Heat resistant tape

Heat-resistant forging

Heat resistant strip

Heat-resistant steel is used in the manufacture of various parts that come into contact with aggressive environments and are subject to significant loads, vibrations and high thermal effects. For example, this includes the following products: turbines, furnaces, boilers, compressors, etc. The following presents the characteristics of heat-resistant, heat-resistant alloys, classification, grades, and features of their application.

Heat-resistant steel (or scale-resistant) is a metal alloy used in an unloaded or lightly loaded state and capable of resisting gas corrosion for a long time at high temperatures (more than 550 ºС). Heat-resistant metals are products that, under high thermal influences, retain their structure, do not collapse, and are not susceptible to plastic deformation. An important characteristic of such metals is the conditional creep limit and long-term strength. Heat-resistant alloys can be heat-resistant, but they are not always so, so in aggressive environments they can quickly become damaged due to oxidation.

Properties of heat-resistant and heat-resistant alloys

To increase heat resistance, alloying additives are used, which also improve the strength of metals. Thanks to alloying, a protective film is formed on the surface of the alloys, which reduces the rate of oxidation of products. Main alloying elements: nickel, chromium, aluminum, silicon. During the heating process, protective oxide films (Cr,Fe)2O3, (Al,Fe)2O are formed. With a content of 5–8% chromium, the heat resistance of steel increases to 700–750 degrees Celsius, with 17% chromium – up to 1000 degrees, with 25% chromium – up to 1100 degrees.

Heat-resistant grades of metals are alloys based on iron, nickel, titanium, cobalt, strengthened by precipitation of excess phases (carbides, carbonitrides, etc.). Chromium-nickel and chromium-nickel-manganese steels have heat resistance. When exposed to high temperatures, they are not prone to creep (slow deformation under constant loads). The melting point of heat-resistant steel is 1400-1500 °C.

Classification of heat-resistant and heat-resistant alloys

At temperatures up to 300 ºС, ordinary structural (carbon) steel is used - a durable and heat-resistant metal. To work in conditions above 350 ºС, the use of heat-resistant metals is required. The main types of alloys with increased heat resistance and thermal strength:

- Pearlitic, martensitic and austenitic;

- cobalt and nickel alloys;

- refractory metals.

Pearlitic heat-resistant steels include boiler steels and silchromes containing a small percentage of carbon. The recrystallization temperature of the material increases due to alloying with molybdenum, chromium, and vanadium. The alloys are characterized by good weldability. The production of martensitic steels is carried out using pearlitic and chromium additives, hardening at 950–1100 ºС. They contain more than 0.15% carbon, 11-17% chromium, small amounts of nickel, tungsten, molybdenum, vanadium. Martensitic steels are resistant to corrosion in alkaline and acidic solutions, high humidity, and when heat treated at 1050 degrees they have high heat resistance.

Heat-resistant austenitic steels can have a homogeneous or heterogeneous structure. An alloy with a homogeneous structure that is not hardened by heat treatment contains a minimum of carbon and many alloying elements, which provides creep resistance. Such materials are suitable for use at temperatures up to 500 °C. In heterogeneous solid solutions, strengthened by heat treatment, carbide, intermetallic, and carbonitride phases are formed, which ensures the use of heat-resistant alloys under stress at temperatures up to 700 °C.

Nickel and cobalt alloys are used at temperatures up to 900 °C: they are used in the production of jet engine turbines and are the best heat-resistant materials. Cobalt alloys are slightly inferior in heat resistance to nickel alloys and are more rare. They are characterized by high thermal conductivity, corrosion resistance at high temperatures, and structural stability during long-term operation.

The nickel content in the nickel alloy is over 55%, carbon 0.06-0.12%. Depending on the structure, there are homogeneous (nichromes) and heterogeneous (nimonics) nickel alloys. Nickel-based nichromes contain chromium as an alloying additive. They are characterized not only by heat resistance, but also by high heat resistance. Nimonics consist of 20% chromium, 2% titanium, 1% aluminum. Alloy grades: KhN77TYU, KhN55VMTFKYu, KhN70MVTYUB.

At temperatures up to 1500 degrees and above, heat-resistant alloys made of refractory metals: tungsten, niobium, vanadium, etc. can work.

| Melting point of refractory metals. | |

| Metal | Melting point, ºC |

| Tungsten | 3410 |

| Tantalum | About 3000 |

| Vanadium | 1900 |

| Niobium | 2415 |

| Zirconium | 1855 |

| Rhenium | 3180 |

| Molybdenum | About 2600 |

The most popular is molybdenum alloy. Elements such as titanium, zirconium, and niobium are used for alloying. To prevent corrosion, the product is siliconized, resulting in a protective coating being formed on the surface. The protective layer allows the heat resistant device to be used at a temperature of 1700 degrees for 30 hours. Other common refractory alloys are tungsten and 30% rhenium, 60% vanadium and 40% niobium, an alloy of iron, niobium, molybdenum and zirconium, tantalum and 10% tungsten.

Nickel-based alloys

Currently, nickel-based alloys are widely used as heat-resistant materials intended for operation in the temperature range of 700...1000 °C. They are used in gas turbines of aircraft engines, ship power and energy installations, the gas industry, aerospace technology, and the petrochemical industry. In an aircraft gas turbine engine, ~70% of its mass is made up of heat-resistant alloys. These are disks, nozzles and turbine blades, combustion chamber elements, etc.

In modern technical literature, there are various classifications of nickel-based alloys, for example, by purpose (disc, blade, boiler, etc.), production method (casting and wrought); degrees of alloying (low-, medium- and high-alloyed), according to their performance at high temperatures (heat-resistant and heat-resistant).

Heat resistance is understood as the ability of an alloy to withstand mechanical loads at high temperatures for a certain time; heat resistance is the ability of an alloy to resist gas corrosion at high temperatures in an unloaded or lightly loaded state.

Nickel alloys in aircraft engine construction usually operate at the limit of their temperature capabilities, since operating temperatures often reach 0.8...0.85 of their melting point. Modern nickel-based heat-resistant alloys are complex alloyed materials: they contain up to seven to nine main alloying elements: Mo, W, Cr, V, Nb, Co, Al, Fe, Cu, Ti. Titanium and aluminum (up to 8...10% in total) form the main strengthening phase – γ`. Chrome and aluminum increase resistance to gas corrosion.

The principles of alloying nickel alloys are the same for casting and wrought alloys, but when creating the latter it is necessary to ensure sufficient technological plasticity during pressure processing, and for casting alloys - satisfactory casting properties (fluidity, porosity).

Hot plastic deformation of high-alloy heat-resistant nickel alloys has the following characteristic features:

- low technological plasticity at all deformation temperatures;

- high resistance to deformation, including deformation in the single-phase region of the solid solution;

- narrow temperature range of deformation, reaching 80...100 °C;

- high sensitivity to overheating.

A characteristic feature of nickel heat-resistant alloys is a high recrystallization temperature, therefore, deviation from the deformation mode leads to the formation of semi-hot work hardening in the metal, which during subsequent heat treatment leads to different or coarse grains. This defect also occurs when stamping alloys in the region of critical degrees of deformation.

The reason for the different grain sizes of rolled products and forgings may be the presence of residual chemical microheterogeneity, expressed in the form of banding or figures reminiscent of the dendrites of the original crystals. The recrystallization temperature depends on the degree of doping. The higher it is, the higher the recrystallization temperature.

The sensitivity of heat-resistant nickel alloys to overheating is expressed in a catastrophic decrease in ductility.

For nickel alloys, the reduction rates per pass must be strictly observed. Moreover, the higher the degree of alloying of the alloy, the lower the permissible degree of reduction during hot forming. At a high degree of deformation, the alloy can locally overheat due to the release of heat during forging, so the upper heating temperature for deformation should be selected taking into account subsequent degrees of compression.

The scope of application, chemical composition, mechanical properties and stamping temperature range for the most commonly used wrought nickel alloys are given in Table. 4–6.

Table 4. Main wrought nickel-based alloys

| Material grade | GOST, TU ___________ | Type of semi-finished product | Pressure treatment | Application area |

| ZN77TYUR (EI 437B) | GOST 23705–79 | Rods | Deforms when hot. The stamping temperature range is 1130…980 °C. Cooling after hot deformation in air | For rotor blades of gas turbines and compressors operating at temperatures up to 750 °C |

| KhN70VMTYu (EI 617) | Deforms when hot. The stamping temperature range is 1180…1050 °C. Cooling after hot deformation in air | For rotor blades of gas turbines operating at temperatures up to 800 °C | ||

| KHN62VMKYU (EI 867) | GOST 23705–79 | Rods | Deforms when hot. The stamping temperature range is 1180…1060 °C. Cooling after hot deformation in air | For rotor blades of gas turbines operating at temperatures up to 900 °C |

| KHN65KYuVMR (EP 617) | TU 14-1-1492–75 | Deforms when hot. The stamping temperature range is 1160…1040 °C. Cooling after hot deformation in air | For working blades and other highly loaded parts of gas turbines and compressors operating for a long time at temperatures up to 900 °C and for a short time at temperatures up to 950 °C | |

| ХН56ВМКУ (EP 109) | TU 14-1-59–73, GOST 23705–79 | Deforms when hot. The stamping temperature range is 1180…1070 °C. Cooling after hot deformation in air | For rotor blades of gas turbines operating at temperatures up to 950 °C | |

| KHN61KMYuVB (EP 874) | TU 14-1-2062–76 | Deforms when hot | ||

| KHN73MBTYU (EI 698) | TU 14-1-1973–77 | Deforms when hot. The stamping temperature range is 1180…1030 °C. Cooling after hot deformation in air | For turbine and compressor discs, deflectors, power rings and long-life fastening bolts operating at temperatures up to 750 °C | |

| ХН62БМКТУ (EP 742) | TU 14-1-3998–85 | Forgings (washers) | Deforms when hot | For turbine and compressor disks operating at temperatures of 550...800 °C and high voltages |

| EK79 (EP 742U) | TU 14-131-561–83 | For turbine and compressor disks operating at temperatures up to 800 °C | ||

| KHN60KMVTYUB (EP 741) | TU 14-131-369–77 | For turbine disks, compressors and other heavily loaded engine parts operating at temperatures up to 850 °C | ||

| KhN60VMB (EP 886, VZh 111) | TU 14-1-4433–88 | Rods | For flame tubes, afterburners and other parts operating for a long time at temperatures up to 1000 °C | |

| ХН60ВТ (EI 868, VZh 98) | TU 14-1-286–72 and 14-131-644–85 | Deforms when hot. Temperature range of stamping 1180…1050 °C | For flame tubes, afterburners and other parts operating for a long time at temperatures up to 900...1000 °C | |

| KHN65VMBU (VZh 131, EP 914) | TU 14-1-3986–85 | Deforms when hot | For welded assemblies operating at temperatures up to 800 °C | |

| KhN62VMTYu (EP 708) | TU 14-1-1018–74 | Deforms when hot. The stamping temperature range is 1180…1000 °C. Cooling after hot deformation in air | For welded power units operating at temperatures up to 850 °C | |

| KHN68MVKTYUR (EP 693) | TU 14-1-3759–84 | Rods | Deforms when hot. The stamping temperature range is 1180…980 °C. Cooling after hot deformation in air | For power welded structures operating for a long time at temperatures of 700...900 °C |

| KHN68VMBTYUK (EP 693M, EK 58) | TU 14-1-3741–84 | For power welded assemblies operating at temperatures up to 950 °C in structures that are subject to increased requirements for heat resistance and ductility | ||

| KhN56VMTYu (EP 199, VZh 101) | TU 14-1-1508–75 | Deforms when hot. The stamping temperature range is 1140…1000 °C. Cooling after hot deformation in air | For welded power units operating at temperatures up to 950 °C | |

| KHN50MVKTYUR (EP 99) | TU 14-1-1476–75 | Deforms when hot. The stamping temperature range is 1160…1050 °C. Cooling after hot deformation in air | For various power welded structures, blades, nozzles of engines operating at temperatures of 700...1000 °C |

Table 5. Chemical composition of nickel-based alloys

| Material grade | GOST, TU | Chemical composition, % | ||||||||

| C | Cr | Al | Ti | Ni | Si | Mn | Ce | Fe | ||

| KHN77TYUR (EI 437B) | GOST 5632–72 | ≤ 0,07 | 19…22 | 0,6…1,0 | 2,4…2,8 | The basis | ≤ 0,6 | ≤ 0,4 | 0,02 | 1 |

| Cu | B | Pb | S | P | – | |||||

| 0,07 | ≤ 0,01 | ≤ 0,001 | ≤ 0,007 | ≤ 0,015 | ||||||

| Material grade | GOST, TU | Chemical composition, % | ||||||||

| C | Cr | Al | Ti | Ni | Si | Mn | Ce | Fe | ||

| KhN70VMTYu (EI 617) | GOST 5632–72 | ≤ 0,12 | 13…16 | 1,7…2,3 | 1,8…2,3 | The basis | ≤ 0,6 | ≤ 0,5 | ≤ 0,02 | ≤ 5 |

| Cu | W | Mo | V | B | S | P | – | |||

| ≤ 0,07 | 5…7 | 2…4 | 0,1…0,5 | ≤ 0,02 | ≤ 0,01 | ≤ 0,015 | ||||

| Material grade | GOST, TU | Chemical composition, % | ||||||||

| C | Cr | Al | Co | Ni | Si | Xie | Fe | Cu | ||

| KhN62VMTYu (EI 867) | GOST 5632–72 | ≤ 0,1 | 8,5… 10,5 | 4,2…4,9 | 4…6 | The basis | ≤ 0,6 | ≤ 0,3 | ≤ 4,0 | ≤ 0,07 |

| W | Mo | B | P | – | ||||||

| 4,3…6,0 | 9,0… 11,5 | ≤ 0,02 | ≤ 0,011 | |||||||

| Material grade | GOST, TU | Chemical composition, % | ||||||||

| C | Cr | Al | Co | Ni | Si | Mn | Ce | Fe | ||

| KHN65KYuVMR (EP 617) | TU 14-1-1492–75 | ≤ 0,1 | 8,5… 10,5 | 4,2…4,9 | 4…6 | The basis | ≤ 0,6 | ≤ 0,3 | ≤ 0,02 | ≤ 1 |

| W | Mo | B | S | P | – | |||||

| 4,5…5,5 | 2,8…3,8 | ≤ 0,02 | ≤ 0,011 | ≤ 0,015 | ||||||

| Material grade | GOST, TU | Chemical composition, % | ||||||||

| C | Cr | Al | Co | Ni | Si | Mn | Ce | Fe | ||

| ХН56ВМКУ (EP 109) | GOST 5632–72 | ≤ 0,1 | 8,5… 10,5 | 6,4…6,2 | 11…13 | The basis | ≤ 0,6 | ≤ 0,3 | ≤ 0,02 | ≤ 1,5 |

| Cu | W | Mo | B | S | P | – | ||||

| ≤ 0,07 | 6,0…7,5 | 6,5…8,0 | ≤ 0,02 | ≤ 0,01 | ≤ 0,015 | |||||

| Material grade | GOST, TU | Chemical composition, % | ||||||||

| C | Cr | Al | Co | Ni | Si | Mn | Ce | Fe | ||

| KHN61KMYuVB (EP 874) | TU 14-1-2062–76 | 0,01…0,08 | 8,5…10,0 | 5,5…6,2 | 11…15 | The basis | ≤ 0,3 | 0,005… 0,002 | ≤ 1 | |

| Cu | W | Mo | Nb | B | Zr | S | P | – | ||

| ≤ 0,07 | 3,5…6,0 | 4,5…7,0 | 0,8…1,5 | 0,005… 0,050 | 0,001… 0,100 | ≤ 0,01 | ≤ 0,0015 | |||

| Material grade | GOST, TU | Chemical composition, % | ||||||||

| C | Cr | Al | Ti | Ni | Si | Mn | Ce | Fe | ||

| KHN73MBTYU (EI 698) | TU 14-1-285–72 | 0,03…0,07 | 13…16 | 1,45…1,8 | 2,35… 2,75 | The basis | ≤ 0,5 | ≤ 0,4 | ≤ 0,005× | ≤ 2 |

| Mo | Nb | B | Pb | S | P | – | ||||

| 2,8…3,2 | 1,9…2,2 | ≤ 0,005× | ≤ 0,001 | ≤ 0,007 | ≤ 0,0015 | |||||

| Material grade | GOST, TU | Chemical composition, % | ||||||||

| C | Cr | Al | Ti | Ni | Si | Mn | Ce | Fe | ||

| ХН62БМКТУ (EP 742) | TU 14-1-1998–85 | 0,04…0,08 | 13…15 | 2,4…2,8 | Basics | ≤ 0,3 | ≤ 0,4 | ≤ 0,01× | ≤ 1 | |

| Cu | W | Mo | V | B | La | S | P | Co | ||

| ≤ 0,07 | ≤ 0,2 | 4,5…5,5 | ≤ 0,2 | ≤ 0,01× | ≤ 0,1 | ≤ 0,01 | ≤ 0,015 | 9…11 | ||

| Nb | – | |||||||||

| 2,4…2,8 | ||||||||||

| Material grade | GOST, TU | Chemical composition, % | ||||||||

| C | Cr | Al | Ti | Ni | Fe | Si | Mn | Ce | ||

| EK 79 (EP 742U) | TU 14-1-131-561–83 | 0,04…0,08 | 10…12 | 2,8…3,3 | 2,4…3,0 | The basis | ≤ 1 | ≤ 0,4 | ≤ 0,01× | |

| Nd | Co | W | Mo | V | B | Nb | La | S | ||

| ≤ 0,05× | 12,5… 16,0 | 2…3 | 4…5 | 0,4… 0,8 | ≤ 0,01× | 2,5… 3,0 | ≤ 0,05× | ≤ 0,01 | ||

| P | Mg | – | ||||||||

| ≤ 0,015 | ≤ 0,05× | |||||||||

| Material grade | GOST, TU | Chemical composition, % | ||||||||

| C | Cr | Al | Ti | Ni | Si | Mn | Ce | Fe | ||

| KHN60KMVTYUB (EP 741) | OST 1-92111–85 | ≤ 0,06 | 8,0… 10,5 | 4,5…5,2 | 1,3…1,7 | The basis | ≤ 0,5 | ≤ 0,01 | ≤ 1 | |

| Co | W | Mo | Mg | B | Zr | S | P | Nb | ||

| 14,6…17,5 | 6,3…7,2 | 2,2…3,0 | ≤ 0,05 | ≤ 0,02× | ≤ 0,025 | ≤ 0,009 | ≤ 0,015 | 1,2…1,6 | ||

| Material grade | GOST, TU | Chemical composition, % | ||||||||

| C | Cr | Al | Ti | Ni | Si | Mn | Ce | Fe | ||

| Х60MVB (EP 886, VZh 111) | TU 14-1-2760–79 | ≤ 0,1 | 23…26 | 0,2…0,7 | 0,2…0,8 | The basis | ≤ 0,5 | ≤ 0,5× | ≤ 0,02× | ≤ 5 |

| Nb | W | Mo | Mg | B | S | P | – | |||

| 0,4…1,0 | 5…7 | 3,0…4,5 | ≤ 0,06× | ≤ 0,005× | ≤ 0,5× | |||||

| Material grade | GOST, TU | Chemical composition, % | ||||||||

| C | Cr | Al | Ti | Ni | Si | Mn | Fe | Cu | ||

| KhN60VMB (EI 868, VZh 98) | TU 4-1-1747–76 | ≤ 0,1 | 23,5… 26,5 | ≤ 0,5 | 0,3…0,7 | The basis | ≤ 0,8 | ≤ 0,5 | ≤ 4 | ≤ 0,07 |

| W | S | P | – | |||||||

| 13…16 | ≤ 0,013 | |||||||||

| Material grade | GOST, TU | Chemical composition, % | ||||||||

| C | Cr | Al | Si | Ni | Mn | Nb | Fe | Nd | ||

| KHN65VMBU (EP 914, VZH 131) | TU 14-1-2689–79 | ≤ 0,06 | 17,0… 18,5 | 1,5…1,9 | ≤ 0,5 | The basis | ≤ 0,5 | 4,0… 4,7 | ≤ 1,5 | 0,1…0,2 |

| W | Mo | B | S | P | – | |||||

| 5,5…7,5 | 3…5 | ≤ 0,006× | ≤ 0,015 | |||||||

| Material grade | GOST, TU | Chemical composition, % | ||||||||

| C | Cr | Al | Ti | Ni | Si | Mn | Ce | Fe | ||

| KhN62VMTYu (EP 708) | TU 14-1-3556–83 | 0,05…0,10 | 17,5… 20,0 | 1,9…2,3 | 1,0…1,4 | The basis | ≤ 0,6 | ≤ 0,5 | ≤ 0,03× | ≤ 4 |

| W | Mo | B | S | P | – | |||||

| 5,5…7,5 | 4…6 | ≤ 0,008* | ≤ 0,015 | |||||||

| Material grade | GOST, TU | Chemical composition, % | ||||||||

| C | Cr | Al | Ti | Ni | Si | Mn | Ce | Fe | ||

| KHN68MVKTYUR (EP 693) | TU 14-1-1960–77 | ≤ 0,1 | 17…20 | 1,6…2,3 | 0,1…1,6 | The basis | ≤ 0,5 | ≤ 0,4 | ≤ 0,005× | ≤ 5 |

| Co | W | Mo | Nb | B | S | P | – | |||

| 5…8 | 5…7 | 3,5…5,0 | ≤ 0,1 | ≤ 0,005× | ≤ 0,015 | |||||

| Material grade | GOST, TU | Chemical composition, % | ||||||||

| C | Cr | Al | Ti | Ni | Si | Mn | Ce | Fe | ||

| KHN68VMBTYUK (EP 693M, EK 58) | TU 14-1-3741–84 | ≤ 0,1 | 16…19 | 1,8…2,4 | 1,0…1,5 | The basis | ≤ 0,5 | ≤ 0,4 | ≤ 0,02× | ≤ 3 |

| Co | W | Mo | Nb | B | Zr | S | P | Mg | ||

| 1,5…3,5 | 2,8…4,8 | 3,5…5,0 | 0,7…1,3 | ≤ 0,02× | ≤ 0,1× | ≤ 0,015 | ≤ 0,05× | |||

| Material grade | GOST, TU | Chemical composition, % | ||||||||

| C | Cr | Al | Ti | Ni | Si | Mn | Fe | W | ||

| KhN56VMTYu (EP 199, VZh 101) | TU 14-1-2479–78 | ≤ 0,1 | 19…22 | 2,1…2,6 | 1,1…1,6 | The basis | ≤ 0,6 | ≤ 0,5 | ≤ 4 | 9…11 |

| Mo | Mg | B | S | P | – | |||||

| 4…6 | ≤ 0,05 | ≤ 0,008 | ≤ 0,015 | |||||||

| Material grade | GOST, TU | Chemical composition, % | ||||||||

| C | Cr | Al | Ti | Ni | Si | Mn | Ce | Fe | ||

| KHN50MVKTYUR (EP 99) | TU 14-1-1747–76 | ≤ 0,1 | 17,5… 19,5 | 2,5…3,0 | 1,0…1,5 | The basis | ≤ 0,3 | ≤ 0,002* | ≤ 3,0 | |

| Cu | W | Mo | Nb | B | Co | S | P | – | ||

| ≤ 0,07 | 5,5…7,0 | 3,5…5,0 | ≤ 1,5 | ≤ 0,005* | 5…8 | ≤ 0,015 | ||||

×Entered by calculation.

Table 6. Heat treatment modes and mechanical properties of the main wrought nickel-based alloys

| Material grade | Type of semi-finished product | Heat treatment | GOST, TU ___________ | Mechanical properties | |||||

| σв, MPa | σ0.2, MPa | δ, % | Ψ, % | ak, (kgf m)/cm2 | НВ, dotp, mm | ||||

| KHN77TYUR (EI 437B) | Hot rolled rods | Quenching at 1080 °C, holding for 8 hours, cooling in air. Aging at 700 °C for 16 hours | GOST 23705–79 | 950… 1100 | 620… 700 | 15 | 30 | 6 | 3,40… 3,45 |

| KhN70VMTYu (EI 617) | First hardening at 1190 °C, holding for 2 hours; second hardening at 1050 °C, holding for 4 hours, cooling in air. Aging at 800 °C for 16 hours | 1140 | 750 | 14 | 15 | 1,5…3,0 | 3,45 | ||

| KHN62VMKYU (EI 867) | Quenching at 1220 °C, holding for 4...6 hours, cooling in air. Aging at 950 °C for 8 hours | 1100… 1250 | 750… 850 | 17 | 20 | 3…5 | 3,25… 3,60 | ||

| KHN65KYuVMR (EP 617) | Quenching at 1220 °C, holding for 4...6 hours, cooling in air. Aging at 850 °C, holding for 24 hours | TU 14-1-1492–75 | 1170… 1200 | 830… 850 | 15… 20 | 16… 19 | 3 | 3,3… 3,6 | |

| ХН56ВМКУ (EP 109) | Quenching at 1220 °C, holding for 4...6 hours, cooling in air. Aging at 925 °C, holding time 8…10 h | GOST 23705–79, TU 14-1-5.9–73 | 1330 | 950 | 16 | – | 4,5 | – | |

| KHN61KMYuVB (EP 874) | Hot rolled rods | Quenching at 1220 °C, holding for 4 hours, cooling in air. First aging at 960°C, holding for 4 hours, second aging at 850°C, holding for 16 hours | TU 14-1-1973–77 | 1100… 1250 | 850… 950 | 10… 15 | 10… 15 | 3…6 | 302.. 388 NV |

| KHN73MBTYU (EI 698) | Quenching at 1120 °C, holding for 8 hours, cooling in air; hardening at 1000 °C, holding for 4 hours, cooling in air. First aging at 775 °C, hold for 16 hours; second aging at 700 °C, holding for 16…24 hours, cooling in air | TU 14-1-1973–77, 14-1-5329–96, 14-1-285–72 and 14-1-2792–79 | 1180 | 740 | 14 | 16 | 4 | 3,5… 3,2 | |

| ХН62БМКТУ (EP 742) | Forgings (washers) | Quenching at 1090…1120 °C, holding for 8 hours, cooling in air. First aging at 850 °C for 6 hours; second aging at 780 °C, holding for 10...16 hours, cooling in air | TU 14-1-3998–85 | 1230 | 770 | 13 | 14 | 3 | 3,15… 3,50 |

| EK 79 (EP 724 U) | Forgings (washers) | Annealing at 1040 °C, holding for 42 hours, cooling in air. Quenching at 1120…1160 °C, holding for 8 hours, cooling in air. First aging at 850 °C, hold for 6 hours; second aging at 780 °C, holding for 10...16 hours, cooling in air | TU 14-1-131-561–83 | 1300 | 900 | 14 | 3,5 | 3,15… 3,45 | |

| KHN60KMVTYUB (EP 741) | Rods | First hardening at 1180 °C, holding for 5 hours, cooling in air; second hardening at 1050 °C, holding for 4 hours, cooling in air. Aging at 910 °C, 12 h | TU 14-131-369–77 | 1400.. 1500 | 950… 1050 | 20… 25 | 25… 30 | 4,0…4,5 | 3,20… 3,45 |

| ХН60ВТ (EI 868, VZh 98) | Quenching at 1150…1200 °C, holding for 1 hour, cooling in air | TU 14-1-286–72 | 750 | – | 30 | – | |||

| KHN65VMBU (EP 914, VZH 131) | Quenching from 1110 °C, cooling in air. Aging at 800 °C, holding time 15 hours | TU 14-1-3986–85 | 1000 | 700 | 35 | 10 | – | ||

| KhN62VMTYu (EP 708) | Quenching from 1140 °C, cooling in air. Aging at 800 °C, holding time 15 hours | TU 14-1-1018–74 | 1100 | 18 | 20 | – | |||

| KHN68MVKTYUR (EP 693) | Rods | Quenching at 1080…1110 °C, holding for 2 hours, cooling in air. Aging at 900 °C, holding time 5 hours | TU 14-1-3759–84 | 950 | 530 | 32 | 37 | – | |

| Quenching at 1000 °C, holding for 4 hours, cooling in air. Aging at 700 °C, holding time 16 hours | 1050 | 680 | 25 | 30 | |||||

| KHN68VMBTYUK (EK 58, EP 693 M) | Quenching at 1150 °C, holding for 3 hours, cooling in air. Aging at 800 °C, holding time 16 hours | TU 14-1-3741–84 | 1100… 1150 | 670… 700 | 35…40 | ||||

| KhN56VMTYu (EP 199, VZh 101) | Quenching at 1150…1200 °C, air cooling | TU 14-1-1508–75 | 1050 | – | 25 | – | |||

| KHN50MVKTYUR (EP 99) | Quenching from 1080...1100 °C, holding for 2...4 hours, cooling in air. Aging at 760 °C, holding time 12…16 h | TU 14-1-2786–79 | 1250 | 800 | 20 | 22 | 3 | – | |

| TU 14-1-1476–75 | 1200 | 17 | 19 | 2,5 | |||||

Grades of heat-resistant and heat-resistant steels

Depending on the state of the structure, austenitic, martensitic, pearlitic and martensitic-ferritic heat-resistant metals are distinguished. Heat-resistant alloys are divided into ferritic, martensitic or austenitic-ferritic types.

| Application of martensitic steels. | |

| Steel grades | Products made of heat-resistant steels |

| 4Х9С2 | Automotive engine valves, operating temperature 850–950 ºC. |

| 1Х12H2ВМФ, Х6СМ, Х5М, 1Х8ВФ, Х5ВФ | Units and parts operating at temperatures up to 600 ºC for 1000–10000 hours. |

| X5 | Pipes operated at operating temperatures up to 650 ºC. |

| 1Х8ВФ | Steam turbine components that operate at temperatures up to 500 ºC for 10,000 hours or more. |

Pearlitic grades having a chromium-silicon and chromium-molybdenum composition of heat-resistant steel: Kh13N7S2, Kh10S2M, Kh6SM, Kh7SM, Kh9S2, Kh6S. Chrome-molybdenum compounds 12МХ, 12ХМ, 15ХМ, 20ХМЛ are suitable for use at 450-550 °С, chrome-molybdenum vanadium 12Х1МФ, 15Х1М1Ф, 15Х1М1ФЛ - at temperatures 550-600 °С. They are used in the production of turbines, shut-off valves, apparatus casings, steam lines, pipelines, and boilers.

Ferritic steel is made by firing and heat treatment, due to which it acquires a fine-grained structure. These include brands X28, X18SYU, 0X17T, X17, X25T, 1X12SYU. The chromium content in such alloys is 25-33%. They are used in the production of heat exchangers, equipment for chemical production (pyrolysis equipment), furnace equipment and other structures that operate for a long time at high temperatures and are not subject to heavy loads. The more chromium in the composition, the higher the temperature at which the steel retains its performance properties. Heat-resistant ferritic steel does not have high strength or heat resistance, but is characterized by good ductility and good technological parameters.

Martensitic-ferritic steel contains 10-14% chromium, alloying additives vanadium, molybdenum, tungsten. The material is used in the manufacture of machine elements, steam turbines, nuclear power plant equipment, heat exchangers for nuclear and thermal power plants, parts intended for long-term operation at 600 ºC. Steel grades: 1Х13, Х17, Х25Т, 1Х12В2МФ, Х6СУ, 2Х12ВМБФР.

Austenitic steels are widely used in industry. The heat-resistant and heat-resistant characteristics of the material are ensured by nickel and chromium and alloying additives (titanium, niobium). Such steels retain technical properties that are resistant to corrosion when exposed to temperatures up to 1000 ºC. Compared to ferritic steels, austenitic alloys have increased heat resistance and the ability to be stamped, drawn, and welded. Heat treatment of metals is carried out by hardening at 1000–1050 °C.

| Application of austenitic grades. | |

| Steel grades | Application of heat-resistant steels |

| 08X18Н9Т, 12Х18Н9Т, 20Х25Н20С2, 12Х18Н9 | Exhaust systems, sheet and section parts, pipes operating at low loads and temperatures up to 600–800 °C. |

| 36Х18Н25С2 | Furnace containers, fittings, operated at temperatures up to 1100 °C. |

| Х12Н20Т3Р, 4Х12Н8Г8МФБ | Engine valves, turbine parts. |

Austenitic-ferritic steels have increased heat resistance compared to conventional high-chromium alloys. Such metals are used in the manufacture of unloaded products, operating temperature is 1150 ºC. Pyrometric tubes are made from grade X23N13, and furnace conveyors, tanks for cementation, pipes are made from grade X20N14S2, 0X20N14S2

Alfa-Steel is:

- A huge range of all types of rental products available in stock.

- Professional logistics: - minimum order delivery time - 1 hour; — minimum delivery cost – 800 rubles. (consolidated cargo).

- Professional advice on any product and service.

We will answer questions and accept orders: +7 (495) 725-66-37

Email: [email protected]

Order metal, receive CP

Our advantages

Blanks We will cut the required size from a sheet, circle, pipe and sell without reserve

. We use black, non-ferrous and stainless steel products for our workpieces.

Deferred payment For regular customers, deferred payment up to RUB 5,000,000. for up to 31 days.

Reliable Return money or goods for any reason, quickly and without problems.

Accredited supplier of the state corporation "Rosatom" Our metal is constantly tested for chemicals. composition - all technical characteristics for the rarest and most complex steels fully correspond to the declared ones.

Wholesale and retail From a rod and a kilogram to a dozen wagons.

Recommendations Check out reviews from our clients

The warehouse is open around the clock. We will load the car and issue documents at any time of the day or night.

Fast and inexpensive delivery We load cars the next day. We release on payment. Low prices: from 2500 rub. with VAT for a separate car.

+ More benefits

Casting heat-resistant nickel alloys

Cast heat-resistant nickel alloys are largely reminiscent of some wrought nickel alloys in chemical and phase composition. For example, foreign nickel heat-resistant alloys Nimocast 80 and 90 differ little from Nimonics 80 and 90, etc.

The highest heat resistance characteristics are found in heat-resistant cast nickel alloys ZhS6-K (12% Cr, 2.75% Ti, 5.5% Al, 4% Mo, 4.5% Co, 5% W, 0.02% B), MAR-M-211 (9% Cr, 2% Ti, 5% Al, 10% Co, 5.5% W, 2.7% Nb, 0.05% Zr, 0.02% B), which have a limit long-term strength at 900° C s100 = 320 MPa, and at 1000° C s100 = 150-180 MPa.

This is explained by the moderate content of alloying elements that reduce the solidus temperature (titanium, niobium, molybdenum, chromium), and the increased content of elements that do not reduce the solidus temperature of alloys (cobalt, tungsten), with a high aluminum content.

Cast heat-resistant nickel alloys are used for the manufacture of blades, gas turbine aircraft engines and other parts. Recently, the ZhS6-K alloy (Fig. 4.21) began to be used in a deformable version (ZhS6-KP) due to improvements in its manufacturing technology.

To increase heat resistance, the use of high-purity (in terms of low-melting impurities) charge materials and protective environments during melting, casting and heat treatment of heat-resistant nickel alloys, which exclude oxidation and depletion of the surface layers of products with alloying elements, is of particular importance.

The hardening temperature of heat-resistant nickel alloys is in a certain way related to their chemical (and phase) composition and the amount of excess hardening phases. The more the main strengthening phase Ni3(Al,Ti) or Ni3Al is in the alloy, the higher, other things being equal, is its quenching temperature. Alloys EI437A, EI437B, as well as nimonics 80 and 80A, containing on average about 10% of the Ni3(Al,Ti) phase, are quenched at 1080 ° C, and alloys EI867, EI929 and nimonics 105 and 115, containing 3-4 times more hardener Ni3(Al,Ti), - from 1220°C. Double hardening is used (1160° C, 2 hours,

air and 1080°C, 4

hours,

air), aging is first carried out at 840°C for 2

hours, and

then at 760°C for 16

hours.

This aging regime provides the most optimal combination of heat resistance and ductility characteristics.

Heat-resistant cobalt alloys

Cobalt is an analogue of nickel, but undergoes a polymorphic transformation. Below 477° C, cobalt has an hcp lattice, and above it has an fcc lattice. According to the characteristics of short-term and long-term heat resistance, cobalt and nickel are similar, although the creep limit during compression of cobalt at 1000 ° C is three times higher than that of nickel. In terms of alloys, the best high-temperature cobalt alloys cannot compete with the best high-temperature nickel alloys. If we add to this that cobalt is a scarce and expensive metal, then it becomes clear why heat-resistant cobalt alloys are trying, where possible, to be replaced with nickel ones. There are American alloys HS-23 (25% Ni, 19% Cr, 10% W, 1.5% Nb, 1% Fe) and YS-27 (10% Ni, 20% Cr, 15% W, 1.5% Mn, 0.5% Si), HS-21 (called Vitallium, 32% Ni, 27% Cr, 5% Mo, 1% Fe, 0.25% C, 0.6% Mn, 0.6% Si)

Refractory metals and alloys based on them

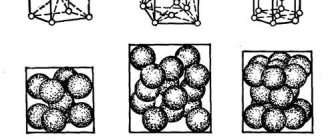

Metallurgy of refractory metals is a relatively new branch of the science of metals. Refractory are metals whose melting point is equal to or higher than the melting point of chromium (1863 0C). There are thirteen such metals in Mendeleev’s periodic table. They belong to the transition metals of the three large periods of the periodic system and are in groups IV-VIIIA (Table 4.4).

Table 4.4.

Arrangement of refractory metals in the periodic table of elements

| Period number | Group number | ||||

| IVA | VА | VIA | VIIA | VIIIA | |

| First | V | Cr | |||

| Second | Nb | Mo | Tc | Ru, Rh | |

| Third | Hf | Ta | W | Re | Os, Jr |

Although most of these metals have been known to science for a long time (only hafnium, rhenium and technetium were discovered in the 20th century), the widespread use of refractory metals as the basis for structural materials began relatively recently, in the post-war years, especially in the 50s and 60s. The development of new branches of technology such as supersonic aviation, rocket technology, nuclear energy, and the electronics industry required the creation of materials that have high strength at temperatures above 1100 0C and even above 20000C. Heat-resistant steels and alloys can operate up to 600-750 0C, heat-resistant alloys based on nickel and cobalt are used up to 950-1050 0C. Modern technology for creating super-alloys: producing rapidly hardened alloys using granular metallurgy, single-crystal casting, directional crystallization and other technologies make it possible to raise the ceiling to 1100-1150 0C.

The disadvantages include their high tendency to cold brittleness. It is especially pronounced in group VIA metals - chromium, molybdenum and tungsten. For these metals of technical purity, the transition temperature from a brittle to a ductile state is above room temperature (chromium, tungsten) or close to room temperature (molybdenum). This creates difficulties in their production and use. Another significant disadvantage of refractory metals is their high tendency to oxidize and interact with other air gases (except oxygen) when heated, i.e. low heat resistance. This makes them low-tech and requires the use of protective environments in the form of inert gases or vacuum in the production of semi-finished products and products. In addition, the low heat resistance of refractory metals necessitates the application of protective coatings to products when operating at high temperatures.

At elevated temperatures, the chemical activity of refractory metals increases sharply. This creates one of the main problems when working with refractory metals – their low heat resistance. Noticeable oxidation of refractory metals begins at low temperatures - 400-6000C. Above a temperature of 6000C, all the metals under consideration, with the exception of chromium, actively interact with oxygen. At operating temperatures, oxidation rates become catastrophically high, so that there can be no question of using them in an oxidizing environment without protective coatings. For example, a molybdenum sheet without protection at 12000C oxidizes through and through in a few minutes. To increase the heat resistance of refractory metals, small amounts of active metals of group IIIA and IVA (V, La, Zr, Ti, Hf) are introduced into the alloys, which form stable oxides. The most commonly used is cladding with more heat-resistant metals (chrome plating, galvanizing); apply thermal diffusion method multilayer coatings, which include chromium, silicon, or oxides (Al2O3, ThO2, ZrO2), silicides MoSi2, etc.; metals are applied by electrolytic method, spraying.

Alloys of refractory metals.

Niobium alloys.

Niobium alloys are the most numerous among the alloys of refractory metals. Since niobium has the lowest density among refractory metals. Therefore, in terms of specific strength and heat resistance in the temperature range 900-13000C. These alloys have good processability compared to molybdenum and tungsten. In addition, niobium alloys are easily weldable and have good corrosion resistance. The main alloying elements are molybdenum, tungsten, zirconium (15% W, 10% Mo, 7% V, 5% Zr). To heterogenize the structure, carbon is introduced into individual alloys (VN3, VN4), and to improve technological properties, some alloys are alloyed (deoxidized) with rare earth metals (La, Ce), for example, alloys VN4, VN5. For example, for the VN3 alloy, at room temperature sB = 770 MPa, at 1100 0C - 450 MPa, and at 1500 0C - 125 MPa.

Tantalum alloys.

The main advantage of tantalum alloys is their high manufacturability during pressure treatment and good weldability, which makes it possible to obtain ductile welded joints at room and lower temperatures. Existing heat-resistant tantalum alloys contain 1-2 alloying elements (tungsten, zirconium, hafnium, niobium, vanadium). These elements, even in large quantities (up to 10%), do not embrittlement tantalum. In terms of strength, thanatl alloys up to 1200 0C are at the level of niobium alloys, and at higher temperatures they are inferior to molybdenum and tungsten alloys. Tantalum alloys require protection against oxidation. The basis of corrosion-resistant alloys are alloys of the Ta-Nb system.

Molybdenum alloys.

When creating heat-resistant alloys, molybdenum is alloyed with elements that strengthen the matrix due to the formation of solid solutions and particles of excess phases. But with such alloying, ductility decreases and the temperature of the brittle transition increases. Therefore, molybdenum alloys are lightly alloyed, the total content of elements is 1-1.5% (alloys TsM2A (0.1% Zr, 0.2% Ti), TsM5 (0.5% Zr, 0.06% C), with operating temperatures of 13000C , sВ=250 MPa and 16000С, sВ=500 MPa, respectively), with the exception of alloys with increased heat resistance - TsMV30 (30% W) and MP47VP (47% Re), which have a cold brittleness threshold below room temperature. All molybdenum alloys require the use of protective coatings.

Tungsten alloys.

The creation of tungsten alloys has its own specific characteristics. These alloys require an increase in high-temperature short-term and long-term strength, as well as an improvement in low-temperature ductility. An increase in strength characteristics can be effectively achieved through strain hardening, but such hardening is effective up to 0.4 of the melting temperature. At higher temperatures, due to developing recrystallization processes, the alloys quickly soften. To reduce the melting point (solidus) to a minimum, Ta, Mo, Nb, and Re are introduced into tungsten alloys. To prevent embrittlement, a group of alloys such as MV, VR and MVR with 15-50% Mo and 5-25% Re was created (such alloys have at 13700C, sB = 324 MPa, sB = 560 MPa, at 16500C, sB = 206 MPa, sB = 210 MPa, respectively). The maximum achieved heat resistance characteristics are associated with heterophase strengthening, i.e. alloys with carbide and oxide hardening (alloy with 0.92% Zr-0.72% C at 16500C have sВ=546 MPa and at 19270С sВ=436 MPa, alloy with 4% Re-0.28%Hf - 0.39 %C at 19270C, sВ=414 MPa). An increase in the heat resistance characteristics of tungsten alloys can be achieved by increasing the volume fraction of strengthening phases, but in this case the manufacturability of the alloys sharply deteriorates. Therefore, it is possible to create other alloys using granule metallurgy, mechanical alloying, etc.

Bearing alloys

Bearing

Alloys are the alloys from which bearing shells are made.

For this purpose, cast iron, bronze and low-melting alloys based on lead, tin, zinc or aluminum, the so-called babbits, are used.

Despite the increasing use of rolling bearings (ball or roller bearings) in machines, plain bearings are used quite widely.

The metal of the liner must have the following properties:

1) the coefficient of friction with the steel surface should be small; 2) both rubbing surfaces should wear out little; 3) this material must withstand sufficient specific pressures.

The first and second requirements are satisfied when the surface of the shaft and liner is separated by a lubricant film. If the structure of the liner is heterogeneous and consists of hard inclusions and a soft base, then after a short period of work (“running in”) a microrelief is formed on the surface of the liner - solid inclusions protrude and a space is formed between the shaft and the liner in which the lubricant is retained (the so-called “Charpy principle” ).

Tin alloys and lead alloys have a similar structure. However, these alloys, due to their low strength, cannot withstand high pressures, and due to their low melting point, they cannot withstand relatively little heating. In modern mechanical engineering, as already indicated, cast iron, bronze and babbitt, as well as porous sintered materials, are used for bearing shells.

Cast iron liners are made of gray pearlitic cast iron (grades AChTs-1 and AChTs-2); this is the cheapest material for liners; it can withstand significant specific pressures, but due to the higher coefficient of friction (for a steel-cast iron pair compared to a bronze-steel or Babbitt-steel pair), cast iron liners should not be used in high-speed engines.

Bronze inserts are made from tin and lead bronze. Due to the heterogeneous structure of bronze (in tin bronze, the a-solid solution is a soft base, and the eutectoid a + b is a solid inclusion), the lubricant is well retained on the surface of the liner. Bronzes have high strength. The above allows the use of bronze liners for critical bearings operating under difficult conditions (high specific pressures, high speeds).

When using very soft, low-melting bearing alloys, less wear of the shaft journal is ensured. Babbitts, in addition, have a minimal coefficient of friction with steel and retain lubricant well. Therefore, along with cast iron and bronze liners, low-melting alloys based on tin, lead, as well as zinc and aluminum are widely used in mechanical engineering for bearing liners.

Bearing

alloys based on tin or lead are poured into a steel or cast iron bearing race (casting alloys). Liquation heterogeneity significantly worsens their performance properties. The rotating shaft and the liner (filled alloy) wear out each other with any, even very good, lubrication. In production conditions, they tend to wear out mainly the liner, which is relatively easy to replace. The shaft should be much harder and wear out much less than the liner, but still the liner should not wear out quickly. The material of the rubbing pair (in this case, the shaft - liner) is selected in such a way as to obtain a minimum coefficient of friction with good thermal conductivity of the liner. Among pure metals paired with steel, only silver satisfies these conditions, which, due to its high cost, is used only for especially critical small-sized aircraft bearings.

In tin and lead alloys, such a combination of opposite properties, the liner material must be both hard and soft at the same time, is carried out if they are two-phase or even multiphase. One of the components must be hard, and the other soft and plastic. There should be less of the hard component and its crystals in the form of inclusions should be evenly distributed in the soft component (base). During the running-in process, the soft base is first abraded and the inclusions of the hard component appear protruding (in relief), then the friction is mainly transferred to them. The lubricant, located in the gap between the shaft and the liner, flows around them and is retained by them. The pressure that occurs at individual points is absorbed due to the fact that the solid inclusions of the alloy are pressed into the soft base.

based alloys,

so-called

babbits

are used as bearings for railway rolling stock.

They are alloyed with antimony (up to 12%) and

copper (up to

6.5%).

Their structure is mainly determined by the Sn–Sb equilibrium diagram (peritectic type diagram). The microstructure of the B83 alloy shows a soft a-phase (dark) and hard crystals of the b-phase (light squares). During solidification, phase b precipitates in the binary alloy first. There is much more antimony in the b-phase than in the liquid phase from which it precipitates. Tin has a much higher density than antimony, and therefore the b-phase floats up - a density segregation is formed. To prevent it, copper is administered. Copper, together with tin, forms the e-phase (~Сu3Sn), and it is refractory and precipitates during solidification before the b-phase. In density it is close to the liquid phase and therefore, when it falls out, it is distributed evenly throughout its entire volume. After this, crystals of the b-phase fall out of the liquid, but their floating in the ternary alloy is prevented by small crystals of the e-phase. Tin based bearing alloys are the best alloys.

Lead-based alloys are their substitutes. Ternary alloys are alloyed with antimony (16-18%) and copper (up to 3%). In ternary alloys containing 3% Cu, antimony is released in the form of regularly faceted primary crystals and is a solid component of the bearing alloy. The soft base is the Pb-Sb eutectic. Although it contains 87% Pb, it is still harder and more brittle than the a-phase in tin-based babbitts. Liquation by specific gravity in Pb-Sb alloys is even greater than in Sn-Sb alloys, since lead has a higher density than tin, and antimony (solid phase) is lighter than the b-phase. The introduction of copper into lead alloys serves the same purpose as its introduction into the B83 alloy. A Cu3Sb compound is formed, which is uniformly suspended in the lead-enriched liquid phase and prevents antimony crystals from floating.

To increase ductility and run-in, tin (up to 16%) is introduced into lead-based bearing alloys, in addition to antimony. The ternary alloy under consideration, 68/16/16 (B 16), is not very fusible - its melting point is 245°C. 1.5-2% Cu is also introduced into it to prevent density segregation. The content in it is limited to about 0.1% of each element. Ni, Cd, As (up to 1%), Te (up to 0.1%) are introduced into B16 type alloys to improve their antifriction properties.

Table 4.18.

Composition and structure of babbitts

| Brand Babbitt | Element content, % | Impurities | Structure | |||||

| Sn | Sb | Cu | Pb | Others | Basic | Solid | ||

| B83 | The basis | 10-12 | 5,5-6,5 | — | — | 0,55 | Sn | SnSb, Cu3Sn |

| B89 | The basis | 7,2-8,2 | 2,5-3,5 | — | — | 0,55 | Sn | Cu3Sn |

| B6 | 5-6 | 14-16 | 2,5-3,0 | The basis | 2.0 Cd | 0,4 | Pb | SnSb, Cu3Sn |

| BT | 9-11 | 14-16 | 0,7-1,1 | The basis | 0.1 Te | 0,6 | Pb | SnSb |

| BN | 9-11 | 13-15 | 1,5-2,0 | The basis | 0.8 As 1.0 Ni 1.5 Cd | 0,35 | Pb | SnSb, SnAs2 |

| B16 | 15-17 | 15-17 | 1,5-2,0 | The basis | — | 0,6 | Pb | SnSb, Cu3Sn |

| BS | — | 16-18 | 1,0-1,5 | The basis | 1.0Ca 0.7Na | 0,5 | Eutectic | Sb |

| BC | — | — | — | The basis | — | 0,7 | Pb | Pb2Ca, Pb3Na |

Shown in Table 4.18. Babbitt compositions can be divided into three groups. The first includes tin-antimony (B83 and B89), the second - lead-tin-antimony (B6, BN, B16), the third - lead babbits that do not contain tin. Babbitts of the second group B6, BN, BT, in addition to tin, antimony and copper, also contain additives of other components. The purpose of these additives is different - arsenic increases fluidity (filling the liner is easier), nickel increases hardness, which reduces wear, and cadmium has a similar effect. The role of tellurium and arsenic is to form small solid inclusions that increase the wear resistance of babbitt.

Tin-antimony babbits (B83 and B89) are the best. Tin base is tough and ductile and less prone to fatigue failure. In second place is tin-lead-antimony babbitt (B16), in which the soft base is lead. Tin-lead-antimony babbits are much cheaper than tin-lead ones, and are not much inferior in quality. Lead-antimony babbitt (BS), which is based on insufficiently plastic eutectic, is worse. Babbitt BC (calcium), used in railway transport, like Babbitt BS, is a relatively cheap alloy, its structure: base - lead, solid inclusions - chemical compounds of lead with calcium and sodium. The properties of these babbitts are given in Table 4.19.

Table 4.19

Properties of babbitts

| Babbitt brand | Density g/cm3 | tmelt,0С | sВ, MPa | d,% | Coeff. friction | a×106 |

| B83 | 7,5 | 380 | 90 | 6 | 0,005 | 21 |

| B89 | 7,3 | 342 | 90 | 9 | — | — |

| B6 | 9,6 | 460 | 70 | 0,5 | 0,005 | 21 |

| BT | — | — | 80 | 2 | 0,009 | 23 |

| BN | 9,5 | 400 | 70 | 1 | 0,006 | — |

| B16 | 9,3 | 410 | 80 | 0,5 | 0,006 | 24 |

| BS | 10,1 | 410 | 40 | 0,5 | 0,007 | 26 |

| BC | 10,5 | 470 | 100 | 2,5 | 0,004 | 26 |

The scarcity of tin, as well as lead, forces us to seek out and use alloys based on another, less scarce base (zinc, aluminum).

TsAM10-5 and TsAM5-10 alloys are used as zinc bearings. Their composition is given in Table 4.20 (the structure and some properties are also indicated there). Zinc alloys TsAM10-5 and TsAM5-10 are inferior to tin-based babbitts in terms of ductility, friction coefficient and linear expansion coefficient and are approximately equivalent to lead babbitts.

There is also a series of aluminum alloys used as bearings. These are two-phase high-alloy alloys in which the aluminum-based solid solution is the soft base, and the chemical compounds are the hard inclusions. The composition and some properties of aluminum bearing alloys are given in Table 4.21. Aluminum bearing alloys have high properties (low friction coefficient and high wear resistance). But in terms of manufacturability they are inferior to ordinary babbits. Their higher hardness is more a disadvantage than an advantage of the alloy, since it requires processing of the journals and liners with increased cleanliness, and the shaft journal must be hard. Observing these conditions will cause accelerated wear. The high coefficient of linear expansion of aluminum babbitts requires more careful assembly with large gaps.

Table 4.20.

Composition and some properties of zinc babbits

| Brand Babbitt | Element content, % | Properties | |||||

| Al | Cu | Density g/cm3 | tmelt,0С | d,% | Coeff. friction | a×106 | |

| TsAM10-5 | 10 | 5 | 6,3 | 395 | 0,5 | 0,009 | 27 |

| TsAM5-10 | 5 | 10 | 7,1 | 500 | 1 | — | 28 |

Notes: 1. The soft base of babbitts is the eutectic Zn+Al+CuZn3; solid inclusions - CuZn3. 2. The tensile strength of the specified babbitts is 300 MPa.

Aluminum babbits are used instead of tin and lead babbits, as well as lead bronze.

Table 4.21.

Composition and some properties of aluminum babbitts

| Brand Babbitt | Element content, % | Tver- dy turn on | Properties | |||||||

| Sb | Pb | Mg | Dr. | Density g/cm3 | tmelt,0С | sВ, MPa | d,% | a×106 | ||

| ACC6-5 | 5,5 | 4,5 | AlSb | 3,1 | 750 | 80 | 14 | 24 | ||

| AFM | 4 | — | 0,6 | AlSb | 2,8 | 750 | 90 | 29 | 24 | |

| AN2.5 | 3.0Ni | Al3Ni | 2,9 | 650 | 140 | 23 | 25 | |||

| Alcusin D | 8.5Cu 2.0Si | CuAl2 | 2,9 | 632 | 160 | 1 | 26 | |||

Purchasing process

- 1. Order Send a request, or dictate the required items to the manager by phone.

For large orders we provide discounts from the price price.We work with more than 13 factories, we can find and supply rare items “to order”.

- 2. Payment

The manager will fill out the contract and advise on all issues.Send a payment order with a bank mark for faster shipment.

- 3. Delivery and pickup

Agree with the manager on the date and time of delivery, send directions and contact details of the receiving person.In case of self-pickup, send your manager the vehicle data.

- 4. Reception and unloading

Unloading is carried out by the buyer, however, in the absence of special equipment, we will help to unload the metal.Please ensure unhindered access of vehicles to the unloading site.

Take shipping documents from the forwarding driver: delivery note, invoice, certificate of completion of work, quality certificates for metal.