This publication presents three tool options for punching holes in sheet metal . If you want to find out what exact templates and drawings to make a hole punch for your workshop, then watch the video of the “Garage 91 Gomel” channel at the very end of the article.

Another master, Ilya Konakov, made a video on his channel about how to make a hand-held hole punch that can easily handle sheet metal. The idea arose during the work on replacing the bottom on the nine. Those who do body repair know what it means to drill a lot of holes.

Everything is welded through the holes. In order not to do this with a screwdriver or drill, the master decided to improve the technology. The firmware took approximately 3 hours. Available materials were used. The video shows the entire mechanism and what it is made of. How to work with sheet metal. The force is small, although it is advisable to press the hole punch with both hands. The holes are 7 millimeters.

The tip is sharpened like a stationery hole punch. The master took the roller from the bearing and hammered it inside. Sharpened it with a hollow. More than one hundred holes were made using this mechanism. The result is a convenient tool for car repair and not only for that.

Another model of a homemade hole punch for metal. This is a hand tool for making holes in plastic, iron, paper, textolite. No drill required. The master shows how convenient it is to work with this tool; no irregularities, burrs, etc. are formed.

Convenient to use in the workshop or at home for installing plasterboard panels. You can also punch holes and install rivets in the same way. The dragon's honor that pierces the metal is called a sleeve. It can be of different sizes. In the previous video it was 7 millimeters, here it is 5. The sleeve also comes in smaller sizes, for example 2, 3 millimeters. Some copies have a window for working with non-standard sheets and parts. Another homemade model of a hole punch - a cutter for metal (Vlad ShchCh channel). What are its features? There is a hole, it is planned to make an adjusting plate and tighten it with a screw. Using this part you can change the depth of the hole. The top part is removable. It can be changed. There are several different options you can make. The master explained what parts the rest of the instrument consists of.

The last video shows the dimensions of the hole punch and how it performed in operation.

A punch is a tool designed for making holes in metal, leather, cardboard and other thin sheet materials. It has a pointed edge, thanks to which it cuts into the surface, creating a hole with ideal geometry. The result obtained from the work of such a tool looks better than when using a drill or awl.

Leather punches

The vast majority of punches are used by leatherworkers. These tools are used to perform various types of work in preparing the leather before stitching it. The fact is that such material has great rigidity, so a significant part of the manipulations for its processing can only be carried out using punches.

Such a tool can be used not only when working with leather, but also with tarpaulin, leatherette, denim and other types of dense fabric.

The punches used by leatherworkers are:

- Lowercase.

- Revolving.

- Ring.

- Curly.

- End

Line punch

The high density of leather does not allow it to be sewn using ordinary sewing equipment . The needle is simply not able to pierce such dense material. To solve this problem, a line punch is used. Based on the principle of operation, such devices can be divided into two fundamentally different types. The first one works like a cutter, simply pressing in and piercing the exit hole, pushing the material apart. In fact, the principle of operation is similar to an ordinary awl. The second type of punch cuts a small cavity, completely removing the material. As a result of its application, a neat hole remains.

The holes resulting from the use of such a tool are subsequently stitched with thread. Line punches usually resemble a dinner fork or comb. Their protruding spines are arranged in one line. The same distance is maintained between them. The tool can be equipped with from 1 to 6 needles. mallet is struck at the end of the punch. The sharp spikes cut into the material, piercing or punching a hole in it.

Read also: How to make a left zero in a private house

The shape of the punch pins may vary. They can be round, triangular, diamond-shaped, rectangular or oblique.

Also important is the cross-sectional thickness of the needles themselves and the distance between them. Smaller ones, for example, such as oblique punches used for French seams, are usually chosen for sewing watch straps, as well as wallets. A cutter with a large diameter of tenons and an increased pitch is suitable for coarser products when the seam needs to be made using thick threads. There is no completely universal device, so each master has at least several sets with different combs.

The more spikes on the line cutter, the faster you can prepare a line for sewing. First, the instrument is placed in place and a blow or several are struck. When he punches a hole, the spikes are removed and the comb is moved so that the last needle enters the outermost of the previously made holes. In this way, it is possible to maintain an even pitch for the further seam.

When working with a tool that has many needles, you will have to make stronger blows to pierce the skin, and also make an effort to pull the spines back. A punch with one or two needles is designed for preparing stitches in narrow places where a 6-pin tool cannot fit.

Less accurate in operation are punches made on the pliers principle. In them, the combs are located on two jaws. The peculiarity of using such a tool is the absence of noise, unlike blows with a mallet. The combs are aligned along the line of the future seam and the handles are compressed, piercing the leather or fabric.

Revolver punches

Tools of this type are pliers, in which a revolver with screwed-in punches for piercing is attached to one jaw. Before using the punch, you need to turn the revolver so as to install the desired type of spike opposite the second jaw. After this, material is placed between the jaws. The punch compresses, punching a hole. Typically, 6 spikes with a diameter of 2 to 4.5 mm are attached to the revolver. To prevent the revolver from turning, there is a special lock on the body.

The use of such a tool makes it possible to punch only one hole at a time, so punches of this type are not suitable for forming a seam. The main purpose of such equipment is to create small holes, for example, on a waist belt. Some revolving devices provide the ability to remove the spikes. This allows you to install various accessories, including devices for mounting buttons and eyelets on clothing.

Ring and figured punches

Tools of this type allow you to punch holes while removing part of the material that falls into their internal cavity. Such equipment makes it possible to prepare larger slots. Typically, a ring or shaped punch is a tube, one end of which is pointed. The principle of operation of such equipment is to apply the pointed part to the material and strike the end of the tool.

The range of shapes and sizes of punches of this type is very extensive. In addition to the circle, such tools can repeat the outlines of a star, eye, oval, rhombus, butterfly, and so on. Round punches of this type are usually sold in sets of 15 pieces. The equipment is represented by tubes with a diameter from 2 to 22 mm. Shaped devices are usually sold separately.

End punches

There are also tools designed for trimming leather. In particular, belt end punches are produced in a fairly wide range. They are a pointed steel plate bent along a certain contour. It is used for cutting leather strips in the manufacture of waist belts. A similar tool also exists in other forms.

Punchers for wads

A tool for cutting out wads used for loading cartridges is offered separately for sale. Externally, it almost completely corresponds to ring punches for leather. Such a device has a diameter corresponding to the caliber of cartridges for which wads need to be prepared. The main difference between a hunting punch is that its main purpose is not to make a hole, but to cut out circles of material. Its design provides a technological hole on the side of the tube, which allows you to remove wads falling into it. Such a tool rarely needs sharpening, since it works with relatively softer materials such as cardboard and felt.

Metal punches

Equipment designed for working with sheet metal is represented by almost as wide a range as for leather. In addition to hand tools, this group also includes mechanized devices. In general, all metal punches can be divided into three types:

Read also: Wood for turning works

Pneumatic

Such equipment requires connection to a compressor . It is used not only for working with thin sheet metal, but also metal tiles, metal profiles and other sheet metal. The capabilities of such a tool are very limited, but with its use it is possible to maintain a fairly high level of labor productivity.

Hydraulic

A hydraulic punch is more like a machine tool than any other piece of equipment. It can prepare holes on thick metal up to a cross-section of several millimeters. The resulting hole looks just perfect compared to the result that can be obtained from drilling. Such machines provide the ability to install various punches. Thus, the equipment makes it possible to change the equipment to create holes of the required parameters.

Manual punches

Tools of this class are very similar to equipment used in leather processing, although they have certain differences. First of all, they are made from very hard tool steel. The body of the tube of such a tool is much thicker, so it is less prone to deformation under strong resistance from the material into which it is being cut. Such punches can be either a completely manual tool or a slightly mechanized one mounted on pliers.

The vast majority of hand-held equipment is a steel tube with a sharpened edge on one end. Often the tool is equipped with a plastic or rubber handle. Its presence allows you to reduce the ringing from hitting the tool with a hammer during operation.

A punch designed for working with metal quickly loses its sharpness. In this regard, to maintain their effectiveness, it is necessary to periodically sharpen the instruments. To do this, it is often necessary to process not only the outside of the punch tube, but also polish the internal cavity. The easiest way to do this is to use an engraver . Small polishing attachments, as well as abrasive equipment, make it possible to speed up the process many times over, compared to using ordinary small files .

A metal punch is an indispensable tool in metalworking. With its help, you can make a hole of an ideal shape without deforming the edges of the metal and changing properties caused by temperature effects on the surface. In addition to metal products, the hole punch will do an excellent job with other materials: plywood, plastic or leather.

DIY metal hole puncher

Hello to all DIY lovers.

In this article I will tell you how to make a metal hole punch with your own hands, which will be useful in creating holes in sheet metal, as well as other materials. The assembly of this homemade product does not require any hard-to-find parts; car parts are sufficient.

Before you start reading the article, I suggest watching a video that shows in detail the assembly process and testing of a homemade tool.

In order to make a hole punch for metal with your own hands, you will need:

* Automotive tie rod * Valve * Cuttings from turning cutters * Disc cutter * Metal lathe * Welding machine * Welding mask, gauntlets * Hammer * Metal plate 2 mm thick * Two M6 bolts * Spring, washer * Gloves, safety glasses, headphones * Angle grinder, cutting disc

Step one.

We install the disk cutter into the three-jaw chuck of a metal lathe using a special mandrel; if you have a milling machine, you can make a groove on it.

You also need to cut a 2 mm thick plate from sheet metal, and then drill two holes in them with a 6 mm drill.

Step five.

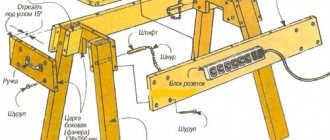

It's time for welding work. We weld two cuts of the cutter to the steering rod with a small gap relative to each other, and one should be about 15 mm longer than the other.

When working with a welding machine, be careful and use a welding helmet and gloves.

This hole punch is useful when working with sheet materials in which you need to quickly and evenly make holes of the same diameter. In this case, the diameter of the holes made using a homemade hole punch is 6 mm; if necessary, this parameter can be changed by making a rod of the required diameter.

That's all for me, thank you all for your attention and creative success.

Areas of application

Metal bending devices are used in various industries. They are used to create folds from roofing iron, make rectangular air ducts from tin or metal sheets, prepare the edges of products for welding, and parts of geometric shapes. Manual edge benders are actively used for construction and repair work. They are in demand during car repairs.

Among the advantages of this technology, in addition to the small thickness of the resulting edges and the low cost of rolled metal, one should add high resistance to wear.

Manual Hole Punch for Sheet Metal

This publication presents three tool options for punching holes in sheet metal . If you want to find out what exact templates and drawings to make a hole punch for your workshop, then watch the video of the “Garage 91 Gomel” channel at the very end of the article.

Another master, Ilya Konakov, made a video on his channel about how to make a hand-held hole punch that can easily handle sheet metal. The idea arose during the work on replacing the bottom on the nine. Those who do body repair know what it means to drill a lot of holes.

Everything is welded through the holes. In order not to do this with a screwdriver or drill, the master decided to improve the technology. The firmware took approximately 3 hours. Available materials were used. The video shows the entire mechanism and what it is made of. How to work with sheet metal. The force is small, although it is advisable to press the hole punch with both hands. The holes are 7 millimeters.

Pneumatic edge bender

Particularly popular among craftsmen are edge benders with pneumatic drive, which work as a “rotary beam”. The pneumatic drive contributes to significant pressure (up to 6.2 bar) on the workpiece. But such equipment can be used when working with sheet metal no thicker than 1.2 mm. In this case, the edge width will be no more than 12 mm.

If you want to make a pneumatic machine with your own hands, you must take into account that its operation requires an air flow of at least 113 l/min.

Pneumatic punch

This is a universal tool model. On one side, the structure is equipped with a mechanism for punching holes, on the other, with jaws for forming an edge.

Manual hole punch for metal: do it yourself and save money

All those who are involved in metalworking work with sheet metal know how important it is to competently and accurately make holes in sheet metal. The quality of the final work directly depends on how accurately these holes are made. Of course, nowadays there are a lot of different devices capable of making high-quality holes in fairly thick metal, but they are all expensive. It’s obvious that we want to save on such a purchase, but is this possible?

This article will talk about how to make a high-quality and effective hole punch with your own hands . Let's get started!

All the necessary items for this project are shown in the photo below. As you can see, we need:

- Two metal parts fastened together using fasteners

- Spring

- Sharp tip

Ordinary metal rods or handles from metal scissors can also act as metal handles. The main thing is that our homemade product creates enough leverage to pierce a sheet of metal.

In order for our tool to acquire the desired functionality, it is necessary to equip it with a special durable tip . The easiest way to make a tip for our device is to grind it out of a metal drill. Such drills are usually made of very durable and high-quality steel with good technical and operational properties. Our homemade product needs similar characteristics if we plan to use it often.

Below is an example of our homemade product in action. For additional comfort, you can equip the device with a return mechanism (a regular spring). This is necessary so that you do not have to return the tool to its original position each time.

Main varieties

Edge bending equipment is available in the form of mobile and stationary models. The designs of the machines are massive and practically cannot be disassembled.

They are mounted directly at the place of use, and are moved only with the help of technical means.

A special place in the product line belongs to segmented manual devices intended for the manufacture of cases, boxes, i.e. products “closed” on all sides.” Due to the different configurations, the segments can be installed arbitrarily. Such equipment allows you to obtain any bending length that does not exceed the working length of the machine.

Tool models differ from each other not only in power, efficiency and thickness of the materials processed, but also in the type of metal.

Portable models of edge benders with gradual shaping consist of:

Roller-type hand-held products have the simplest design. The whole process is carried out by a handle, and the main task of deforming the metal is performed by rollers. The bending width is regulated by a special limiter installed on the tool guides.

In a roller edge bender, friction during sliding of the jaws replaces rolling friction during rotation of the rollers. In this case, the forming force is significantly reduced, but the design of the tool is less universal, because it is impossible to change the edge formation parameters due to one pair of rollers. In addition, edge benders with rollers do not make it possible to carry out beading of small radii inside the product.

A significant disadvantage of portable models of hand tools is their lack of accuracy. As the device moves along the line of the future edge, the error gradually increases, which can reach more than a millimeter. This is unacceptable for work such as auto body repair, so the quality of the edges depends on the experience of the specialist. Because of these technical characteristics, it is advisable to use a roller edge bender only for solving simple problems.

A machine with a hydraulic drive is more functional. Thanks to its high power, it copes well with workpieces made of metal sheets, even of considerable thickness.

How to make a paper hole punch with your own hands

To make it easier to pierce the sheet, it is better to preheat the awl on a gas burner. You can also use a regular lighter.

In this case, it is important to carefully monitor how hot the soldering iron is; if you are careless, you can make a large hole and get burned.

A hole punch is a mechanical device that is designed to quickly punch holes in paper. There are tools that can be used to work with denser materials. Manufacturers offer hole punchers that can make one or four holes at a time.

In some cases, you don’t have the right tool at hand and you should know what you can use to replace the hole punch.

To make neat holes in the paper or card through which the sheet will later be fixed, you can use an awl. Such tools can be of different diameters; you can experiment if you don’t have a hole punch at hand.

An awl can also be used to make holes in thin plastic. It is better to warm up the rod first, this will make the work much easier. During the process, do not forget about safety rules so as not to get injured.

Alternative options

There are also more labor-intensive processes that few people want to work with.

- Beautiful holes in a homemade postcard can be made with a brass tube, well sharpened, on one side. To make everything look original, you should choose a tube with a square cross-section. In this case, you need to place a soft board under the postcard, and gently tap the tube with a hammer until a hole is created.

- Instead of a hole punch, holes can be made with a scalpel or even a stationery knife. The work is quite painstaking, but the result will be the same as originally wanted. You can get a shaped hole by cutting it out with 2 screwdrivers.

At home, you can easily find something to replace a hole punch with. It all depends on the availability of free time and the tools that are at hand.

Hello to all DIY lovers. In this article I will tell you how to make a metal hole punch with your own hands, which will be useful in creating holes in sheet metal, as well as other materials.

The assembly of this homemade product does not require any hard-to-find parts; car parts are sufficient.

Before you start reading the article, I suggest watching a video that shows in detail the assembly process and testing of a homemade tool.

In order to make a hole punch for metal with your own hands, you will need:

* Automotive tie rod * Valve * Cuttings from turning cutters * Disc cutter * Metal lathe * Welding machine * Welding mask, gauntlets * Hammer * Metal plate 2 mm thick * Two M6 bolts * Spring, washer * Gloves, safety glasses, headphones * Angle grinder, cutting disc

Self-production

Following the drawings, you can make your own manual edge bender for processing metal of small thickness during car repair.

It is enough for him:

Preparatory stage

To make it easier to turn the machine while bending a sheet of metal, attach handles on both sides. Using clamps, attach the machine to the table.

For processing, the product is placed between the profile and the corner. The gap for it is formed after unscrewing the corner. The metal sheet is aligned along the edge and bent by turning the device by the handles.

Long straight edge bending machine

Making your own manual edge bender for long straight edges should begin with studying the drawings, as well as selecting the equipment and necessary materials:

4 main details:

First, you need to chamfer the edge of the crimping punch and weld the axles to it. The axes of the bar itself must coincide with the edge of the angle. Samples are made at the ends of the working part of the clamp.

For assembly, the base with the punch is clamped in a vice. In this case, the walls of the first and second shelves must be in the same plane. The gap between the parts will be created by a cardboard spacer. After this, the elements are firmly fixed in a vice.

Brushes with metal bristles are placed on the punch axis. These components are attached to the base using a clamp - a frame with a movable clamp.

Then the brushes are welded to the channel, and holes are drilled in the base into which the clamping bolts are screwed. Screw nuts onto hardware studs. Then they are welded to the channel.

After unscrewing, the bolts are inserted into the clamping holes and the limiting nuts are screwed onto them.

The handle-bracket is welded to the corner. The final stage of assembling the structure is installation in a vice.