Steel circle is a type of rolled steel with a continuous cross-section in the shape of a circle. The production of hot-rolled products is regulated by GOST 2590-88, the range of diameters is 5.0-270.0 mm, more than 270 mm - in agreement with the consumer. The production of a calibrated circle with a cross-section of 3.0-100.0 mm is carried out in accordance with GOST 7417-75. When drawing up technical documentation or planning purchases, it is necessary to convert the footage of rolled metal into its equivalent by weight. There are several options: calculation using a formula, searching in tables, online calculator.

Formula for calculating the mass of 1 m of metal rod

To determine the theoretical weight of a linear meter of a steel circle, use the formula M = π*ρ*(D 2 /4) , in which:

M – mass of 1 m, kg;

π – constant, approximately equal to 3.14;

ρ is the average value of steel density, usually taken equal to 7850 kg/m3;

D – cross-sectional diameter, m.

If you need to find out the mass of a metal rod made of copper, aluminum and other metals, substitute the density of these metals, kg/m3, into the formula:

- aluminum – 2700;

- titanium – 4500;

- zinc – 7140;

- tin – 7290;

- copper – 8940;

- lead – 11340.

How to find out the mass of a hexagonal profile?

Solid metal rods with a hexagonal cross-section are often used. The calculation method for such products remains the same. It is necessary to remember from the school geometry course how the volume of a regular hexagonal parallelepiped is calculated.

The task is greatly simplified if you know the size or number of such a rental. All numbers are given in a standardized table.

The hexagonal profile with the smallest number 10 weighs only 0.68 kg, the largest number 60 weighs 24.5 kg.

The calculations are based on a formula for calculating the volume of a regular hexagonal prism. Having calculated this volume, it is multiplied by the density of the metal. A mass of hexagonal product is obtained.

It should be remembered that the use of simplified methods gives approximate results. They are used for express assessments. When developing design documentation in detail, more accurate indicators are used.

Determination of the mass of rolled products with a round cross-section using the table

A convenient option is a table from which you can find out the weight of 1 meter of steel circle, and then, multiplying by the total footage, get the mass of the rod or the entire batch.

| D, mm | M, kg | D, mm | M, kg | D, mm | M, kg | D, mm | M, kg |

| 5,5 | 0,186 | 23 | 3,26 | 41 | 10,36 | 100 | 61,65 |

| 6 | 0,222 | 24 | 3,55 | 42 | 10,88 | 110 | 74,6 |

| 7 | 0,302 | 25 | 3,85 | 43 | 11,4 | 120 | 88,78 |

| 8 | 0,395 | 26 | 4,17 | 44 | 11,94 | 130 | 104,2 |

| 9 | 0,499 | 27 | 4,5 | 45 | 12,48 | 140 | 120,78 |

| 10 | 0,616 | 28 | 4,83 | 46 | 13,05 | 150 | 138,65 |

| 11 | 0,746 | 29 | 5,18 | 47 | 13,75 | 160 | 157,75 |

| 12 | 0,888 | 30 | 5,55 | 48 | 14,2 | 170 | 178,09 |

| 13 | 1,041 | 31 | 5,92 | 49 | 14,8 | 180 | 199,66 |

| 14 | 1,21 | 32 | 6,31 | 50 | 15,42 | 190 | 222,46 |

| 15 | 1,39 | 33 | 6,71 | 55 | 18,65 | 200 | 246,49 |

| 16 | 1,58 | 34 | 7,13 | 60 | 22,19 | 210 | 271,76 |

| 17 | 1,78 | 35 | 7,55 | 65 | 26,05 | 220 | 298,25 |

| 18 | 2,0 | 36 | 7,99 | 70 | 30,21 | 230 | 325,98 |

| 19 | 2,23 | 37 | 8,44 | 75 | 34,68 | 240 | 354,95 |

| 20 | 2,47 | 38 | 8,9 | 80 | 39,46 | 250 | 385,14 |

| 21 | 2,72 | 39 | 9,38 | 85 | 44,54 | 260 | 416,57 |

| 22 | 2,98 | 40 | 9,86 | 90 | 49,94 | 270 | 449,23 |

If you have access to the Internet, you can quickly determine the mass of a bar made of steel of any grade, non-ferrous metals and alloys using an online calculator. This is the most accurate method, since this calculation option uses the density of a specific metal.

Source: treydmetall.ru

What is a conversion factor?

It allows you to calculate the weight of products made of any material. It is obtained as the ratio of the density of the selected material to the density of steel. Next, to calculate the required parameter, it is enough to calculate such a parameter of a steel product of a given shape. The resulting result will be multiplied by the conversion factor for this material.

The coefficient is a dimensionless quantity. It has its own specific meanings for various metals and alloys. For example, aluminum has 0.34, copper - 1.14, and 1.12 is used for OTS5-5-5 bronze.

To calculate the weight of a sheet made of the specified bronze, it is necessary to obtain the parameter of the same sheet of steel, multiplying with a conversion factor.

Metal conversion factor

The same calculation method, the use of a conversion factor, can be fairly applied to non-metallic rectangular products. For example, to textolite with a coefficient of 0.18, organic glass - 0.15. The results obtained will satisfy the accuracy requirements.

Calculation of the weight of a steel circle

Steel circle is a type of rolled product produced by hot rolling. Hot-rolled products have good strength characteristics, but have low dimensional accuracy and surface quality. To improve aesthetic and dimensional parameters, calibration or other cold deformation methods are used. Hot-rolled products are used both as rolled products in the production of cold-deformed products, and in the manufacture of fasteners, products for construction, and for fencing. Calibrated circle – metal products used in automobile and mechanical engineering to create functional and decorative structures in construction and architecture.

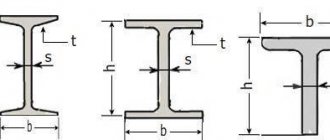

How to calculate the mass of an angle, channel, I-beam

The parameter is calculated using data on the width of the shelf and the thickness of the metal. The product is considered as half of a rectangular profile.

There are ready-made calculation tables for the entire range of rolled metal products.

However, corners from different manufacturers have real weight characteristics that differ from the tabular data. They deliberately reduce the thickness of the shelf. They are motivated by the desire to reduce the cost of products. The parameter difference differs significantly from the parameters provided by GOST.

The weight characteristics of the channel and I-beams are determined according to the tables. This is caused by the difficulties of calculating the volume of complex geometric shapes.

If you find an error, please select a piece of text and press Ctrl+Enter.

The issue of calculating the weight of rolled metal is relevant not only for specialists, but also for private developers and home craftsmen. If you have a reference book at hand and, especially, an online metal calculator, it is not difficult to make the appropriate calculations. What if you only have a tape measure and a calculator on your phone? It is difficult to obtain accurate results with such an arsenal, but it is quite possible to approximately determine the weight of some metal products.

Read also: Cyatim 221 composition and properties

Main characteristics of the steel circle

Rolled steel with a round cross-section is made from “black” unalloyed steels, low-alloy, corrosion-resistant, heat-resistant and heat-resistant. Their density depends on the specific brand and is in the range of 7700-7900 kg/m3.

In regulatory documentation and reference books, to calculate the mass of 1 linear meter of steel circle, the average steel density is used - 7.85 kg/dm 3. More accurate calculations are carried out using online calculators, which use exact densities of the main steel grades for calculations.

The range of hot-rolled wheels is determined by GOST 2590-2006. In accordance with this standard, hot-rolled round steel is produced in the diameter range - 5-270 mm. Circles with diameters of 270-300 mm are manufactured only according to individual orders. Cold-rolled products are produced in accordance with GOST 7417-77, diameter range - 3-100 mm.

Volume of a truncated pyramid

The enclosing caps, protective latches and doors have the shape of a truncated pyramid. In such situations, a dependency is used:

, Where:

- h – height of the truncated pyramid;

- F is the area of its larger base;

- f is the area of the smaller base.

If the pyramidal part of the structure sold for scrap is somewhat deformed, then the missing volume is added or removed from each side.

Determining the weight of 1 m of a metal circle using the formula

To calculate the mass of 1 linear meter of rolled steel with a round cross-section, use the formula M = 7.85*π*(d 2 /4000) , in which:

- 7,85 – average value of steel density, kg/dm 3 ;

- π – 3,14;

- d – outer diameter of rolled products with a round cross-section, mm.

The result according to this formula is in kilograms. Using the same formula, you can calculate the mass of a linear meter for other metals and alloys, substituting the density of a specific material instead of the value of 7.85 kg/dm 3.

- aluminum – 2.7 kg/dm 3 ;

- titanium – 4.5 kg/dm 3 ;

- zinc – 7.14 kg/dm3;

- tin – 7.29 kg/dm3;

- copper – 8.94 kg/dm3;

- lead – 11.34 kg/dm3.

To determine the mass of a steel circle, you can use the table.

Weight table for 1m steel circle

| Diameter, mm | Weight 1 m, kg | Diameter, mm | Weight 1 m, kg | Diameter, mm | Weight 1 m, kg |

| 5 | 0,154 | 34 | 7,13 | 110 | 74,6 |

| 6 | 0,222 | 36 | 7,99 | 120 | 88,78 |

| 7 | 0,302 | 38 | 8,9 | 130 | 104,2 |

| 8 | 0,395 | 40 | 9,86 | 140 | 120,84 |

| 9 | 0,499 | 42 | 10,88 | 150 | 138,72 |

| 10 | 0,616 | 45 | 12,48 | 160 | 157,83 |

| 11 | 0,746 | 48 | 14,2 | 170 | 178,18 |

| 12 | 0,888 | 50 | 15,42 | 180 | 199,76 |

| 13 | 1,041 | 53 | 17,32 | 190 | 222,57 |

| 14 | 1,21 | 56 | 19,32 | 200 | 246,62 |

| 16 | 1,58 | 58 | 20,74 | 210 | 271,89 |

| 18 | 2,0 | 60 | 22,19 | 220 | 298,4 |

| 20 | 2,47 | 65 | 26,05 | 230 | 326,15 |

| 22 | 2,98 | 70 | 30,25 | 240 | 355,13 |

| 24 | 3,55 | 75 | 34,68 | 250 | 385,34 |

| 26 | 4,17 | 80 | 39,46 | 260 | 416,57 |

| 28 | 4,83 | 85 | 44,54 | 270 | 449,22 |

| 30 | 5,55 | 90 | 49,94 | 280 | 483,12 |

| 32 | 6,31 | 100 | 61,65 | 554,6 |

What is a conversion factor

Let's complicate the task. Suppose you need to buy a sheet of non-ferrous metal. Let's use a conversion factor, which is the ratio of the density of a particular metal or alloy to the average density of steel. By multiplying the weight of a steel product of a certain range and size by the coefficient of the desired metal or alloy, we obtain the weight of the part.

| Name of metal or alloy | Coefficient |

| Aluminum | 0,34 |

| Copper | 1,14 |

| Brass LS59 | 1,08 |

| Bronze OTS 5-5-5 | 1,12 |

| Gray cast iron | 0,9 |

Example - let's calculate the mass of a bronze sheet with a thickness of 2 mm and an area of 2 m2.

7.85x2x2x1.12 =”” 35.2 kg

Attention! The same simple algorithm can be applied to non-metallic sheet materials, for which there are also conversion factors. For example, for rubber - 0.17-0.23, organic glass - 0.15, caprolon - 0.15, textolite - 0.18, rubber - 0.17-0.23.

Determination of the mass of a batch of rolled steel round section

The standard length of round rods depends on the grade of steel used to manufacture the product. The following standards have been established for hot-rolled metal products:

- rolled products from “black” unalloyed grades of ordinary quality and low-carbon steel – 2-12 m;

- metal products made of high-quality carbon steel and alloy grades - 2-6 m;

- products made of high-alloy steel – 1-6 m.

For cold rolled steel:

- from “black”, low-alloy, automatic, low-alloy, alloy steel – 2-6.5 m;

- from high-alloy grades - 1.5-6.5 m.

To determine the mass of a round rolled product batch, the length of the sections is multiplied by their number, and then by the mass of 1 linear meter.

Source: metallz.ru

How to calculate the mass of a rectangular profile?

A rectangular profile is a parallelepiped with a given wall thickness. The wall thickness is specified in the technical documentation for a specific sample.

Mass calculation can be done in two ways. In the first method, the cross-sectional area is calculated: for a sheet of a given thickness. Calculate the mass of a rectangular parallelepiped based on its external dimensions. Then the same calculations are made for a parallelepiped with internal dimensions. The difference between the two values will be the desired characteristic.

In the second method, the weight of one wall of the structure is calculated. If the cross-section is square, multiply by four. If it is rectangular, the sizes of the smaller and larger walls will be calculated separately. Then multiply each value by two and add the results to get the final figure.

Square profile weight

To simplify the process, special tables have been developed.

Weight of a steel circle. Table.

steel circles as blanks for making parts using mechanical processing. The circle is cut into blanks of the required length of the part, and then the turner produces the part we need on the machine. Also, steel circles are used in production (circles of small diameter), they are used in the manufacture of metal structures of varying complexity.

Round metal products are manufactured with a diameter of 5 to 300 millimeters; sizes larger than a diameter of 270 are manufactured at the discretion of the customer. According to the manufacturing method, they are distinguished: hot-rolled, calibrated (cold-rolled, cold-drawn) .

According to the degree of accuracy, round rolled metal can be: 1. High precision (indicated by the letter “A”), maximum deviations from the specified parameter will be from +0.3mm to -0.9mm; 2. Increased accuracy (indicated by the letter “B”), from +0.6mm to -2.0mm; 3. Normal accuracy (indicated by the letter “B”), from +0.8mm to -4.0mm.

The length of the rolled product depends on the quality of the steel, for example:

— rolled ordinary carbon and low-alloy steel is produced in the range from 2 to 12 meters;

— rolling of high-quality carbon and alloy steels — from 2 to 6 meters;

— low-alloy rolled products — from 1 to 6 meters.

Also, at the customer’s discretion, the circle can be made from 2 to 24 meters in length.

During production, they are guided by maximum deviations along the length of rolled products. There are three types of length deviations, namely: 1. up to 4 meters, 2. from 4 to 6 meters, 3. from 6 meters. In the first case, the value should not exceed 30 mm, in the second 50 mm, and in the third 70 mm. These deviations can be ignored at the discretion of the customer.

Volume of wedge and obelisk

The wedge in the technique is often a pentahedron, the base of which is a rectangle, and the side faces are isosceles triangles or trapezoids. The formula for calculating the volume of a wedge is:

, Where:

- a – side of the base of the wedge foot;

- а1 – width of the wedge top;

- b – wedge thickness;

- h is the height of the wedge.

An obelisk is a hexagon, the base of which is rectangles located in parallel planes. The opposite faces are symmetrically inclined to the base of the obelisk. Volume of this geometric body:

, Where:

- a and b – dimensions of the length and width of the larger base of the obelisk;

- and a1 and b1 – the smaller base of the obelisk;

- h – height of the obelisk.

Weight of a steel circle: Table, Assortment, Calculation formula.

Most often, turners use a steel circle for workpieces, cutting it to the required length, and then machining it. After the required weight and length have been cut, the craftsman makes the required part from it. The metal circle is also used in heavy manufacturing to create metal structures.

The photo shows a steel circle

The round steel product is available in diameters from 5 to 300 mm. Anything above 270 millimeters is created only by pre-order. And, to make it easier to work with this rolled metal, you need to know the weight of the steel circle. This article will provide information about the assortment, the calculation formula, as well as a table of steel wheel weights. It will detail the weight and number of meters per ton of all sections of round metal.

Metal structures subject to fire protection

The protection of metal structures from fire is regulated by the legislation in force in the Russian Federation:

- building codes and regulations (SNiP 21-01-97 (SP 112.13330.2011), SP 2.13130.2012, SP 21-101, 21-102);

- GOST R 53295-2009, NPB 236-97, 30247.0-94;

- work production projects (WPP);

- technical regulations;

- reference books to Federal Law No. 123 “Manual for determining fire resistance limits.”

Supporting metal structures, load-bearing and open ones, are protected from fire. Here it is worth noting the fastenings and connection points. Most often, fire protection is used for structures made of cast iron, steel, and aluminum.

If all measures to protect metal structures from fire are not followed, then the construction project can neither be created nor put into operation. However, these rules do not apply to parts that are not part of the structure.

It should be noted that the choice of re-treatment method, means, as well as the timing of its implementation depend on the fire resistance limit. This concept means the ability of a metal to prevent the spread of fire while maintaining its functions over a certain period of time.

To designate this value, numbers and Latin letters are used, among which

- R – load-bearing function of the metal;

- I – thermal insulation value when the temperature rises to the limit values;

- E – material integrity.

The lowest fire resistance is observed in metal structures that do not have a coating, and the maximum is observed in reinforced concrete products. So, for example, the R120 value indicates that the load-bearing functions of the metal structure will begin to deteriorate after 120 minutes; this is the maximum fire resistance.

Hot rolled circle range

This product comes with:

- with a diameter of up to 9 mm - in skeins;

- with a diameter over 9 mm - in rods.

Depending on what they are intended for, circles are made:

- measured length;

- length, a multiple of the measured length;

- of unmeasured length.

Depending on the length of round metal, they are made from the following steel:

- from 2 to 12 m - from carbon steel of ordinary quality and low-alloy steel;

- from 2 to 6 m - from high-quality carbon and alloy steel;

- from 1 to 6 m - made of high-alloy steel.

Depending on the standardized indicators, rolled products are divided into numbered sections: 1, 2, 3, 4, 5. To designate a category, a category number is added to the designation of the steel grade, for example, St3sp1, St3ps5.

Weight calculation formula

The theoretical weight of 1 meter of a circle is determined by the formula: Mcr = L • ρу, where L is the length of the circle; ρу - theoretical mass of 1 m circle, calculated from its nominal dimensions:

With a steel density ρ = 7850 kg/m 3: ρу = 0.0061654 • d 2, (kg/m), where d is the diameter of the circle in mm.

The most common round bars Ø 16, 18 and 20 have the following weights: 1.578, 1.998, 2.466 kg, respectively.

How to find out the mass of a pipe

Finding the parameter of a metal pipe of any diameter is carried out similarly to the method for a round profile. Calculate the difference in the areas of two circles. The first has the outer radius of the pipe. The second has the inner radius of the pipe.

The resulting difference is multiplied by the length of the pipe, calculating the volume of metal. Multiplying by the density of steel, the mass of a pipe of a given length is found. Operations with non-ferrous metal products are simplified through the use of a conversion factor.

When working with ready-made tables, you should find data for a 1 m bar with a radius equal to the outer diameter. Calculate the diameter of the rod, which is equal to the internal diameter. Subtract the smaller value from the larger value to get the desired result. It should be multiplied by the length of the sample.

Steel circle weight table

The theoretical mass of 1 linear meter of a circle will be given in the table below. It will describe data on all cut diameters from 5 to 300 mm. And also the number of meters in a ton.

| Circle diameter, mm | Meter weight, kg | Meters per ton |

| Circle 5 | 0.154 | 6493.51 |

| Circle 5.5 | 0.187 | 5347.59 |

| Circle 6 | 0.222 | 4504.5 |

| Circle 6.3 | 0.245 | 4081.63 |

| Circle 6.5 | 0.261 | 3831.42 |

| Circle 7 | 0.302 | 3311.26 |

| Circle 8 | 0.395 | 2531.65 |

| Circle 9 | 0.499 | 2004.01 |

| Circle 10 | 0.617 | 1620.75 |

| Circle 11 | 0.746 | 1340.48 |

| Circle 12 | 0.888 | 1126.13 |

| Circle 13 | 1.042 | 959.69 |

| Circle 14 | 1.208 | 827.81 |

| Circle 15 | 1.387 | 720.98 |

| Circle 16 | 1.578 | 633.71 |

| Circle 17 | 1.782 | 561.17 |

| Circle 18 | 1.998 | 500.5 |

| Circle 19 | 2.226 | 449.24 |

| Circle 20 | 2.466 | 405.52 |

| Circle 21 | 2.719 | 367.78 |

| Circle 22 | 2.984 | 335.12 |

| Circle 23 | 3.262 | 306.56 |

| Circle 24 | 3.551 | 281.61 |

| Circle 25 | 3.853 | 259.54 |

| Circle 26 | 4.168 | 239.92 |

| Circle 27 | 4.495 | 222.47 |

| Circle 28 | 4.834 | 206.87 |

| Circle 29 | 5.185 | 192.86 |

| Circle 30 | 5.549 | 180.21 |

| Circle 31 | 5.925 | 168.78 |

| Circle 32 | 6.313 | 158.4 |

| Circle 33 | 6.714 | 148.94 |

| Circle 34 | 7.127 | 140.31 |

| Circle 35 | 7.553 | 132.4 |

| Circle 36 | 7.990 | 125.16 |

| Circle 37 | 8.440 | 118.48 |

| Circle 38 | 8.903 | 112.32 |

| Circle 39 | 9.378 | 106.63 |

| Circle 40 | 9.865 | 101.37 |

| Circle 41 | 10.364 | 96.49 |

| Circle 42 | 10.876 | 91.95 |

| Circle 43 | 11.400 | 87.72 |

| Circle 44 | 11.936 | 83.78 |

| Circle 45 | 12.485 | 80.1 |

| Circle 46 | 13.046 | 76.65 |

| Circle 47 | 13.619 | 73.43 |

| Circle 48 | 14.205 | 70.4 |

| Circle 50 | 15.413 | 64.88 |

| Circle 52 | 16.671 | 59.98 |

| Circle 53 | 17.319 | 57.74 |

| Circle 54 | 17.978 | 55.62 |

| Circle 55 | 18.650 | 53.62 |

| Circle 56 | 19.335 | 51.72 |

| Circle 58 | 20.740 | 48.22 |

| Circle 60 | 22.195 | 45.06 |

| Circle 62 | 23.700 | 42.19 |

| Circle 63 | 24.470 | 40.87 |

| Circle 65 | 26.049 | 38.39 |

| Circle 67 | 27.676 | 36.13 |

| Circle 68 | 28.509 | 35.08 |

| Circle 70 | 30.210 | 33.1 |

| Circle 72 | 31.961 | 31.29 |

| Circle 73 | 32.855 | 30.44 |

| Circle 75 | 34.680 | 28.84 |

| Circle 78 | 37.510 | 26.66 |

| Circle 80 | 39.458 | 25.34 |

| Circle 82 | 41.456 | 24.12 |

| Circle 85 | 44.545 | 22.45 |

| Circle 87 | 46.666 | 21.43 |

| Circle 90 | 49.940 | 20.02 |

| Circle 92 | 52.184 | 19.16 |

| Circle 95 | 55.643 | 17.97 |

| Circle 97 | 58.010 | 17.24 |

| Circle 100 | 61.654 | 16.22 |

| Circle 105 | 67.973 | 14.71 |

| Circle 110 | 74.601 | 13.4 |

| Circle 115 | 81.537 | 12.26 |

| Circle 120 | 88.781 | 11.26 |

| Circle 125 | 96.334 | 10.38 |

| Circle 130 | 104.195 | 9.6 |

| Circle 135 | 112.364 | 8.9 |

| Circle 140 | 120.841 | 8.28 |

| Circle 145 | 129.627 | 7.71 |

| Circle 150 | 138.721 | 7.21 |

| Circle 155 | 148.123 | 6.75 |

| Circle 160 | 157.834 | 6.34 |

| Circle 165 | 167.852 | 5.96 |

| Circle 170 | 178.179 | 5.61 |

| Circle 175 | 188.815 | 5.3 |

| Circle 180 | 199.758 | 5.01 |

| Circle 185 | 211.010 | 4.74 |

| Circle 190 | 222.570 | 4.49 |

| Circle 195 | 234.438 | 4.27 |

| Circle 200 | 246.615 | 4.05 |

| Circle 210 | 271.893 | 3.68 |

| Circle 220 | 298.404 | 3.35 |

| Circle 230 | 326.148 | 3.07 |

| Circle 240 | 355.126 | 2.82 |

| Circle 250 | 385.336 | 2.6 |

| Circle 260 | 416.779 | 2.4 |

| Circle 270 | 449.456 | 2.22 |

Having the above table at hand, you will always know the exact weight of a steel circle of all diameters. And also their number of meters in one ton, which will not allow you to spend extra money when purchasing this rolled metal.

Source: domstrousam.ru

How to find out the mass of a pipe

To determine the mass of pipes, it is optimal to use tables.

| Nominal diameter, inch/mm | Wall thickness, mm | Weight, kg | Nominal diameter, inch/mm | Wall thickness, mm | Weight, kg |

| 1/4 (8) | 2,35 | 0,65 | 1 1/4 (32) | 3,25 | 3,14 |

| 1/2 (15) | 2,65 | 1,22 | 1 1/2 (40) | 3,25 | 3,61 |

| 3/4 (20) | 2,65 | 1,58 | 2 (50) | 3,65 | 5,1 |

| 1 (25) | 3,25 | 2,44 | 2 1/2 (65) | 3,65 | 6,51 |

If you don’t have access to reference materials, and simple geometric formulas are not an obstacle for you, calculate the weight yourself. To do this, we find the difference between the area of the circle along the outer radius and the area along the inner radius. We multiply the resulting difference by the length of the pipe and the density of the steel - 7,850 kg/m3.

For pipes made of non-ferrous metals, the conversion factors that we discussed above are used.

Next, you select the product size.

To make the calculator easier to use, we have developed an interactive search bar that will make it easier to select product sizes

If it is round steel, then the list shows the diameters (rebar 10, 12, etc., circle).

If you want to know the weight of the pipe, then pay attention to the wall thickness.

To find out the weight of the sheet, you need to select the thickness, and then the weight will be calculated per square meters.

What does reduced metal thickness mean?

In the process of calculating materials used to process structures in order to protect them from fire, the given thickness of the metal in millimeters is of great importance. The fire resistance limit of a structure largely depends on it. Despite the fact that the structural elements of buildings that are made of metal are not subject to combustion, when they are exposed to fire, for example, in a fire, they can lose their protective and load-bearing functions, which often causes the collapse of the structure.

The maximum amount of time during which a metal structure is not subject to deformation under the influence of high temperature and open fire is called the fire resistance limit.

VT-metall offers services:

Special protective coatings can increase the fire resistance limit. Most often, paint that contains fire retardants is used for this purpose, which increases the resistance of the metal to fire. The product is applied to the material in such an amount that, firstly, the layer is sufficient to ensure the required effect, and secondly, the structure should not be made heavier. This layer is called adhesive.

Since its thickness directly affects how much paint is required to process the metal structure, the cost of the fire-resistant coating will also depend on this parameter. To determine its optimal thickness, this indicator is calculated.

According to the data specified in NPB 236-97, the reduced metal thickness is calculated as the ratio of the cross-sectional area (S, sq. cm) to the part of the perimeter exposed to fire (heated perimeter (P, cm)).

Then data in meters or tons is entered into one of the fields

If you enter values in the "meters" field ("square meters" to find out the weight of the sheet), then you will know the total weight of the entire length (for example, the weight of the reinforcement).

If you are interested in calculating length by weight, then you need to enter data in the “tons” field.

What makes calculating the weight of metal more difficult?

A serious difference in the data obtained for calculating the mass of a steel product is the technology of its production. The difference between cold-rolled metal and hot-rolled metal can be quite significant. We are talking about the accuracy of geometric characteristics while maintaining density along the entire length of the product.

The use of continuous heating and subsequent cooling leads to such negative phenomena as oxidation and recrystallization. The unevenness of these processes causes a change in such a parameter as thickness.

The accuracy of calculations for cold-rolled and hot-rolled metal profiles will differ. The error caused by thickness instability requires obtaining some average value.

Read also: What can be made from a megaohmmeter

Volumes of rolled profiles

Most often it is necessary to determine the weight of tees, I-beams, channels, and angles. The following dependencies are used for this:

For the brand

,where b and b1 are the width of the shelf and wall of the tee, respectively; h and h1 – thickness of the base and flange of the tee; H – height of the T-bar fragment;

For I-beam

,where H is the height/length of the I-beam; a – I-beam wall thickness; с and с1 – thickness of the I-beam flange at the base and at the end, respectively;

For the corner

,where H is the length of the corner; l1 – angle thickness; h1 and h2, respectively, are the width of each shelf.