- What is an I-beam?

- Production of steel beams Hot rolled

- Automatic welding

- With parallel shelves

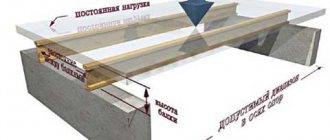

When constructing road, industrial, public and other large facilities, reliable reinforcement is required. To ensure increased strength, steel I-beams are used in supporting structures. They can easily handle heavy loads.

What is an I-beam

One of the most popular types of shaped metal products is the I-beam, for the manufacture of which simple carbon or low-alloy steel is used. Externally, the product looks like a long metal profile with a specific symmetrical cross-section - a neck and two parallel shelves, reminiscent of the letter “H” laid on its side.

This shape gives the structure additional rigidity and stability, allowing you to achieve the necessary load distribution. I-beams are several times superior to angles and square profiles in these parameters. All parameters of the manufactured beams are described in the state standard GOST R 57837-2017.

About beam production

Metallurgical plants produce I-beams in a large assortment. According to the manufacturing method, metal structures are divided into two large groups: hot-rolled and welded. Each of them has its own advantages and disadvantages.

Hot rolled production

The production process is carried out in accordance with GOST on rail and beam rolling mills. It consists of deformation of a steel rectangular profile (bloom), heated to a temperature of 1100-12000C. Using compression by drive rollers, the workpiece is given the required shape.

Advantages of hot rolled beams:

- solidity;

- simple manufacturing process;

- strength and rigidity indicators are higher than those of welded beams.

The disadvantages of such products are considered to be a not entirely smooth surface, remnants of roller marks and scale on the surface. The equipment is designed for certain rental sizes and does not have the ability to quickly adapt to a special order.

Automatic welding

This method is used by small metalworking plants with small-scale production. Sheet steel is cut into blanks. Next, the edges are processed on a milling machine. The elements are assembled using tacks and welded on a welding machine using flux. Checked using ultrasound. Welding production of I-beams has its advantages:

- In addition to standard products according to GOST, it is possible to make individual beams according to customer drawings.

- It is possible to produce a product with reinforced thick sections according to special projects.

- It is possible to produce bimetallic I-beams with elements made from different grades of steel.

Welded beams have a more marketable appearance. They are free of scale and rust after being shot blasted. The metal consumption of welded structures is lower than hot-rolled ones, which means their price is also lower.

Classification of steel I-beams

In addition to the differences between I-beams according to the production method, they are classified according to other criteria:

- In shape - with inclined edges of the internal shelves (from 6 to 12%) and with parallel edges. The areas of application of both types are different.

- According to the size ratio - normal (B), narrow flange (U), medium flange (D), wide flange (W), support-column (K).

- By length – measured length, unmeasured length, multiple of measured length.

Metal structures with inclined internal edges can only be manufactured using the hot-rolled method. They are divided into:

- O - ordinary, tilt angle according to GOST 8239-89 from 6 to 12%;

- M – monorails for overhead tracks with an angle of no more than 12%;

- C – special with an inclination angle of up to 16%.

I-beams with inclined edges can be produced with normal accuracy (B) and increased accuracy (B).

Types of beam floors

Different types of beams are used for different buildings and parts of it. The most commonly used elements are wood, metal, concrete and reinforced concrete.

By material

Let's take a closer look at what floor beams can be based on materials.

Wooden

Such beams are used mainly in private construction when constructing a house from timber, logs or frame houses. Wood is an environmentally friendly material, inexpensive, and lightweight, so it is easier to install such parts yourself.

But there are certain restrictions on the use of wooden elements - this is the span length. For interfloor spaces, the maximum span length is 5 m, and for attic spaces no more than 6 m.

More information about wooden beams here.

Metal

These beam floors are thinner, more reliable, and their service life is longer than wooden ones, but despite this they are used less often. This is because they are heavier and have lower heat and sound insulation values . With the help of metal elements it is possible to make spans longer than 6 m; metal does not burn, does not rot or mold, and is more durable.

But iron parts have a high price and heavy weight, which requires the use of technology. Metal is rarely used in private construction, but it is popular in the construction of multi-apartment buildings.

More detailed information about metal beams in this article.

Concrete and reinforced concrete

Reinforced concrete floor elements are economically beneficial for the construction of multi-storey buildings and other large structures. Such beams allow spans above 7 m and are high-strength. The only disadvantage of such structures is the use of heavy equipment in the form of a crane.

This article on our website talks in detail about reinforced concrete and concrete beams.

By type of construction

There are 4 structural types.

Farms

Increasingly, wooden trusses are used in construction, which are made using MiTek technology developed by Canadian specialists. These are lightweight, quickly assembled and reliable structures. They look like two parallel beams, fastened together by braces using iron toothed plates.

Trusses are beam elements manufactured in industrial conditions . For their production, coniferous wood of classes C-22 and C24 is used. There is no need to make holes in these elements; they have a lattice structure, which allows pipes to be passed through the trusses.

With the help of wooden trusses you can cover spans up to 8 m long and higher. They do not curl or dry out.

You can learn more about floor trusses from this article.

Crossbars

This is a supporting structure that is installed horizontally and serves as the basis for a frame that is assembled from beams. There are crossbars :

- reinforced concrete;

- iron;

- wooden.

The scope of application of a crossbar is wider than that of a conventional beam; it is sometimes installed on a foundation. Using this element, you can fasten parts of the structure without relying on the base, connecting them together. The literal translation of the crossbar is rectifier, i.e. a part that helps straighten and strengthen the structure.

I-beam

This is a profile (metal or wood) whose cross-section resembles the letter H, which makes it stronger and more rigid than square beams.

I-beams are often used for:

- bridge construction;

- when installing floors;

- for reinforcing mine shafts.

The scope of their application depends on its length, height, width, radius of curvature of the flow and radius of the internal curvature.

Full information about I-beams is here.

Twin

To enhance the load-bearing capacity of the structure, double beams are used. For example, two wooden beams 50 mm wide, fastened together, can withstand a greater load than one beam 100 mm thick. Double elements “do not play” and become stronger and more rigid, which is why they are often used for large spans.

By role in the design

Beams are divided by type of construction:

- The supporting structures are horizontal beams fixed parallel to one another. They are designed to support the floors of the upper floors. Support elements often span a room from one wall to another. As a rule, they are left open, mounted under ceilings and covered with wood panels. The support beams are supported by wooden blocks placed between them.

- Load-bearing beams are a tetrahedral log element that acts as a support for ceilings, floors and flat roofs. Such structures are called lags. The load-bearing elements are made of wood; they have a rectangular cross-section, where the width is 50-160 mm, height 140-240 mm. Load-bearing parts are laid at a distance of 0.6 m to 1 m. The size of the section depends on the planned load.

- Secondary beams are solid members that rest on the main beams and exterior walls.

Marking features

The designation of a metal structure is based on the cross-sectional shape and the ratio of geometric dimensions. The main size of the I-beam is the distance between the outer edges of the shelves, i.e. his high.

Let's look at a few examples.

With parallel shelves

In accordance with the homological series of GOST, the dimensions change:

- height – from 10 to 100 cm;

- width from 55 to 400 cm.

Example 1

16B2 is a normal beam with a height of 16 cm, the number after the letter is the profile size of this series.

Example 2

26Ш1 – wide-flange I-beam with a height of 255 mm and profile size series 1.

With sloped internal edges

The following beams are produced according to the size range:

- height – 100-600 mm;

- width – 55-190 mm;

- tilt angle – 6-12%.

The marking includes a number indicating the height in cm. Next comes a letter indicating the manufacturing accuracy.

Example 1

14B – I-beam with inclined edges of increased precision with a height of 140 mm.

The product is marked on the ends using permanent paint indicating the order number, drawing and beam designation.

Classification of I-beams with parallel internal edges of flanges according to geometric characteristics

The assortment of the new GOST R 57837-2017 fully complies with the assortment of STO ASChM 20-93 - another standard that previously operated in parallel with GOST 26020-83. The marking of metal products with an I-beam profile, according to GOST, indicates:

- number – characteristic that determines the height of the wall (h) of the I-beam;

- letter – characterizes the type of design;

- index - the higher it is, the more massive the cross section.

In addition to the wall height, the cross-section of an I-beam profile is characterized by: wall thickness (s), flange width (b), flange thickness (t). According to their design, products are distinguished - beam, wide-flange, column, pile.

Beam

The height of the wall of a normal beam I-beam, designated in the marking by the letter B, is significantly greater than the width of the shelves. The main area of application of the I-beam is the arrangement of structural systems that work in bending, the creation of lattice beam systems. The products are also used in arranging roofs, stairs, and for reinforcing foundations.

Table of dimensional characteristics of a normal beam I-beam

| I-beam No. | h | b | s | t | r | F | M | P |

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

| 10B1 | 100 | 55 | 4,1 | 5,7 | 7 | 10,32 | 8,1 | 16,512 |

| 12B1 | 117,6 | 64 | 3,8 | 5,1 | 7 | 11,03 | 8,7 | 17,648 |

| 12B2 | 120 | 64 | 4,4 | 6,3 | 7 | 13,21 | 10,4 | 21,136 |

| 14B1 | 137,4 | 73 | 3,8 | 5,6 | 7 | 13,39 | 10,5 | 21,424 |

| 14B2 | 140 | 73 | 4,7 | 6,9 | 7 | 16,43 | 12,9 | 26,288 |

| 16B1 | 157 | 82 | 4 | 5,9 | 9 | 16,18 | 12,7 | 25,888 |

| 16B2 | 160 | 82 | 5 | 7,4 | 9 | 20,09 | 15,8 | 32,144 |

| 18B1 | 177 | 91 | 4,3 | 6,5 | 9 | 19,58 | 15,4 | 31,328 |

| 18B2 | 180 | 91 | 5,3 | 8 | 9 | 23,95 | 18,8 | 38,32 |

| 20B0 | 198 | 99 | 4,5 | 7 | 11 | 23,18 | 18,2 | 37,088 |

| 20B1 | 200 | 100 | 5,5 | 8 | 11 | 27,16 | 21,3 | 43,456 |

| 20B2 | 203 | 101 | 6,5 | 9,5 | 11 | 32,19 | 25,3 | 51,504 |

| 20B3 | 208 | 102 | 8 | 12 | 11 | 40,24 | 31,6 | 64,384 |

| 25B1 | 248 | 124 | 5 | 8 | 12 | 32,68 | 25,7 | 52,288 |

| 25B2 | 250 | 125 | 6 | 9 | 12 | 37,66 | 29,6 | 60,256 |

| 25B3 | 255 | 126 | 7,5 | 11,5 | 12 | 47,62 | 37,4 | 76,192 |

| 25B4 | 260 | 127 | 9 | 14 | 12 | 57,68 | 45,3 | 92,288 |

| 30B1 | 298 | 149 | 5,5 | 8 | 13 | 40,8 | 32 | 65,28 |

| 30B2 | 300 | 150 | 6,5 | 9 | 13 | 46,78 | 36,7 | 74,848 |

| 30B3 | 305 | 151 | 8 | 11,5 | 13 | 58,74 | 46,1 | 93,984 |

| 30B4 | 310 | 152 | 9,5 | 14 | 13 | 70,8 | 55,6 | 113,28 |

| 35B1 | 346 | 174 | 6 | 9 | 14 | 52,68 | 41,4 | 84,288 |

| 35B2 | 350 | 175 | 7 | 11 | 14 | 63,14 | 49,6 | 101,024 |

| 35B3 | 355 | 176 | 8,5 | 13,5 | 14 | 77,08 | 60,5 | 123,328 |

| 35B4 | 361 | 177 | 10 | 16,5 | 14 | 92,89 | 72,9 | 148,624 |

| 40B1 | 396 | 199 | 7 | 11 | 16 | 72,16 | 56,6 | 115,456 |

| 40B2 | 400 | 200 | 8 | 13 | 16 | 84,12 | 66 | 134,592 |

| 40B3 | 406 | 201 | 9,5 | 16 | 16 | 102,05 | 80,1 | 163,28 |

| 40B4 | 412 | 202 | 11 | 19 | 16 | 120,1 | 94,3 | 192,16 |

| 45B1 | 446 | 199 | 8 | 12 | 18 | 84,3 | 66,2 | 134,88 |

| 45B2 | 450 | 200 | 9 | 14 | 18 | 96,76 | 76 | 154,816 |

| 45B3 | 456 | 201 | 10,5 | 17 | 18 | 115,43 | 90,6 | 184,688 |

| 45B4 | 462 | 202 | 12 | 20 | 18 | 134,22 | 105,4 | 214,752 |

| 50B1 | 492 | 199 | 8,8 | 12 | 20 | 92,38 | 72,5 | 147,808 |

| 50B2 | 496 | 199 | 9 | 14 | 20 | 101,27 | 79,5 | 162,032 |

| 50B3 | 500 | 200 | 10 | 16 | 20 | 114,23 | 89,7 | 182,768 |

| 50B4 | 508 | 201 | 12 | 20 | 20 | 139,99 | 109,9 | 223,984 |

| 50B5 | 516 | 202 | 15 | 24 | 20 | 170,59 | 133,9 | 272,944 |

| 55B1 | 543 | 220 | 9,5 | 13,5 | 24 | 113,36 | 89 | 181,376 |

| 55B2 | 547 | 220 | 10 | 15,5 | 24 | 124,74 | 97,9 | 199,584 |

| 55B3 | 553 | 221 | 12 | 18,5 | 24 | 148,63 | 116,7 | 237,808 |

| 55B4 | 560 | 222 | 14 | 22 | 24 | 174,86 | 137,3 | 279,776 |

| 60B1 | 596 | 199 | 10 | 15 | 22 | 120,45 | 94,6 | 192,72 |

| 60B2 | 600 | 200 | 11 | 17 | 22 | 134,41 | 105,5 | 215,056 |

| 60B3 | 604 | 201 | 12,5 | 19 | 22 | 151,28 | 118,8 | 242,048 |

| 60B4 | 612 | 202 | 15 | 23 | 22 | 181,97 | 142,8 | 291,152 |

| 70B1 | 691 | 260 | 12 | 15,5 | 24 | 164,74 | 129,3 | 263,584 |

| 70B2 | 697 | 260 | 13 | 18,5 | 24 | 186,94 | 146,7 | 299,104 |

| 70B3 | 702 | 261 | 14,5 | 21 | 24 | 210,26 | 165,1 | 336,416 |

| 70B4 | 710 | 262 | 17 | 25 | 24 | 248,14 | 194,8 | 397,024 |

Beam wide flange

The width of the flanges of a wide-flange I-beam is close to the height of the wall. The wide flange profile can withstand 40% higher forces compared to a normal beam. Such products, as a rule, are used in cases where it is necessary to provide a significant area of support for structures on a profile or, conversely, beams on a base surface. They are in demand when covering large rooms with floor slabs, the length of which is slightly less than the distance between load-bearing walls.

Table of assortment of beam wide-flange I-beams

| I-beam No. | h | b | s | t | r | F | M | P |

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

| 20Ш0 | 190 | 149 | 5 | 7 | 13 | 31,11 | 24,4 | 49,776 |

| 20Ш1 | 194 | 150 | 6 | 9 | 13 | 39,01 | 30,6 | 62,416 |

| 20Ш2 | 199 | 151 | 7,5 | 11,5 | 13 | 49,38 | 38,8 | 79,008 |

| 20Ш3 | 204 | 152 | 9 | 14 | 13 | 59,85 | 47 | 95,76 |

| 20Ш4 | 211 | 155 | 11 | 17,5 | 13 | 75,06 | 58,9 | 120,096 |

| 20Ш5 | 218 | 157 | 13 | 21 | 13 | 90,27 | 70,9 | 144,432 |

| 20Ш6 | 228 | 159 | 16 | 26 | 13 | 112,29 | 88,1 | 179,664 |

| 25Ш0 | 240 | 174 | 6 | 9 | 16 | 46,84 | 36,8 | 74,944 |

| 25Ш1 | 244 | 175 | 7 | 11 | 16 | 56,24 | 44,1 | 89,984 |

| 25SH2 | 249 | 176 | 8,5 | 13,5 | 16 | 68,59 | 53,8 | 109,744 |

| 25SH3 | 256 | 177 | 10,5 | 17 | 16 | 85,69 | 67,3 | 137,104 |

| 25Ш4 | 264 | 182 | 13 | 21 | 16 | 107,5 | 84,4 | 172 |

| 25Ш5 | 274 | 184 | 16 | 26 | 16 | 133,4 | 104,7 | 213,44 |

| 25Ш6 | 286 | 186 | 19 | 32 | 16 | 163,42 | 128,3 | 261,472 |

| 30Ш0 | 290 | 199 | 7 | 10 | 18 | 61,48 | 48,3 | 98,368 |

| 30Ш1 | 294 | 200 | 8 | 12 | 18 | 72,38 | 56,8 | 115,808 |

| 30Ш2 | 300 | 201 | 9 | 15 | 18 | 87,38 | 68,6 | 139,808 |

| 30Ш3 | 306 | 203 | 11 | 18 | 18 | 105,56 | 82,9 | 168,896 |

| 30Ш4 | 314 | 206 | 13 | 22 | 18 | 128,52 | 100,9 | 205,632 |

| 30Ш5 | 326 | 208 | 16 | 28 | 18 | 162,46 | 127,5 | 259,936 |

| 30Ш6 | 342 | 210 | 20 | 36 | 18 | 207,98 | 163,3 | 332,768 |

| 35Ш1 | 334 | 249 | 8 | 11 | 20 | 83,17 | 65,3 | 133,072 |

| 35Ш2 | 340 | 250 | 9 | 14 | 20 | 101,51 | 79,7 | 162,416 |

| 35Ш3 | 347 | 252 | 11 | 17,5 | 20 | 125,95 | 98,9 | 201,52 |

| 35Ш4 | 354 | 254 | 13 | 21 | 20 | 150,67 | 118,3 | 241,072 |

| 35Ш5 | 364 | 258 | 16 | 26 | 20 | 187,51 | 147,2 | 300,016 |

| 35Ш6 | 376 | 260 | 19 | 32 | 20 | 229,11 | 179,9 | 366,576 |

| 35Ш7 | 392 | 262 | 23 | 40 | 20 | 284,79 | 223,6 | 455,664 |

| 40Ш1 | 383 | 299 | 9,5 | 12,5 | 22 | 112,91 | 88,6 | 180,656 |

| 40Ш2 | 390 | 300 | 10 | 16 | 22 | 135,95 | 106,7 | 217,52 |

| 40Ш3 | 397 | 302 | 12 | 19,5 | 22 | 164,89 | 129,4 | 263,824 |

| 40Ш4 | 406 | 304 | 14,5 | 24 | 22 | 201,98 | 158,6 | 323,168 |

| 40Ш5 | 418 | 309 | 17,5 | 30 | 22 | 252,2 | 198 | 403,52 |

| 40Ш6 | 430 | 311 | 21 | 36 | 22 | 303,25 | 238,1 | 485,2 |

| 40Ш7 | 446 | 313 | 25 | 44 | 22 | 369,09 | 289,7 | 590,544 |

| 45Ш0 | 434 | 299 | 10 | 15 | 24 | 135,04 | 106 | 216,064 |

| 45Ш1 | 440 | 300 | 11 | 18 | 24 | 157,38 | 123,5 | 251,808 |

| 45Ш2 | 446 | 302 | 13 | 21 | 24 | 184,3 | 144,7 | 294,88 |

| 45Ш3 | 452 | 304 | 15 | 24 | 24 | 211,46 | 166 | 338,336 |

| 45Ш4 | 464 | 308 | 18 | 30 | 24 | 262,46 | 206 | 419,936 |

| 45Ш5 | 476 | 310 | 21 | 36 | 24 | 312,98 | 245,7 | 500,768 |

| 45Ш6 | 492 | 312 | 25 | 44 | 24 | 380,5 | 298,7 | 608,8 |

| 50Ш1 | 482 | 300 | 11 | 15 | 26 | 145,52 | 114,2 | 232,832 |

| 50Ш2 | 487 | 300 | 14,5 | 17,5 | 26 | 176,34 | 138,4 | 282,144 |

| 50Ш3 | 493 | 300 | 15,5 | 20,5 | 26 | 198,86 | 156,1 | 318,176 |

| 50Ш4 | 499 | 300 | 16,5 | 23,5 | 26 | 221,38 | 173,8 | 354,208 |

| 50Ш5 | 508 | 302 | 19 | 28 | 26 | 260,8 | 204,7 | 417,28 |

| 50Ш6 | 518 | 310 | 22 | 33 | 26 | 309,84 | 243,2 | 495,744 |

| 50Ш7 | 532 | 312 | 26 | 40 | 26 | 372,92 | 292,7 | 596,672 |

| 50Ш8 | 548 | 314 | 30 | 48 | 26 | 442,84 | 347,6 | 708,544 |

| 60Ш1 | 582 | 300 | 12 | 17 | 28 | 174,49 | 137 | 279,184 |

| 60Ш2 | 589 | 300 | 16 | 20,5 | 28 | 217,41 | 170,7 | 347,856 |

| 60Ш3 | 597 | 300 | 18 | 24,5 | 28 | 252,37 | 198,1 | 403,792 |

| 60Ш4 | 605 | 300 | 20 | 28,5 | 28 | 287,33 | 225,6 | 459,728 |

| 60Ш5 | 616 | 302 | 23 | 34 | 28 | 338,13 | 265,4 | 541,008 |

| 60Ш6 | 630 | 315 | 27 | 41 | 28 | 412,99 | 324,2 | 660,784 |

| 60Ш7 | 644 | 317 | 31 | 48 | 28 | 480,93 | 377,5 | 769,488 |

| 60Ш8 | 664 | 319 | 36 | 58 | 28 | 574,05 | 450,6 | 918,48 |

| 70Ш1 | 692 | 300 | 13 | 20 | 28 | 211,49 | 166 | 338,384 |

| 70Ш2 | 698 | 300 | 15 | 23 | 28 | 242,53 | 190,4 | 388,048 |

| 70Ш3 | 707 | 300 | 18 | 27,5 | 28 | 289,09 | 226,9 | 462,544 |

| 70Ш4 | 715 | 300 | 20,5 | 31,5 | 28 | 329,39 | 258,6 | 527,024 |

| 70Ш5 | 725 | 300 | 23 | 36,5 | 28 | 375,69 | 294,9 | 601,104 |

| 70Ш6 | 740 | 313 | 27 | 44 | 28 | 458,21 | 359,7 | 733,136 |

| 70Ш7 | 758 | 315 | 32 | 53 | 28 | 549,27 | 431,2 | 878,832 |

| 70Ш8 | 780 | 317 | 38 | 64 | 28 | 660,25 | 518,3 | 1056,4 |

Columned

The width of the flanges of column I-beams relates to the height of the wall, approximately 1:1. Such rolled products are very stable along the vertical axis. It is used in structures experiencing compression, tension, compression and bending forces. Areas of use for column I-beams are the production of rods for massive large-sized trusses, vertical columns and supports installed at civil, industrial, agricultural or warehouse facilities under construction. This rental does not require complex processing or the use of additional fasteners. Such beams can be cut along the vertical axis to create lattice structures.

Column I-beam assortment table

| I-beam No. | h | b | s | t | r | F | M | P |

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

| 15K1 | 147 | 149 | 6 | 8,5 | 11 | 34,17 | 26,8 | 54,672 |

| 15K2 | 150 | 150 | 7 | 10 | 11 | 40,14 | 31,5 | 64,224 |

| 15K3 | 155 | 151 | 8,5 | 12,5 | 11 | 49,84 | 39,1 | 79,744 |

| 15K4 | 160 | 152 | 10 | 15 | 11 | 59,64 | 46,8 | 95,424 |

| 15K5 | 166 | 153 | 12 | 18 | 11 | 71,72 | 56,3 | 114,752 |

| 20K1 | 196 | 199 | 6,5 | 10 | 13 | 52,69 | 41,4 | 84,304 |

| 20K2 | 200 | 200 | 8 | 12 | 13 | 63,53 | 49,9 | 101,648 |

| 20K3 | 204 | 201 | 9 | 14 | 13 | 73,57 | 57,8 | 117,712 |

| 20K4 | 210 | 201 | 10,5 | 17 | 13 | 88,27 | 69,3 | 141,232 |

| 20K5 | 214 | 202 | 12 | 19 | 13 | 99,33 | 78 | 158,928 |

| 20K6 | 220 | 202 | 14 | 22 | 13 | 114,97 | 90,3 | 183,952 |

| 20K7 | 226 | 203 | 16 | 25 | 13 | 131,11 | 102,9 | 209,776 |

| 20K8 | 234 | 203 | 18 | 29 | 13 | 150,87 | 118,4 | 241,392 |

| 25K1 | 246 | 249 | 8 | 12 | 16 | 79,72 | 62,6 | 127,552 |

| 25K2 | 250 | 250 | 9 | 14 | 16 | 92,18 | 72,4 | 147,488 |

| 25K3 | 253 | 251 | 10 | 15,5 | 16 | 102,21 | 80,2 | 163,536 |

| 25K4 | 257 | 252 | 11 | 17,5 | 16 | 114,82 | 90,1 | 183,712 |

| 25K5 | 262 | 253 | 12,5 | 20 | 16 | 131,15 | 102,9 | 209,84 |

| 25K6 | 267 | 253 | 14 | 22,5 | 16 | 147,13 | 115,5 | 235,408 |

| 25K7 | 274 | 258 | 16 | 26 | 16 | 171,88 | 134,9 | 275,008 |

| 25K8 | 281 | 259 | 18 | 29,5 | 16 | 194,97 | 153 | 311,952 |

| 25K9 | 288 | 260 | 20 | 33 | 16 | 218,2 | 171,3 | 349,12 |

| 25K10 | 298 | 261 | 23 | 38 | 16 | 251,62 | 197,5 | 402,592 |

| 30K1 | 298 | 299 | 9 | 14 | 18 | 110,8 | 87 | 177,28 |

| 30K2 | 300 | 300 | 10 | 15 | 18 | 119,78 | 94 | 191,648 |

| 30K3 | 300 | 305 | 15 | 15 | 18 | 134,78 | 105,8 | 215,648 |

| 30K4 | 304 | 301 | 11 | 17 | 18 | 134,82 | 105,8 | 215,712 |

| 30K5 | 308 | 301 | 12 | 19 | 18 | 149,56 | 117,4 | 239,296 |

| 30K6 | 312 | 302 | 13 | 21 | 18 | 164,72 | 129,3 | 263,552 |

| 30K7 | 316 | 302 | 14,5 | 23 | 18 | 180,85 | 142 | 289,36 |

| 30K8 | 316 | 357 | 14,5 | 23 | 18 | 206,15 | 161,8 | 329,84 |

| 30K9 | 322 | 358 | 16 | 26 | 18 | 232,14 | 182,2 | 371,424 |

| 30K10 | 328 | 359 | 18 | 29 | 18 | 259,6 | 203,8 | 415,36 |

| 30K11 | 334 | 360 | 20 | 32 | 18 | 287,18 | 225,4 | 459,488 |

| 30K12 | 341 | 361 | 22 | 35,5 | 18 | 318,49 | 250 | 509,584 |

| 30K13 | 350 | 362 | 24 | 40 | 18 | 357,18 | 280,4 | 571,488 |

| 30K14 | 356 | 371 | 27 | 43 | 18 | 394,74 | 310 | 631,584 |

| 30K15 | 364 | 372 | 30 | 47 | 18 | 433,46 | 340 | 693,536 |

| 30K16 | 374 | 373 | 33 | 52 | 18 | 479,8 | 377 | 767,68 |

| 30K17 | 384 | 374 | 36 | 57 | 18 | 526,34 | 413 | 842,144 |

| 30K18 | 396 | 375 | 39 | 63 | 18 | 580,58 | 456 | 928,928 |

| 30K19 | 408 | 385 | 43 | 69 | 18 | 650,18 | 510 | 1040,288 |

| 30K20 | 422 | 387 | 47 | 76 | 18 | 717,92 | 564 | 1148,672 |

| 30K21 | 440 | 389 | 52 | 85 | 18 | 804,48 | 632 | 1287,168 |

| 35K1 | 342 | 348 | 10 | 15 | 20 | 139,03 | 109,1 | 222,448 |

| 35K1.5 | 346 | 349 | 11 | 17 | 20 | 156,41 | 122,8 | 250,256 |

| 35K2 | 350 | 350 | 12 | 19 | 20 | 173,87 | 136,5 | 278,192 |

| 35K3 | 355 | 351 | 13,5 | 21,5 | 20 | 196,48 | 154,2 | 314,368 |

| 35K4 | 360 | 352 | 15 | 24 | 20 | 219,19 | 172,1 | 350,704 |

| 35K5 | 365 | 353 | 16,5 | 26,5 | 20 | 242 | 190 | 387,2 |

| 35K6 | 369 | 360 | 18 | 28,5 | 20 | 264,79 | 207,9 | 423,664 |

| 35K7 | 376 | 361 | 20 | 32 | 20 | 296,87 | 233 | 474,992 |

| 35K8 | 382 | 362 | 22 | 35 | 20 | 325,47 | 255,5 | 520,752 |

| 35K9 | 389 | 363 | 24 | 38,5 | 20 | 357,82 | 280,9 | 572,512 |

| 35K10 | 396 | 364 | 26,5 | 42 | 20 | 391,87 | 307,6 | 626,992 |

| 35K11 | 404 | 374 | 29 | 46 | 20 | 437,99 | 344 | 700,784 |

| 35K12 | 414 | 375 | 32 | 51 | 20 | 485,77 | 381 | 777,232 |

| 35K13 | 424 | 376 | 35 | 56 | 20 | 533,75 | 419 | 854 |

| 35K14 | 434 | 377 | 38 | 61 | 20 | 581,93 | 457 | 931,088 |

| 35K15 | 446 | 378 | 42 | 67 | 20 | 640,99 | 503 | 1025,584 |

| 35K16 | 458 | 392 | 46 | 73 | 20 | 719,27 | 565 | 1150,832 |

| 35K17 | 472 | 393 | 50 | 80 | 20 | 788,23 | 619 | 1261,168 |

| 35K18 | 488 | 394 | 55 | 88 | 20 | 868,47 | 682 | 1389,552 |

| 35K19 | 506 | 395 | 60 | 97 | 20 | 956,93 | 751 | 1531,088 |

| 35K20 | 520 | 409 | 65 | 104 | 20 | 1056,95 | 830 | 1691,12 |

| 35K21 | 540 | 411 | 71 | 114 | 20 | 1162,03 | 912 | 1859,248 |

| 35K22 | 562 | 413 | 77 | 125 | 20 | 1276,17 | 1002 | 2041,872 |

| 35K23 | 580 | 426 | 84 | 134 | 20 | 1407,19 | 1105 | 2251,504 |

| 35K24 | 604 | 430 | 92 | 146 | 20 | 1546,07 | 1214 | 2473,712 |

| 40K1 | 394 | 398 | 11 | 18 | 22 | 186,81 | 146,6 | 298,896 |

| 40K2 | 400 | 400 | 13 | 21 | 22 | 218,69 | 171,7 | 349,904 |

| 40K3 | 406 | 403 | 16 | 24 | 22 | 254,87 | 200,1 | 407,792 |

| 40K4 | 414 | 405 | 18 | 28 | 22 | 295,39 | 231,9 | 472,624 |

| 40K4.5 | 420 | 403 | 20 | 31 | 22 | 325,61 | 255,6 | 520,976 |

| 40K5 | 429 | 400 | 23 | 35,5 | 22 | 370,49 | 290,8 | 592,784 |

| 40K6 | 438 | 370 | 25 | 40 | 22 | 389,65 | 306 | 623,44 |

| 40K7 | 448 | 371 | 28 | 45 | 22 | 438,29 | 344 | 701,264 |

| 40K8 | 458 | 372 | 31 | 50 | 22 | 487,13 | 382 | 779,408 |

| 40K9 | 470 | 373 | 35 | 56 | 22 | 547,21 | 430 | 875,536 |

| 40K10 | 484 | 374 | 39 | 63 | 22 | 615,01 | 483 | 984,016 |

| 40K11 | 494 | 392 | 43 | 68 | 22 | 691,21 | 543 | 1105,936 |

| 40K12 | 510 | 393 | 48 | 76 | 22 | 773,35 | 607 | 1237,36 |

| 40K13 | 528 | 394 | 53 | 85 | 22 | 863,69 | 678 | 1381,904 |

| 40K14 | 548 | 395 | 59 | 95 | 22 | 965,87 | 758 | 1545,392 |

| 40K15 | 564 | 410 | 65 | 103 | 22 | 1081,45 | 849 | 1730,32 |

| 40K16 | 588 | 412 | 72 | 115 | 22 | 1209,51 | 949 | 1935,216 |

| 40K17 | 616 | 414 | 80 | 129 | 22 | 1358,67 | 1067 | 2173,872 |

| 40K18 | 638 | 430 | 87 | 140 | 22 | 1519,61 | 1193 | 2431,376 |

| 40K19 | 668 | 435 | 96 | 155 | 22 | 1696,33 | 1332 | 2714,128 |

Pile

This is the smallest category, including only 14 standard sizes. The product is distinguished by its massive cross-section. The height of the wall is approximately equal to the width of the shelves, and the thickness of the wall is approximately equal to the thickness of the shelves. Pile I-beam metal products are capable of withstanding high loads.

Pile I-beam assortment table

| I-beam No. | h | b | s | t | r | F | M | P |

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

| 13С1 | 128 | 118 | 9 | 9 | 12 | 32,38 | 56,2 | 51,808 |

| 20С1 | 200 | 204 | 12 | 12 | 13 | 71,53 | 56,2 | 114,448 |

| 25С1 | 244 | 252 | 11 | 11 | 16 | 82,06 | 64,4 | 131,296 |

| 25С2 | 250 | 255 | 14 | 14 | 16 | 104,68 | 82,2 | 167,488 |

| 30С1 | 294 | 302 | 12 | 12 | 18 | 107,66 | 84,5 | 172,256 |

| 30С2 | 300 | 305 | 15 | 15 | 18 | 134,78 | 105,8 | 215,648 |

| 32С1 | 326,7 | 320 | 24,8 | 24,8 | 15 | 229,28 | 105,8 | 366,848 |

| 32С2 | 337,9 | 326 | 30,3 | 30,4 | 15 | 283,97 | 105,8 | 454,352 |

| 35С1 | 338 | 351 | 13 | 13 | 20 | 135,25 | 106,2 | 216,4 |

| 35С2 | 344 | 354 | 16 | 16 | 20 | 166,63 | 130,8 | 266,608 |

| 35С3 | 350 | 357 | 19 | 19 | 20 | 198,37 | 155,7 | 317,392 |

| 40С1 | 388 | 402 | 15 | 15 | 22 | 178,45 | 140,1 | 285,52 |

| 40С2 | 394 | 405 | 18 | 18 | 22 | 214,39 | 168,3 | 343,024 |

| 40С3 | 400 | 408 | 21 | 21 | 22 | 250,69 | 196,8 | 401,104 |

Additional beams and columns

Products from additional series have the letter D at the beginning of the marking. Their presence allows you to select a beam that optimally matches the planned operating conditions.

Assortment table for additional beam I-beams

| I-beam No. | h | b | s | t | r | F | M | P |

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

| 20DB1 | 207 | 133 | 5,8 | 8,4 | 7,6 | 33,87 | 26,6 | 54,192 |

| 20DB2 | 210 | 134 | 6,4 | 10,2 | 7,6 | 39,97 | 31,3 | 63,952 |

| 25DB1 | 251 | 146 | 6 | 8,6 | 7,6 | 39,64 | 31,1 | 63,424 |

| 25DB2 | 256 | 146 | 6,3 | 10,9 | 7,6 | 47,08 | 37 | 75,328 |

| 25DB3 | 260 | 147 | 7,2 | 12,7 | 7,6 | 54,73 | 43 | 87,568 |

| 25DB4 | 258 | 146 | 6,1 | 9,1 | 7,6 | 41,7 | 32,7 | 66,72 |

| 25DB5 | 262 | 147 | 6,6 | 11,2 | 7,6 | 49,24 | 38,5 | 78,784 |

| 25DB6 | 266 | 148 | 7,6 | 13 | 7,6 | 57,22 | 44,8 | 91,552 |

| 30DB1 | 309 | 102 | 6 | 8,9 | 7,6 | 36,12 | 28,3 | 57,792 |

| 30DB2 | 313 | 102 | 6,6 | 10,8 | 7,6 | 41,76 | 32,7 | 66,816 |

| 30DB3 | 310 | 165 | 5,8 | 9,7 | 8,9 | 49,54 | 38,7 | 79,264 |

| 30DB4 | 313 | 166 | 6,6 | 11,2 | 8,9 | 57,04 | 44,5 | 91,264 |

| 30DB5 | 317 | 167 | 7,6 | 13,2 | 8,9 | 66,85 | 52 | 106,96 |

| 30DB6 | 303 | 165 | 6 | 10,2 | 8,9 | 51,3 | 40,3 | 82,08 |

| 30DB7 | 307 | 166 | 6,7 | 11,8 | 8,9 | 58,84 | 46,1 | 94,144 |

| 30DB8 | 310 | 167 | 7,9 | 13,7 | 8,9 | 68,76 | 54 | 110,016 |

| 35DB1 | 349 | 127 | 5,8 | 8,5 | 10,2 | 41,74 | 32,9 | 66,784 |

| 35DB2 | 353 | 128 | 6,5 | 10,7 | 10,2 | 49,84 | 39 | 79,744 |

| 35DB3 | 352 | 171 | 6,9 | 9,8 | 10,2 | 57,34 | 44,6 | 91,744 |

| 35DB4 | 355 | 171 | 7,2 | 11,6 | 10,2 | 64,45 | 51 | 103,12 |

| 35DB5 | 358 | 172 | 7,9 | 13,1 | 10,2 | 72,17 | 58 | 115,472 |

| 35DB6 | 363 | 173,2 | 9,1 | 15,7 | 10,2 | 85,45 | 67,1 | 136,72 |

| 35DB7 | 353 | 254 | 9,5 | 16,4 | 16 | 115,93 | 91 | 185,488 |

| 35DB8 | 357 | 255 | 10,5 | 18,3 | 16 | 129,17 | 101 | 206,672 |

| 35DB9 | 360 | 256 | 11,4 | 19,9 | 16 | 140,59 | 110 | 224,944 |

| 35DB10 | 363 | 257 | 13 | 21,7 | 16 | 155,28 | 122 | 248,448 |

| 40DB1 | 399 | 140 | 6,4 | 8,8 | 10,2 | 49,94 | 38,8 | 79,904 |

| 40DB2 | 403 | 140 | 7 | 11,2 | 10,2 | 58,9 | 46,1 | 94,24 |

| 40DB3 | 403 | 177 | 7,5 | 10,9 | 10,2 | 68,07 | 53 | 108,912 |

| 40DB4 | 407 | 178 | 7,7 | 12,8 | 10,2 | 75,83 | 60 | 121,328 |

| 40DB5 | 410 | 179 | 8,8 | 14,4 | 10,2 | 85,99 | 67 | 137,584 |

| 40DB6 | 413 | 180 | 9,7 | 16 | 10,2 | 95,45 | 75 | 152,72 |

| 40DB7 | 417 | 181 | 10,9 | 18,2 | 10,2 | 108,26 | 85 | 173,216 |

| 45DB1 | 450 | 152 | 7,6 | 10,8 | 10,2 | 66,28 | 52 | 106,048 |

| 45DB2 | 455 | 153 | 8 | 13,3 | 10,2 | 75,86 | 60 | 121,376 |

| 45DB3 | 459 | 154 | 9,1 | 15,4 | 10,2 | 87,29 | 68 | 139,664 |

| 45DB4 | 462 | 154,4 | 9,6 | 17 | 10,2 | 94,48 | 74,2 | 151,168 |

| 45DB5 | 466 | 155,3 | 10,5 | 18,9 | 10,2 | 104,56 | 82,1 | 167,296 |

| 45DB6 | 453 | 189,9 | 8,5 | 12,7 | 10,2 | 85,47 | 67,1 | 136,752 |

| 45DB7 | 457 | 190 | 9 | 14,5 | 10,2 | 94,51 | 74 | 151,216 |

| 45DB8 | 460 | 191 | 9,9 | 16 | 10,2 | 104,39 | 82 | 167,024 |

| 45DB9 | 463 | 192 | 10,5 | 17,7 | 10,2 | 113,76 | 89 | 182,016 |

| 45DB10 | 466 | 193 | 11,4 | 19 | 10,2 | 123,03 | 97 | 196,848 |

| 45DB11 | 469 | 194 | 12,6 | 20,6 | 10,2 | 134,72 | 106 | 215,552 |

| 53DB3 | 533 | 209 | 10,2 | 15,6 | 12,7 | 117,78 | 92,5 | 188,448 |

| 53DB4 | 537 | 210 | 10,9 | 17,4 | 12,7 | 129,2 | 101,4 | 206,72 |

| 53DB5 | 539 | 211 | 11,6 | 18,8 | 12,7 | 138,88 | 109 | 222,208 |

| 53DB6 | 544 | 212 | 13,1 | 21,2 | 12,7 | 156,98 | 123,2 | 251,168 |

| 53DB7 | 549 | 214 | 14,7 | 23,6 | 12,7 | 176,16 | 138,3 | 281,856 |

| 60DB1 | 599 | 178 | 10 | 12,8 | 12,7 | 104,29 | 82 | 166,864 |

| 60DB2 | 603 | 179 | 10,9 | 15 | 12,7 | 117,54 | 92 | 188,064 |

| 60DB3 | 603 | 228 | 10,5 | 14,9 | 12,7 | 129,51 | 101 | 207,216 |

| 60DB4 | 608 | 228 | 11,2 | 17,3 | 12,7 | 144,49 | 113 | 231,184 |

| 60DB5 | 612 | 229 | 11,9 | 19,6 | 12,7 | 159,32 | 125 | 254,912 |

| 60DB6 | 617 | 230 | 13,1 | 22,2 | 12,7 | 178,52 | 140 | 285,632 |

Assortment table for additional column I-beams

| I-beam No. | h | b | s | t | r | F | M | P |

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

| 10DK1 | 96 | 100 | 5 | 8 | 12 | 21,2 | 16,7 | 33,92 |

| 10DK2 | 100 | 100 | 6 | 10 | 12 | 26 | 20,4 | 41,6 |

| UDKZ | 120 | 106 | 12 | 20 | 12 | 53,2 | 41,8 | 85,12 |

| 12DK1 | 114 | 120 | 5 | 8 | 12 | 25,3 | 19,9 | 40,48 |

| 12DK2 | 120 | 120 | 6,5 | 11 | 12 | 34 | 26,7 | 54,4 |

| 12DKZ | 140 | 126 | 12,5 | 21 | 12 | 66,4 | 53,1 | 106,24 |

| 14DK1 | 133 | 140 | 5,5 | 8,5 | 12 | 31,4 | 24,7 | 50,24 |

| 14DK2 | 140 | 140 | 7 | 12 | 12 | 43 | 33,7 | 68,8 |

| 14DKZ | 160 | 145 | 13 | 22 | 12 | 80,6 | 63,2 | 128,96 |

| 15DK1 | 152 | 152 | 5,8 | 6,6 | 7,6 | 28,61 | 22,5 | 45,776 |

| 15DK2 | 157 | 153 | 6,6 | 9,3 | 7,6 | 38,09 | 29,8 | 60,944 |

| 15DKZ | 162 | 154 | 8,1 | 11,6 | 7,6 | 47,47 | 37,1 | 75,952 |

| 16DK1 | 152 | 160 | 6 | 9 | 15 | 38,8 | 30,4 | 62,08 |

| 16DK2 | 160 | 160 | 8 | 13 | 15 | 54,3 | 42,6 | 86,88 |

| 16DKZ | 180 | 166 | 14 | 23 | 15 | 97,1 | 76,2 | 155,36 |

| 18DK1 | 171 | 180 | 6 | 9,5 | 15 | 45,3 | 35,5 | 72,48 |

| 18DK2 | 180 | 180 | 8,3 | 14 | 15 | 65,3 | 51,2 | 104,48 |

| 18DKZ | 200 | 186 | 14,5 | 24 | 15 | 113,3 | 88,9 | 181,28 |

| 20DK1 | 203 | 203 | 7,2 | 11 | 10,2 | 58,59 | 46,1 | 93,744 |

| 20DK2 | 206 | 204 | 7,9 | 12,6 | 10,2 | 66,58 | 52 | 106,528 |

| 20DKZ | 210 | 205 | 9,1 | 14,2 | 10,2 | 75,64 | 59 | 121,024 |

| 20DK4 | 216 | 206 | 10,2 | 17,4 | 10,2 | 91,06 | 71 | 145,696 |

| 20DK5 | 222 | 209 | 13 | 20,6 | 10,2 | 110,51 | 86 | 176,816 |

| 20DK6 | 229 | 210 | 14,5 | 23,7 | 10,2 | 126,77 | 100 | 202,832 |

| 25DK1 | 253 | 254 | 8,6 | 14,2 | 12,7 | 92,84 | 73 | 148,544 |

| 25DK2 | 256 | 255 | 9,4 | 15,6 | 12,7 | 102,08 | 80 | 163,328 |

| 25DKZ | 260 | 256 | 10,7 | 17,3 | 12,7 | 114,08 | 89 | 182,528 |

| 25DK4 | 264 | 257 | 11,9 | 19,6 | 12,7 | 128,88 | 101 | 206,208 |

Scope of application

Since the I-beam is a load-bearing element and gives strength and rigidity to any structure, it is used everywhere in the construction of objects for a wide variety of purposes.

This reinforcement is irreplaceable wherever it is necessary to withstand high loads under vertical transverse impact. The product is used in the construction of:

- bridges;

- overhead tracks;

- underground passages, parking lots;

- railway tunnels;

- crane tracks;

- stadiums, sports swimming pools;

- overpasses

The I-beam is part of the floors between floors of buildings, roofs, and plays an important role in the construction of heavily loaded buildings, for example, skyscrapers. I-beams are also used in the construction of pit wall structures and monorails.

How to do it yourself?

Wooden I-beam floors can be made independently. This allows you to save money and also immediately make beams of the required size, so as not to adjust the material during installation.

First of all, you need to choose the right material , since the quality of the elements depends on the wood.

Timber . The best timber is laminated timber, because it deforms less, rots and swells less often. This is a durable and strong material, but it can also absorb moisture.- Larch is an ideal wood for making beams. Thanks to its resin, larch only becomes stronger when wet.

For the rack, OSB board or multi-layer plywood is suitable. OSB is a stronger and more durable material. To fasten the timber and the rack of the floor beams of a residential building, the adhesive should be chosen with a non-toxic composition.

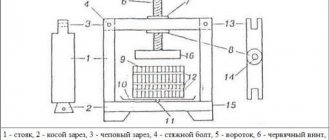

I-beam assembly process

- Prepare bars of the required size. Grooves are cut along each beam to secure the rack.

- Cut vertical posts from OSB board. The edges of the slabs are beveled so that the stand fits tightly into the groove of the beam.

- The grooves in the beams are lubricated with glue. A stand is inserted into the groove of the lower beam, covered with a second beam on top, and the entire structure is pressed tightly.

- The prefabricated structure is left until the glue has completely dried (according to its instructions).

For better joining of beam elements, channels are placed on the bars and tightened with ropes or belts until the glue hardens. After this, the parts can be used to construct floors.

Advantages and disadvantages

Compared to other types of rolled metal, an I-beam has the highest strength characteristics, thanks to its cross-sectional shape, which distributes force loads throughout the entire metal structure.

The advantages of an I-beam also include:

- insensitivity to mechanical and atmospheric influences;

- resistance to building shrinkage;

- low weight in relation to the loads that the metal structure can withstand;

- resistance to bending and compression;

- the ability to use welding during installation, which speeds up the construction process;

- constancy of geometric parameters;

- cost-effectiveness - allows you to do without additional reinforcement elements.

The disadvantages of an I-beam are:

- Low corrosion resistance.

- Poor resistance to torsion.

- Low fire resistance. In the event of a fire, the building may be destroyed.

- Impossibility of use on large spans.

Basic criteria for choosing an I-beam

To choose the right I-beam, you need to decide:

- with the material of the product - it can be carbon steel of ordinary quality, construction, bridge construction, low-alloy rolled steel or aluminum alloys.

- with the method of its manufacture - hot-rolled or welded;

- with the purpose of the beam - loaded or non-loaded structures.

Next you need to determine the dimensions of the beam. To do this, use the current SNiP standards and formulas for calculating from strength of materials. You also need to know and use the expected static and dynamic loads that the object must withstand during its operation.

The strength of the beam depends on the cross-sectional area, the length of the beam, the material, and the method of fixing the metal structure. They need to be correctly calculated and selected.

Where can I buy?

If you are interested in an I-beam, you can buy it here https://metallbase.com/production/balka-dvutavr . This is the website of our metal warehouse, which sells rolled products of any type. Here you will find products with heights from 100 to 691 mm. The catalog contains products with narrow, medium, normal and wide shelves. We can also offer you column and special beams. A list of available products and their characteristics are available for viewing on the website.

If you have not yet decided on the choice of rolled metal supplier, check out the advantages of our company. They attract new clients to us every day. Our main advantages:

- Cooperation with leading metal plants of the Russian Federation. We do not purchase goods from dubious persons, so we can confidently say that we sell high-quality rolled metal products.

- Large selection of products. You will find an I-beam of any size in the catalog, therefore, you do not have to wait for its production. In addition, we have many other types of metal products, not just beams. If you are a professional builder, you know that when constructing a large project, I-beams alone will not be enough. You will have to buy fittings and other rental products. By collaborating with us, you will do this at the same time, without delaying construction work and without overpaying for delivery.

- Affordable prices. Since we take goods directly from metal plants, and not through intermediaries, we do not have to purchase them at a higher price. Accordingly, our clients receive rolled metal at the manufacturer’s price.

- Operational support. If you don't know which I-beam is suitable for your needs, ask our specialist for help. He will find you a product with optimal characteristics.

- Promotions and sales that allow you to save on your purchase.

- Useful additional services. We not only sell rolled products, but also weld and cut them.

To order an I-beam, check the cost of the product and wait for delivery. If you indicated an address in St. Petersburg, we will deliver the goods by our own car. In other cases, the products will be sent by a transport company suitable for you.

The photos used in the article are for illustration purposes and are not images of the company's products.