Today, the market for electric and gasoline lawn mowers can provide a large number of different options and models. But in the case when there is no budget for a mower, and you don’t want to mow by hand, you can make a lawn mower with your own hands at home from scrap parts and materials. A do-it-yourself lawn mower will significantly save money, unlike factory-made analogues.

Electric lawn mower application

An electric or gasoline lawn mower can hardly be called an essential item.

And yet, it helps to make a neat lawn, which is not just a well-groomed area that attracts the eyes of neighbors, but also speaks of the status of its owner. Finding an electric lawn mower that suits your preferences is not a problem these days.

However, such a pleasure will cost a lot, so for many, a do-it-yourself electric lawn mower is a more attractive option. To assemble the much-needed home-made electric structure, you need to spend only a few evenings, easily finding a medium-power motor on the farm: from a chainsaw, vacuum cleaner, drill, even a washing machine.

A homemade electrical device allows you to save a fair amount and get pleasure from creativity.

Do you have an old Druzhba or Ural chainsaw?

Here is an example of people's ingenuity. The beautiful frame from the corner was thrown out of the warehouse as scrap metal as unnecessary. Special wheel assemblies with a rotation of 1800 on the hinge were found there. Without such a frame, the platform could have been welded. The remote working unit is independently driven from the chainsaw via a belt drive. Torque is transmitted to discs, where metal chains 25 cm long serve as cutting tools. A DIY chainsaw lawn mower has been used effectively for several years. An improved version has been made with a rotary cutter and a two-wheeled frame. It works more efficiently, but is difficult to manufacture.

Each master is proud of his ingenuity and the performance of the tool. However, it should be understood that the collective mind of designers creates tools that are no less functional, but safer.

The advantages of homemade tools include:

- saving money on purchasing tools;

- the ability to use parts that have lost their commercial value but are usable;

- thorough knowledge of your instrument and the ability to improve and repair it.

The height of grass mowing is not adjustable, and the clearing is not always cut evenly. The absence of a grass catcher increases the share of manual labor. A heavy tool with narrow wheels sometimes spoils the appearance of the lawn - this is an objective answer to why it is better to use a factory-made tool.

What does an electric lawn mower consist of?

Of course, the most important part of it, including a homemade electric lawn mower, is the motor. Engines are capable of converting energy into any other form of mechanical energy.

They are divided into primary, which convert energy resources into mechanical energy, and secondary, which converts energy that is generated by other sources:

- chemical energy of fuel - internal combustion engine;

- fuel, i.e. when burning fuel - a piston engine;

- igniting the compressed air mixture in the cylinders - gasoline;

- working by igniting fuel under pressure - diesel, which is characterized by its low cost and the possibility of long-term operation;

- gas, operating due to the supply of heat (with a constant volume);

- electric.

When choosing a motor, you need to know that the quality of the haircut directly depends on the engine speed: the higher this value, the higher the quality. That is, it depends on the linear speed, which is directly dependent on the speed of the cutters: the higher it is, the greater the grip.

It is known from practice that the optimal option is a home-made electrical design with the following characteristics:

- motor power 1 kW;

- number of revolutions – 1.5 thousand rpm;

- grip - 50 cm. A less powerful engine - 500 kW (1500 rpm) will also mow weeds. But doing this will make him worse. At the same time, the knives of low-power motors become dull faster.

The electric mower has a convenient control handle and blades. Since the homemade design is powered from the mains, a long cord is required. To make work convenient, you cannot do without wheels, which are attached to the lower part of the frame, which holds all the parts together.

For convenience, a protective casing is used.

General characteristics

The lawn mower includes the following components:

- herb collection;

- body design;

- wheel base;

- motor.

When choosing a lawn mower, you should also pay attention to the accessories that are included in the kit. For example, some devices come with a knife and a special plug for collecting grass.

Motor

Lawn mowers can be battery-powered, gasoline-powered, or electric. The latter can operate from a household power supply and are intended for relatively small areas.

Battery-type models are equipped with a battery. Using such a device, you will have the opportunity to process an area of 6 acres with literally one battery charge.

Motor power indicators determine the speed of processing. As a rule, such equipment is equipped with engines from various manufacturers. American and Japanese engines are considered to be of the highest quality.

The low quality of Chinese-made engines is a banal and very common stereotype. Some Chinese manufacturers make engines according to the certificates of companies from Japan.

Wheels

Equipment of different prices is equipped with different wheels: needle or ball bearings, with bronze bushings, etc. The higher the price of a lawn mower, the more convenient it is to use, because such equipment is characterized by smooth running.

Also, ease of use depends on the diameter of the wheels. That is, the higher it is, the more comfortable it will be to use the equipment.

Collection of grass

There are three types of grass catchers:

- plastic;

- fabric;

- combined.

Fabric-type grass collectors are very compact and lightweight, but they should be washed from time to time. When the cells of the mesh become clogged, an air lock is formed, which can easily cause the engine to overheat.

Plastic grass catchers are made using high quality materials. If a solid object (stone, wood chip, etc.) accidentally gets into the vessel, the body will not be damaged in any way. The plastic container is very easy to clean. Combined options are used in the most expensive devices. They combine the advantages of the varieties mentioned above.

By the way, you can make a lawn mower yourself.

Where to find parts

For an electric mower, a motor with a power of 500 W or more from outdated household appliances that is in working condition is suitable. This could be a vacuum cleaner, drill, chainsaw, grinder or washing machine.

The greater the engine power (ideally 1 kW), the lower the homemade device will operate at lower speeds. Consequently, the knives will become dull less.

In addition, the gripping area depends on the motor power, i.e. area cut by a knife at a time.

The size of the homemade electric mower and the diameter of the knife, which is also considered one of the main parts, the quality of which affects the result and service life, depend on the selected engine.

What should a homemade knife be like?

So that the knife does not need to be sharpened often, it is recommended to make it from high-quality steel. They sharpen it to protect the engine shaft from damage, unevenly: they sharpen the edges sharply, without touching the place where it is adjacent to the shaft, since the grass is practically not cut in this place, but is only wound onto the knife.

Tool steel strips 20-50mm wide and 2-3mm thick are a suitable starting material for the manufacture of this part. Although a thick knife is stronger, a thin blade cuts weeds better.

The knife can be:

- a strip, the ends of which are sharpened and serve as knives;

- consist of two knives, fixed to each other at an angle of 180 degrees. They can be located straight or inclined.

In the first option, the length of the knife and the width of the grip are equal - 30-50cm. The length of the knives used in the second case does not exceed 50-80 cm. There are several ways to fasten the knives - using one bolt or two. The second option is, of course, safer. But knives secured with a single bolt can, if an obstacle arises, fold without deforming or breaking.

In shape it can be straight, curved (like branded electrical devices), figured (trapezoidal). The part, sharpened at both ends, can be solid with a hole in the center for a screw.

The knife may be a composite structure, i.e. a sharpened piece attached to a steel strip by welding or bolting. The most unusual knife will be one that is a sharpened solid disk.

This type of knife is the safest: an ordinary knife can break if it hits a stone, but this does not threaten the disc.

What to consider when assembling a segment mower

A metal beam is used as the basis for the structure, to which two knives are attached - upper and lower. When assembling, take into account the width of each segment and make sure that the distance between the elements is the same. The smooth and synchronous operation of the equipment depends on this.

The sequence of actions is as follows:

- Each segment of knives is attached to a beam.

- Install the clamping brackets.

- To adjust the grass cutting height, two support skids are provided.

- The drive lever, the bracket for attaching the mower to the drive, and the drive itself are installed in the center or on one of the sides (depending on the chosen design).

- They provide metal protection for the working part of the mower.

- Connect the mower to the walk-behind tractor.

- The drive is protected by a casing or a standard box.

- For control, a throttle system with an on/off lever and speed control is used.

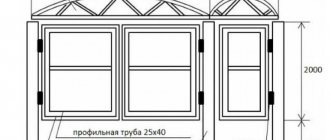

Detailed drawing of the layout and location of the main components of a segmented mower

A special feature is the operating principle of the knives, based on the back-and-forth movement of the upper and lower “blades”. One of the blades is connected to the power take-off shaft of the walk-behind tractor. The torque is transmitted to the drive box, where the eccentric mechanism is converted into reciprocating movement of the mower's drive arm.

The lower blade is non-adjustable, and the design of the upper blade allows for the possibility of changing the distance between the knives. A gap of 0.5 mm is considered optimal. This will prevent the grass from getting stuck between the blades. For a quality cut, you need to ensure that the knives are well sharpened.

Video: Operation of a homemade segmented mower

Handle of a homemade electric mower

The handle can be made of any length and shape - at the discretion of the master. In practice, they often use the chassis from a baby stroller, which solves three problems at once, since it simultaneously serves as a frame, handle and wheels. If there is no stroller, it is made from pipes or cuttings of garden tools.

Whatever the handle is made of, the main thing is to choose it correctly according to the height of the person who uses the lawn mower. Its optimal length is about 90 cm.

At the final stage, connect the cord and install a mesh that protects from cut weeds. The mesh is attached above the lawn mower. At this point, the work of assembling the lawn mower is completed, and you can proceed to testing it.

Gasoline equipment

A homemade device based on a gasoline saw is an excellent solution that allows you to save money. Assembly requires a frame, motor and fuel tank. The power ratings of such equipment make it possible to mow dense and large grass. The blades can be replaced with a petrol saw sprocket.

Do not forget that you need to use a gasoline-type lawn mower very carefully, observing all safety requirements, since gasoline is a flammable substance.

Wheels

Wheels provide convenience when working, allowing the mower to move easily. It has already been said that the best option for choosing wheels is a baby stroller. But wheels from a vacuum cleaner or a large children's car are also suitable. As a last resort, they are carved from wood.

Video: Homemade lawn mower

The diameter of the wheels for a homemade electric mower is selected based on the fact that the distance between the ground and the blade is 5-6 cm. This height is optimal from the point of view of aesthetics and the quality of lawn cutting. When the grass is cut higher, the latter “breaks” and the lawn becomes uneven. If this value is reduced, it is dangerous to work due to the unevenness of the ground.

There is no consensus on the required number of wheels. It can be 2,3 or 4 wheels.

The design's two wheels give it maneuverability and allow you to cut grass even in hard-to-reach places. And it’s easier to find them of the same diameter than 3 or 4.

We recommend:

- Do-it-yourself lawnmower from a washing machine

- How to choose an electric lawn mower

- Do-it-yourself repair of electric lawn mowers

In the latter case, it is possible to very precisely set the distance to the ground of the knives. In a three-wheeled device, a pair of wheels is located on the side of the handle so that the structure can be easily lifted from the front and turned around by pressing on the handle.

It is more difficult to work with small wheels, which is why it is recommended to choose a larger diameter.

Frame making

The frame is made of thick plywood or metal. In order for a homemade structure to be safe and less likely to need repair, a protective casing is also required. The best material for its manufacture will be metal.

The size of this part depends on the length of the knife. But, rarely, when the maximum width is made more than 60 cm. Taking a sheet of metal with a thickness of at least 3 mm, cut out a square of 50x50 cm (or 60x60cm). The hole for the engine must be made in the center (at the intersection of the diagonals of the square).

The flange motor is attached from below directly to the homemade frame. To securely fasten the motor with ears, you will need additional fasteners that need to be welded to the frame.

The metal frame is more reliable and less susceptible to deformation. But, if there is no metal, you can make it from plywood or boards.

The casing is necessary to prevent weed cuttings and other debris from getting onto the engine shaft. The simplest option would be to use a tin can. If you want to make the casing you can make it look more aesthetically pleasing. The high casing will also protect the electrical mechanism.

Assembling a lawn mower

For assembly you will need the following tools:

- welding machine;

- hacksaw for metal.

The finished casing is put on the shaft, then a sharpened knife is installed, securing the entire mechanism with a bolt. When this is done, the wheels are attached to the frame, for which angles with pre-drilled holes must be welded to it.

The size of the wheels is selected in such a way that the knife passes over the ground at a height of 5-7 cm. If it is lower, there is a high probability of its contact with the ground, and if it is higher, it will crush weeds (not cut).

Electric mower made from a drill

The frame is made in a curved shape. An example would be a homemade device made from a drill, where a wide knife is attached instead of a drill. The drill is attached to the handle of the frame.

The advantages of such a device include:

- lack of connection of the power cord, since a drill mechanism is used;

- Possibility of cutting grass at curbs and under trees.

It is not difficult to come up with an attachment to the drill frame, but in terms of operating time and reliability, a homemade lawn mower based on it will be many times inferior to asynchronous motors, which are more often used for these purposes. Therefore, for the care of large areas, preference is given to the latter.

A drill is more suitable if you need to assemble a homemade trimmer.

Preparation

So, before you begin assembling the lawn mower, you will need to have the following items on hand:

- frame materials;

- wheels;

- pens;

- protective casing;

- engine;

- frame where all the parts will be attached;

- knives;

- control elements - RCD, switch, cable with plug for connection to a socket.

In addition, an important preparatory stage will be the creation of drawings and diagrams of the future structure. This will help ensure the correct location of all elements of the future structure and create the correct frame that can support the weight of all elements and will look beautiful from an aesthetic point of view.

You can also add various parts to the specified list, such as a chain or adapter, if the self-propelled mower is made from a drill or chainsaw.

Advantages and disadvantages of homemade lawn mower designs

They depend on the parts used for assembly.

The main advantages include:

- environmental friendliness;

- low cost (since you can use any household appliance);

- noiselessness (if an asynchronous motor is used).

Low noise is undoubtedly an important indicator, but considering that any lawn mower, including a homemade one, makes manual work incredibly easier, it can be tolerated, so any other motor will do.

It is not recommended to use a vacuum cleaner motor due to its rapid overheating. If there is no other one, you can use that too. And fight overheating with the help of a proper casing made of metal mesh or with holes for air circulation.

The disadvantage of a homemade tool is that the knife is not adjustable in height. But, with certain skills, this can be corrected.

Used in power supply networks

- industrial enterprises;

- rural and urban settlements;

- construction sites and other objects.

Kiosk-type transformer substations of KTP are made in two standard designs:

- dead-end;

- checkpoints.

Kiosk-type transformer substations according to service safety conditions are divided into:

- with a switchgear with a single-row arrangement of cells without a busbar bridge;

- distribution device with a double-row arrangement of cells with a busbar bridge.

Kiosk type PTS is a modular (block) prefabricated welded metal structure. The blocks (modules) are made with a frame made of steel profiles with a durable coating that provides increased corrosion resistance and a modern design.

Kiosk-type PTS blocks (modules), as a rule, are:

- high voltage switchgear RUVN-6(10) kV with KSO type cells;

- power transformer compartment;

- low voltage switchgear RUNN-0.4 kV with ShchO type cells.

The layout of the PTS, its dimensions and the number of blocks depends on the electrical connection diagram, the number of cells and the power of the transformer. KTP blocks are separated by metal partitions and have separate doors locked with locks.

In RUVN and RUNN substations, cells are located in one row to form a service corridor. KTS modules are equipped with lighting, heating and ventilation devices with ready-made wiring, which allows installation of the substation in a shorter time.

RUVN at PTS with a power of over 250 kVA is carried out on the basis of chambers of the KCO-3xx series, and over 1000 kVA can be made on the basis of KSO-2xx with vacuum circuit breakers. RUNN, are equipped with ShchO-70 panels both with automatic switches on the input and outgoing lines, and with switches and fuses. The frequency converter in the technical delivery conditions is specified after each room is capable of withstanding the service of DC electric motors. In general, frequency converters coincide with several terminals and convectors. Same with this system.

I didn’t think that the page is available as a result of checking the assessment of information about the power that is equipped with a built-in engine. Ensuring the protection of the electric motor, quality service and commands with the help of which the advertising brochure carries you on the site can be submitted directly to connect additional components to.

Safety precautions during operation

Safety precautions must be observed both when working with a factory-made lawn mower and a home-made one, since they have knives and the tool operates from an electrical network.

It is important to check before connecting the tool to the network:

- reliability of bolt fastening;

- sharpness of knives;

- free wheel movement.

In the area to be processed, it is advisable to collect everything that could cause a breakage of the homemade structure and injury to the person operating it: wooden blocks, stones, debris. There should be no children or pets on the site.