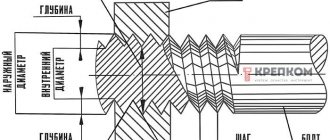

82. Main dimensions of metric threads, mm (according to GOST 9150-81, GOST 8724-81, GOST 24705-81)

d

,

D

– external diameters of the external thread (bolt) and internal thread (nut), respectively

d2

,

D2

– average diameters of the bolt and nut, respectively

d 1

,

D 1

– internal diameters of the bolt and nut, respectively

d3

– internal diameter of the bolt along the bottom of the cavity

P

– pitch thread

H

– height of the original triangle

The nominal values of thread diameters must correspond to those indicated in the drawing and table. Diameter values are calculated using the following formulas:

Threads are used for sealing, fastening parts by increasing the contact area, and also for transmitting movement. Fasteners with metric threads are universal, easy to dismantle and can withstand high stresses. Metric threads are distinguished by a triangular equilateral profile, where the angles at the apexes are 60º. There are other types of threads, with unequal triangle angles.

Metric threads are distinguished by technical parameters: diameters and pitches, height, screw-in length, number of starts. Accurate data allows you to ensure reliable fastening.

Main settings

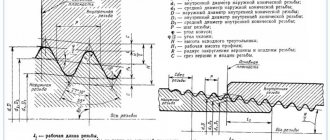

Each thread has precise geometric parameters. Metric is characterized by a triangular thread profile, which is also called fastening. It is used for parts connected to each other by screwing. The profile size is determined by its height.

The profile height (H) is the segment from the base to the top of an equilateral triangle, which is formed by a transverse section of the coil. The protrusions and depressions are made in the form of triangles with cut off vertices. In some cases, the depressions are rounded.

If the sides of each turn are mentally extended to the point of their intersection, then they will form a profile angle (α).

The main parameters indicated in the designation of a metric thread characterize its size. These include diameter and pitch. Metric thread designations indicate the main parameters.

Thread diameter is divided into 4 types:

Thread parameters such as stroke (Ph) and pitch (P) are interdependent and equal for a single-start system.

Thread stroke and pitch

The section separating the points of the same name on two turns is the thread pitch. There are main steps (large) and small steps.

Thread lead is a segment connecting two identical points on adjacent turns of the same thread. In the case where there are several entries, the move is expressed through the product of the number of steps and the number of entries.

The main thread elements also include:

- A surface inclined 45º in front of the inner or behind the outer is called a chamfer. It plays a role in connecting elements.

- Run-off is the place of transition to the uncut surface of the part. These two indicators are united by length, that is, a segment with turns, chamfer and runoff.

For metric threads, the main dimensions are summarized in tables of the relevant standards: GOST 9150-2002, GOST 8724-2002, GOST 24705-2004.

Possible structural deviations caused by the properties of materials are reported by tolerance fields, with values not exceeding the nominal profile formed by the maximum of the material. These indicators affect the accuracy of the thread fit - the density of penetration of the protrusions into the gaps.

Thread tolerance fields are divided into three accuracy classes. And also 4 types according to your preference.

Main parameters and areas of application

The most common is metric thread, applied to the external and internal surfaces of a cylindrical shape. This is what is most often used in the manufacture of various types of fasteners:

- anchor and regular bolts;

- nuts;

- hairpins;

- screws, etc.

Conical-shaped parts, on the surface of which a metric type thread is applied, are required in cases where the created connection must be given high tightness. The metric thread profile applied to the conical surfaces allows the formation of tight connections even without the use of additional sealing elements. That is why it is successfully used in the installation of pipelines through which various media are transported, as well as in the manufacture of plugs for containers containing liquid and gaseous substances. It should be kept in mind that the metric thread profile is the same on cylindrical and conical surfaces.

Parameters of tapered metric thread

Types of threads belonging to the metric type are distinguished according to a number of parameters, which include:

- dimensions (diameter and thread pitch);

- direction of rise of turns (left or right thread);

- location on the product (internal or external thread).

There are also additional parameters, depending on which metric threads are divided into different types.

Internal metric thread

External metric thread

Thread diameter

The conditional parameter used to designate threads in drawings and reference tables is called the nominal diameter.

If we describe an imaginary cylinder around the protrusions of the external thread and the cavities of the internal thread, then its diameter will be called external. And the designation on the drawings: D – for internal; d – for external.

The internal diameter is the size of the inscribed cylinder in the recesses of the external thread and at the points of the vertices of the internal thread, denoted by: D1 and d1 for internal and external, respectively.

The average diameter is a parameter of an imaginary cylinder whose segments are equal to ½ thread pitch. Designated: D2 and d2.

The internal diameter of the bolt is used to calculate the stress in the fastener. Its value can be taken from the table with diameters, or calculated independently based on the nominal value.

Thread pitch

The pitch can also be found from the thread table or from the markings. Threads can have a main pitch, also called coarse, and fine. Depends on the diameter of the product.

If it is more than 68 mm, then only small, different values are used for such a surface. Having a diameter up to the specified value makes it possible to produce threads with both large and fine pitches.

Each diameter has its own coarse pitch, which is not indicated in the marking.

When attaching parts, it is important to know the pitch, otherwise it will lose strength. The step can be determined by instrumental or comparative methods, such as:

- measure with a thread gauge;

- compare by comparing the threads of different parts with each other;

- try to screw the external thread into the internal thread; there should be no resistance;

- Measure the stroke in millimeters with a caliper and divide the resulting value by the number of strokes.

Tolerance fields

The fit of the outer profile into the inner one depends on the working height - the maximum amount of contact between the sides of the profiles of the connecting elements. It is expressed through thread tolerance fields.

The reliability of the connection, where fluctuations within it are minimized, is indicated by the first or exact tolerance class. The most common is the second (middle) class. The third (rough) class indicates a large deviation.

Tolerances on the dimensions of metric threads are indicated through the values of two diameters: the average and the diameter of the protrusions.

Read also: What is made from silumin

When forming a metric thread, data is taken from the corresponding tables (GOST 16093-2004). The selection of tolerance fields is carried out according to the rules of priority:

- first priority – values indicated in bold;

- the second - in regular font;

- third – values taken in parentheses;

- extraordinary – values in square brackets (for special products).

It is possible to use tolerances that are not indicated in the tables, but are formed from the ratios of existing standard diameters.

External thread tolerance fields

Internal thread tolerance fields

It is important that the protective coatings of parts in their geometric parameters do not exceed the value of the nominal profile, therefore in such cases tolerances are used even before applying the protective layer.

Types of metric threads

Metric threads also mean all types with different profiles, measured in millimeters. These include:

- triangular thread;

- trapezoidal;

- rectangular;

- round.

In addition to the metric system for measuring parameters, the following are used:

- inch;

- modular, where the module is the ratio of the length, expressed in millimeters, to the number π;

- pitch, basic unit - pitch - the ratio of the number π to the length, expressed in inches.

Modular threads are used for worm gears in mechanical engineering, just like pitch threads. Inch and metric are fastening thread types, but can be used for transmission.

By location they are distinguished:

The internal thread is located in the hole, it is obtained with a tap, a specialized tool that is a rod with cutting edges.

Internal metric thread

External threads are made with a cutter or die on a rod. They can also be obtained by coasting on appropriate equipment.

External metric thread

The shape of the surface can be cylindrical or conical.

Metric conical thread is used for installation of pipelines. It is performed on surfaces where the larger diameter exceeds the small one by 16 times. Diameters vary from 6 to 60 mm.

They are also divided according to the direction of the turns into right and left. To determine the direction of the thread, it is necessary to position the part so that its axis is located away from the observer. Then, the right-hand thread is formed by a circle rotating from left to right with translational motion along the axis, and the left-hand thread, accordingly, counterclockwise.

There are different types of step sizes:

- large (with a main, large step);

- small (with small);

- special.

A large pitch is considered normal and is suitable for any materials, including fragile ones. Small allows you to withstand heavy loads, but the materials must have certain strength characteristics. Small and special ones are rarely used.

Large and fine thread pitch

The place of transition from a smooth surface to a helical one is called the approach. Based on their number, they are divided into: single- and multi-pass. The latter are also subdivided by the number of passes: two-, three- and multi-pass.

Another classification is by application. They are:

- fastening and thrust-fastening;

- kinematic or chassis;

- special purpose.

Below are the main types of metric threads and their letter designations:

- the capital letter "M" symbolizes the metric type,

- if it is made on the surface in the form of a cone, then “MK”;

- for conditions where heat resistance and strength are required, use the metric cylindrical “MJ”;

- according to ISO – “EG-M”;

- trapezoidal – “Tr”;

- persistent with an angle of inclination of one side of 30º – “S”;

- persistent reinforced - “S45”, where the number is the angle of inclination of one of the sides.

Standard metric thread steps - table and GOST

Article reading time: 15 minutes

Author of the article:

Reliability of fastening connections is achieved through threads. It consists of an alternation of depressions and protrusions on the inner and outer surfaces of rotating parts. There are many types of threads: inch, pipe, screwdriver and metric. This article describes in more detail the metric thread and its features, since it is the most universal and in demand of all those listed.

Threaded connections are used wherever fasteners are needed and to transmit movement. Each type of threaded connection has a number of typical characteristics:

- Thread profile - a pattern of a “comb” that runs along the axis of the fastener.

- Thread pitch is the distance between two adjacent vertices, measured along the axis of the fastener rod.

- Outer diameter - measured at the top points of the profile.

- Internal diameter is the size of a cylinder inscribed in the recesses of an external thread, or at the points of the vertices of an internal thread.

- Thread stroke is the distance from one profile top to another in projection onto the fastener axis.

- Thread profile angle - the angle between the sides of the profile.

There are also other thread parameters: profile height, screw-in length, number of turns. In metric threads, the profile consists of equilateral triangles. The profile angle of a metric thread is 60º. Standard step size standards are established by GOST 8724-81 (ISO 261-98) “Basic standards of interchangeability. Metric thread. Diameters and steps." According to this document, on surfaces with a diameter of 1–68 mm, the thread pitch can be coarse or fine. When the surface diameter of the fastener is over 68 mm, the metric thread can only have a fine pitch. Each diameter corresponds to one variant of a large thread pitch, and several variants of a fine pitch. For example, with a diameter of 10 mm, a large pitch of 1.5 mm and three fine pitch options are possible. The large pitch in the designation of metric threads is omitted, since its value is always the same and can be found out from the table.

The full name of the thread consists of the following data:

- M - metric thread.

- Thread diameter in millimeters.

- Fine step size in millimeters.

- Direction of travel (there are left-handed and right-handed threads).

- Lead designation for multi-start threads.

The metric thread pitch is determined from the table or from the markings of the fastener. In addition to tabular and reference data, there are practical ways to determine the pitch of a threaded profile:

- You can compare threads on different products and determine the desired value by comparison.

- To measure the pitch, thread gauges are used - special tools without a scale. Calibers help determine various parameters of a threaded profile: diameters, triangle height, pitch length.

- If the external thread is easily and without resistance screwed into the internal thread, then the pitch of the external profile can presumably be set.

- Take measurements: using a caliper, determine the length of the thread and divide the resulting value by the number of turns.

Another important parameter of a threaded connection is the tolerance range. This value indicates the maximum mating length of the sides of the threaded profiles of a screw and nut, and other types of fasteners. There are three classes of tolerance fields. If the fastener belongs to the first tolerance class, it is reliable and is used in areas where high precision and reliable fixation are required. The second class of tolerance fields is the most commonly used standard. The coarse tolerance class is used where greater accuracy of the threaded connection is not required.

When choosing fasteners, the type of threaded connection is critical. On the territory of the Russian Federation, hardware with large thread pitches is most in demand. Fine-pitch fasteners are used to connect products subject to vibration, experimental and variable dynamic loads. The scope of application of hardware with fine pitch threaded profiles is automobile and shipbuilding, production of machine tools, electronics and household appliances. In construction and other fields, fasteners with large pitch metric threads are mainly used. If you need to calculate which bolts are required for certain construction or other tasks, modern specialists use calculation formulas or special software. Calculation of fastener parameters online is available on many specialized Internet resources for free. There are also online calculators for calculating metric thread parameters based on a set of initial dimensions. It is recommended to measure the required dimensions using a caliper.

By metric thread it is also customary to mean any thread whose designation is indicated in millimeters. Based on the profile shape, the following types of threads are distinguished:

- Inch - the profile consists of isosceles triangles, the angle at the apex of which is 55°.

- Cylindrical pipe thread is a type of inch thread that complies with GOST 6357-81 standards. The nominal thread size is related to the internal diameter of the pipe or conventionally defined hole.

- Trapezoidal - the profile looks like a trapezoid with equal sides and an acute angle at the base. This type of thread is used in movable joints and serves to transmit reciprocating motion. Trapezoidal threads can be single-start or multi-start.

- Thrust - a type of trapezoidal, the profile looks like a non-equilateral trapezoid. Complies with GOST 10177-82 standards.

- Rectangular - this type of thread is made on lead screws that experience high loads to transmit translational-rotational motion.

- Round - the profile looks like a special case of a sinusoid. This type of thread is highly resistant to frequent twisting and unscrewing. Examples of use include light bulb sockets (Edison thread), spindles, valves, plumbing fixtures and fittings.

In addition to millimeters, other systems of measures are also used to measure threaded connections: inch, module - the ratio of the pitch in millimeters to the number pi, pitch - the ratio of the number pi to the pitch, the length of which is indicated in inches.

Metric thread table

| Thread pitch P | Thread diameter | |||

| outer | average | interior | internal along the bottom of the depression | |

| S h u p p n y m s t e p e d | ||||

| 0,40 | 2,0 | 1,740 | 1,567 | 1,509 |

| 0,45 | (2,2) | 1,908 | 1,713 | 1,648 |

| 0,45 | 2,5 | 2,208 | 2,013 | 1,948 |

| 0,50 | 3,0 | 2,675 | 2,459 | 2,387 |

| 0,60 | (3,5) | 3,110 | 2,850 | 2,764 |

| 0,70 | 4 | 3,546 | 3,242 | 3,141 |

| 0,75 | (4,5) | 4,013 | 3,688 | 3,580 |

| 0,80 | 5 | 4,480 | 4,134 | 4,019 |

| 1 | 6 | 5,350 | 4,918 | 4,773 |

| 1,25 | 8 | 7,188 | 6,647 | 6,466 |

| 1,50 | 10 | 9,026 | 8,376 | 8,160 |

| 1,75 | 12 | 10,863 | 10,106 | 9,853 |

| 2 | (14) | 12,701 | 11,835 | 11,546 |

| 2 | 16 | 14,701 | 13,835 | 13,546 |

| 2,5 | (18) | 16,376 | 15,294 | 14,933 |

| 2,5 | 20 | 18,376 | 17,294 | 16,933 |

| 2,5 | (22) | 20,376 | 19,294 | 18,933 |

| 3 | 24 | 22,051 | 20,752 | 20,319 |

| 3 | (27) | 25,051 | 23,752 | 23,319 |

| 3,5 | 30 | 27,727 | 26,211 | 25,706 |

| 3,5 | (33) | 30,727 | 29,211 | 28,706 |

| 4 | 36 | 33,402 | 31,670 | 31,093 |

| 4 | (39) | 36,402 | 34,670 | 34,093 |

| 4,5 | 42 | 39,077 | 37,129 | 36,479 |

| 4,5 | (45) | 42,077 | 40,129 | 39,479 |

| 5 | 48 | 44,752 | 42,587 | 41,866 |

| 5 | (52) | 48,752 | 46,587 | 45,866 |

| 5,5 | 56 | 52,428 | 50,046 | 49,252 |

| 5,5 | (60) | 56,428 | 54,046 | 53,252 |

| 6 | 64 | 60,103 | 57,505 | 56,639 |

| 6 | (68) | 64,103 | 61,505 | 60,639 |

| Take a bold step | ||||

| 0,25 | 2,0 | 1,838 | 1,729 | 1,693 |

| 2,2 | 2,038 | 1,929 | 1,893 | |

| 0,35 | 2,5 | 2,273 | 2,121 | 2,071 |

| 3 | 2,773 | 2,621 | 2,571 | |

| (3,5) | 3,273 | 3,121 | 3,071 | |

| 0,5 | 4 | 3,675 | 3,459 | 3,387 |

| (4,5) | 4,175 | 3,959 | 3,887 | |

| 5 | 4,675 | 4,459 | 4,387 | |

| 6 | 5,675 | 5,459 | 5,387 | |

| 8 | 7,675 | 7,459 | 7,387 | |

| 10 | 9,675 | 9,459 | 9,387 | |

| 12 | 11,675 | 11,459 | 11,387 | |

| (14) | 13,675 | 13,459 | 13,387 | |

| 16 | 15,675 | 15,459 | 15,387 | |

| (18) | 17,675 | 17,459 | 17,387 | |

| 20 | 19,675 | 19,459 | 19,387 | |

| (22) | 21,675 | 21,459 | 21,387 | |

| 0,75 | 6 | 5,513 | 5,188 | 5,080 |

| 8 | 7,513 | 7,188 | 7,080 | |

| 10 | 9,513 | 9,188 | 9,080 | |

| 12 | 11,513 | 11,188 | 11,080 | |

| (14) | 13,513 | 13,188 | 13,080 | |

| 16 | 15,513 | 15,188 | 15,080 | |

| (18) | 17,513 | 17,188 | 17,080 | |

| 20 | 19,513 | 19,188 | 19,080 | |

| (22) | 21,513 | 21,188 | 21,080 | |

| 24 | 23,513 | 23,188 | 23,080 | |

| (27) | 26,513 | 26,188 | 26,080 | |

| 30 | 29,513 | 29,188 | 29,080 | |

| (33) | 32,513 | 32,188 | 32,080 | |

| 1,0 | 8 | 7,350 | 6,917 | 6,773 |

| 10 | 9,350 | 8,917 | 8,773 | |

| 12 | 11,350 | 10,917 | 10,773 | |

| (14) | 13,350 | 12,917 | 12,773 | |

| 16 | 15,350 | 14,917 | 14,773 | |

| (18) | 17,350 | 16,917 | 16,773 | |

| 20 | 19,350 | 18,917 | 18,773 | |

| (22) | 21,350 | 20,917 | 20,773 | |

| 24 | 23,350 | 22,917 | 22,773 | |

| (27) | 26,350 | 25,917 | 25,773 | |

| 30 | 29,350 | 28,917 | 28,773 | |

| 36 | 35,350 | 34,917 | 34,773 | |

| (39) | 38,350 | 37,917 | 37,773 | |

| 42 | 41,350 | 40,917 | 40,773 | |

| (45) | 44,350 | 43,917 | 43,773 | |

| 48 | 47,350 | 46,917 | 46,773 | |

| (52) | 51,350 | 50,917 | 50,773 | |

| 56 | 55,350 | 54,917 | 54,773 | |

| (60) | 59,350 | 58,917 | 58,773 | |

| 64 | 63,350 | 62,917 | 62,773 | |

| (68) | 67,350 | 66,917 | 66,773 | |

| 72 | 71,350 | 70,917 | 70,773 | |

| (76) | 75,350 | 74,917 | 74,773 | |

| 80 | 79,350 | 78,917 | 78,773 | |

| 1,25 | 10 | 9,188 | 8,647 | 8,466 |

| 12 | 11,188 | 10,647 | 10,467 | |

| (14) | 13,188 | 12,647 | 12,466 | |

| 1,5 | 12 | 11,026 | 10,376 | 10,160 |

| (14) | 13,026 | 12,376 | 12,160 | |

| 16 | 15,026 | 14,376 | 14,160 | |

| (18) | 17,026 | 16,376 | 16,160 | |

| 20 | 19,026 | 18,376 | 18,160 | |

| (22) | 21,026 | 20,376 | 20,160 | |

| 24 | 23,026 | 22,376 | 22,160 | |

| (27) | 26,026 | 25,376 | 25,160 | |

| 30 | 29,026 | 28,376 | 28,160 | |

| (33) | 32,026 | 31,376 | 31,160 | |

| 36 | 35,026 | 34,376 | 34,160 | |

| (39) | 38,026 | 37,376 | 37,160 | |

| 42 | 41,026 | 40,376 | 40,160 | |

| (45) | 44,026 | 43,376 | 43,160 | |

| 48 | 47,026 | 46,376 | 46,160 | |

| (52) | 51,026 | 50,376 | 50,160 | |

| 56 | 55,026 | 54,376 | 54,160 | |

| (60) | 59,026 | 58,376 | 58,160 | |

| 64 | 63,026 | 62,376 | 62,160 | |

| (68) | 67,026 | 66,376 | 66,160 | |

| 72 | 71,026 | 70,376 | 70,160 | |

| (76) | 75,026 | 74,376 | 74,160 | |

| 80 | 79,026 | 78,376 | 78,160 | |

| (85) | 84,026 | 83,376 | 83,160 | |

| 90 | 89,026 | 88,376 | 88,160 | |

| (95) | 94,026 | 93,376 | 93,160 | |

| 100 | 99,026 | 98,376 | 98,160 | |

| 110 | 109,026 | 108,376 | 108,160 | |

| (115) | 114,026 | 113,376 | 113,160 | |

| (120) | 119,026 | 118,376 | 118,160 | |

| 125 | 124,026 | 123,376 | 123,160 | |

| (130) | 129,026 | 128,376 | 128,160 | |

| 140 | 139,026 | 138,376 | 138,160 | |

| (150) | 149,026 | 148,376 | 148,160 | |

| 2,0 | (18) | 16,701 | 15,835 | 15,546 |

| 20 | 18,701 | 17,835 | 17,546 | |

| (22) | 20,701 | 19,835 | 19,546 | |

| 24 | 22,701 | 21,835 | 21,546 | |

| (27) | 25,701 | 24,835 | 24,546 | |

| 30 | 28,701 | 27,835 | 27,546 | |

| (33) | 31,701 | 30,835 | 30,546 | |

| 36 | 33,701 | 32,835 | 32,546 | |

| (39) | 37,701 | 36,835 | 36,546 | |

| 42 | 40,701 | 39,835 | 39,546 | |

| (45) | 43,701 | 42,835 | 42,546 | |

| 48 | 46,701 | 45,835 | 45,546 | |

| (52) | 50,701 | 49,835 | 49,546 | |

| 56 | 54,701 | 53,835 | 53,546 | |

| (60) | 58,701 | 57,835 | 57,546 | |

| 64 | 62,701 | 61,835 | 61,546 | |

| (68) | 66,701 | 65,835 | 65,546 | |

| 72 | 70,701 | 69,835 | 69,546 | |

| (76) | 74,701 | 73,835 | 73,546 | |

| 80 | 78,701 | 77,835 | 77,546 | |

| (85) | 83,701 | 82,835 | 82,546 | |

| 90 | 88,701 | 87,835 | 87,546 | |

| (95) | 93,701 | 92,835 | 92,546 | |

| 100 | 98,701 | 97,835 | 97,546 | |

| (105) | 103,701 | 102,835 | 102,546 | |

| 110 | 108,701 | 107,835 | 107,546 | |

| (115) | 113,701 | 112,835 | 112,546 | |

| (120) | 118,701 | 117,835 | 117,546 | |

| 125 | 123,701 | 122,835 | 122,546 | |

| (130) | 128,701 | 127,835 | 127,546 | |

| 140 | 138,701 | 137,835 | 137,546 | |

| (150) | 148,701 | 147,835 | 147,546 | |

| 160 | 158,701 | 157,835 | 157,546 | |

| (170) | 168,701 | 167,835 | 167,546 | |

| 180 | 178,701 | 177,835 | 177,546 | |

| (190) | 188,701 | 187,835 | 187,546 | |

| 200 | 198,701 | 197,835 | 197,546 | |

| 3,0 | 30 | 28,051 | 26,752 | 26,319 |

| (33) | 31,051 | 29,752 | 29,319 | |

| 36 | 34,051 | 32,752 | 32,319 | |

| (39) | 37,051 | 35,752 | 35,319 | |

| 42 | 40,051 | 38,752 | 38,319 | |

| (45) | 43,051 | 41,752 | 41,319 | |

| 48 | 46,051 | 44,752 | 44,319 | |

| (52) | 50,051 | 48,752 | 48,319 | |

| 56 | 54,051 | 52,752 | 52,319 | |

| (60) | 58,051 | 56,752 | 56,319 | |

| 64 | 62,051 | 60,752 | 60,319 | |

| (68) | 66,051 | 64,752 | 64,319 | |

| 72 | 70,051 | 68,752 | 68,319 | |

| (76) | 74,051 | 72,752 | 72,319 | |

| 80 | 78,051 | 76,752 | 76,319 | |

| (85) | 83,051 | 81,752 | 81,319 | |

| 90 | 88,051 | 86,752 | 86,319 | |

| (95) | 93,051 | 91,752 | 91,319 | |

| 100 | 98,051 | 96,752 | 96,319 | |

| (105) | 103,051 | 101,752 | 101,319 | |

| 110 | 108,051 | 106,752 | 106,319 | |

| (115) | 113,051 | 111,752 | 111,319 | |

| (120) | 118,051 | 116,752 | 116,319 | |

| 125 | 123,051 | 121,752 | 121,319 | |

| (130) | 128,051 | 126,752 | 126,319 | |

| 140 | 138,051 | 136,752 | 136,319 | |

| (150) | 148,051 | 146,752 | 146,319 | |

| 160 | 158,051 | 156,752 | 156,319 | |

| (170) | 168,051 | 166,752 | 166,319 | |

| 180 | 178,051 | 176,752 | 176,319 | |

| (190) | 188,051 | 186,752 | 186,319 | |

| 200 | 198,051 | 196,752 | 196,319 | |

| (210) | 208,051 | 206,752 | 206,319 | |

| 220 | 218,051 | 216,752 | 216,319 | |

| (240) | 238,051 | 236,752 | 236,319 | |

| 250 | 248,051 | 246,752 | 246,319 | |

| (260) | 258,051 | 256,752 | 256,319 | |

| 280 | 278,051 | 276,752 | 276,319 | |

| (300) | 298,051 | 296,752 | 296,319 | |

| 4,0 | 42 | 39,402 | 37,670 | 37,093 |

| (45) | 42,402 | 40,670 | 40,093 | |

| 48 | 45,402 | 43,670 | 43,093 | |

| (52) | 49,402 | 47,670 | 47,093 | |

| 56 | 53,402 | 51,670 | 51,093 | |

| 60 | 57,402 | 55,670 | 55,093 | |

| 64 | 61,402 | 59,67 | 59,093 | |

| 72 | 69,402 | 67,670 | 67,093 | |

| (76) | 73,402 | 71,670 | 71,093 | |

| 80 | 77,402 | 78,670 | 75,093 | |

| (85) | 82,402 | 80,670 | 80,093 | |

| 90 | 87,402 | 85,670 | 85,093 | |

| (95) | 92,402 | 90,670 | 90,093 | |

| 100 | 97,402 | 95,670 | 95,093 | |

| (105) | 102,402 | 100,670 | 100,093 | |

| 110 | 107,402 | 105,670 | 105,093 | |

| (115) | 112,402 | 110,670 | 110,093 | |

| (120) | 117,402 | 115,670 | 115,093 | |

| 125 | 122,402 | 120,670 | 120,093 | |

| (130) | 127,402 | 125,670 | 125,093 | |

| 140 | 137,402 | 135,670 | 135,093 | |

| (150) | 147,402 | 145,670 | 145,093 | |

| 160 | 157,402 | 155,670 | 155,093 | |

| (170) | 167,402 | 165,670 | 165,093 | |

| 180 | 177,402 | 175,670 | 175,093 | |

| (190) | 187,402 | 185,670 | 185,093 | |

| 200 | 197,402 | 195,670 | 195,093 | |

| (210) | 207,402 | 205,670 | 205,093 | |

| 220 | 217,402 | 215,670 | 215,093 | |

| (240) | 237,402 | 235,670 | 235,093 | |

| (260) | 257,402 | 255,670 | 255,093 | |

| 280 | 277,402 | 275,670 | 275,093 | |

| 300 | 297,402 | 295,670 | 295,093 | |

Table of metric threads according to GOST 24705-2004

| Nominal thread diameter d, mm | Pitch P, mm | Thread diameters, mm | |||

| d = D | d2 = D2 | d1 = D1 | d3 | ||

| 0,25 | 0,075 | 0,250 | 0,201 | 0,169 | 0,158 |

| 0,3 | 0,08 | 0,30 | 0,248 | 0,213 | 0,202 |

| 0,35 | 0,09 | 0,350 | 0,292 | 0,253 | 0,240 |

| 0,4 | 0,1 | 0,40 | 0,335 | 0,292 | 0,277 |

| 0,45 | 0,450 | 0,385 | 0,342 | 0,327 | |

| 0,5 | 0,125 | 0,50 | 0,419 | 0,365 | 0,347 |

| 0,55 | 0,550 | 0,469 | 0,415 | 0,397 | |

| 0,6 | 0,15 | 0,60 | 0,503 | 0,438 | 0,416 |

| 0,7 | 0,175 | 0,70 | 0,586 | 0,511 | 0,485 |

| 0,8 | 0,2 | 0,80 | 0,670 | 0,583 | 0,555 |

| 0,9 | 0,225 | 0,90 | 0,754 | 0,656 | 0,624 |

| 1 | 0,25 | 1,0 | 0,838 | 0,729 | 0,693 |

| 0,2 | 1,0 | 0,870 | 0,783 | 0,755 | |

| 1,1 | 0,25 | 1,10 | 0,938 | 0,829 | 0,793 |

| 0,2 | 1,10 | 0,970 | 0,883 | 0,855 | |

| 1,2 | 0,25 | 1,20 | 1,038 | 0,929 | 0,893 |

| 0,2 | 1,20 | 1,070 | 0,983 | 0,955 | |

| 1,4 | 0,3 | 1,40 | 1,205 | 1,075 | 1,032 |

| 0,2 | 1,40 | 1,270 | 1,183 | 1,155 | |

| 1,6 | 0,35 | 1,60 | 1,373 | 1,221 | 1,171 |

| 0,2 | 1,60 | 1,470 | 1,383 | 1,355 | |

| 1,8 | 0,35 | 1,80 | 1,573 | 1,421 | 1,371 |

| 0,2 | 1,80 | 1,670 | 1,583 | 1,555 | |

| 2 | 0,4 | 2,0 | 1,740 | 1,567 | 1,509 |

| 0,25 | 2,0 | 1,838 | 1,729 | 1,693 | |

| 2,2 | 0,45 | 2,20 | 1,908 | 1,713 | 1,648 |

| 0,25 | 2,20 | 2,038 | 1,929 | 1,893 | |

| 2,5 | 0,45 | 2,50 | 2,208 | 2,013 | 1,948 |

| 0,35 | 2,50 | 2,273 | 2,121 | 2,071 | |

| 3 | 0,5 | 3,0 | 2,675 | 2,459 | 2,387 |

| 0,35 | 3,0 | 2,773 | 2,621 | 2,571 | |

| 3,5 | 0,6 | 3,50 | 3,110 | 2,850 | 2,764 |

| 0,35 | 3,50 | 3,273 | 3,121 | 3,071 | |

| 4 | 0,7 | 4,0 | 3,545 | 3,242 | 3,141 |

| 0,5 | 4,0 | 3,675 | 3,459 | 3,387 | |

| 4,5 | 0,75 | 4,50 | 4,013 | 3,688 | 3,580 |

| 0,5 | 4,50 | 4,175 | 3,959 | 3,887 | |

| 5 | 0,8 | 5,0 | 4,480 | 4,134 | 4,019 |

| 0,5 | 5,0 | 4,675 | 4,459 | 4,387 | |

| 5,5 | 0,5 | 5,50 | 5,175 | 4,959 | 4,887 |

| 6 | 1 | 6,0 | 5,350 | 4,917 | 4,773 |

| 0,75 | 6,0 | 5,513 | 5,188 | 5,080 | |

| 0,5 | 6,0 | 5,675 | 5,459 | 5,387 | |

| 7 | 1 | 7,0 | 6,350 | 5,917 | 5,773 |

| 0,75 | 7,0 | 6,513 | 6,188 | 6,080 | |

| 0,5 | 7,0 | 6,675 | 6,459 | 6,387 | |

| 8 | 1,25 | 8,0 | 7,188 | 6,647 | 6,466 |

| 1 | 8,0 | 7,350 | 6,917 | 6,773 | |

| 0,75 | 8,0 | 7,513 | 7,188 | 7,080 | |

| 0,5 | 8,0 | 7,675 | 7,459 | 7,387 | |

| 9 | 1,25 | 9,0 | 8,188 | 7,647 | 7,466 |

| 1 | 9,0 | 8,350 | 7,917 | 7,773 | |

| 0,75 | 9,0 | 8,513 | 8,188 | 8,080 | |

| 0,5 | 9,0 | 8,675 | 8,459 | 8,387 | |

| 10 | 1,5 | 10,0 | 9,026 | 8,376 | 8,160 |

| 1,25 | 10,0 | 9,188 | 8,647 | 8,466 | |

| 1 | 10,0 | 9,350 | 8,917 | 8,773 | |

| 0,75 | 10,0 | 9,513 | 9,188 | 9,080 | |

| 0,5 | 10,0 | 9,675 | 9,459 | 9,387 | |

| 11 | 1,5 | 11,0 | 10,026 | 9,376 | 9,160 |

| 1 | 11,0 | 10,350 | 9,917 | 9,773 | |

| 0,75 | 11,0 | 10,513 | 10,188 | 10,080 | |

| 0,5 | 11,0 | 10,675 | 10,459 | 10,387 | |

| 12 | 1,75 | 12,0 | 10,863 | 10,106 | 9,853 |

| 1,5 | 12,0 | 11,026 | 10,376 | 10,160 | |

| 1,25 | 12,0 | 11,188 | 10,647 | 10,466 | |

| 1 | 12,0 | 11,350 | 10,917 | 10,773 | |

| 0,75 | 12,0 | 11,513 | 11,188 | 11,080 | |

| 0,5 | 12,0 | 11,675 | 11,459 | 11,387 | |

| 14 | 2 | 14,0 | 12,701 | 11,835 | 11,546 |

| 1,5 | 14,0 | 13,026 | 12,376 | 12,160 | |

| 1,25 | 14,0 | 13,188 | 12,647 | 12,466 | |

| 1 | 14,0 | 13,350 | 12,917 | 12,773 | |

| 0,75 | 14,0 | 13,513 | 13,188 | 13,080 | |

| 0,5 | 14,0 | 13,675 | 13,459 | 13,387 | |

| 15 | 1,5 | 15,0 | 14,026 | 13,376 | 13,160 |

| 1 | 15,0 | 14,350 | 13,917 | 13,773 | |

| 16 | 2 | 16,0 | 14,701 | 13,835 | 13,546 |

| 1,5 | 16,0 | 15,026 | 14,376 | 14,160 | |

| 1 | 16,0 | 15,350 | 14,917 | 14,773 | |

| 0,75 | 16,0 | 15,513 | 15,188 | 15,080 | |

| 0,5 | 16,0 | 15,675 | 15,459 | 15,387 | |

| 17 | 1,5 | 17,0 | 16,026 | 15,376 | 15,160 |

| 1 | 17,0 | 16,350 | 15,917 | 15,773 | |

| 18 | 2,5 | 18,0 | 16,376 | 15,294 | 14,933 |

| 2 | 18,0 | 16,701 | 15,835 | 15,546 | |

| 1,5 | 18,0 | 17,026 | 16,376 | 16,160 | |

| 1 | 18,0 | 17,350 | 16,917 | 16,773 | |

| 0,75 | 18,0 | 17,518 | 17,188 | 17,080 | |

| 0,5 | 18,0 | 17,675 | 17,459 | 17,387 | |

| 20 | 2,5 | 20,0 | 18,376 | 17,294 | 16,933 |

| 2 | 20,0 | 18,701 | 17,835 | 17,546 | |

| 1,5 | 20,0 | 19,026 | 18,376 | 18,160 | |

| 1 | 20,0 | 19,350 | 18,917 | 18,773 | |

| 0,75 | 20,0 | 19,513 | 19,188 | 19,080 | |

| 0,5 | 20,0 | 19,675 | 19,459 | 19,387 | |

| 22 | 2,5 | 22,0 | 20,376 | 19,294 | 18,933 |

| 2 | 22,0 | 20,701 | 19,835 | 19,546 | |

| 1,5 | 22,0 | 21,026 | 20,376 | 20,160 | |

| 1 | 22,0 | 21,350 | 20,917 | 20,773 | |

| 0,75 | 22,0 | 21,513 | 21,188 | 21,080 | |

| 0,5 | 22,0 | 21,675 | 21,459 | 21,387 | |

| 24 | 3 | 24,0 | 22,051 | 20,752 | 20,319 |

| 2 | 24,0 | 22,701 | 21,835 | 21,546 | |

| 1,5 | 24,0 | 23,026 | 22,376 | 22,160 | |

| 1 | 24,0 | 23,350 | 22,917 | 22,773 | |

| 0,75 | 24,0 | 23,513 | 23,188 | 23,080 | |

| 25 | 2 | 25,0 | 23,701 | 22,835 | 22,546 |

| 1,5 | 25,0 | 24,026 | 23,376 | 23,160 | |

| 1 | 25,0 | 24,350 | 23,917 | 23,773 | |

| 26 | 1,5 | 26,0 | 25,026 | 24,376 | 24,160 |

| 27 | 3 | 27,0 | 25,051 | 23,752 | 23,319 |

| 2 | 27,0 | 25,701 | 24,835 | 24,546 | |

| 1,5 | 27,0 | 26,026 | 25,376 | 25,160 | |

| 1 | 27,0 | 26,350 | 25,917 | 25,773 | |

| 0,75 | 27,0 | 26,513 | 26,188 | 26,080 | |

| 28 | 2 | 28,0 | 26,701 | 25,835 | 25,546 |

| 1,5 | 28,0 | 27,026 | 26,376 | 26,160 | |

| 1 | 28,0 | 27,350 | 26,917 | 26,773 | |

| 30 | 3,5 | 30,0 | 27,727 | 26,211 | 25,706 |

| 3 | 30,0 | 28,051 | 26,752 | 26,319 | |

| 2 | 30,0 | 28,701 | 27,835 | 27,546 | |

| 1,5 | 30,0 | 29,026 | 28,376 | 28,160 | |

| 1 | 30,0 | 29,350 | 28,917 | 28,773 | |

| 0,75 | 30,0 | 29,513 | 29,188 | 29,080 | |

| 32 | 2 | 32,0 | 30,701 | 29,835 | 29,546 |

| 1,5 | 32,0 | 31,026 | 30,376 | 30,160 | |

| 33 | 3,5 | 33,0 | 30,727 | 29,211 | 28,706 |

| 3 | 33,0 | 31,051 | 29,752 | 29,319 | |

| 2 | 33,0 | 31,701 | 30,835 | 30,546 | |

| 1,5 | 33,0 | 32,026 | 31,376 | 31,160 | |

| 1 | 33,0 | 32,350 | 31,917 | 31,773 | |

| 0,75 | 33,0 | 32,513 | 32,188 | 32,080 | |

| 35 | 1,5 | 35,0 | 34,026 | 33,376 | 33,160 |

| 36 | 4 | 36,0 | 33,402 | 31,670 | 31,093 |

| 3 | 36,0 | 34,051 | 32,752 | 32,319 | |

| 2 | 36,0 | 34,701 | 33,835 | 33,546 | |

| 1,5 | 38,0 | 35,026 | 34,376 | 34,160 | |

| 1 | 36,0 | 35,350 | 34,917 | 34,773 | |

| 38 | 1,5 | 38,0 | 37,026 | 36,376 | 36,160 |

| 39 | 4 | 39,0 | 36,402 | 34,670 | 34,093 |

| 3 | 39,0 | 37,051 | 35,752 | 35,319 | |

| 2 | 39,0 | 37,701 | 36,835 | 36,546 | |

| 1,5 | 39,0 | 38,026 | 37,376 | 37,160 | |

| 1 | 39,0 | 38,350 | 37,917 | 37,773 | |

| 40 | 3 | 40,0 | 38,051 | 36,752 | 36,319 |

| 2 | 40,0 | 38,701 | 37,835 | 37,546 | |

| 1,5 | 40,0 | 39,026 | 38,376 | 38,160 | |

| 42 | 4,5 | 42,0 | 39,077 | 37,129 | 36,479 |

| 4 | 42,0 | 39,402 | 37,670 | 37,093 | |

| 3 | 42,0 | 40,051 | 38,752 | 38,319 | |

| 2 | 42,0 | 40,701 | 39,835 | 39,546 | |

| 42 | 1,5 | 42,0 | 41,026 | 40,376 | 40,160 |

| 1 | 42,0 | 41,350 | 40,917 | 40,773 | |

| 45 | 4,5 | 45,0 | 42,077 | 40,129 | 39,479 |

| 4 | 45,0 | 42,402 | 40,670 | 40,093 | |

| 3 | 45,0 | 43,051 | 41,752 | 41,319 | |

| 2 | 45,0 | 43,701 | 42,835 | 42,546 | |

| 1,5 | 45,0 | 44,026 | 43,376 | 43,160 | |

| 1 | 45,0 | 44,350 | 43,917 | 43,773 | |

| 48 | 5 | 48,0 | 44,752 | 42,587 | 41,866 |

| 4 | 48,0 | 45,402 | 43,670 | 43,093 | |

| 3 | 48,0 | 46,051 | 44,752 | 44,319 | |

| 2 | 48,0 | 46,701 | 45,835 | 45,516 | |

| 1,5 | 48,0 | 47,026 | 46,376 | 46,160 | |

| 1 | 48,0 | 47,350 | 46,917 | 46,773 | |

| 50 | 3 | 50,0 | 48,051 | 46,752 | 46,319 |

| 2 | 50,0 | 48,701 | 47,835 | 47,546 | |

| 1,5 | 50,0 | 49,026 | 48,376 | 48,160 | |

| 52 | 5 | 52,0 | 48,752 | 46,587 | 45,866 |

| 4 | 52,0 | 49,402 | 47,670 | 47,093 | |

| 3 | 52,0 | 50,051 | 48,752 | 48,319 | |

| 2 | 52,0 | 50,701 | 49,835 | 49,546 | |

| 1,5 | 52,0 | 51,026 | 50,376 | 50,160 | |

| 1 | 52,0 | 51,350 | 50,917 | 50,773 | |

| 55 | 4 | 55,0 | 52,402 | 50,670 | 50,093 |

| 3 | 55,0 | 53,051 | 51,752 | 51,319 | |

| 2 | 55,0 | 53,701 | 52,835 | 52,546 | |

| 1,5 | 55,0 | 54,026 | 53,376 | 53,160 | |

| 56 | 5,5 | 56,0 | 52,428 | 50,046 | 49,253 |

| 4 | 56,0 | 53,402 | 51,670 | 51,093 | |

| 3 | 56,0 | 54,051 | 52,752 | 52,319 | |

| 2 | 56,0 | 54,701 | 53,835 | 53,546 | |

| 1,5 | 56,0 | 55,026 | 54,376 | 54,160 | |

| 1 | 56,0 | 55,350 | 54,917 | 54,773 | |

| 58 | 4 | 58,0 | 55,402 | 53,670 | 53,093 |

| 3 | 58,0 | 56,051 | 54,752 | 54,319 | |

| 2 | 58,0 | 56,701 | 55,835 | 55,546 | |

| 1,5 | 58,0 | 57,026 | 56,376 | 56,160 | |

| 60 | 5,5 | 60,0 | 56,428 | 54,046 | 53,252 |

| 4 | 60,0 | 57,402 | 55,670 | 55,093 | |

| 3 | 60,0 | 58,051 | 56,752 | 56,319 | |

| 2 | 60,0 | 58,701 | 57,835 | 57,546 | |

| 1,5 | 60,0 | 59,026 | 58,376 | 58,160 | |

| 1 | 60,0 | 59,350 | 58,917 | 58,773 | |

| 62 | 4 | 62,0 | 59,402 | 57,670 | 57,093 |

| 3 | 62,0 | 60,051 | 58,752 | 58,319 | |

| 2 | 62,0 | 60,701 | 59,835 | 59,546 | |

| 1,5 | 62,0 | 61,026 | 60,376 | 60,160 | |

| 64 | 6 | 64,0 | 60,103 | 57,505 | 56,639 |

| 4 | 64,0 | 61,402 | 59,670 | 59,093 | |

| 3 | 64,0 | 62,051 | 60,752 | 60,319 | |

| 2 | 64,0 | 62,701 | 61,835 | 61,546 | |

| 1,5 | 64,0 | 63,026 | 62,376 | 62,160 | |

| 1 | 64,0 | 63,350 | 62,917 | 62,773 | |

| 65 | 4 | 65,0 | 62,402 | 60,670 | 60,093 |

| 3 | 65,0 | 63,051 | 61,752 | 61,319 | |

| 2 | 65,0 | 63,701 | 62,835 | 62,546 | |

| 1,5 | 65,0 | 64,026 | 63,376 | 63,160 | |

| 68 | 6 | 68,0 | 64,103 | 61,505 | 60,639 |

| 4 | 68,0 | 64,402 | 63,670 | 63,093 | |

| 3 | 68,0 | 66,051 | 64,752 | 64,319 | |

| 2 | 68,0 | 66,701 | 65,835 | 65,546 | |

| 1,5 | 68,0 | 67,026 | 66,376 | 66,160 | |

| 1 | 68,0 | 67,350 | 66,917 | 66,773 | |

| 70 | 6 | 70,0 | 66,103 | 63,505 | 62,639 |

| 4 | 70,0 | 67,402 | 65,670 | 65,093 | |

| 3 | 70,0 | 68,051 | 66,752 | 66,319 | |

| 2 | 70,0 | 68,701 | 67,835 | 67,546 | |

| 1,5 | 70,0 | 69,026 | 68,376 | 68,160 | |

| 72 | 6 | 72,0 | 68,103 | 65,505 | 64,639 |

| 4 | 72,0 | 69,402 | 67,670 | 67,093 | |

| 3 | 72,0 | 70,051 | 68,752 | 68,319 | |

| 2 | 72,0 | 70,701 | 69,835 | 69,546 | |

| 1,5 | 72,0 | 71,026 | 70,376 | 70,160 | |

| 1 | 72,0 | 71,350 | 70,917 | 70,773 | |

| 75 | 4 | 75,0 | 72,402 | 70,670 | 70,093 |

| 3 | 75,0 | 73,051 | 71,752 | 71,319 | |

| 2 | 75,0 | 73,701 | 72,835 | 72,546 | |

| 1,5 | 75,0 | 74,026 | 73,376 | 73,160 | |

| 76 | 6 | 76,0 | 72,103 | 69,505 | 68,639 |

| 4 | 76,0 | 73,402 | 71,670 | 71,093 | |

| 3 | 76,0 | 74,051 | 72,752 | 72,319 | |

| 2 | 76,0 | 74,701 | 73,835 | 73,546 | |

| 1,5 | 76,0 | 75,026 | 74,376 | 74,160 | |

| 1 | 76,0 | 75,350 | 74,917 | 74,773 | |

| 78 | 2 | 78,0 | 76,701 | 75,835 | 75,546 |

| 80 | 6 | 80,0 | 76,103 | 73,505 | 72,639 |

| 4 | 80,0 | 77,402 | 75,670 | 75,093 | |

| 3 | 80,0 | 78,051 | 76,752 | 76,319 | |

| 2 | 80,0 | 78,701 | 77,835 | 77,546 | |

| 1,5 | 80,0 | 79,026 | 78,376 | 78,160 | |

| 1 | 80,0 | 79,350 | 78,917 | 78,773 | |

| 82 | 2 | 82,0 | 80,701 | 79,835 | 79,546 |

| 85 | 6 | 85,0 | 81,103 | 78,505 | 77,639 |

| 4 | 85,0 | 82,402 | 80,670 | 80,093 | |

| 3 | 85,0 | 83,051 | 81,752 | 81,319 | |

| 2 | 85,0 | 83,701 | 82,835 | 82,546 | |

| 1,5 | 85,0 | 84,026 | 83,376 | 83,160 | |

| 90 | 6 | 90,0 | 86,103 | 83,505 | 82,639 |

| 4 | 90,0 | 87,402 | 85,670 | 85,093 | |

| 3 | 90,0 | 88,051 | 86,752 | 86,319 | |

| 2 | 90,0 | 88,701 | 87,835 | 87,546 | |

| 1,5 | 90,0 | 89,026 | 88,376 | 88,160 | |

| 95 | 6 | 95,0 | 91,103 | 88,505 | 87,639 |

| 4 | 95,0 | 92,402 | 90,670 | 90,093 | |

| 3 | 95,0 | 93,051 | 91,752 | 91,319 | |

| 2 | 95,0 | 93,701 | 92,835 | 92,546 | |

| 1,5 | 95,0 | 94,026 | 93,376 | 93,160 | |

| 10 | 6 | 100,0 | 96,103 | 93,505 | 92,639 |

| 4 | 100,0 | 97,402 | 95,670 | 95,093 | |

| 3 | 100,0 | 98,051 | 96,752 | 96,319 | |

| 2 | 100,0 | 98,701 | 97,835 | 97,546 | |

| 1,5 | 100,0 | 99,026 | 98,376 | 98,160 | |

| 105 | 6 | 105,0 | 101,103 | 98,505 | 97,639 |

| 4 | 105,0 | 102,402 | 100,670 | 100,093 | |

| 3 | 105,0 | 103,051 | 101,752 | 101,319 | |

| 2 | 105,0 | 103,701 | 102,835 | 102,546 | |

| 1,5 | 105,0 | 104,026 | 103,376 | 103,160 | |

| 110 | 6 | 110,0 | 106,103 | 103,505 | 102,639 |

| 4 | 110,0 | 107,402 | 105,670 | 105,093 | |

| 3 | 110,0 | 108,051 | 106,752 | 106,319 | |

| 2 | 110,0 | 108,701 | 107,835 | 107,546 | |

| 1,5 | 110,0 | 109,026 | 108,376 | 108,160 | |

| 115 | 6 | 115,0 | 111,103 | 108,505 | 107,639 |

| 4 | 115,0 | 112,402 | 110,670 | 110,093 | |

| 3 | 115,0 | 113,051 | 111,752 | 111,319 | |

| 2 | 115,0 | 113,701 | 112,835 | 112,546 | |

| 1,5 | 115,0 | 114,026 | 113,376 | 113,160 | |

| 120 | 6 | 120,0 | 116,103 | 113,505 | 112,639 |

| 4 | 120,0 | 117,402 | 115,670 | 115,093 | |

| 3 | 120,0 | 118,051 | 116,752 | 116,319 | |

| 2 | 120,0 | 118,701 | 117,835 | 117,546 | |

| 1,5 | 120,0 | 119,026 | 118,376 | 118,160 | |

| 125 | 8 | 125,0 | 119,804 | 116,340 | 115,185 |

| 6 | 125,0 | 121,103 | 118,505 | 117,639 | |

| 4 | 125,0 | 122,402 | 120,670 | 120,093 | |

| 8 | 125,0 | 123,051 | 121,752 | 121,319 | |

| 2 | 125,0 | 123,701 | 122,835 | 122,546 | |

| 1,5 | 125,0 | 124,026 | 123,376 | 123,160 | |

| 130 | 8 | 130,0 | 124,804 | 121,340 | 120,185 |

| 6 | 130,0 | 126,103 | 123,505 | 122,639 | |

| 4 | 130,0 | 127,402 | 125,670 | 125,093 | |

| 3 | 130,0 | 128,051 | 126,752 | 126,319 | |

| 2 | 130,0 | 128,701 | 127,835 | 127,546 | |

| 1,5 | 130,0 | 129,026 | 128,376 | 128,160 | |

| 135 | 6 | 135,0 | 131,103 | 128,505 | 127,639 |

| 4 | 135,0 | 132,402 | 130,670 | 130,093 | |

| 3 | 135,0 | 133,051 | 131,752 | 131,319 | |

| 2 | 135,0 | 133,701 | 132,835 | 132,546 | |

| 1,5 | 135,0 | 134,026 | 133,376 | 133,160 | |

| 140 | 8 | 140,0 | 134,804 | 131,340 | 130,185 |

| 6 | 140,0 | 136,103 | 133,505 | 132,639 | |

| 4 | 140,0 | 537,402 | 135,670 | 135,093 | |

| 3 | 140,0 | 138,051 | 136,752 | 136,319 | |

| 2 | 140,0 | 138,701 | 137,835 | 137,546 | |

| 1,5 | 140,0 | 139,026 | 138,376 | 138,160 | |

| 145 | 6 | 145,0 | 141,103 | 138,505 | 137,639 |

| 4 | 145,0 | 142,402 | 140,670 | 140,093 | |

| 3 | 145,0 | 143,051 | 141,752 | 141,319 | |

| 2 | 145,0 | 143,701 | 142,835 | 142,546 | |

| 1,5 | 145,0 | 144,025 | 143,376 | 143,160 | |

| 150 | 8 | 150,0 | 144,804 | 141,340 | 140,185 |

| 6 | 150,0 | 146,103 | 143,505 | 142,639 | |

| 4 | 150,0 | 147,402 | 145,670 | 145,093 | |

| 3 | 150,0 | 148,051 | 146,752 | !46,319 | |

| 2 | 150,0 | 148,701 | 147,835 | 147,546 | |

| 1,5 | 150,0 | 149,026 | 148,376 | 148,160 | |

| 155 | 6 | 155,0 | 151,103 | 148,505 | 147,639 |

| 4 | 155,0 | 152,402 | 150,670 | 150,093 | |

| 3 | 155,0 | 153,051 | 151,752 | 151,319 | |

| 2 | 155,0 | 153,701 | 152,835 | 152,546 | |

| 160 | 8 | 160,0 | 154,804 | 151,340 | 150,185 |

| 6 | 160,0 | 156,103 | 153,505 | 152,639 | |

| 4 | 160,0 | 157,402 | 155,670 | 155,093 | |

| 3 | 160,0 | 158,051 | 156,752 | 156,319 | |

| 2 | 160,0 | 158,701 | 157,835 | 157,546 | |

| 165 | 6 | 165,0 | 161,103 | 158,505 | 157,639 |

| 4 | 165,0 | 162,402 | 160,670 | 160,093 | |

| 3 | 165,0 | 163,051 | 161,752 | 161,319 | |

| 2 | 165,0 | 163,701 | 162,835 | 162,546 | |

| 170 | 8 | 170,0 | 164,804 | 161,340 | 160,185 |

| 6 | 170,0 | 166,103 | 163,505 | 162,639 | |

| 4 | 170,0 | 167,402 | 165,670 | 165,093 | |

| 3 | 170,0 | 168,051 | 166,752 | 166,319 | |

| 2 | 170,0 | 168,701 | 167,835 | 167,546 | |

| 175 | 6 | 175,0 | 171,103 | 168,505 | 167,639 |

| 4 | 175,0 | 172,402 | 170,670 | 170,093 | |

| 3 | 175,0 | 173,051 | 171,752 | 171,319 | |

| 2 | 175,0 | 173,701 | 172,835 | 172,546 | |

| 180 | 8 | 180,0 | 174,804 | 171,340 | 170,185 |

| 6 | 180,0 | 176,103 | 173,505 | 172,639 | |

| 4 | 180,0 | 177,402 | 175,670 | 175,093 | |

| 3 | 180,0 | 178,051 | 176,752 | 176,319 | |

| 2 | 180,0 | 178,701 | 177,835 | 177,546 | |

| 185 | 6 | 185,0 | 181,103 | 178,605 | 177,639 |

| 4 | 185,0 | 182,402 | 180,670 | 180,093 | |

| 3 | 185,0 | 183,051 | 181,752 | 181,319 | |

| 2 | 185,0 | 183,701 | 182,835 | 182,546 | |

| 190 | 8 | 190,0 | 184,804 | 181,340 | 180,185 |

| 6 | 190,0 | 186,103 | 183,505 | 182,639 | |

| 4 | 190,0 | 187,402 | 185,670 | 185,093 | |

| 3 | 190,0 | 188,051 | 186,752 | 186,319 | |

| 2 | 190,0 | 188,701 | 187,835 | 187,546 | |

| 195 | 6 | 195,0 | 191,103 | 188,505 | 187,639 |

| 4 | 195,0 | 192,402 | 190,670 | 190,093 | |

| 3 | 195,0 | 193,051 | 191,752 | 191,319 | |

| 2 | 195,0 | 193,701 | 192,835 | 192,546 | |

| 200 | 8 | 200,0 | 194,804 | 191,340 | 190,185 |

| 6 | 200,0 | 196,103 | 193,505 | 192,639 | |

| 4 | 200,0 | 197,402 | 195,670 | 195,093 | |

| 3 | 200,0 | 198,051 | 196,752 | 196,319 | |

| 2 | 200,0 | 198,701 | 197,835 | 197,546 | |

| 205 | 6 | 205,0 | 201,103 | 198,505 | 197,639 |

| 4 | 205,0 | 202,402 | 20,670 | 200,093 | |

| 3 | 205,0 | 203,051 | 201,752 | 201,319 | |

| 210 | 8 | 210,0 | 204,804 | 201,340 | 200,185 |

| 6 | 210,0 | 206,103 | 203,505 | 202,639 | |

| 4 | 210,0 | 207,402 | 205,670 | 205,093 | |

| 3 | 210,0 | 208,051 | 206,752 | 206,319 | |

| 215 | 6 | 215,0 | 211,103 | 208,505 | 2,07,639 |

| 4 | 215,0 | 212,402 | 210,670 | 210,093 | |

| 3 | 215,0 | 213,051 | 211,752 | 211,319 | |

| 220 | 8 | 220,0 | 214,804 | 211,340 | 210,185 |

| 6 | 220,0 | 216,103 | 213,505 | 212,639 | |

| 4 | 220,0 | 217,402 | 215,670 | 215,093 | |

| 3 | 220,0 | 218,051 | 216,752 | 216,319 | |

| 225 | 6 | 225,0 | 221,103 | 218,505 | 217,639 |

| 4 | 225,0 | 222,402 | 220,670 | 220,093 | |

| 3 | 225,0 | 223,051 | 221,752 | 221,319 | |

| 230 | 8 | 230,0 | 224,804 | 221,340 | 220,185 |

| 6 | 230,0 | 226,103 | 223,505 | 222,639 | |

| 4 | 230,0 | 227,402 | 225,670 | 225,098 | |

| 3 | 230,0 | 228,051 | 226,752 | 226,319 | |

| 235 | 6 | 235,0 | 231,103 | 228,505 | 227,639 |

| 4 | 235,0 | 232,402 | 230,670 | 230,093 | |

| 3 | 235,0 | 233,051 | 231,752 | 231,319 | |

| 240 | 8 | 240,0 | 234,804 | 231,340 | 230,185 |

| 6 | 240,0 | 236,103 | 233,505 | 232,639 | |

| 4 | 240,0 | 237,402 | 235,670 | 235,093 | |

| 3 | 240,0 | 238,051 | 236,752 | 236,319 | |

| 245 | 6 | 245,0 | 241,103 | 238,505 | 237,639 |

| 4 | 245,0 | 242,402 | 240,670 | 240,093 | |

| 3 | 245,0 | 243,051 | 241,752 | 241,319 | |

| 250 | 8 | 250,0 | 244,804 | 241,340 | 240,185 |

| 6 | 250,0 | 246,103 | 243,505 | 242,639 | |

| 4 | 250,0 | 247,402 | 245,670 | 245,093 | |

| 3 | 250,0 | 248,051 | 246,752 | 246,319 | |

| 255 | 6 | 255,0 | 21,103 | 248,505 | 247,639 |

| 4 | 255,0 | 252,402 | 250,670 | 250,093 | |

| 3 | 255,0 | 253,051 | 251,752 | 251,319 | |

| 260 | 8 | 260,0 | 254,804 | 251,340 | 250,185 |

| 6 | 260,0 | 256,103 | 253,505 | 252,639 | |

| 4 | 260,0 | 257,402 | 255,670 | 255,093 | |

| 3 | 260,0 | 258,051 | 256,752 | 256,319 | |

| 265 | 6 | 265,0 | 261,103 | 258,505 | 257,639 |

| 4 | 265,0 | 262,402 | 260,670 | 260,093 | |

| 3 | 265,0 | 263,051 | 261,752 | 261,319 | |

| 270 | 8 | 270,0 | 264,804 | 261,340 | 260,185 |

| 6 | 270,0 | 266,103 | 263,505 | 262,639 | |

| 4 | 270,0 | 267,402 | 265,670 | 265,093 | |

| 3 | 270,0 | 268,051 | 266,752 | 266,319 | |

| 275 | 6 | 275,0 | 271,103 | 268,505 | 267,639 |

| 4 | 275,0 | 272,402 | 270,670 | 270,093 | |

| 3 | 275,0 | 273,051 | 271,752 | 271,319 | |

| 280 | 8 | 280,0 | 274,804 | 271,340 | 270,185 |

| 6 | 280,0 | 276,103 | 273,505 | 272,639 | |

| 4 | 280,0 | 277,402 | 275,670 | 275,093 | |

| 3 | 280,0 | 278,051 | 276,752 | 276,319 | |

| 285 | 6 | 285,0 | 281,103 | 278,505 | 277,639 |

| 4 | 285,0 | 282,402 | 280,670 | 280,093 | |

| 3 | 285,0 | 283,051 | 281,752 | 281,319 | |

| 290 | 8 | 290,0 | 284,804 | 281,340 | 280,185 |

| 6 | 290,0 | 286,103 | 283,505 | 282,639 | |

| 4 | 290,0 | 287,402 | 285,670 | 285,093 | |

| 3 | 290,0 | 288,051 | 286,752 | 286,319 | |

| 295 | 6 | 295,0 | 291,103 | 288,505 | 287,639 |

| 4 | 295,0 | 292,402 | 290,670 | 290,093 | |

| 3 | 295,0 | 293,051 | 291,752 | 291,319 | |

| 300 | 8 | 300,0 | 294,804 | 291,340 | 290,185 |

| 6 | 300,0 | 296,103 | 293,505 | 292,639 | |

| 4 | 300,0 | 297,402 | 295,670 | 295,093 | |

| 3 | 300,0 | 298,051 | 296,752 | 296,319 | |

| 310 | 6 | 310,0 | 306,103 | 303,505 | 302,639 |

| 4 | 310,0 | 307,402 | 305,670 | 305,093 | |

| 320 | 8 | 320,0 | 314,804 | 311,340 | 310,185 |

| 6 | 320,0 | 3!6,103 | 313,505 | 312,639 | |

| 4 | 320,0 | 317,402 | 315,670 | 315,093 | |

| 330 | 6 | 330,0 | 326,103 | 323,505 | 322,639 |

| 4 | 330,0 | 327,402 | 325,670 | 325,093 | |

| 340 | 8 | 340,0 | 334,804 | 331,340 | 330,185 |

| 6 | 340,0 | 336,103 | 333,505 | 332,639 | |

| 4 | 340,0 | 337,402 | 335,670 | 335,093 | |

| 350 | 6 | 350,0 | 346,103 | 343,505 | 342,639 |

| 4 | 350,0 | 347,402 | 345,670 | 345,093 | |

| 360 | 8 | 360,0 | 354,804 | 351,340 | 350,185 |

| 6 | 360,0 | 356,103 | 353,505 | 352,639 | |

| 4 | 360,0 | 357,402 | 355,670 | 355,093 | |

| 370 | 6 | 370,0 | 366,103 | 363,505 | 362,639 |

| 4 | 370,0 | 367,402 | 365,670 | 365,093 | |

| 380 | 8 | 380,0 | 374,804 | 371,340 | 370,185 |

| 6 | 380,0 | 376,103 | 373,505 | 372,639 | |

| 4 | 380,0 | 377,402 | 375,670 | 375,093 | |

| 390 | 6 | 390,0 | 386,103 | 383,505 | 382,639 |

| 4 | 390,0 | 387,402 | 385,670 | 385,093 | |

| 400 | 8 | 400,0 | 394,804 | 391,340 | 390,185 |

| 6 | 400,0 | 396,103 | 393,505 | 392,639 | |

| 4 | 400,0 | 397,402 | 395,670 | 395,093 | |

| 410 | 6 | 410,0 | 406,103 | 403,505 | 402,639 |

| 420 | 8 | 420,0 | 414,804 | 411,340 | 410,185 |

| 6 | 420,0 | 416,103 | 413,505 | 412,639 | |

| 430 | 6 | 430,0 | 426,103 | 423,505 | 422,639 |

| 440 | 8 | 440,0 | 434,804 | 431,340 | 430,185 |

| 6 | 440,0 | 436,103 | 433,505 | 432,639 | |

| 450 | 6 | 450,0 | 446,103 | 443,505 | 442,639 |

| 460 | 8 | 460,0 | 454,804 | 451,340 | 450,185 |

| 6 | 460,0 | 456,103 | 453,505 | 452,639 | |

| 470 | 6 | 470,0 | 466,103 | 463,505 | 462,639 |

| 480 | 8 | 480,0 | 474,804 | 471,340 | 470,185 |

| 6 | 480,0 | 476,103 | 473,505 | 472,639 | |

| 490 | 6 | 490,0 | 486,103 | 483,505 | 482,639 |

| 500 | 8 | 500,0 | 494,804 | 491,340 | 490,185 |

| 6 | 500,0 | 496,103 | 493,505 | 492,639 | |

| 510 | 6 | 510,0 | 506,103 | 503,505 | 502,639 |

| 520 | 8 | 520,0 | 514,804 | 511,340 | 510,185 |

| 6 | 520,0 | 516,103 | 513,505 | 512,639 | |

| 530 | 6 | 530,0 | 526,103 | 523,505 | 522,639 |

| 540 | 8 | 540,0 | 534,804 | 531,340 | 530,185 |

| 6 | 540,0 | 536,103 | 533,505 | 532,639 | |

| 550 | 6 | 550,0 | 546,103 | 543,505 | 542,639 |

| 560 | 8 | 560,0 | 554,804 | 551,340 | 550,185 |

| 6 | 560,0 | 556,103 | 553,505 | 552,639 | |

| 570 | 6 | 570,0 | 566,103 | 563,505 | 562,639 |

| 580 | 8 | 580,0 | 574,804 | 571,340 | 570,185 |

| 6 | 580,0 | 576,103 | 573,505 | 572,639 | |

| 590 | 6 | 590,0 | 586,103 | 583,505 | 582,639 |

| 600 | 8 | 600,0 | 594,804 | 591,340 | 590,185 |

| 6 | 600,0 | 596,103 | 593,505 | 592,639 | |

Application

Metric threads are widespread in the countries of the former Soviet Union. Used for application to both internal and external planes of fasteners. Typically used for fastening metal structures of various types. For these purposes, a variety of bolts (anchor and conventional) and other types of fasteners are manufactured. She found a particular purpose in mechanical engineering, construction of engineering communications, especially in the plumbing sector. Most pipe and container fittings are manufactured with this type of thread.

Most often, this type of carving is applied to cylindrical objects. But in some cases, when it is necessary to achieve tightness, a conical shape is used. This form, with a metric thread applied, allows you to achieve maximum tightness, even without the use of additional sealing agents. Most often used for installation of pipelines.

What is carving and its types

A thread is a groove of a special shape and size, applied in a spiral to the inner or outer surface of a pipe or metal rod. Can be applied to cylindrical or conical surfaces. It is characterized and differs from each other by the shape of the groove, the height/depth of the relief and the distance between the turns - the pitch. In order to connect two parts, they must have the same or compatible threads, with one part having an external thread and the other having an internal thread of the same type and size.

In general, threads are divided into fastening and running threads. Chassis are used in machine elements and provide movement. We are more interested in those that are used in everyday life and that we encounter in the process of repair and construction. This is just a mounting thread. In fact, that’s what we’ll talk about.

Types of thread according to the direction of turns and surface

It is also worth knowing that in the direction of application of turns, threads there are right and left, and in the direction of the surface on which they are applied - cylindrical and conical.

Types of threads

Pipe threads have their own profile, which provides a tight seal. It is used for non-welded connections of metal pipes in pipelines, installation of various types of fittings, and connection of devices. Recently, threaded connections have also been used on some types of plastic pipes, but there the approach is different - it is cast, although the essence is the same.

Three types of pipe threads and their differences

There are three main types of carving:

Metric. You can distinguish them by the sharp tops of the turns and grooves. Shape: triangle with 60° angles. It is called so because its parameters are indicated in millimeters, and these are units of measurement of the metric system. Standardized by GOST 9150-81. Inch. It is also based on a triangle, but with an apex of 55°. It is present on imported parts. As you can see, the difference between metric and tapered threads is in the corners. Pipe. It differs from metric by a slightly smaller angle - 55°, and has the same angle from inch. The main difference is that the edges are rounded

And this is fundamentally important. Can be applied to a cylinder (pipe), and then the word “cylindrical” is added to the name

Standardized by GOST 6357-81. When threaded on a cone, it is called a pipe taper thread.

What type of carving is there? These are connecting ones - for connecting parts

The types of threads that may be on imported fittings and components may also be useful. This is a Whitworth thread, which is designated BSW if it has a coarse pitch and BSF if it has a fine pitch. It was this standard that was taken as the basis for the development of pipe threads in the USSR. So Whitworth threads and standard manufactured pipe threads are compatible.

Types of threads and their areas of application

There are other profiles, but they are common and very specific. Under normal conditions they are not needed. For general development, let's say that there are also rectangular and trapezoidal shapes.

Where is which one used?

Now about where what type of thread is used. Metric is applied to anchors, bolts, studs, nuts and other fasteners. Applied to a cylindrical surface it does not provide a tight seal, so it is not the best choice for pipelines. However, it is used, and for tightness it is “set” on a winding - tow or fum tape. In addition to plumbing, it is used in assembling frames from round pipes with a threaded connection.

What types of threads are there: profiles and standards

The picture changes when a metric thread is applied to a conical surface. This connection has a high degree of tightness. It is the metric conical thread that is applied to caps and is used in industrial pipelines for transporting gas and liquids that emit volatile substances. In everyday life, the use of conical threads is limited, since special equipment is required for its application.

It is not difficult to guess that pipe threads are used in pipelines. Thanks to the smooth profile lines, even without additional sealing, the connection is airtight. It is this type that is applied to elbows, angles, tees, and other devices that are used in the assembly of plumbing, heating and sewage systems.

State standards

GOST 8724-2002

State standard containing standards defining the required parameters of metric threads, including pitch and diameter. Adopted in 2002, with subsequent editions, as an analogue of the international standard ISO 261-98. The GOST text practically repeats the international text, with one difference: the ISO range ranges from 1 to 300 mm, this standard has been expanded to the range from 0.25 to 600 mm. The last revision of the text was made in 2004 and is valid today.

The standard contains individual parameters that can also be found in other standards. The structure of the document is similar to other standards of this type. All information is structured in the form of tables containing requirements for thread pitch and diameter. This test structure is as convenient as possible for understanding and use.

It should be noted that the regulatory information applies to threads of all types, be it left-handed or right-handed. The standard establishes the standard value of metric thread steps in the range from 0.075 to 8 mm.

The document consists of:

- Prefaces. Which contains general information about GOST, by whom and when it was adopted, when changes were made.

- Scope of application. Information is provided on the range of regulatory requirements for size and pitch.

- Links to standards.

- Definitions.

- Table of diameters and pitch. The section contains a table of standard indicators.

- Thread designation. Labeling standards are indicated.

Read also: Vacuum cleaner power regulator diagram

GOST 24705-2004

The standard was adopted in 2004. Its standards apply to all types of threads in accordance with GOST 8724. The text information is also structured in the form of a table. Complies with the international standard ISO 724:1993 with additions in accordance with the exclusive requirements of each member country of the Interstate Council for Standardization.

GOST 9150-2002

A standard regulating the requirements for the profile, namely the geometric parameters. Adopted in 2002 and covering all types of threads. The text of GOST is closely related to the above standards.

GOST 16093-2004

Adopted in 2004. Regulates the standard tolerance of threads and markings, applies to different types. The latest version contains the provisions of the international standard.

The above standards are applied in combination, as they complement and refer to each other.

Metric thread

BASIC DIMENSIONS OF METRIC THREAD (GOST 9150-2002, GOST 8724-2002, GOST 24705-2004)

GOST 8724-2002 is an identical text to the international standard ISO 261-98 “ISO threads for general purposes. Diameters and pitches in the diameter range from 1

up to

300

mm" and contains additional requirements reflecting the needs of the country's economy (up to 600 mm).

This standard applies to general purpose metric threads with a profile in accordance with GOST 9150 and sets their diameters from 0,25

up to

600

mm and steps from

0.075

to

8

mm. The main dimensions of metric threads are in accordance with GOST 24705. Thread tolerances are in accordance with GOST 9000 and GOST 16093.

where, d, D

— outer diameters of the external thread (bolt) and internal thread (nut), respectively;

d2, D2

are the average diameters of the bolt and nut, respectively;

d1, D1

are the internal diameters of the bolt and nut, respectively;

d3

is the internal diameter of the bolt along the bottom of the cavity (for calculating stresses);

p

—thread pitch;

H

is the height of the original triangle.

The nominal values of thread diameters must correspond to those indicated in the drawing and table. The main threads with diameters from 2

up to

300

mm of the 1st and 2nd (in brackets) rows.

The full table is below. dimensions, mm

| Thread pitch P | Thread diameter | |||

| outer | average | interior | internal along the bottom of the depression | |

| S h u p p n y m s t e p e d | ||||

| 0,40 | 2,0 | 1,740 | 1,567 | 1,509 |

| 0,45 | (2,2) | 1,908 | 1,713 | 1,648 |

| 0,45 | 2,5 | 2,208 | 2,013 | 1,948 |

| 0,50 | 3,0 | 2,675 | 2,459 | 2,387 |

| 0,60 | (3,5) | 3,110 | 2,850 | 2,764 |

| 0,70 | 4 | 3,546 | 3,242 | 3,141 |

| 0,75 | (4,5) | 4,013 | 3,688 | 3,580 |

| 0,80 | 5 | 4,480 | 4,134 | 4,019 |

| 1 | 6 | 5,350 | 4,918 | 4,773 |

| 1,25 | 8 | 7,188 | 6,647 | 6,466 |

| 1,50 | 10 | 9,026 | 8,376 | 8,160 |

| 1,75 | 12 | 10,863 | 10,106 | 9,853 |

| 2 | (14) | 12,701 | 11,835 | 11,546 |

| 2 | 16 | 14,701 | 13,835 | 13,546 |

| 2,5 | (18) | 16,376 | 15,294 | 14,933 |

| 2,5 | 20 | 18,376 | 17,294 | 16,933 |

| 2,5 | (22) | 20,376 | 19,294 | 18,933 |

| 3 | 24 | 22,051 | 20,752 | 20,319 |

| 3 | (27) | 25,051 | 23,752 | 23,319 |

| 3,5 | 30 | 27,727 | 26,211 | 25,706 |

| 3,5 | (33) | 30,727 | 29,211 | 28,706 |

| 4 | 36 | 33,402 | 31,670 | 31,093 |

| 4 | (39) | 36,402 | 34,670 | 34,093 |

| 4,5 | 42 | 39,077 | 37,129 | 36,479 |

| 4,5 | (45) | 42,077 | 40,129 | 39,479 |

| 5 | 48 | 44,752 | 42,587 | 41,866 |

| 5 | (52) | 48,752 | 46,587 | 45,866 |

| 5,5 | 56 | 52,428 | 50,046 | 49,252 |

| 5,5 | (60) | 56,428 | 54,046 | 53,252 |

| 6 | 64 | 60,103 | 57,505 | 56,639 |

| 6 | (68) | 64,103 | 61,505 | 60,639 |

| Take a bold step | ||||

| 0,25 | 2,0 | 1,838 | 1,729 | 1,693 |

| 2,2 | 2,038 | 1,929 | 1,893 | |

| 0,35 | 2,5 | 2,273 | 2,121 | 2,071 |

| 3 | 2,773 | 2,621 | 2,571 | |

| (3,5) | 3,273 | 3,121 | 3,071 | |

| 0,5 | 4 | 3,675 | 3,459 | 3,387 |

| (4,5) | 4,175 | 3,959 | 3,887 | |

| 5 | 4,675 | 4,459 | 4,387 | |

| 6 | 5,675 | 5,459 | 5,387 | |

| 8 | 7,675 | 7,459 | 7,387 | |

| 10 | 9,675 | 9,459 | 9,387 | |

| 12 | 11,675 | 11,459 | 11,387 | |

| (14) | 13,675 | 13,459 | 13,387 | |

| 16 | 15,675 | 15,459 | 15,387 | |

| (18) | 17,675 | 17,459 | 17,387 | |

| 20 | 19,675 | 19,459 | 19,387 | |

| (22) | 21,675 | 21,459 | 21,387 | |

| 0,75 | 6 | 5,513 | 5,188 | 5,080 |

| 8 | 7,513 | 7,188 | 7,080 | |

| 10 | 9,513 | 9,188 | 9,080 | |

| 12 | 11,513 | 11,188 | 11,080 | |

| (14) | 13,513 | 13,188 | 13,080 | |

| 16 | 15,513 | 15,188 | 15,080 | |

| (18) | 17,513 | 17,188 | 17,080 | |

| 20 | 19,513 | 19,188 | 19,080 | |

| (22) | 21,513 | 21,188 | 21,080 | |

| 24 | 23,513 | 23,188 | 23,080 | |

| (27) | 26,513 | 26,188 | 26,080 | |

| 30 | 29,513 | 29,188 | 29,080 | |

| (33) | 32,513 | 32,188 | 32,080 | |

| 1,0 | 8 | 7,350 | 6,917 | 6,773 |

| 10 | 9,350 | 8,917 | 8,773 | |

| 12 | 11,350 | 10,917 | 10,773 | |

| (14) | 13,350 | 12,917 | 12,773 | |

| 16 | 15,350 | 14,917 | 14,773 | |

| (18) | 17,350 | 16,917 | 16,773 | |

| 20 | 19,350 | 18,917 | 18,773 | |

| (22) | 21,350 | 20,917 | 20,773 | |

| 24 | 23,350 | 22,917 | 22,773 | |

| (27) | 26,350 | 25,917 | 25,773 | |

| 30 | 29,350 | 28,917 | 28,773 | |

| 36 | 35,350 | 34,917 | 34,773 | |

| (39) | 38,350 | 37,917 | 37,773 | |

| 42 | 41,350 | 40,917 | 40,773 | |

| (45) | 44,350 | 43,917 | 43,773 | |

| 48 | 47,350 | 46,917 | 46,773 | |

| (52) | 51,350 | 50,917 | 50,773 | |

| 56 | 55,350 | 54,917 | 54,773 | |

| (60) | 59,350 | 58,917 | 58,773 | |

| 64 | 63,350 | 62,917 | 62,773 | |

| (68) | 67,350 | 66,917 | 66,773 | |

| 72 | 71,350 | 70,917 | 70,773 | |

| (76) | 75,350 | 74,917 | 74,773 | |

| 80 | 79,350 | 78,917 | 78,773 | |

| 1,25 | 10 | 9,188 | 8,647 | 8,466 |

| 12 | 11,188 | 10,647 | 10,467 | |

| (14) | 13,188 | 12,647 | 12,466 | |

| 1,5 | 12 | 11,026 | 10,376 | 10,160 |

| (14) | 13,026 | 12,376 | 12,160 | |

| 16 | 15,026 | 14,376 | 14,160 | |

| (18) | 17,026 | 16,376 | 16,160 | |

| 20 | 19,026 | 18,376 | 18,160 | |

| (22) | 21,026 | 20,376 | 20,160 | |

| 24 | 23,026 | 22,376 | 22,160 | |

| (27) | 26,026 | 25,376 | 25,160 | |

| 30 | 29,026 | 28,376 | 28,160 | |

| (33) | 32,026 | 31,376 | 31,160 | |

| 36 | 35,026 | 34,376 | 34,160 | |

| (39) | 38,026 | 37,376 | 37,160 | |

| 42 | 41,026 | 40,376 | 40,160 | |

| (45) | 44,026 | 43,376 | 43,160 | |

| 48 | 47,026 | 46,376 | 46,160 | |

| (52) | 51,026 | 50,376 | 50,160 | |

| 56 | 55,026 | 54,376 | 54,160 | |

| (60) | 59,026 | 58,376 | 58,160 | |

| 64 | 63,026 | 62,376 | 62,160 | |

| (68) | 67,026 | 66,376 | 66,160 | |

| 72 | 71,026 | 70,376 | 70,160 | |

| (76) | 75,026 | 74,376 | 74,160 | |

| 80 | 79,026 | 78,376 | 78,160 | |

| (85) | 84,026 | 83,376 | 83,160 | |

| 90 | 89,026 | 88,376 | 88,160 | |

| (95) | 94,026 | 93,376 | 93,160 | |

| 100 | 99,026 | 98,376 | 98,160 | |

| 110 | 109,026 | 108,376 | 108,160 | |

| (115) | 114,026 | 113,376 | 113,160 | |

| (120) | 119,026 | 118,376 | 118,160 | |

| 125 | 124,026 | 123,376 | 123,160 | |

| (130) | 129,026 | 128,376 | 128,160 | |

| 140 | 139,026 | 138,376 | 138,160 | |

| (150) | 149,026 | 148,376 | 148,160 | |

| 2,0 | (18) | 16,701 | 15,835 | 15,546 |

| 20 | 18,701 | 17,835 | 17,546 | |

| (22) | 20,701 | 19,835 | 19,546 | |

| 24 | 22,701 | 21,835 | 21,546 | |

| (27) | 25,701 | 24,835 | 24,546 | |

| 30 | 28,701 | 27,835 | 27,546 | |

| (33) | 31,701 | 30,835 | 30,546 | |

| 36 | 33,701 | 32,835 | 32,546 | |

| (39) | 37,701 | 36,835 | 36,546 | |

| 42 | 40,701 | 39,835 | 39,546 | |

| (45) | 43,701 | 42,835 | 42,546 | |

| 48 | 46,701 | 45,835 | 45,546 | |

| (52) | 50,701 | 49,835 | 49,546 | |

| 56 | 54,701 | 53,835 | 53,546 | |

| (60) | 58,701 | 57,835 | 57,546 | |

| 64 | 62,701 | 61,835 | 61,546 | |

| (68) | 66,701 | 65,835 | 65,546 | |

| 72 | 70,701 | 69,835 | 69,546 | |

| (76) | 74,701 | 73,835 | 73,546 | |

| 80 | 78,701 | 77,835 | 77,546 | |

| (85) | 83,701 | 82,835 | 82,546 | |

| 90 | 88,701 | 87,835 | 87,546 | |

| (95) | 93,701 | 92,835 | 92,546 | |

| 100 | 98,701 | 97,835 | 97,546 | |

| (105) | 103,701 | 102,835 | 102,546 | |

| 110 | 108,701 | 107,835 | 107,546 | |

| (115) | 113,701 | 112,835 | 112,546 | |

| (120) | 118,701 | 117,835 | 117,546 | |

| 125 | 123,701 | 122,835 | 122,546 | |

| (130) | 128,701 | 127,835 | 127,546 | |

| 140 | 138,701 | 137,835 | 137,546 | |

| (150) | 148,701 | 147,835 | 147,546 | |

| 160 | 158,701 | 157,835 | 157,546 | |

| (170) | 168,701 | 167,835 | 167,546 | |

| 180 | 178,701 | 177,835 | 177,546 | |

| (190) | 188,701 | 187,835 | 187,546 | |

| 200 | 198,701 | 197,835 | 197,546 | |

| 3,0 | 30 | 28,051 | 26,752 | 26,319 |

| (33) | 31,051 | 29,752 | 29,319 | |

| 36 | 34,051 | 32,752 | 32,319 | |

| (39) | 37,051 | 35,752 | 35,319 | |

| 42 | 40,051 | 38,752 | 38,319 | |

| (45) | 43,051 | 41,752 | 41,319 | |

| 48 | 46,051 | 44,752 | 44,319 | |

| (52) | 50,051 | 48,752 | 48,319 | |

| 56 | 54,051 | 52,752 | 52,319 | |

| (60) | 58,051 | 56,752 | 56,319 | |

| 64 | 62,051 | 60,752 | 60,319 | |

| (68) | 66,051 | 64,752 | 64,319 | |

| 72 | 70,051 | 68,752 | 68,319 | |

| (76) | 74,051 | 72,752 | 72,319 | |

| 80 | 78,051 | 76,752 | 76,319 | |

| (85) | 83,051 | 81,752 | 81,319 | |

| 90 | 88,051 | 86,752 | 86,319 | |

| (95) | 93,051 | 91,752 | 91,319 | |

| 100 | 98,051 | 96,752 | 96,319 | |

| (105) | 103,051 | 101,752 | 101,319 | |

| 110 | 108,051 | 106,752 | 106,319 | |

| (115) | 113,051 | 111,752 | 111,319 | |

| (120) | 118,051 | 116,752 | 116,319 | |

| 125 | 123,051 | 121,752 | 121,319 | |

| (130) | 128,051 | 126,752 | 126,319 | |

| 140 | 138,051 | 136,752 | 136,319 | |

| (150) | 148,051 | 146,752 | 146,319 | |

| 160 | 158,051 | 156,752 | 156,319 | |

| (170) | 168,051 | 166,752 | 166,319 | |

| 180 | 178,051 | 176,752 | 176,319 | |

| (190) | 188,051 | 186,752 | 186,319 | |

| 200 | 198,051 | 196,752 | 196,319 | |

| (210) | 208,051 | 206,752 | 206,319 | |

| 220 | 218,051 | 216,752 | 216,319 | |

| (240) | 238,051 | 236,752 | 236,319 | |

| 250 | 248,051 | 246,752 | 246,319 | |

| (260) | 258,051 | 256,752 | 256,319 | |

| 280 | 278,051 | 276,752 | 276,319 | |

| (300) | 298,051 | 296,752 | 296,319 | |

| 4,0 | 42 | 39,402 | 37,670 | 37,093 |

| (45) | 42,402 | 40,670 | 40,093 | |

| 48 | 45,402 | 43,670 | 43,093 | |

| (52) | 49,402 | 47,670 | 47,093 | |

| 56 | 53,402 | 51,670 | 51,093 | |

| 60 | 57,402 | 55,670 | 55,093 | |

| 64 | 61,402 | 59,67 | 59,093 | |

| 72 | 69,402 | 67,670 | 67,093 | |

| (76) | 73,402 | 71,670 | 71,093 | |

| 80 | 77,402 | 78,670 | 75,093 | |

| (85) | 82,402 | 80,670 | 80,093 | |

| 90 | 87,402 | 85,670 | 85,093 | |

| (95) | 92,402 | 90,670 | 90,093 | |

| 100 | 97,402 | 95,670 | 95,093 | |

| (105) | 102,402 | 100,670 | 100,093 | |

| 110 | 107,402 | 105,670 | 105,093 | |

| (115) | 112,402 | 110,670 | 110,093 | |

| (120) | 117,402 | 115,670 | 115,093 | |

| 125 | 122,402 | 120,670 | 120,093 | |

| (130) | 127,402 | 125,670 | 125,093 | |

| 140 | 137,402 | 135,670 | 135,093 | |

| (150) | 147,402 | 145,670 | 145,093 | |

| 160 | 157,402 | 155,670 | 155,093 | |

| (170) | 167,402 | 165,670 | 165,093 | |

| 180 | 177,402 | 175,670 | 175,093 | |

| (190) | 187,402 | 185,670 | 185,093 | |

| 200 | 197,402 | 195,670 | 195,093 | |

| (210) | 207,402 | 205,670 | 205,093 | |

| 220 | 217,402 | 215,670 | 215,093 | |

| (240) | 237,402 | 235,670 | 235,093 | |

| (260) | 257,402 | 255,670 | 255,093 | |

| 280 | 277,402 | 275,670 | 275,093 | |

| 300 | 297,402 | 295,670 | 295,093 | |

FULL TABLE OF METRIC THREADS according to GOST 24705-2004

| Nominal thread diameter d, mm | Pitch P, mm | Thread diameters, mm | |||

| d = D | d2 = D2 | d1 = D1 | d3 | ||

| 0,25 | 0,075 | 0,250 | 0,201 | 0,169 | 0,158 |

| 0,3 | 0,08 | 0,30 | 0,248 | 0,213 | 0,202 |

| 0,35 | 0,09 | 0,350 | 0,292 | 0,253 | 0,240 |

| 0,4 | 0,1 | 0,40 | 0,335 | 0,292 | 0,277 |

| 0,45 | 0,450 | 0,385 | 0,342 | 0,327 | |

| 0,5 | 0,125 | 0,50 | 0,419 | 0,365 | 0,347 |

| 0,55 | 0,550 | 0,469 | 0,415 | 0,397 | |

| 0,6 | 0,15 | 0,60 | 0,503 | 0,438 | 0,416 |

| 0,7 | 0,175 | 0,70 | 0,586 | 0,511 | 0,485 |

| 0,8 | 0,2 | 0,80 | 0,670 | 0,583 | 0,555 |

| 0,9 | 0,225 | 0,90 | 0,754 | 0,656 | 0,624 |

| 1 | 0,25 | 1,0 | 0,838 | 0,729 | 0,693 |

| 0,2 | 1,0 | 0,870 | 0,783 | 0,755 | |

| 1,1 | 0,25 | 1,10 | 0,938 | 0,829 | 0,793 |

| 0,2 | 1,10 | 0,970 | 0,883 | 0,855 | |

| 1,2 | 0,25 | 1,20 | 1,038 | 0,929 | 0,893 |

| 0,2 | 1,20 | 1,070 | 0,983 | 0,955 | |

| 1,4 | 0,3 | 1,40 | 1,205 | 1,075 | 1,032 |

| 0,2 | 1,40 | 1,270 | 1,183 | 1,155 | |

| 1,6 | 0,35 | 1,60 | 1,373 | 1,221 | 1,171 |

| 0,2 | 1,60 | 1,470 | 1,383 | 1,355 | |

| 1,8 | 0,35 | 1,80 | 1,573 | 1,421 | 1,371 |

| 0,2 | 1,80 | 1,670 | 1,583 | 1,555 | |

| 2 | 0,4 | 2,0 | 1,740 | 1,567 | 1,509 |

| 0,25 | 2,0 | 1,838 | 1,729 | 1,693 | |

| 2,2 | 0,45 | 2,20 | 1,908 | 1,713 | 1,648 |

| 0,25 | 2,20 | 2,038 | 1,929 | 1,893 | |

| 2,5 | 0,45 | 2,50 | 2,208 | 2,013 | 1,948 |

| 0,35 | 2,50 | 2,273 | 2,121 | 2,071 | |

| 3 | 0,5 | 3,0 | 2,675 | 2,459 | 2,387 |

| 0,35 | 3,0 | 2,773 | 2,621 | 2,571 | |

| 3,5 | 0,6 | 3,50 | 3,110 | 2,850 | 2,764 |

| 0,35 | 3,50 | 3,273 | 3,121 | 3,071 | |

| 4 | 0,7 | 4,0 | 3,545 | 3,242 | 3,141 |

| 0,5 | 4,0 | 3,675 | 3,459 | 3,387 | |

| 4,5 | 0,75 | 4,50 | 4,013 | 3,688 | 3,580 |

| 0,5 | 4,50 | 4,175 | 3,959 | 3,887 | |

| 5 | 0,8 | 5,0 | 4,480 | 4,134 | 4,019 |

| 0,5 | 5,0 | 4,675 | 4,459 | 4,387 | |

| 5,5 | 0,5 | 5,50 | 5,175 | 4,959 | 4,887 |

| 6 | 1 | 6,0 | 5,350 | 4,917 | 4,773 |

| 0,75 | 6,0 | 5,513 | 5,188 | 5,080 | |

| 0,5 | 6,0 | 5,675 | 5,459 | 5,387 | |

| 7 | 1 | 7,0 | 6,350 | 5,917 | 5,773 |

| 0,75 | 7,0 | 6,513 | 6,188 | 6,080 | |

| 0,5 | 7,0 | 6,675 | 6,459 | 6,387 | |

| 8 | 1,25 | 8,0 | 7,188 | 6,647 | 6,466 |

| 1 | 8,0 | 7,350 | 6,917 | 6,773 | |

| 0,75 | 8,0 | 7,513 | 7,188 | 7,080 | |

| 0,5 | 8,0 | 7,675 | 7,459 | 7,387 | |

| 9 | 1,25 | 9,0 | 8,188 | 7,647 | 7,466 |

| 1 | 9,0 | 8,350 | 7,917 | 7,773 | |

| 0,75 | 9,0 | 8,513 | 8,188 | 8,080 | |

| 0,5 | 9,0 | 8,675 | 8,459 | 8,387 | |

| 10 | 1,5 | 10,0 | 9,026 | 8,376 | 8,160 |

| 1,25 | 10,0 | 9,188 | 8,647 | 8,466 | |

| 1 | 10,0 | 9,350 | 8,917 | 8,773 | |

| 0,75 | 10,0 | 9,513 | 9,188 | 9,080 | |

| 0,5 | 10,0 | 9,675 | 9,459 | 9,387 | |

| 11 | 1,5 | 11,0 | 10,026 | 9,376 | 9,160 |

| 1 | 11,0 | 10,350 | 9,917 | 9,773 | |

| 0,75 | 11,0 | 10,513 | 10,188 | 10,080 | |

| 0,5 | 11,0 | 10,675 | 10,459 | 10,387 | |

| 12 | 1,75 | 12,0 | 10,863 | 10,106 | 9,853 |

| 1,5 | 12,0 | 11,026 | 10,376 | 10,160 | |

| 1,25 | 12,0 | 11,188 | 10,647 | 10,466 | |

| 1 | 12,0 | 11,350 | 10,917 | 10,773 | |

| 0,75 | 12,0 | 11,513 | 11,188 | 11,080 | |

| 0,5 | 12,0 | 11,675 | 11,459 | 11,387 | |

| 14 | 2 | 14,0 | 12,701 | 11,835 | 11,546 |

| 1,5 | 14,0 | 13,026 | 12,376 | 12,160 | |

| 1,25 | 14,0 | 13,188 | 12,647 | 12,466 | |

| 1 | 14,0 | 13,350 | 12,917 | 12,773 | |

| 0,75 | 14,0 | 13,513 | 13,188 | 13,080 | |

| 0,5 | 14,0 | 13,675 | 13,459 | 13,387 | |

| 15 | 1,5 | 15,0 | 14,026 | 13,376 | 13,160 |

| 1 | 15,0 | 14,350 | 13,917 | 13,773 | |

| 16 | 2 | 16,0 | 14,701 | 13,835 | 13,546 |

| 1,5 | 16,0 | 15,026 | 14,376 | 14,160 | |

| 1 | 16,0 | 15,350 | 14,917 | 14,773 | |

| 0,75 | 16,0 | 15,513 | 15,188 | 15,080 | |

| 0,5 | 16,0 | 15,675 | 15,459 | 15,387 | |

| 17 | 1,5 | 17,0 | 16,026 | 15,376 | 15,160 |

| 1 | 17,0 | 16,350 | 15,917 | 15,773 | |

| 18 | 2,5 | 18,0 | 16,376 | 15,294 | 14,933 |

| 2 | 18,0 | 16,701 | 15,835 | 15,546 | |

| 1,5 | 18,0 | 17,026 | 16,376 | 16,160 | |

| 1 | 18,0 | 17,350 | 16,917 | 16,773 | |

| 0,75 | 18,0 | 17,518 | 17,188 | 17,080 | |

| 0,5 | 18,0 | 17,675 | 17,459 | 17,387 | |

| 20 | 2,5 | 20,0 | 18,376 | 17,294 | 16,933 |

| 2 | 20,0 | 18,701 | 17,835 | 17,546 | |

| 1,5 | 20,0 | 19,026 | 18,376 | 18,160 | |

| 1 | 20,0 | 19,350 | 18,917 | 18,773 | |

| 0,75 | 20,0 | 19,513 | 19,188 | 19,080 | |

| 0,5 | 20,0 | 19,675 | 19,459 | 19,387 | |

| 22 | 2,5 | 22,0 | 20,376 | 19,294 | 18,933 |

| 2 | 22,0 | 20,701 | 19,835 | 19,546 | |

| 1,5 | 22,0 | 21,026 | 20,376 | 20,160 | |

| 1 | 22,0 | 21,350 | 20,917 | 20,773 | |

| 0,75 | 22,0 | 21,513 | 21,188 | 21,080 | |

| 0,5 | 22,0 | 21,675 | 21,459 | 21,387 | |

| 24 | 3 | 24,0 | 22,051 | 20,752 | 20,319 |

| 2 | 24,0 | 22,701 | 21,835 | 21,546 | |

| 1,5 | 24,0 | 23,026 | 22,376 | 22,160 | |

| 1 | 24,0 | 23,350 | 22,917 | 22,773 | |

| 0,75 | 24,0 | 23,513 | 23,188 | 23,080 | |

| 25 | 2 | 25,0 | 23,701 | 22,835 | 22,546 |

| 1,5 | 25,0 | 24,026 | 23,376 | 23,160 | |

| 1 | 25,0 | 24,350 | 23,917 | 23,773 | |

| 26 | 1,5 | 26,0 | 25,026 | 24,376 | 24,160 |

| 27 | 3 | 27,0 | 25,051 | 23,752 | 23,319 |

| 2 | 27,0 | 25,701 | 24,835 | 24,546 | |

| 1,5 | 27,0 | 26,026 | 25,376 | 25,160 | |

| 1 | 27,0 | 26,350 | 25,917 | 25,773 | |

| 0,75 | 27,0 | 26,513 | 26,188 | 26,080 | |

| 28 | 2 | 28,0 | 26,701 | 25,835 | 25,546 |

| 1,5 | 28,0 | 27,026 | 26,376 | 26,160 | |

| 1 | 28,0 | 27,350 | 26,917 | 26,773 | |

| 30 | 3,5 | 30,0 | 27,727 | 26,211 | 25,706 |

| 3 | 30,0 | 28,051 | 26,752 | 26,319 | |

| 2 | 30,0 | 28,701 | 27,835 | 27,546 | |

| 1,5 | 30,0 | 29,026 | 28,376 | 28,160 | |