Steel tempering is the final stage of heat treatment and is used to reduce excess hardness, reduce brittleness and eliminate internal stresses of the metal. It is most often applied to carbon steels that have been hardened to martensite, that is, heated slightly above 727 ºC and cooled at a high rate in an aqueous environment.

Typically, steel products are tempered at temperatures that are several times lower than the quenching temperature, while maintaining the martensitic structure, which ensures the hardness of the metal. Cutting tools and other products made from tool steels are mainly subjected to this heat treatment.

However, there are types of tempering with heating close to quenching (on troostite and perlite), after which the metal acquires the required elasticity and its impact strength increases. Alloying additives slow down the process of formation of the required structure, so parts made of alloy steels are tempered at higher temperatures.

Traditional tempering technology involves heating the product to a standard value and cooling it in the open air, although some types of steel products are tempered in oil or molten media. You can release the entire product or part of it. For example, only the butt and handle of knives are tempered, while maintaining the full hardening of the blade.

What it is

Thermal tempering technology is used for hardened parts. The need for it is due to the occurrence of internal stresses in the manufacturing metal during its hardening. For this reason, it becomes brittle and becomes unable to withstand severe external loads.

Elimination of these consequences is carried out by performing the following actions:

- heating products in ovens. Temperature (designation T) can take values from a wide range: + 100 °C≤Т≤ +650 °C;

- holding for the required time interval - from fifteen minutes to several hours;

- slow gradual cooling.

As a result of this sequence of events, excess carbon (element C) will be released, the structure of the alloy will be rebuilt and become more ordered, and the crystalline structure will get rid of defects. The processed materials will acquire plasticity. In addition, their fragility will decrease, and their strength will remain at a sufficient level.

Heating the metal

All steel hardening methods consist of:

Carbon steel products are heated in chamber furnaces. In this case, preheating is not required, since these steel grades are not subject to cracking or warping.

Complex products (for example, a tool with protruding thin edges or sharp transitions) are preheated:

Heating of all parts of the product should proceed evenly. If this cannot be achieved in one step (large forgings), then two holding times are made for through heating.

If only one part is placed in the oven, the heating time is reduced. For example, one 24 mm thick disk cutter heats up within 13 minutes, and ten such products heat up within 18 minutes.

Varieties

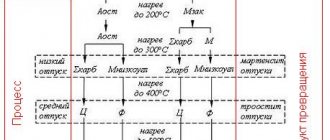

The most important characteristic of the tempering procedure is the temperature at which it is performed. According to this indicator, this heat treatment is divided into three types. Let's look at them in a little more detail.

Low Vacation

Heat treatment of this type involves heating the part to a temperature varying within + 100 °C≤T≤ +250 °C. The duration of the technical process usually fits into a time interval of one to three hours. The exact value of this parameter is determined by the dimensions of the workpiece and its type. During low tempering, the phenomenon of diffusion of microparticles of carbon-containing components is observed, which is not accompanied by recrystallization, as well as polygonization of the molecular lattice. This improves a number of material properties:

- degree of chemical inertness;

- hardness index;

- the level of plasticity increases;

- strength characteristics increase.

Low release is classified as a universal technology. However, in most cases it is used for products for which high-carbon steel and containing alloying additives were used as raw materials (for example, cutting tools in the form of knives, kitchen utensils, etc.).

The main requirement for low tempering is formulated as follows: it is necessary to exclude the possibility of heating the metal above +250 °C. Otherwise, it will fall within the range of the type I fragility island, which can cause the part to become irreversibly unusable.

Average holiday

This heat treatment method is performed by heating the metal and holding it while maintaining the temperature in the range + 300 °C≤T≤ +450 °C, usually for at least 2 and no more than 4 hours. Cooling occurs in open space under natural environmental conditions. At the same time, the above-mentioned processes such as

- restructuring of the metal, accompanied by ordering of its dislocation structure - polygonization;

- formation and increase in size of some crystal grains at the expense of others - recrystallization

do not appear during active diffusion of particles of the element carbon (C).

The main goal of heat treatment of the type under consideration is to give parts the required elasticity, relaxation stability, and toughness without sacrificing high strength properties. Alloys obtained by the medium tempering method are characterized by a troostite structure and are characterized by a hardness determined by the Rockwell method at a level from 45HRC to 50HRC.

This heat treatment method is relevant mainly for structural elements and hardware, in the production of which spring-type steels were used. (eg 65C2BA. 70C3A). Such products include: bent steel strips connected together with brackets - springs; forging single- and multi-strand dies; elastic elements in the form of a spiral - springs; saws designed for working with wood, etc. The following basic requirement is put forward to them: resistance to the effects of variable dynamic loads.

High holiday

Heat treatment of this type involves heating parts to a temperature ranging from + 500 °C≤Т≤ +680 °C. The duration of the high holiday is approximately 2-3 hours. Very complex items can take up to 6 hours to process.

As a result:

- internal stress occurring in the metal is reduced by 95 percent;

- the impact strength indicator increases;

- the level of plasticity of the material increases.

But all this happens against the background of a decrease in the strength characteristics of the alloy. Its structure becomes sorbitol-like. That is, the processed metal in this case is a mixture of cementite and ferrite, which have a granular structure. When heated to a temperature fluctuating around +680 °C, the structure of the alloy will be distinguished by the predominance of granular pearlite.

High tempering heat treatment is used for products that are exposed to increased pulse loads during operation. These are, for example, moving parts connecting the piston to the connecting rod journal of the crankshaft of the power unit - connecting rods; forging hammers of all types, from steam-air, including hydraulic and ending with pneumatic; press.

How does experience affect?

To qualify for leave, an employee must have work experience at a specific enterprise.

Annual basic leave of 28 days is granted after 12 months from the date of commencement of continuous employment in this organization. This period is a working year, and it is individual for each employee. If there were periods during the year that were not included in the length of service, the end of the working year is postponed by the appropriate number of days.

Starting from the second working year, an employee can take another vacation at any time he chooses or in accordance with the vacation schedule approved by the enterprise. If he uses it and is fired before the end of the current work year, compensation for those days will be withheld from him.

As soon as an employee has worked for the organization for six months, he is entitled to use the main leave. By agreement with the management or in accordance with the established rules of the organization, recorded in local regulations, rest can be provided before this period, “in advance”. Moreover, it is fully paid

.

The employer is obliged to provide leave before the expiration of six months upon application:

- employees who have not reached the age of majority;

- women during the period before and after childbirth (and their husbands at their request);

- those who have adopted young children (up to three months);

- part-time workers, if they are granted leave at their main place;

- spouses of military personnel (simultaneously with the spouse's main leave);

- people exposed to radiation during the Chernobyl disaster;

- war veterans;

- honorary donors.

If an employee works under an employment agreement for a period of two months or less, he is also entitled to paid leave and compensation in the amount of two days for each month worked.

Seasonal workers also have the right to rest; it is calculated in the same way - 2 days per month.

Tempering of alloy steels. Peculiarities

This type of steel is produced by introducing certain alloying additives into the iron-carbon alloy, including elements such as tungsten (W), vanadium (V) and chromium (Cr). Due to this, the totality of its physical and chemical characteristics undergoes significant changes. It is the alloying components that, under certain temperature conditions of the heating and cooling processes, become centers of crystallization. Therefore, the choice of heat treatment conditions requires a particularly careful approach.

All the main properties of steels with alloying additives - physical and chemical characteristics, phase characteristics, including equilibrium states, structure - are parameters derived from the heating temperature. This factor causes a certain problem to arise. It is formulated as follows: martensite, due to the presence of the above impurities, decomposes more slowly, in comparison with the tempering process, when they are absent. This problem is solved by setting a higher temperature in the furnace in which the alloy alloy is heat treated.

General description of the process

The main stages of the vacation were:

- heating the alloy to temperatures at which phase transformations begin;

- holding at the required temperature;

- cooling at the set speed.

As a result of this type of technical equipment, the required technical characteristics of products are obtained and internal stresses are minimized. The higher the heat treatment temperature and the lower the cooling rate, the more effectively the residual stresses are eliminated.

The cooling rate depends on the chemical composition of the alloy and the intended result:

- intensive cooling after tempering at +550…+650°C increases the endurance limit of steel due to the preservation of residual compressive stresses in the surface layer;

- metal products of complex configurations are cooled slowly after high-temperature tempering, which avoids warping;

- semi-finished products from alloy steels, which are characterized by temper brittleness, after tempering at +550...+650°C are cooled only at an accelerated pace.

Depending on the heating temperature, there are three types of steel tempering - high, medium and low.

Islands of fragility

The heat treatment in question requires careful adherence to temperature requirements throughout the entire cycle. The reason is the possibility of the appearance of the so-called. tempering fragility.

This phenomenon occurs when the temperature of the workpiece begins to take values out of certain ranges of numerical values. It is these ranges that are called “islands of fragility.” This phenomenon is accompanied by structural changes (can be either reversible or irreversible) in structural alloys and steels with alloying additives, causing a deterioration in their characteristics. This appears in:

- uneven course of the process of diffusion of particles of carbon-containing components;

- violation of the crystalline structure of the metal;

- an increase in the fragility of the alloy to a critical level.

Tempering brittleness is usually divided into two types. Whether this characteristic belongs to one of them determines the temperature range, as well as factors associated with disturbances that have occurred in the structure of the material.

Fragility of the first kind

Such fragility is most often observed when the temperature of the part is within the range of + 250°C≤T≤ +400°C. It appears in almost all carbon structural alloys and is irreversible. If the metal passes into this state, it loses its usability and is usually sent for remelting. It is possible to prevent the appearance of type I fragility. To do this, you need to heat the part so that its temperature is outside the range in which the “island of temper brittleness” is located.

Fragility of the second type (reversible)

Brittleness of the second type appears, as a rule, when the product is heated to a temperature in the range + 500°C≤T≤ +550°C. The reason for its occurrence lies in the excessively slow cooling of the processed part. But type II fragility can be corrected. To do this, additional heat treatment is carried out, including the following steps:

- the product is reheated to at least 500°C;

- the part is placed in an environment that changes its state of aggregation - oil, where it is provided with accelerated cooling.

There is another solution to the problem: elements such as tungsten or molybdenum are added to the alloy. The amount of the first should be somewhere around 1% of the total weight of the alloy, and the second should be no less than 0.3% and no more than 0.4%.

Well, the most reliable way to avoid the need to solve this problem is to heat the product so that its temperature does not reach a value in the range of the “island of tempering brittleness of the second type.”

Duration

Basic leave is calculated in calendar days

. Holidays are not included. The minimum duration is 28 days. The maximum is not limited by law.

Vacation is granted in full. By agreement of the parties, it can be divided into parts, and at least one of them should not be less than 14 days. An employee may be on leave as necessary by the organization, but only with his consent. In this case, the unused days will have to be provided at any convenient time or added to the next 28-day vacation of the next working year.

Features of heat treatment of tool steels

All of the above methods for tempering alloys are suitable for heat treatment of steel products with a carbon element content not exceeding 0.7%. For tool steel (carbon is present in larger quantities), other technologies are used. Let's briefly consider only the main ones.

High-speed tool alloys

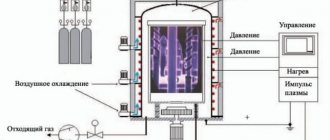

It is not recommended to temper such alloys due to the presence of vanadium, cobalt (Co), molybdenum, and tungsten in their composition. When heated, the physicochemical characteristics of these elements do not undergo changes, since they are very resistant to elevated temperatures. Tempering can be replaced by multi-stage hardening, which involves heating:

- primary – up to temperature T=800°C;

- secondary – up to T=1050°C;

- finishing – up to temperature T=1200°C;

followed by accelerated cooling in an oil working environment.

Conventional tool alloys

Heat treatment of alloys of this type is a two-stage process:

- hardening in molten salts. Carried out at a temperature of + 450°C≤Т≤ +500 °C;

- double tempering for a duration not exceeding one hour, at a temperature of +550°C≤Т≤+600°C.

One important point should be taken into account regarding the type II tempering ability: when tool steels are heated, it is eliminated.

Coolants

The main coolant for steel is water. If you add a small amount of salts or soap to the water, the cooling rate will change. Therefore, under no circumstances should the quenching tank be used for other purposes (for example, washing hands). To achieve the same hardness on the hardened surface, it is necessary to maintain the coolant temperature at 20 - 30 degrees. You should not change the water in the tank frequently. It is absolutely unacceptable to cool the product in running water.

The disadvantage of water hardening is the formation of cracks and warping. Therefore, only products of simple shapes or cemented ones are hardened using this method.

The vapors generated during quenching in a caustic solution are harmful to humans, so the quenching bath must be equipped with exhaust ventilation.

Be careful not to let water get into the oil bath, as this may cause the product to crack. What is interesting: in oil heated to a temperature above 100 degrees, the ingress of water does not lead to the appearance of cracks in the metal.

The disadvantage of an oil bath is:

Do you need to cut metal quickly and efficiently? Use a plasma cutter! How to do it correctly, read this article.

If you are interested in how to turn metal products, read the article at https://elsvarkin.ru/obrabotka-metalla/tokarnaya-obrabotka-metalla-obshhie-svedeniya/ link.

Steel tempering in domestic conditions

Home craftsmen most often heat treat vehicle parts, as well as kitchen utensils - metal mugs, forks and knives. But household metallurgy has many limitations. And the average person may simply not know them. Let's name just a few of the problems that he will most likely have to address.

- In ordinary home furnaces, it is simply impossible to heat the alloy to the required high temperature. Therefore, two types of vacation are available in everyday life - only low-temperature or medium. Although theoretically it is possible to make an attempt aimed at re-equipping or, so to speak, “strengthening” the furnace in order to increase the heating temperature, a person who does not have experience in this matter will not cope with the solution of such a task.

- Carrying out heat treatment involves working in a protective environment in the form of nitrate - ammonium, potassium, etc., alkaline compounds or oils. However, each substance has individual temperature differences. You don't have to look far for examples. Thus, compositions based on nitrate can explode when heated to high (critical) temperatures. This will negatively affect the health of the home handyman.

- Tempering without using a protective environment will negatively affect the quality characteristics of the metal itself. The reason is that without it the material will cool at an accelerated pace. This will lead to the appearance of oxides, plastic (i.e. irreversible) deformation, the production of bends, and an increase in the degree of fragility.

- Also, type I thermal brittleness (+250°C≤Т≤+400°C) should be taken into account. Incorrect temperature conditions will seriously affect the quality of the metal, including its irreversible destruction.

A child’s illness is not a reason to extend a parent’s vacation

If an employee falls ill during his vacation, then it should be extended or the rest days transferred to another time (by agreement with the employee). However, if the illness overtakes the child, then the parent’s leave is not extended, because such a right is not enshrined in the Labor Code of the Russian Federation.

However, due to its financial capabilities, the employer has the right to extend vacation in such a situation, if this is enshrined in a local act.

Editor's note:

Similar conclusions are contained in the Letter of Rostrud dated 06/01/2012 No. PG/4629-6-1.