 m. The following dimensions emerged: 2.8 * 5.8 m, height - 2.5 m. The frame was welded from an angle with a shelf 75 mm, thickness 6 mm.

The foundation is made on pillars cast independently: construction began in the fall, and there’s still nothing more to be done. So it was decided to fill in reinforced columns: six pieces. First, the area was marked, after which the locations for the foundation columns were determined.

Marking the area and the base for the posts

Holes were dug 50*50 cm, total depth about 30 cm. Crushed stone was poured onto the bottom in a layer of about 10-15 cm and compacted tightly. There is the same amount of sand on top, also with a tamper. As a result, the bedding came to the same level as the ground.

Roofing material is laid at the bottom so that moisture does not escape from the concrete, and it “ripes” normally and does not dry out. Next, the formwork was assembled and the reinforcement was laid in it.

This is what the formwork for the post and reinforcement looks like

The area is dry, the water drains normally, so there should be no problems. I just mastered welding, so it’s not clear whether the reinforcement is welded or twisted.

Before pouring concrete

Everything is filled with concrete, covered with film: the end of October, and in order for the concrete to be of normal strength, it needs to be wrapped.

The columns are wrapped up

The frame frame took a long time to cook - all winter: frosts, workload, did not allow us to operate with the required frequency. The base was made from a 75 mm corner, 6 mm thick, and 40*2 mm was used for reinforcement.

The beginning of the cabin frame from a metal corner - the bottom frame

The side parts were cooked entirely, then with the help of 4 people they were placed in a vertical position and fixed in this way. Profiled pipes 40*40*2 mm were used on the racks to which the window and door frames would be attached.

Frames are assembled lying down

The most inconvenient moment is measuring diagonals alone. You have to constantly monitor them, but doing it alone is inconvenient. But it is necessary to set everything, otherwise there will be a distortion.

To give greater rigidity, I welded strips of metal in the corners. I got them by loosening the corner (40 mm). It was possible to buy an additional strip, but I used cuttings of a corner.

Strips for rigidity in the corners of the frame View from inside the corner

It was difficult when we were installing the frames: in the cold we only wore thick gloves, and it was difficult to hold them firmly. That’s why they propped it up with boards and whatever they could. But the angle was strictly maintained.

The first circuit is exposed

To ensure a rigid attachment to the frame, metal plates are welded at an angle.

Having exposed the sides of the frame, they were rigidly connected using a metal angle

The entire frame was gradually assembled.

The sidewalls are raised and welded We weld the plates in the corners: at the top and bottom We weld several beams at the top. Now the frame for the change house is "iron" The frame from the metal corner for the change house is ready

Now all that remains is the casing. It can be anything: even the same lining, block house, or an economical option - plywood and OSB. To attach the bleach to the corner, it is more convenient to screw the beam, and then attach the sheathing and everything else to it. The same situation applies to the rafter system: a block is screwed around the perimeter with self-tapping screws and pre-aligned, and the rafters are attached to it.

Features of constructing a frame for a change house

The frame shed is based on a pair of rectangles made of timber with a cross-section of 100x100 mm or larger, connected by vertical posts. The lower rectangle is laid out from 150x100 mm timber. The overall dimensions of the frame are 6x3 m - the most optimal and versatile option in terms of weight, area and building materials.

Internal partitions will be needed if you plan to use the building as temporary housing. In this case, kitchen, toilet, storage areas and others are separated from the residential part.

It is necessary to strengthen the lower rectangle with a central longitudinal support beam. A second 100x100 beam is placed on top, as well as transverse floor joists in increments of 0.6 m from 100x50 timber. To ensure the correct slope of the roof, higher front vertical posts are installed, half a meter longer in height than the building. That is, if you expect to get a ceiling height of 2.5 meters, the front pillars will reach a level of 2.8 meters, and the rear ones - 2.3 meters.

Now regarding the installation of additional vertical racks :

- for each end of the frame shed there will be two elements made of 100x50 timber;

- on the front facade - four racks depending on the location of the door and window openings;

- on the rear - three, evenly spaced in 1.5 m increments.

Each vertical corner post requires diagonal bracing - from both sides to the top. For these purposes, a 100x40 board is used. The same braces, at least on one side, must be arranged for corner auxiliary posts that are not secured by future windows and doors. An alternative would be short braces to each post on both sides.

To install the rafters, the basis is the upper frontal beam of the frame, which rises 0.5 m above the lower one. For the rafters, a 100x50 beam is used, located evenly in increments of 0.6 m across the frame of the cabin. The rafters extend 30 cm on both sides beyond the perimeter of the frame. Additional fastening with transverse boards of the first and last rafters to the end upper beams will be required.

Layout and drawings

Despite the fact that the building is considered temporary, it often turns into a bathhouse or guest house. That’s why even in a change house there is such a thing as a layout. Even temporary housing should be relatively comfortable.

Cabin trailer

There are two main types of cabins: trailer and vest. In a “trailer” type building, the entrance is on the side, there is no separation inside; in extreme cases, they put a partition - 1.5-2 meters from the entrance. This room is used as a vestibule-dressing room and a warehouse for storing instruments. This is the simplest possible option.

Drawing of a trailer cabin with dimensions

Yandex.RTB RA-1479455-3

The drawings will contain graphic and digital symbols, their explanation is in the photo below.

Designation on drawings

Yandex.RTB RA-1479455-8

Baby vest

The most popular layout is the vest. This is when the entrance is in the middle. Moreover, the middle is fenced off and used as a vestibule, storage room, etc. The purpose of the other two rooms may be different. Some people use both as bedrooms, others use one as a kitchen.

Two rooms and a vestibule with a fenced-off small storage room

Only vestibule without storage room

Change house with toilet and shower

Not everyone agrees, even at a construction site or at a dacha, even temporarily, to lead a Spartan lifestyle. At least basic amenities are required. Although, it is probably better to build them separately.

Read how to build a toilet in your country house here.

The sanitary block is located on the edge - a wiser decision, especially if you make a separate entrance with a toilet

Having chosen a drawing, do not forget, when developing a frame for a change house, that racks must be installed at the junction of the walls. If doors are attached to the racks, they must be reinforced - double.

Construction of a change house at the dacha with your own hands

We offer step-by-step instructions on how to build a shed from scratch using frame technology with your own hands.

How to make a frame for a country house with your own hands

- Prepare a site on the land. Ideally, this should be a horizontal surface with solid soil. This will save time and money on excavation work.

- Before installing the foundation, carry out preparatory work. They include removing 30 cm of soil over the entire area of the future shed with removal of half a meter beyond the perimeter. Replace the removed soil with compacted sand, preferably laid on geotextiles.

- The choice of foundation is yours; it can be a cast concrete option for a steel support, cinder block or brick pillars, or concrete blocks. Lay the pillars to a depth of more than 30 cm; be guided by the cords, marked according to the drawing of the cabin frame and aligned horizontally. A typical foundation for a 6x3 cabin consists of 15 pillars every 1.5 meters (3 pieces in width, 5 in length).

- Construction work cannot be carried out on a fresh, damp foundation for a whole week.

- Saw the wood according to the drawing parameters, treat with hydrophobic and antiseptic compounds. Fire protection treatment is also desirable.

- Before installing the base of the cabin frame, supplement the pillars with 2-layer roofing material waterproofing. The base will consist of 150x100 timber: three longitudinal ones and a pair of transverse ones. Based on the drawing, lay the beams with the wide side down, then level them and secure them with reinforcement ties or anchors to the columns.

- Next will be the installation of the lower trim of the frame cabin. Strictly along the perimeter of the structure, a 100x100 beam is attached to the crown. There is no need for strapping on the middle beam. In the final stage of this stage, a 50 mm step appears along the entire inner edge.

- Install the logs on the floor correctly, that is, on 3 longitudinal beams of the base, edge down, with a pitch of 60 mm. The timber will fit into the 30mm slots in the bottom trim of the cabin frame. The logs are made from 100x50 timber.

- If desired, you can install an underground floor . This is done in order to extend the life of the cabin, as well as for additional insulation of the structure. Place construction waste in the gaps between the posts around the perimeter, and then fill the subfloor with expanded clay.

- Next, all that remains is to install and level the vertical corner posts (beam with a section of 100x100) using a level, organize the top trim and strengthen the frame of the cabin with vertical additional posts (they require a 100x50 beam).

Further stages of arranging a country house

After erecting the frame, perform the following types of work:

- limit windows and doors with horizontal bars 50x50mm;

- Replace the temporary rack braces with permanent ones (40x100mm boards will be needed);

- install rafters, sheathing and roofing material;

- lay the subfloor in a continuous flooring of 30x150 tongue and groove boards, complete with a waterproofing and vapor-proof membrane;

- insulate the space between the joists with mineral wool or expanded polystyrene, lay a polyethylene membrane on top;

- Lay the flooring from a 40x150 edged board across the joists;

- sheathe the outside frame of the cabin with vapor-proof material, cover it with clapboard or plywood panels;

- install doors and windows;

- carry out engineering communications;

- the ceiling and internal lining are covered with polyethylene and thermal insulation, then with sheet building materials in the form of plywood, chipboard, OSB or fiberboard;

- After the construction of the frame cabin, decorative work awaits you.

Video: frame assembly

Foundation for a cabin

Since the structure is temporary and light, the foundation is usually columns or blocks. More often - blocks. Preferably concrete, standard. No - you can use any construction materials, but they are high-density and not hollow.

Example of a column for a foundation for a cabin

They are placed on a prepared base. If the soils are normal, you can simply remove the turf and level the areas. For greater reliability, dig a small pit for each block about 20-25 cm deep. Medium-fraction crushed stone is poured into it and compacted well. Blocks are placed on such a substrate.

Note! The top edge must be level (in the same horizontal plane). It is also necessary to check the geometry of the foundation: the angles are strictly 90°, the diagonals are equal.

If the width of the cabin is no more than 2.5 m and wooden beams are used for the frame, blocks are placed in each corner, as well as under those places where the partitions extend. If the building is without partitions, the spacing - every 1.5-2 m - depends on the cross-section of the timber and the planned cladding, as well as the weight of the roofing material. With a width of 3 m or more, an intermediate beam and a base under it are required. In this case, three rows of blocks are obtained.

An example of a foundation for a three-meter wide country house

To prevent dampness from entering the premises, waterproofing is laid on the blocks. You can use two layers of roofing felt, or you can use another waterproofing material, even a film. Another option is to coat it with bitumen mastic. At this point the foundation can be considered ready.

What is a change house and its purpose

A change house is a small-sized, inexpensive and comfortable structure that is easily transported or moved. It can be made from different types of building materials. The main purpose of the change house is to store equipment and accommodate construction crews in it. In addition, it can be equipped as a production or office temporary structure.

Metal cabins with one room are designed to accommodate construction crews and store various equipment

Types of modern cabins

Depending on the material used, there are the following types of cabins:

- metal - the service life of such a design is at least 10 years. The metal change house has a strong frame, so it can be moved frequently;

The metal shed has standard dimensions that allow it to be transported on the platform of a crane.

Wooden cabins are more often used in summer cottages and country houses

Depending on its purpose, the change house can be used for the device:

- Wagon-house. This type of mobile structure is equipped with runners in winter, and wheels in summer. This car-house is intended for people working on a rotational basis or film crews. In addition, it can be used as an office, a room for drying work clothes or a recreation area.

A movable car-house on wheels can be attached to a tractor and towed to the desired location

Racks are placed inside the storage shed for convenient storage of goods.

The canteen can be used for catering at construction sites

Stationary office huts are installed on construction and retail sites, parking lots and other open areas

People can live in specially decorated cabins for a long time

Choosing a place to build a shed

When choosing a location for our house, we take into account a couple of important points.

Firstly, we think about whether we will transport the structure somewhere in the future. For example, you are going to build a lightweight house for a couple of seasons, and then remove it to another place. If moving is part of your plans, it is best to place the change house as close as possible to the exit from the site.

Secondly, we decide on the purpose of the room. If the shed will be used only as a shed for storing various tools and other household supplies, it is best to install it approximately in the center of the long side of the main house so that it can be easily reached from any side of the site.

Helpful advice! If you do not rule out that in the future the shed will be converted into a bathhouse, build it in a remote, secluded corner of the site, keeping in mind the fire safety rules.

Preparation for construction

In terms of technological processes, building a shed is not very difficult, since there is no need for special training, the use of rare and expensive tools, or extensive knowledge in the field of construction. But you should not hope that all stages of construction of the cabin structure will go smoothly and without problems, especially for novice craftsmen.

Project drawings for standard frame cabins

The most convenient size is a change house measuring 3 x 6 meters, since it is universal in weight, area, as well as the availability of building materials of a suitable size and price. However, for each individual case, its own layout is designed, which is based on a standard frame layout with the addition of the necessary partitions and openings. If the structure is temporary or you need to divide the room into certain zones (kitchen, bathroom, warehouse, etc.), then the internal partitions must be indicated in the drawing.

The traditional configuration of a 3 x 6 meter cabin design implies the presence of the following premises: a central room 4.5 x 3 meters with amenities and heating, a corridor that prevents the entry of cold air, a bathroom and a storage room with dimensions of 1.5 x 1.5 meters. The roof is made from corrugated sheets, regardless of the model of the cabin.

Photo gallery: various layouts of cabins

Selection of material for the frame and foundation base

On the modern market you can find a huge amount of building materials for building a shed: panels, plastic, metal, wood slabs, and so on. Therefore, when choosing them, it is worth taking into account the technical properties and design configuration.

The main part of the cabin is the frame. For its construction you can use:

- A metal profile that is connected by welding. This profile is durable and resistant to various mechanical damage. Change houses with a metal frame are used for frequent moves.

The welded metal frame has sufficient strength for repeated transportation of the cabin

The wooden frame of the cabin is usually insulated with one or two layers of mineral wool, which is protected by a waterproofing film

Metal parts of the cabin frame must be painted with powder enamel

It is better to make the foundation of the cabin from brick pillars, cinder block supports or concrete blocks. Under heavy metal frames, a cast concrete foundation is made.

For the external cladding of the cabin, it is better to choose galvanized steel sheets. They are quite durable and very convenient to use. You can also use wooden paneling.

Wood-based cabins cost much less than wooden structures, but they can emit various chemicals that have a negative impact on human health. You should not chase after cheap materials for construction and subsequent cladding, as you risk wasting your money. When choosing a building material for constructing a shed, proceed primarily from your individual preferences, standards of durability, practicality, ease of design and its reliability.

Material calculation and necessary tools

When calculating the cost of a 6x3 meter wooden cabin, you must take into account the cost of materials, as well as how much their delivery will cost. To erect a temporary structure of the above dimensions, you need to purchase the following materials:

- geotextiles - 30 m2;

- anchors - 9 pcs.;

- sand - from 3 to 6 cubes;

- expanded clay - up to 3 cubes;

- material for pillars or ready-made foundation blocks;

- insulation - 8 m 3 or plates - 81 m 2;

- timber 150x100 mm - 18 linear. m or 0.27 cubic meters;

- beam 100x100 mm - 47 linear. m or 0.47 cubic meters;

- lining - 22 linear m;

- edged board 40x150 mm - 0.72 cubes;

- tongue and groove board 30x150 mm - 0.54 cubic meters;

- OSB - 63 m2;

- board 40x100 mm - 40 m or 0.16 cube;

- timber 50x100 mm - 95 meters or 0.47 cubic meters;

- sheathing beam 50x500 - 50 m or 0.125 cubic meters;

- polyethylene - 81 m2;

- waterproofing membrane - 81 m2;

- corrugated sheeting - 21 m2;

- metal corners for fastening;

- self-tapping screws for the roof - 180 pcs.;

- self-tapping screws 70 or 80 mm - as needed;

- nails 150 mm;

- windows, as well as internal and external doors - in accordance with the drawing.

- various types of partitions;

- decorative finishing;

- technical and engineering systems.

The final calculation of building materials should be made only according to the drawing.

You will need the following tools for work:

- bow saw with a sharp blade;

- shovels - bayonet and shovel;

- sherhebel;

Sherhebel is a special plane for the primary processing of unplaned wood.

Cabin layout

Today there are quite a lot of traditional layouts of cabins. They differ in the location of windows, the configuration of rooms and other characteristics. However, the main types of layouts are:

- Construction of 2 rooms. One is a work room, the other is a hallway. There is a door opposite the hallway and one window.

- Construction of 3 rooms. The peculiarity of such a change house is the separation of two hallway rooms. Each room has one window. Such cabins are called vests.

- Change house from room and hallway. In this case, the hallway will be larger than the room. The length of the hallway is equal to the width of the entire structure.

- The simplest option is a one-room cabin with one window.

- A cabin without windows.

There are other layouts of cabins. They differ in the area of the premises, the location of windows and doors. However, traditionally such structures do not provide more than 3 rooms, since the total area of the cabins is very limited.

Self-assembly of a cabin according to the drawing

The easiest way is to make a wooden structure using frame construction technology.

The difference between a frame change house and an ordinary small frame house will be the lack of a foundation and its size.

The role of a columnar foundation can be performed by placed bricks.

Frame of a cabin made of timber with a pitched roof

First of all we will make the floor panel. It will consist of chipboard or OSB-3 panels, boards, between which we place insulation and waterproofing.

You can save money on a vapor barrier, since this room is not intended for permanent residence.

Instead of expensive synthetic insulation (mineral wool), you can use sawdust. Instead of waterproofing - a regular film.

When the floor is ready, we proceed to the walls. We make the frame of the cabin from timber or boards 100x150.

The easiest way is to make a wall separately on the ground, in this case it is much easier to check the geometry, the evenness of the corners and diagonals.

When the wall frame is ready, we install it and check the verticality again. The angle between the wall and the floor should be exactly 90 degrees.

Scheme of the frame of a cabin made of timber

We install all 4 walls one by one according to the drawings. The finished frame of the change house must be connected into one structure using the upper frame. We perform the strapping with a board or timber.

For it to be level, the walls must be the same height. If some wall is lower, we place a wooden chip, block or part of the board under the lining board.

After installing all the walls, we begin to make the roof. The roof can be gable or single-pitch, for which we attach several boards or beams to the top of one of the walls.

Thus, by raising one of the walls, we form a roof slope.

Approximate view of a wooden frame for a change house

If you plan to use the change house only in the summer, the roof can be made flat without slope.

Tip: Use foam sheets along with mineral wool. They will serve not only as insulation, but also as complete wind protection.

The roof must be insulated with foam sheets or mineral wool. For waterproofing we use cheaper roofing felt.

Roofing material for a change house can be as follows:

- slate

- ondulin

- tiles

- metal

If the building will be used for overnight accommodation in winter, it is recommended to install a stove with a chimney. Instead of a stove, you can use a potbelly stove.

A change house with a window and a pitched, almost flat roof

Equip the building with a simplified drainage system mounted on bars.

Exterior finishing can be done with lining, followed by painting with an antiseptic, or siding.

Step-by-step instructions for making a change house

In order to build a change house, it is necessary to carry out the following types of work:

- Site preparation. The shed must be placed on a horizontal surface. The soil must be hard, otherwise heavy excavation work cannot be avoided.

To place the change house, it is necessary to prepare a flat area on which drainage bedding will be laid

To protect the foundation base from groundwater, it is covered with a layer of sand and thoroughly compacted

The wooden beam is sawn according to specifications and treated with an antiseptic

The lower frame frame is laid on the foundation pillars through a double layer of waterproofing

Floor joists are laid in 60 cm increments

The vertical posts are plumb and temporarily secured with struts until they are connected by the upper frame

The front side of the frame is made higher than the back side to ensure the required roof slope

The rafters are laid on the beams of the upper frame and form the frame of the future roof

The sheathing connects the structure of the rafter joists and serves as the basis for the roofing material

Subfloor boards are nailed to the bottom of the floor joists

It is necessary to leave a ventilation gap between the insulation and the waterproofing film to remove moisture

The finishing material is pressed onto a layer of vapor-proof membrane

The insulation material is placed into the prepared frame with little effort and stays there without additional fastening

Video: do-it-yourself summer house

Interior decoration of the cabin

A mobile temporary structure performs a wide variety of functions. And this is achieved thanks to the interior decoration. It is this that makes the cabin suitable for temporary or permanent residence of people. At the moment, the following types of materials are mainly used for finishing the structure:

- Laminated chipboard is an attractive material that has a dense laminated surface that is resistant to negative temperatures. In addition, laminated board has different colors, textures and textures. Change houses made from laminated chipboard are practical and quite durable, but more expensive.

Laminated chipboard is one of the best materials for interior decoration of a cabin

Lining for interior decoration is most often used when it is necessary to build a change house with a beautiful and inexpensive interior

How to make a change house with your own hands? Drawings, list of building materials

When there is serious construction ahead, you need to temporarily live somewhere, relax, store some things - in a word, you need to set up a temporary home. For this purpose, a small house is built - a change house, in some cases temporary, but it is more reasonable to provide for its use in the future, for example, as a guest house, a small garage, a summer kitchen, a place to store equipment and household items. The structure can become a decoration for your site.

Such a small house can be made with your own hands. Let's consider several options. There are three main options: wood, metal profiles and a finished trailer. The dimensions of the cabin are usually 5-6 m in length and 2.5-3 m in width. But everyone decides for themselves, taking into account plans for the further use of the building.

Frame change house made of wooden beams

A wooden change house is the most common option; it is usually chosen when you plan to use the structure in the future as a guest house, a bathroom or a summer kitchen.

For such a change house you will need timber with a thickness of 70-90 mm. The box is placed on a concrete foundation, supports, piles. The structure can be insulated if you plan to use it in winter, or left without insulation and used from May to October.

The most common option today is to sheathe the outside of structures with OSB boards. This material is similar in characteristics to plywood, but is distinguished by high sound and heat insulation. Compared to plywood, OSB boards are less durable, but it is their use in frame structures that makes it possible to obtain an excellent combination of strength and security. The inside of a frame house is most often covered with plywood.

The process of constructing a frame shed from OSB can be seen in the video, and under the video the author has posted an estimate and materials, which will help you navigate.

Change house from a construction trailer

Don’t want to bother with assembling the frame and other related activities? You can buy a ready-made trailer and equip it for a cabin. Such trailers do not even need their own foundation - you just need to carefully level the site and install the container (trailer).

If you equip a used trailer as a cabin, carefully examine its condition. Clean off traces of rust, replace heavily damaged cladding elements with similar ones, weld patches onto the through holes, coat the metal with a special primer and paint.

The installed structure must be insulated. The rest of the arrangement is at the discretion of the owner. These points will be discussed separately below.

You can also buy a trailer on wheels. The option is mobile and very easy to use. After completing all the measures for arranging such a trailer, it is installed on the frame of the trailer.

Step-by-step instruction

To build a change house with your own hands, you need to choose a place, take into account fire safety rules, if in the future the change house will be used as a Russian bath or shower.

After the location is chosen, they prepare the construction site. It is necessary to clear the area of bushes, weeds and debris. Next, we describe one of the most popular options for building a cabin.

The area where construction is planned must be leveled and a plastic film prepared, which must be at least a meter larger than the planned structure on all sides. This is necessary to protect the base from moisture.

Next we install the foundation. To do this, you will need concrete blocks or brick supports up to 200 mm.

We remove a layer of earth and turf along the perimeter, carefully compact it, cover it with film, fill it with sand and crushed stone screenings.

After this, you can install the supports. For a standard cabin size, 12 columns are used: three rows of four each. They must be leveled in height and covered with sheets of roofing material, securing the sheets with mastic insulation.

Timber boxes are installed on the bases.

The next step is installation of the frame. Usually, to create a supporting structure, they take wooden beams with a cross-section of 90 mm or more and align each rack strictly vertically, using temporary side struts for this: they are attached directly to the frame using auxiliary steel corners, which are sold in construction markets. The heads of the racks are cut to the same level.

When the frame is ready, doors and windows are installed.

Precise markings are made on the racks in advance to simplify this process.

The installation can be considered complete after laying the thermal insulation - its edges are tucked under the window frames.

Next, the roof is made. This is usually a single-slope structure. Its implementation involves securing a number of vertical posts, the front sides of which should protrude by 400 mm and be higher than the supports of the rear side of the frame. The rafters should rest on a frame of two parallel bars. The rafters are covered with lathing, film insulation and a layer of thermal insulation material made of mineral wool, sheathed with plywood, after which the roofing material of your choice is laid.

Now you can install the floor. The floor can be made of boards or slabs. The flooring material is laid on a surface covered with vapor barrier tiles. Plywood boards, linoleum, laminate - this is your choice and depends on the further use of the building.

After this they do the exterior finishing. For it they use:

- Insulation made of mineral wool or polystyrene foam.

- Scotch tape for joining joints.

- Windproof membrane.

- OSB boards.

- Corrugated sheeting or wood on top of OSB for improvement.

We are building a wooden cabin

Let's start building the frame of our cabin. First, we lay a wooden beam around the perimeter of the future structure, as well as in its center to further strengthen the structure.

We connect the opposite sides of the beam. To do this, we fasten the logs to the beam of the lower trim. You can connect in any suitable way. Connections using the tongue-and-groove method, using metal corners and anchors, have proven themselves well. We made preliminary selections to connect the elements and additionally strengthened the fastening points with nails.

We install vertical corner and intermediate posts. We install intermediate supports in meter increments. To do this, we use timber with a cross section of 15x15 mm. Don't forget to leave an opening for the door. To securely connect the frame elements, we use metal corners and self-tapping screws. At the same stage, we install support pillars for the future porch, if its presence is provided for by the design of the cabin.

Important! The height of the vertical supports on the rear and front sides of the cabin should differ by approximately 50 cm. Such a difference will ensure an optimal slope of the roof and precipitation will not linger on it.

We mount the beam of the upper trim. The support posts of our cabins have different heights, so we work as follows: first we lay the timber on the tops of the higher supports, then we connect the low posts and install the side crossbars perpendicular to them. We make connections using the already familiar method with samples and nails.

As a result, our frame will be divided into a number of rectangular sections. To strengthen the structure, we connect the opposite lower and upper corners of each such section with jibs made of boards.

We attach the rafter beams to the top roof sheathing. We use the boards that are as even as possible to make lathing easier in the future. We install the rafters in increments of about 500-600 mm. We pay special attention to the strength of connections on roof beams.

We construct the roof so that it protrudes slightly beyond the boundaries of the frame. This will allow us to arrange a base for drainage on the back side of the cabin, and mount a canopy on the front part.

We choose the material for the finishing roofing at our discretion. For example, ondulin is good. We lay it with an overlap, starting from the bottom of the slope. Before laying ondulin, you should lay out a continuous sheathing of boards and attach a waterproofing film on top of them. Instead of ondulin, you can use slate or other material of your choice.

Prices for various types of timber

timber

Construction materials

For a wooden change house you will need a board and timber to install the frame.

To create the base you will need a 10x5 cm beam for strapping beams or racks. To insulate the rack - timber up to 15 cm.

For rafters and joists you will need a 50x100 mm edged board. For lintels - timber with a section of 50x50 mm. For sheathing under the roof, boards of 25x100 mm are used.

OSB is used as sheathing, and insulation is used under the sheathing.

You will also need mineral wool for insulation and a wind barrier for protection from the outside. Exterior finishing is often done with corrugated board, clapboard or block house. Inside they use plastic panels or other options to taste. For the roof, you can choose ondulin, slate, corrugated board and other materials.

The amount of materials depends on the construction scheme.

Shelter scheme

We offer a standard 6x3 shed layout for DIY construction.

A typical frame diagram would be something like this:

The internal arrangement can be organized according to the following standard scheme:

A typical cabin consists of 3 rooms:

- room 3x4.5 with heating and amenities,

- a 1.5x1.5 room is used as a corridor and serves as a temperature gateway,

- another room 1.5x1.5 is used for a storage room and toilet.

Much depends on the purpose for which the change house is used: each case requires its own project, but most often it will not differ much from the one proposed - only additional openings and partitions will be added.