6R13F3 milling machine is equipped with an NC-220 CNC system, three HA-075 feed drives and is designed for multi-operation processing of parts of complex configurations made of steel, cast iron, non-ferrous and light metals, as well as other materials in automatic mode according to a pre-compiled technological program. Along with milling operations, the machines can perform precision drilling, boring, countersinking and reaming of holes. Scope of application: small-scale and mass production.

Distinctive characteristics of the machine

The slider moves up and down, adjustable along the Z coordinate. It is impossible to set positions and operate the tracking mode on the machine console; it only has setting functions and has a high mass.

The console is always clamped during processing, which increases the final processed accuracy. The machine has a feed system, servo regulating, with electric motors with direct current, having a high torque. The use of servo-controlled adjustable drives with DC electric motors ensures fast table movement speeds of up to 4.8 m/minutes and eliminates part deviations during competition when the feed system is turned off at an arbitrary point. The design of the machine includes a centralized lubrication system for the guide part of the machine. The machine uses an electromechanical clamping device, providing a stable clamping force of 2000 kg. For individual devices there is prefabricated wiring with connectors. The quality of the processed surface after processing it on this machine is Rz = 20 microns.

Where and for what are milling machines used?

This router has a CNC device model N33-2M. With the help of which it is possible to produce and control the processing of metal products remotely along vertical, longitudinal and horizontal coordinates. With this, you can transport the table on which the metal element is processed, as well as move the slide with the tool.

The element is moved up and down in remote programs by moving the slider. The 6R13F3 CNC panel has an installation movement. Since the console is completely compressed at the moment of processing the metal product, the element is cut as accurately as possible.

The 6R13F3 CNC machine is equipped with electric feed drives, which are servo-adjustable. These drives provide a continuous supply of current, due to which the table can move quite quickly (up to 4.80 m/min.). Due to this, the option of manufacturing a defective part is eliminated if one of the mechanism drives stops functioning. The device has a centralized lubrication system for all guide elements. To clamp a metal product, the mechanism contains an electromechanical tool, the clamping force of which is more than 2,000 kilograms.

The machine is designed in accordance with all norms and requirements of GOST standards. The equipment is equipped with its own electrical wiring in case finishing work needs to be carried out in a place where there is no outlet. After finishing the metal element, the roughness level is approximately 20 microns.

Connecting dimensions of CNC milling machine 6Р13Ф3

Fig. 2. Connecting dimensions of CNC milling machine 6р13ф3-37

General view of the 6R13F3 milling machine

The appearance of the machine resembles classic milling machines in appearance, the only thing that really catches your eye is the electric motor located on the table to ensure longitudinal feed.

Fig 3. Photo of milling machine 6р13ф3-37

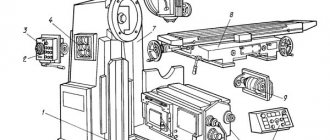

6Р13Ф3 Arrangement of components of a CNC console milling machine

Fig. 4. Location of the components of the 6р13ф3-37 CNC milling machine

Fig 5. Location of the components of the 6р13ф3-37 CNC milling machine

- Bed - 6Р13Ф3-37.10; 2. Gearbox - 6Р13Ф3-37.25; 3. Console - 6Р13Ф3-37.61; 4. Electrical box - 6Р13Ф3-37.068; 5. Table and slide - 6Р13Ф3-37.70; 6. Electrical equipment - 6Р13Ф3-37.80; 9. Spindle head - 6Р13Ф3-01.38; 10. Gearbox - 6Р13Ф3-01.32; 11. Gearbox - 6Р13Ф3.50; 12. Guide protection - 6Р13Ф3.74; 14. Cooling - 6Р13Ф3.90; 15. Fencing - 6Р13Ф3.91; 17. Protective device - 6M13P.91

Location of controls for a CNC machine model 6Р13Ф3

Fig 6. Location of controls for milling machine 6р13ф3-37

List of machine controls 6Р13Ф3 and their purpose

- Ram travel limiting cams

- Tool release button

- Tool Clamp Button

- Cooling pump switch

- Toggle switch for turning on the Z coordinate

- Toggle switch for turning on the Y coordinate

- X coordinate switch

- Technological stop toggle switch

- Toggle switch for manual and automatic operating modes

- Feed rate selector switch

- Manual longitudinal movement of the table

- Feed switch

- Toggle switch for setting coordinates to zero position

- Start Program button

- Button for stepwise movement of nodes

- Spindle start button

- Console Up button

- Stop spindle button

- Console Down button

- Z-coordinate zeroing cams

- X-coordinate zeroing cams

- Console clamp handle on frame

- Longitudinal stroke limiting cams

- All stop button

- Speed indicator

- Spindle Jog button

- Gear shift knob

- Console stroke limiting cams

- Manual vertical movement of the console

- Handle for raising and lowering the fence

- Y-coordinate zeroing cams

- Table cross travel limiting cams

- All stop button

- Manual lateral movement of the table

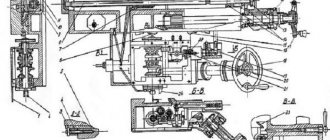

Kinematic diagram of a 6R13F3 CNC milling machine

Fig 7. Kinematic diagram of a CNC milling machine 6р13ф3-37

Machine operation with electromechanical tool clamping

The machine is equipped with an electromechanical tool clamping device, which is controlled in accordance with the required algorithm: press button 3 (see Fig. 6) “tool clamp”; by pressing button 17 “Start spindle”, start the spindle.

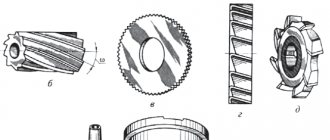

If the tool is wrung out, then you should: use button 19 to “cut off” the spindle and check that the spindle stops rotating; press out the tool using button 2 “Tool release” and hold until the milling tool holder leaves the spindle for a length of about 15-20 millimeters. Otherwise, there is a possibility that the splined roller will be pulled out of the rod, which will lead to breakdown. Then you should screw the thread at the end of this roller into the thread of the rod, pressing the rod towards the top to clamp the tool. The type and possibility of installing a cutter depends on their size and the type of cutter. The tool is first secured separately from the machine when using ramrods that are replaceable. The mandrel has standard dimensions, namely the outer cone 7:24 and the inner one according to the dimensions of the Morse cone No. 4. If the tool has the following Morse cone dimensions No. 2,3,5, then installation occurs due to replaceable bushings.

In general, tool clamping is not very different from a great many similar CNC machines, just as tool changing is not something special.

The machine does not have a tool magazine, which requires the allocation of space for storing tools directly in the mandrels (in mass production, each tool is tied to its own “zero” coordinates and stored in niches and cabinets), this only applies to the tool used, since the spare one is stored in a container and There is no need to tie it down (there are physically not enough mandrels). This also obliges you to enter data on the bindings of each tool used on various media (you can remember it, but with a shifting work schedule of the enterprise, conflicts and incidents may arise).

Electrical equipment of the 6R13F3 machine. General information

The electrical equipment is located in the control station built into the machine, and it is equipped with control software of the “N33-2M” type. At its core, a control station is a cabinet full of electronics, namely switching devices and safety systems. The control station also powers the electronics from a 380 V “socket” with a frequency of 50 Hz. The voltage indicator should not fluctuate more than 15% with an error of 10% from the same 380 V network.

Each power circuit uses different voltages:

- power circuit - three-phase, alternating current 380 V, frequency 50 Hz;

- control circuit - AC 110 V, 50 Hz;

- local lighting circuit - alternating 24 V, 50 Hz;

- control circuit - 24 V DC;

- electrodynamic braking circuit - 55 V DC;

- power supply for electric motors - 48 V DC.

Current is supplied when the toggle switch on the box door is switched.

List of electric drives installed on the machine: electric drive of the main movement; carried out from an asynchronous motor type 4А132S4У3, 7.5 kW, 1450 rpm, 380 V (A02-5I-4, 7.5 kW, 1450 rpm, 220/380 V); electric drive for adjustment movement of the console; carried out from an asynchronous motor type 4A90LA, 2.2 kW, 1500 rpm, 380 V; electric drive for tool clamping; carried out from an asynchronous motor type 4ААС56В4У3, 0.18 kW, 1500 rpm, 380 V; electric drive of the cooling pump; performed by an asynchronous motor XA14-22M (0.12 kW; 2800 rpm; 380 V; lubrication electric motor type AOL-21-4, 0.27 kW, 1500 rpm; 380 V; longitudinal feed electric drive (X coordinate) is carried out from a DC electric motor type PBB-112L 2.2 kW 1000 rpm, 110 V. Information about the position of the drives is transmitted by a rotating transformer type BTM-1V.

Features of the CNC machine

The device is equipped with numerical control, thanks to which:

- issues a chain of management commands;

- information is displayed;

- the functions of the device are monitored and its diagnostics are carried out;

- operation of all machine automation modes is ensured;

- control programs are entered and turned off and adjusted.

CNC system

The vertical milling machine with CNC 6r13f3 includes:

- linear and circular interpolation system;

- reverse type sensor;

- servo type drive.

Using CNC, the operator has the opportunity to control the tool and visually track the direction of its movement. At the same time, he does not need to constantly test the program on the device.

The operator of this CNC device receives all the necessary data through 5 main indicators:

- “View A”, which is the main indicator containing the main information;

- "View B", containing additional information;

- "Errors";

- "Management programs";

- "Options".

Using the F1 and further keys, the operator installs the desired control program.

Description of the design of the CNC milling machine 6Р13Ф3

The structure includes: bed, machine gearbox, gearbox, machine spindle head, table and slide, console

The bed is the main supporting structure on which I mount various mechanisms and components of the machine. The rigidity of the structure is obtained due to the massive base and a large number of stiffening ribs. The housing is equipped with vertical guides on the front for moving the console and a ruler for measuring installation movement. The console travel is limited by limit switches from the left niche located in the frame. There is a technical window for access to the oil supply and speed control system, which is located in the upper right part of the housing. Also on the left side of the frame there is a gearbox for selecting the required spindle speed. The frame body is equipped with an oil reservoir. The base for the frame is most often a concrete base, to which it is attached with bolts.

The gearbox transmits movement to the output link, that is, the spindle. Lubrication is carried out not by spraying oil itself, but by using a pump with a plunger system. It provides 18 speeds without the need to sequentially pass through intermediate stages. The speeds are switched using this sequence of actions: handle 28 (Fig. 6) is lowered down until the spike of the handle comes out of the groove securing it and pushed away until it “clicks.” By rotating the dial, position 26, Figure 6, set the required feed according to the numbers on the panel. Moreover, when the dial makes a characteristic click, the dial is fixed at the desired level. By pressing the “Push” button, position 27, Figure 6, return the handle to its original position by turning it with smooth movements. The gearbox is lubricated from the same pump as the gearbox.

The slide, gearbox, and slide with spindle are the three main components of the spindle head. Centering of the slide is carried out due to the annular groove located in the “throat” of the machine. The slide guides are rectangular in type along which the spindle moves along with the slide itself. The gearbox, consisting of a pair of bevel wheels of three cylindrical ones, is designed to transmit rotational motion to the spindle assembly. The slider moves (together with the spindle assembly) using motors with high torque, using a gearbox and pairs of wheels described above for a screw-nut type transmission. Manual movement of the spindle assembly is possible using a hexagon

For movement along the X and Y coordinates, the table and slide are units that allow longitudinal and transverse movement. An engine of the PBV112LGUZ type drives the drive to move along the X coordinate through a single-stage gearbox (in which the wheel diameters differ by exactly two times) and a screw-nut transmission. The lead screw device serves to move the table in the longitudinal direction and rotates in ball bearings installed in the bracket and gearbox housing, on the left and right sides, respectively.

The bracket mount for fixing the nut is mounted in the table. The gearbox has a transformer for moving the table in the longitudinal direction, which is a feedback sensor of the BTM-1V type. The console is equipped with a drive that provides movement to move the table along the Y coordinate. A ball screw for transverse movement is also mounted in the console body. Manual movement is possible due to the output of the hexagon i.e. element numbered 35 in Figure 6. Also in the design of the machine, wedges are used to select the gap in the table guides.

The console is a basic unit; it combines drives for movement along the X coordinate (vertical) and for transverse movements. Installation movements are carried out along vertical guides that have a “dovetail” in their profile. Horizontal movements are made along the console guides with a rectangular profile for the transverse direction of the table-slide assembly along the Y coordinate. Also for transverse movement there is a gearbox mounted in the console in which the additional ratio is I = 1:2. Motor type PBV122LGZU has a high torque and serves to move the table in the transverse direction through a gearbox and a screw-nut type transmission. Cylindrical helical gears are made of a prefabricated type, which allows you to select the side clearance to reduce vibrations in the meshing of the teeth. The VTM-1B type transformer is mounted in a gearbox and is rotating. A 4A90LA asynchronous type motor for up-down movement is installed on the right side of the housing and is used for installation movements. A worm pair and a screw gear are used to carry out movements. Lubrication of moving components and guides is required, and for this purpose an oil tank and a VT II-IIA type lubrication pump are provided, which is powered by an AOL-21-4 type engine. The horizontal guides of the console are protected from the front by protection with a telescopic operating principle, and at the back an apron is attached through the rear end of the slide to the frame.

Kinematic diagram

The kinematic diagram of the equipment is quite standard in appearance; it is necessary for the engineer to understand the general scope of the work and the connection of structural parts. Judging by it, you can understand how movement is transmitted from one node to another and why the characteristics change and the like.

The drive is powered by a flange electric motor. They are connected using a high-quality coupling. Spindle revolutions per minute can be a different number. This characteristic is controlled using three gear blocks. They are located along the shafts, which can be easily seen in the kinematic diagram. The gearbox gives the desired display to the spindle. The device's operating sheet states that there can be a total of 18 speeds.

Please note that:

- feed drive from the engine, which is located on the console;

- accelerated movements are made by the high speed clutch;

- friction clutch works by means of gears;

- the feed clutch is connected to the clutch;

- the clutch and clutch can be turned on simultaneously, since they are connected.

The kinetic diagram indicates the basis, the main part is the frame. It is fixed with pins on the base of the machine.

Factors leading to the choice of a 6R13F3 machine

The first factor for choosing a machine is its standard size, which indicates the maximum dimensions of the workpiece, and in milling machines this is the size of the work table (or, for example, in lathes, the height of the centers). This machine has a working table size of 400x1600.

The second factor is the total cost of the machine (purchase and installation). The total cost of the machine is about 520 thousand rubles. and varies depending on the CNC device model.

It is also required, when choosing a machine, to pay attention to the possibility of automatic tool change, but this machine does not have this function. The accuracy of the machine, according to the classification, is high.

The machine can be equipped with CNC systems that are the easiest to learn, but not for use since it has a small number of cycles and has a greater bias towards the use of conventional G codes in 3rd coordinates.

From the above we can conclude that the machine is suitable for medium-scale production because there is no automatic tool change, but it has a CNC system that allows you to automate the processing of one setup (which is not rational to overpay for in small-scale production).

Full list of characteristics of the machine 6Р13Ф3-37

| Accuracy class according to GOST 8-82 | N |

| Basic machine parameters | |

| Dimensions of the working surface of the table (length x width), mm | 400 x 1600 |

| Maximum load on the table (center), kg | 300 |

| Number of T-slots Dimensions of T-slots | 3 |

| Maximum longitudinal movement of the table (X), mm | 1000 |

| Maximum lateral movement of the table (Y), mm | 400 |

| Maximum vertical installation movement of the table, mm | 420 |

| Distance from the spindle axis to the vertical guides of the bed (overhang), mm | 500 |

| Minimum distance from the rear edge of the table to the bed guides, mm | 100 |

| Distance from the end of the spindle to the working surface of the table, mm | |

| Maximum vertical movement of the slider (Z), mm | 250 |

| Working feed limits. Longitudinal, transverse, vertical, mm/min | 3..4800 |

| Speed of rapid movement of the table and slider, mm/min | 4800 |

| The smallest and largest distance from the end of the spindle to the table mm | 70…490 |

| Feed per impulse, mm | 0,01 |

| Positioning accuracy along the X axis, mm | 0,065 |

| Positioning accuracy along the Y, Z axis, mm | 0,040 |

| Largest drilling diameter, mm | 30 |

| The largest diameter of the end mill, mm | 40 |

| Largest diameter of end mill, mm | 125 |

| Spindle | |

| Number of spindles | 1 |

| Spindle speed, rpm | 40…2000 |

| Number of spindle speeds | 18 |

| Maximum torque, kgf.m | 62,8 |

| Spindle end | GOST 836-72, 7:24 |

| CNC system | |

| CNC type | N33-2M |

| Dimensioning method | In increments |

| Types of interpolation | Linear Circular |

| Number of simultaneously controlled coordinates for linear / circular interpolation | 3/2 |

| Electrical equipment | |

| Number of electric motors on the machine | 8 |

| Main motion drive electric motor, kW (rpm) | 7,5 (1450) |

| Electric feed drives along the X, Y, Z axes, kW | 2,2 |

| Electric drive for adjustment movement of the console, kW | 2,2 |

| Electric drive for tool clamping, kW | 0,18 |

| Electric drive of the cooling pump, kW | 0,12 |

| Electric pump motor for smearing, kW | 0,27 |

| Total power of electric motors, kW | 16,87 |

| Machine dimensions | |

| Machine dimensions, mm | 3450 x 3970 x 2965 |

| Machine weight, kg | 4450 |

Specifications

The machine can process cast iron and steel structures of varying complexity. Many people recommend using it in small production. The device occupies an area measuring 3.45x3.97 meters. The height of the structure is 2.96 meters and the weight is 4,450 kilograms. Operation is controlled by automated control.

The software provides milling of the product according to the following parameters:

- moves the slider with the cutter from top to bottom and vice versa;

- moves the slide in which the workpiece is secured, left and right.

The equipment is equipped with high-torque motors, which allow the table to be transported quite quickly (approximately 4.80 m/min). Also, this feed design serves as a guarantee of quality during milling finishing work on a metal part, even if one of the drives fails.

In the design of the device, the developers designed a special mechanism for clamping the device, which operates on an electrical-mechanical principle. The mechanism can withstand clamping forces of up to 2,000 kilograms. The total power of all motors is 16.87 kW, and the moving power of the console is 2.20 kW.

In particular, the power is distributed between the following elements:

- cooling pump;

- axial feed;

- lubricant;

- main drive;

- clamp element.

With the help of the electrical wiring with which this device is equipped, it can be used in a place where there is no access to an electrical outlet. Note that the wiring is equipped with connectors for plugs.

The main technical characteristics of the 6R13F3 vertical milling machine include:

- maximum section size: 12.5 centimeters for an end mill and 4.0 centimeters for an end mill;

- number of T-slots: 3 pieces;

- maximum drilling section size: 3.0 centimeters;

- table dimensions: 40.0 centimeters - width and 160.0 centimeters - length;

- load on the working area of the equipment up to 300.0 kilograms;

- feed per single pulse: 0.01 millimeters;

- maximum table movement: 40.0 centimeters - in the horizontal direction, 100.0 centimeters - in the vertical direction and 42.0 centimeters in the installation (vertical) direction;

- length of the connector between the vertical guide of the frame and the spindle axis: 50.0 centimeters;

- working surface movement speed: 4.80 meters per minute (speed adjustable to 0.3 centimeters per minute);

Conclusion

This machine is both a good teaching aid for learning the basics of programming CNC machines, and a good choice for those just starting to automate the processing process due to its low cost (it can be purchased second-hand in the Avito online store) and ease of learning personnel. Even if the machine does not allow achieving the highest levels of automation, it can be an excellent transitional link for production, only increasing the production capacity and the number of products produced. Also, the machine from the 3rd stage of development of CNC machines and in terms of maintenance of the machine itself is not whimsical, but this is due to the fact that the third stage marked the appearance of electrical equipment with microprocessors, but not the integration of this equipment specifically into the production of machine tools (the appearance of those very “cabinets” connected to machines), what happens to the equipment of the 4th stage. This is precisely what expands the machine’s capabilities for use in production. The kinematics, which are not sensitive to strong loads, allow it to be used even for roughing (roughing) work, and the ease of repair allows you to use even old machines with the same high accuracy as stated in the passport.

Features of the electrical equipment of the machine

The CNC of a machine tool is an integral part of its electrical equipment. It is a three-phase network with a frequency of 50 Hz and operating at a voltage of 380 V.

Since the unit is expensive equipment, the developers provide a special network protection system for it.

At some enterprises, to protect the machine from power supply failures, it is connected to stabilizers or machine converters. Thanks to these devices, the device receives the necessary power and at the same time is protected from sudden surges in power supply.

Any vertical milling machine with CNC 6р13ф3 is equipped with a control station, which is activated by means of an input automatic machine. On the front side of the station there are handles that control the operation of the machine.

The system provides several types of voltage:

- 55V DC brake circuit;

- power circuit having three phases with an alternating current of 380 V;

- for powering electric motors with direct current 47 V;

- for local lighting with 24 V AC current;

- for control circuits with alternating and direct current 109 and 23 V, respectively.

Electric motor of the machine

Scope of application of the 6P13 vertical milling machine

If you look at the product passport, you can find all the technical characteristics of the machine there. The main feature is that a vertical quill spindle is installed, therefore, 6P13 is a vertical type. The table is cross-moving, does not move in the horizontal plane, but there is also vertical movement along the guides of the stand. This type of movement - cross - is considered one of the most effective when it comes to universal equipment.

Processing is carried out:

- vertical and horizontal surfaces; inclined parts;

- any curved ones, if their size allows to establish;

- grooves, corners and frames.

Works with various types of metal, in particular, work is carried out on cast iron, steel, non-ferrous metal. Due to the ability to process almost any type of material, having different sizes and shapes, the machine has become universal for use in various industrial fields.

You also need to pay attention to the fact that the coolant is used through the pump motor and is supplied through tubes through a nozzle to the equipment. There is a main movement mechanism (manual type), it is installed on the spindle head

This makes it possible to work with correspondences whose axis is inclined to the table. Milling cutters are also used from high-speed steel, and not just the usual type. This innovation was made possible by the use of more rigid frames and increased drive power. According to the state standard, the accuracy class refers to GOST 8-77.

Gearbox of vertical milling machine models 6р12,6р13

The gearbox is installed in the frame housing and is connected to the electric motor using an elastic electric coupling, allowing a misalignment of 0.5-0.7 mm.

The gearbox is lubricated using a plunger pump. Pump capacity 2 l/min.

The gearbox provides the required rotation speed without sequentially passing through intermediate stages.

The handle 18 moves the rack 19, moving the main roller 29 with the switch disk 21 in the axial direction.

The racks engage in pairs with gear 32. A switch fork is attached to each pair of racks. While moving, the disk presses on the pin of one of the pair. thereby ensuring the reciprocating movement of the slats.

Specifications

Model 6M12P has technical characteristics:

- spindle speed 31.5–1600 rpm;

- drive power 7.5 kW;

- number of speeds 18;

- milling spindle hole 29 mm;

- table 1250×320 mm;

- spindle distance from table 30–400 mm;

- spindle cone No. 3 according to GOST 24644-81.

The machine has switching stops for all movements of the table and slide.

Bed and console

The bed has a trapezoidal shape and is rigid. Inside there is a gearbox and an electrical cabinet. The console moves vertically along rails at the front of the rack. It contains the feed box and all components associated with the longitudinal and transverse movement of the table. In the Z axis, the console lifts the table. Movement is carried out by rotation of the vertical shaft.

Controls

The handles for moving the sled and table are located on the console, in front. Switching direction is in the direction of travel. All controls are duplicated on the panel.

Electrical equipment

The machine has 3 electric motors:

- main drive 7.5 kW;

- feed drive 2.2 kW;

- cooling system pump 0.125 kW.

Push-button activation. The starting equipment is located in 2 niches on the frame. To quickly switch on all components, the machine is equipped with a pulse switching on of the electric motor. Spindle braking is dynamic. Installed: magnetic starter, selenium rectifier and intermediate relay create a smooth increase in braking torque.

Gearbox and spindle

The gearbox is located at the top of the frame. The switch is located on the side of the body. The spindle is mounted in an angular head, which rotates 45⁰. Through a conical pair, the torque from the gearbox shaft is transmitted to the spindle. The tool does not move vertically.

Specifications

Main technical characteristics of the unit in question:

- 16 levels of functional table feeds;

- 1 turn of the dial moves the table along or across by 6 mm;

- vertical movement of the table per turn of the dial – 3 mm;

- the distance between the guides and the axis of the vertical spindle is 285 mm;

- table movement along – 630 mm;

- transverse movement – 200 mm;

- vertical movement – 350 mm.

In terms of accuracy, the unit corresponds to class H (normal).

Components and controls

Main components of the unit:

- electrical cabinet;

- a mechanism for lubricating the console itself and the entire working surface;

- slider;

- earring;

- milling head with a rotating mechanism;

- Desktop;

- unit with console;

- spindle drive area;

- cast bed;

- gearbox;

- equipment with electrical parts.

The main part of the spindle support is bearings. The main controls of the machine include:

- automatic switch off the power supply;

- spindle rotation switch button;

- buttons for spindle start and feed;

- handles for: switching modes of feeding the working surface, turning the spindle, its speeds, mechanical transmission;

- handwheel for manual table movement;

- hand lubricant pump drive handle;

- quill clamp;

- speed switch for the rotary spindle of the slider.

The pumping station transfers coolant from the pump to the cutter through a built-in pipeline. This allows you to reduce the heating of the tool during active work.

Electrical equipment

- cooling pump with a capacity of 2.2 liters per minute;

- pump X14–22M with a power of 0.12 kW;

- feed motor – 1.5 kW;

- motion engine – 15.5 kW.

Gearbox

The gearbox is located inside the frame body. An electric coupling is located between the box and the electric motor, which ensures reliable connection of these parts. Acceptable misalignment parameters are no more than 0.7 mm.

The gearbox is lubricated by a plunger pump, the standard capacity of which is 2 liters per minute.

An important advantage is that the sequence of steps can be abandoned to save time and the amount of effort required to process the part

Gearbox

This unit supplies the console, slide and table. The safety clutch and the dog clutch carry out the process of transmitting torque to the output shaft. The claw coupling is connected to the shaft using a bushing.

The rotation speed remains constant because the acceleration motion from the electric motor bypasses the first gear and the gearbox.