During construction and during finishing work, it is often necessary to create a coating with improved properties - even, moderately durable. Chipboard (chipboard) has the necessary characteristics. The sheets are made from wood, but the base is not solid wood, but shavings. The slabs are susceptible to moisture, but this disadvantage is outweighed by their advantages. When choosing, you should consider different options for materials; they differ in appearance, properties, and therefore are used under different conditions.

Features of the material, history of appearance

Previously, the issue of recycling wood chips obtained during production for various purposes often arose. It was solved thanks to the appearance of slabs made from this raw material. Wood-based products first began to be used in the thirties of the last century. They were used for commercial purposes later - in the 40-50s. XX century Since then, the material has been used more and more often, and annual production has increased several times.

Raw materials: chipboard

Chipboard is a type of board made from shredded wood. They got their name due to the type of raw material that underlies them (wood shavings). Particles of different sizes are used, they are held together with a binder of non-mineral origin (synthetic glue, often based on phenol-formaldehyde resins). This feature limits the scope of application. The material contains a certain amount of toxic components, their dose is minimal, it is regulated by standards, and therefore the sheets are not prohibited. They are often used, including in the production of various pieces of furniture, and when performing finishing work.

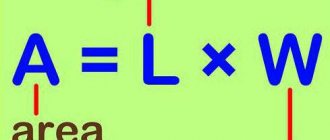

Why do you need to know the dimensions of hardboard in advance?

When performing construction and finishing work, one usually always buys whole slabs. To do this, calculate their total area with a margin for cutting. In some cases, small pieces of fiberboard can be purchased at woodworking shops or trading and manufacturing companies that cut boards into blanks for further production. In this case, the retail trade receives leftovers, the cost of which includes services for sawing them.

To economically cut sheets for thermal insulation or finishing work, carefully measure the walls, ceiling or floor. After this, standard slabs of different dimensions are compared, cutting plans are drawn up and the number of scraps is compared. As a result, the best option is chosen to reduce costs.

Knowing the required dimensions of fiberboards will allow you to decide on the choice of transport and find a convenient place to store the sheets

Stages and features of production

To make chipboard, raw materials of different sizes and types are used:

- chips: they are produced on rotary-type machines;

- chips are the result of the operation of special equipment (for example, a chipper or a knife shaft).

To produce particle boards, you need raw materials whose particles correspond to standard parameters with deviations (to a lesser extent from the specified values):

- thickness – 0.5 mm;

- width – 5 mm;

- length – 40 mm.

The quality of the finishing material depends more on the thickness of the chips. It is better if it is as thin as possible. When specially harvested wood is used, rather than production waste, round timber or large boards will be needed. After preparation (removing the bark, dividing into smaller pieces, soaking), the material is crushed. This is how the raw materials are obtained, which are used to produce the top layer of the slab. Inside there are large chips, they are compressed, but in the section you can see the difference between the structure of the layers. To improve the quality of the raw material, it is additionally dried and sifted, then re-grinded.

Stages of plate production:

- All types of raw materials (for internal and external layers) require drying. This is done after calibrating it in size.

- The chips fall into the mixers, which are constantly rotating. Here it is mixed with binding components. It is important that every particle is coated with resin. This result is achieved by blowing a stream of air along with drops of the binder component. The resin envelops the chips.

- The mass falls on the conveyor belt, where future sheets are formed - layers of material of different thicknesses are created.

- The layer is cut into slabs and compacted using the vibrocompression method at a temperature of +180°...+220°C.

- Heating can increase the strength of the boards, which is achieved due to the effect of temperatures on the resin.

- Products are cooled. Moreover, to obtain materials with the desired properties, a gradual decrease in the temperature of the plates is required - in a natural way.

INTERESTING: What is cement made from?

Then sanding is done. Chipboard is cut in accordance with standards.

Attention! There are 2 methods of molding with pressing: direct, extrusion. The second option involves the use of an extruder - equipment of this type allows you to squeeze out a mass based on chips and resin. Pressure testing occurs during this process, which helps reduce the strength of the slabs.

When producing chipboard, another production stage can be included in the technological process - lamination. As a result, a slightly different material is obtained - chipboard. It is covered with film.

Manufacturing Basics

The characteristics of the material are largely determined by the properties of the chips, which form the basis of slabs of all types and sizes. To produce chipboard, chips are taken from different tree species, using both high-quality chips and crushed production waste.

Raw materials must have standardized dimensions, deviations from which may affect the properties. Grinding is carried out using special equipment that allows you to regulate the speed of the process and the size of the resulting pieces. The raw material should not be very small; the shape and size of each unit of the chip mixture influence the formation of the chipboard surface.

The crushed wood pulp is well dried in ovens, then subjected to mandatory tarring to increase adhesion during subsequent treatment with adhesives.

The prepared wood material is compressed after preliminary distribution of polymer resins on layers of chipboard. The glue must be carefully applied over the entire surface; a spot left uncoated, even a small one, can cause a deterioration in the quality of the finished panels.

Some manufacturers using defective raw materials increase the amount of resin-like impregnation. The aldehyde polymer helps bind different types of shavings into a single slab, but the product loses quality. The mass fraction of the polymer composite should not exceed 12%, ideally it could be 6%.

Overview of types of chipboard

In its original form, chipboard is used without additives, auxiliary layers, or structural elements. However, it is often necessary to use improved material. This led to the emergence of different types of slabs:

- laminated (laminated chipboard): coatings of several varieties are tried on (paper-resin film, plastic and paper-laminated material), which can affect the properties of the product;

laminated chipboard

- fire-resistant boards: contain fire retardants, making the material more resistant to high temperatures;

- moisture-resistant: they contain urea-melamine resins, hydrophobic polymer additives; boards of this type can be distinguished by their greenish tint;

Moisture-resistant chipboard

- veneered: similar to solid wood, but only externally, because the outside is covered with veneer, due to which the material imitates natural wood;

- tongue-and-groove (chipboard Quick Deck): they differ in the configuration of the cuts; grooves and tenons are formed here, making it possible to assemble a seamless durable coating.

Tongue-and-groove chipboards.

Separately, perforated boards should be noted. They are produced by extrusion. This type of material is used primarily in the production of door panels (laid inside), so it is not found on the open market. Features of such plates:

- presence of through holes;

- high sound insulation qualities;

- increased thermal insulation;

- resistance to deformation due to exposure to temperature changes.

The narrow scope of application of such chipboard is also due to its insufficiently high strength. Veneered material differs from this variety. For the coating, veneers of different species are used, but more often - oak, ash, which improves the quality of the slab, it becomes stronger, and better resists mechanical loads. Veneer, like lamination, gives the material decorative qualities. At the same time, wear resistance increases. At the same time, moisture resistance increases.

Important! Even if the material is covered with veneer or polymer film, this does not make it waterproof. Such slabs withstand exposure to a humid environment better. However, prolonged contact with water is not recommended. The material remains hygroscopic, depending on the type, it swells by 5-30%, which means it is deformed in such an environment.

Varieties of particle boards

There are several main types of products, differing in decorative coating:

- Untreated (sanded) chipboards. They are used for roughing work on various surfaces inside the house.

- Laminated. The most popular type of particle boards. To create the top coating, special resin-impregnated paper consisting of several layers is used. As a result of hot pressing, it literally “eats” into the base, allowing you to imitate various coatings. An alternative could be lacquered products.

- Veneered. A thin cut of valuable wood is used as cladding. It has excellent decorative properties, but the cost of such material can significantly exceed the previous one.

- Laminated. Paper of the desired shade is glued onto a well-prepared base. Rarely encountered due to low wear resistance.

The purpose of the material largely depends on the type of coating.

Products made from chipboard are tongue-and-groove (having a locking connection, which greatly facilitates installation) and moisture-resistant (impregnated with special substances, after which they become more stable even at high humidity).

The material is also divided according to formaldehyde emission class: E1 and E2. At the moment, the first variety is more common.

The locking connection greatly simplifies the installation process

Chipboard size range

Most often, sheets of certain characteristics are produced. Dimensions are regulated by GOST 10632-2014:

- 2440x1220 mm;

- 2440x1830 mm;

- 2750x1830 mm.

INTERESTING: Thermal conductivity of materials table, SNiP

There is another variety on sale with dimensions of 2800x2070 mm. These are products of foreign companies. If desired, you can order slabs according to your sizes. For this purpose, the method of cutting finished products is used. It is possible to purchase ready-made slabs of non-standard sizes, their edges are already protected with film. Permissible deviations from standard dimensions:

- length and width: +/-0.5 mm;

- thickness: +/-0.3 mm (for polished), -0.3/+1.7 (for unpolished).

| Chipboard thickness in mm. | Length in mm. | Width in mm. |

| 10 | 2750 | 1830 |

| 16 | 2750 | 1830 |

| 16 | 2440 | 1830 |

| 18 | 2750 | 1830 |

| 18 | 2440 | 1830 |

| 22 | 2440 | 1830 |

| 25 | 2440 | 1830 |

Chipboard thickness

Dimensions of laminated chipboard sheet

With some stretch, we can say that there are standard sizes of laminated chipboard sheets.

However, this statement is controversial. The fact is that each manufacturer, for the convenience of consumers, operates with its own chipboard sheet sizes. Let's show this with an example.

Swisspan products

. The sizes of her products will be as follows.

- 2440x1830 with a thickness of 25 mm.

- 2440x1830 - 22.

- 2440x1830 - 18.

- 2440x1830 - 16.

- 2750x1830 - 16.

- 2750x1830 - 18.

- 2750x1830 - 10.

From Kronospan Russia

two options for laminated chipboard sizes - the standard length can be 2800 or 2620, and the width can be 1830-2070 mm. As for thicknesses, their range is as follows: 8, 10, or 12 and 16, 18, as well as 22, 25 or 28 mm.

Egger company

It was even simpler - the size of its laminated sheet is also standard and equal to 2800x2070 mm. Thicknesses have values of 10, 16, 18, 19, 25 mm.

Why is there such a variation in thickness? It all depends on the destination. It is clear that where special strength is required, a plate of greater thickness is used. For finishing or ceiling work - less.

Now about the main thing - the price of the sheet. This is perhaps the main advantage of laminated chipboard.

Classification

One of the first parameters that people pay attention to is the type of surface treatment. There are 2 options: sanded and unpolished slabs. They differ in the quality of the coating, which determines the area of application of the material. In addition, the slabs are distinguished by structure:

- ordinary (designated by the first letter – O);

- fine-textured (M).

The second option is used in the production of laminated boards. This is due to the fact that the film adheres better to the surface of such a product.

Surface quality

Slabs of different types are produced, differing in the number of defects:

- 1st grade – without changes in the structure of the material, defects;

- Grade 2 – a certain amount of damage is acceptable (regulated by regulatory documentation).

Due to average strength and moisture resistance, chipboard with more significant defects is not used, since it will not perform its main functions. The service life of the material will be significantly reduced.

Emission class

There are types of stoves that differ in the degree of danger to human health. They contain varying amounts of toxic components (in particular formaldehyde):

- E0.5;

- E1;

- E2.

Is chipboard harmful?

If you need to use the material indoors, only the first two options are considered. The concentration of formaldehyde in the structure of the binder component and when released into the surrounding space is minimal and is considered acceptable. However, the rule here is: the less, the better, so option E0.5 is preferable.

Strength level

There are types:

- P1 – general purpose;

- P2 – products intended for the manufacture of furniture and finishing work indoors.

The second option is more durable, so the scope of application of the slabs of this group is wider. P1 products are more often used for rough finishing, temporary structures or as auxiliary material. The strength of chipboard varies: 550-750 cubic meters. m. At the same time, the range of density values is also different: 0.5-1.0 g/cubic. see. Tensile strength is also taken into account:

- when bending – 10-25 MPa;

- when stretching - 0.2-03.5 MPa.

INTERESTING: Membrane roofing materials: types and installation technologies

Advantages and disadvantages

First, it is necessary to note the positive qualities of the material:

- the products are resistant to deformation due to long-term use (the slabs do not crack or dry out);

- the material is not susceptible to fungal development;

- does not attract insects;

- Chipboard is not subject to flare-up, does not ignite well, and the combustion process is not intense;

- you can make a coating no worse than a monolithic one - the slabs fit together and form an ideal coating without cracks;

- The products cost much less than other wood materials.

Chipboard also has disadvantages:

- low thermal insulation properties, such products are used as auxiliary;

- the material is still flammable, although its combustion rate is low;

- the plates are hygroscopic, it is not recommended to use them in damp rooms;

- Do not screw in self-tapping screws from the end side, this reduces the strength of the product;

- the composition contains toxic components, the material does not belong to environmentally friendly coatings;

- low bending strength.

Main characteristics of chipboard

Strength and density of chipboard

The strength of chipboard is determined by its belonging to one of two groups - P1 or P2. P2 slabs have higher bending strength - 11 MPa versus 10 MPa for the P1 group. They are almost one and a half times more resistant to delamination. The density of sheets of both groups is 550 – 820 kg/m3.

One aspect of strength is the ability to hold fasteners. A screw screwed into the face of the slab can withstand a pull-out load of 3.5 to 5.5 kg per millimeter of length. When installed at the end, the maximum force is less - 3.0-4.5 kg/mm.

| Index | P1 plate | P2 slabs |

| Density, kg/m3 | 550-820 | |

| Impact strength, J/m2 | 4000-8000 | |

| Hardness, MPa | 20-40 | |

| Specific resistance to pulling out screws, N/mm, from the plastic | 55-35 | |

| Specific resistance to pulling out screws, N/mm, from the edge | 45-30 | |

Moisture resistance of chipboard

The resistance of chipboard to moisture is not regulated. This material is intended for dry conditions only. Although there are moisture-resistant versions of it, which are produced with the addition of a water repellent.

Biological resistance

The biological resistance of particle boards is quite high. They are not damaged by insects, and fungus does not take root on them. The slab may completely collapse from moisture, but there will be no rot on it.

Fire safety

When assessing the fire hazard, chipboard should be considered as wood. The composite belongs to the same flammability group G4, although it does not catch fire and spread fire as readily as wood.

Environmental friendliness

Chipboard is quite safe for people, but when using it, you need to pay attention to the emission class, which depends on the level of formaldehyde released into the air. Material of class E2 cannot be used inside residential premises; slabs of class E1 are intended for this. For children's rooms, schools, kindergartens, nurseries, and hospitals, slabs of class E0.5 should be used, which contain a very small amount of formaldehyde and their effect on the composition of indoor air is negligible.

Thermal conductivity

The thermal insulation qualities of chipboard are low, but they should be taken into account when using it as wall, ceiling or floor cladding. The average thermal conductivity of the slabs is 0.15 W/(m∙K). With a thickness of 16 mm, the thermal resistance of the skin per square meter of area will be 0.1 (m2∙K)/W. For comparison: a wall made of ceramic bricks 390 mm thick has a thermal resistance of 2.22 (m2∙K)/W, and a layer of mineral wool 100 mm thick has a thermal resistance of 0.78 (m2∙K)/W. And yet, chipboard sheathing, especially together with the air gap behind it, can become a noticeable addition to insulation.

Vapor permeability

Water vapor permeability is an important characteristic of chipboard if it is used in external building envelopes. With a permeability of 0.13 mg/(m∙h∙Pa), the material cannot serve as a vapor barrier, but when cladding the outside, good vapor permeability will help remove moisture from the wall.

Application area

The main direction of use of particle boards is furniture production. Certain types of chipboard are used in construction and interior finishing. Problems that can be solved using this material:

- fencing at construction sites;

- formwork for the foundation (dismantled);

- building structures (minor elements);

- interior doors;

- a substrate for the subfloor that prevents abrasion of the main structural elements;

- ramps;

- panels (for finishing walls, ceilings);

- floor finishing material;

- insert stands;

- roof structural element (cladding);

- storage container.

When it is planned to install temporary structures or permanent structural elements, waterproofing (film materials) is used. Chipboard is not used for finishing facades. The exception is when good protection from water is simultaneously created and an effective ventilation system for the structure is installed.

Application of sheets of different thicknesses

To choose the right sheet of material, you need to know its optimal thickness.

It affects the strength of the slab during transportation, as well as further use. The thicker the slab, the stronger it is, so it can be used in more loaded structures. The most popular sheet thicknesses are: 8-10 mm - most often used as a material for decorative partitions and unloaded furniture elements;

16-18 mm - common for laying floors (especially under linoleum and laminate), as well as for the production of most furniture products. The most wear-resistant floors can be obtained by using a heavier and thicker 20 mm slab;

22-25 mm - serve as the basis for thick doors, kitchen tables and loaded furniture structures;

28-38 mm - used to create especially durable tabletops and shelves that operate under heavy loads. Most bar counters are made from this thick chipboard.

What sheet properties depend on size?

The main parameter influenced by the thickness of the sheet is its strength and ability to resist external loads. As thickness increases, resistance to deformation increases, but flexibility decreases.

Thinner chipboard sheets have the ability to bend under mechanical stress. Thick canvases are much less elastic and are more likely to break than bend.

When purchasing a whole sheet of chipboard, do not forget to take into account the dimensions of corridors and staircase openings. Long sheets may not “fit” when turning or will break when trying to bend them.

Particle boards have high hardness, which also increases with increasing thickness. Impacts on heavy and thick slabs are likely to leave only small dents, while thin sheets may break through.

Calculation of the required amount of chipboard

To calculate the required amount of material, you can go in two ways - calculate the necessary layout of the cuts yourself or use special computer programs. In the first case, you will have to show perseverance and ingenuity, since finding the optimal layout of cutting lines will be quite difficult.

When choosing the right size of material, draw a cutting plan. Try to place the lines of different parts as compactly as possible. This will increase the ratio of the resulting useful surface to waste unsuitable for use. Having located the necessary parts within a rectangular shape on the drawing, you can begin to select a sheet of suitable sizes for sale.

Calculator

In the absence of good geometric imagination, models of the necessary parts can be cut out on paper, observing aspect ratios and a single scale. It is quite easy to combine cut out figures, alternating options for their relative arrangement.

Programs that help you decide on a cutting pattern are designed for interior design. The required number and shape of parts are entered into them, after which the optimal layout scheme on a canvas of specific dimensions is automatically calculated. A similar method is used in construction stores that cut materials to order from the client.

Comparison of prices of chipboard sheets of various sizes and manufacturers

The cheapest are slabs with a thickness of 10 mm. Blades 8, 12 mm and larger are more expensive. Let's consider the prices (rubles per sheet) of some common sizes of chipboard with the most popular thickness of 16 mm.

Table of dependence of chipboard sizes and prices per sheet (t. 16 mm) in rubles:

| Sheet size | Manufacturer | |||

| "Cherepovets FMK" | "Tomlesdrev" | "KRONOSPAN" | "Altai-Forest" | |

| 3500 × 1750 mm (6.1250 m2) | 854 | — | — | 943 |

| 2750 × 1830 mm (5.0325 m2) | 702 | 704 | 1051 | 760 |

| 3030 × 1830 mm (5.5998 m2) | 781 | — | — | — |

There are differences between the prices of chipboard from different manufacturers - the further the plant is located, the higher the cost will be after transportation to another region. Foreign manufacturers have even higher prices, but not always better quality. When planning your work, focus on commercially available materials - usually 4-6 options for sheet sizes are available, and the rest are delivered to order.

Before purchasing, look for a chipboard manufacturer in your area. Delivery of large quantities from the factory is much cheaper than from resellers.

Planning a chipboard cutting pattern is an important stage in construction and repair. The correct approach to sizing allows you to minimize material waste while reducing financial costs. Adequate selection of the thickness of the blades optimizes the weight and strength of the structure. The cost of the material increases with increasing dimensions and depends on the manufacturer.

Subtleties of using chipboard in furniture production

Chipboards (the laminated variety) are often found in the form of furniture walls, shelves, countertops, facades (inexpensive items), and frames. The advantage of chipboard compared to natural wood in such production is that there is no need to additionally process the material, sand it, or paint it. It is enough to determine the dimensions of the structural elements, cut them, and assemble the product using standard fasteners.

However, there is a difficulty when working with laminated chipboards - edge processing. To protect it, an impenetrable material is glued at the production stage, which serves as a decorative and protective element. It is difficult to use such film on your own.

Gradually, laminated chipboard, like chipboard, is replacing MDF - this is another type of particle board, but it is more expensive. However, such plates have improved characteristics.