To view the video, you need a modern browser that supports HTML5 video.

Milling aluminum parts is a complex process even for an experienced miller, let alone a beginner. Although this metal has been processed using machine tools for two centuries. Why is aluminum milling considered difficult, and is there equipment on which this operation can be performed without errors?

CNC milling of aluminum can be performed on various types of machines: from “semi-household” (four-axis) machines to fully computerized lines capable of fulfilling orders for the aviation, ship, space and military industries. The middle price segment of custom aluminum milling equipment includes machines that are purchased by auto repair services.

Differences in processing aluminum on CNC machines

Custom CNC milling of aluminum is complicated by the fact that the material produces very abundant chips. Waste clogs the cutter itself and accumulates on the cutting tool. Therefore, even when milling an aluminum profile, it is recommended to periodically clean the working areas and tools.

Excessive plasticity of the metal also plays a negative role: for example, when cutting aluminum using CNC, there is a high probability of “overdoing it” and damaging the workpiece. The metal is so delicate that it can be deformed even at the stage of fastening in equipment. CNC processing of aluminum profiles with vacuum fixing capabilities helps solve the problem.

“It was smooth on paper...”

The unconditional attractiveness of tandem technology, VSO + increased cutting depth, contains its own “fly in the ointment”. This is a problem of increasing vibration. This phenomenon is inevitable and highly undesirable. And it will not be possible to fight it using traditional methods. Ensuring high rigidity of a four-link system, including a machine tool, a fixture for fixing, a processing tool, and a workpiece, is no longer enough.

It is necessary to take into account the harmonic law, according to which the cutter and spindle vibrate. Simply put, it is necessary to take into account, in addition to the static, also the dynamic characteristics of the resulting vibrations.

Example. Theoretical calculations, confirmed by practice, show that HCA machining of Al parts is best performed with an end mill having 3 spiral grooves. An increase in their number reduces the efficiency of chip removal due to a reduction in the cross-section of each groove in proportion to the increase in their number.

The reverse option, reducing their number to 2, also does not work. It will lead to an increase in unwanted harmonics. This is due to the following. The frequency with which the cutter oscillates no longer coincides with the number of blows that a pair of cutting edges make on the part (at spindle speeds reaching 20,000 rpm).

Special software products allow you to evaluate the optimal speed of its rotation. They allow you to evaluate the tonality of the device’s own vibrations. To do this, “listening” of the machine-tool system is carried out. The problem is solved by a specially designed microphone connected to the PC.

Milling of aluminum in Moscow and the Moscow region

The specialists of our metalworking shop know how to not only work with the material, but also “feel” it. We offer CNC milling services for aluminum not only in Moscow, but also in the Moscow region. If you have equipment, but do not have professional labor, we can send a specialist in CNC aluminum processing to complete the project. If you require complex operations, such as 3D milling of aluminum, we will deliver it to the workshop on our transport and solve the problem assigned to us.

Features of working with aluminum and advantages of the material

Aluminum is a popular material in the modern world, which has the following advantages:

- is characterized by high strength;

- has a relatively light weight;

- Corrosion resistant;

- has low thermal conductivity;

- is an electrical conductor;

- has a low cost.

CNC milling machine SolidCraft CNC-4060 Light (800W)

- Power supply AC110V/ 220V±10% / 50~60Hz

- Dimensions, mm 890x680x530

- Software NC Studio, Mach3

- Weight, kg 70

- Spindle speed 24,000 rpm

- Max. processing speed, mm/min 15000

- Maximum speed 4000 mm/min

- Spindle power 800 W

- Spindle cooling Air

- Repeatability 0.05 mm

- Working field 400x590x75 mm

- File format HPGL, G-code

- LPT interfaces

- Motor type stepper

- Price 190,564 rub.

Go to product

When processing aluminum blanks, some features should be taken into account:

- Since aluminum is a highly plastic material, its processing requires strict adherence to the accepted sequence. If it is not followed, the material will be deformed and the workpiece will be damaged.

- Incorrect fastening of the material on the working surface of the machine can lead to damage to the workpiece, therefore, when working with aluminum, it is preferable to use a vacuum-type table.

- The material is highly sensitive to vibration.

- When processing parts, special attention should be paid to the process of balancing the collet and the accuracy of selecting the optimal processing mode for a particular case.

Aluminum milling services

Our craftsmen offer CNC milling of aluminum, the price of which can compete for the title of the best for the customer. We produce in batches of any volume housing parts for equipment in demand:

- in the automotive industry,

- aircraft industry,

- spacecraft assembly,

- chemical industry,

- production of electronics and optical equipment.

CNC milling of aluminum to order can also be carried out to solve smaller problems, but in any case it will be of high quality and professional.

Is it possible to assemble it yourself?

To create a working device that will perform the functions of a milling machine, it is enough to have a hand drill with you. It is recommended that you first familiarize yourself with the drawings of the machine you like, since it is important to assemble special parts for folding a simple device for cutting metal or wood at home. It may even require an electric motor.

Even though you are making the machine with your own hands, you are still trying to recreate the device that has been put into mass production, only in a simpler design. The components should be selected of high quality, since the reliability of the entire structure directly depends on this.

Frequently asked questions about milling aluminum

When ordering aluminum milling in Moscow for the first time, our clients usually ask:

- can we complete the task only according to the sample, without a project;

- Is 3D CNC milling of aluminum within our competence?

- how to place an order quickly and without unnecessary red tape;

- what to do if parts are needed, but the customer does not have his own material;

- whether we mill aluminum to order individually or work only with serial projects.

Our managers give the most detailed answers to all these questions. And the overwhelming majority are positive. By offering CNC milling of aluminum in Moscow, we practically never say “no” to our clients. Except for those cases when we find their organizations on the blacklists of other performers.

Design Features

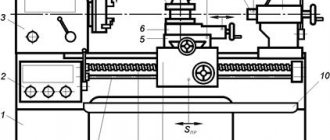

CNC milling machines come in both cantilever and non-cantilever types. The most popular are console ones, since they are more versatile in the way they process materials.

In cantilever-type structures, the spindle is fixed in one position, while the working tool already carries out the entire range of available movements. In the non-cantilever type, the spindle moves in two directions - horizontal and vertical. However, the move feature is also available for the desktop.

Why should you trust us to cut aluminum?

When studying the price list, customers note the main advantage of our aluminum milling cutting - the price. But this is just the tip of the iceberg, under which they are “hidden”, but ready to be revealed to you at any moment:

- high competence of our specialists;

- conducting a turnkey project: from the development of drawings to the delivery of finished aluminum parts to order by CNC machine to your warehouse;

- the ability to fulfill single orders and produce truly gigantic volumes;

- Individual price offers for milling aluminum to order in large wholesale.

Specifications

What should you know about the technical parameters of CNC milling machines? The quality of aluminum processing largely depends on setting the correct parameters for the working field of the machine. The possibility of processing in one pass is configured in advance so that there is no need to change the position of the material, etc.

When choosing milling equipment, pay attention to the quality of the portal material. The portal of the machine is those two vertical columns that hold the bank of devices in a horizontal position.

The spindle shaft must be made of high-quality material, and it has left and right rotation speeds. The versatility of its use depends on the design features of the milling machine itself.

Why is it profitable to order 3D milling services from us?

In recent years, the service of 3D milling of aluminum has become increasingly popular. Do you need an original part that has no analogues in the world? Such orders are special to us. We will not only prepare a detailed sketch for you, but also “sculpt” the future product in three-dimensional format. After final approval, it will be “born” in the metal - in the process of creating and milling aluminum parts.

Where is aluminum milling most in demand?

And yet, we have listed for you works of the “exclusive” class. In daily practice, our workshop carries out more ordinary and serial orders: for example, cutting aluminum with a milling cutter, CNC processing of aluminum profiles with the further production of housings and other components for equipment. Mechanical engineering and instrument making continue to be our main customers.

Does the processing cost depend on the aluminum alloy?

When calculating the cost of milling aluminum, the type of alloy does not significantly affect the price, but it still affects the price. When alloying elements are included, the material may acquire additional properties, including those that complicate its processing.

What is the maximum size of aluminum you mill on your machine?

This question is asked to us by customers who are interested in custom CNC milling of aluminum in large volumes. We cannot give specific figures for only one reason: our workshop has enough workers and equipment to fulfill an order of any size. If necessary, we can talk about processing hundreds of parts per day.

Customer's aluminum

Our company also specializes in custom CNC milling of aluminum from the customer’s material. If you have high-quality aluminum blanks, we will turn them into parts of the required shape and size.

Subtleties of milling modes

The pliability of Al, contrary to popular belief, does not mean that it is simple and easy to process at any selected cutting conditions, including extreme ones.

There is a high probability of situations occurring, even at moderate milling speeds, when metal shavings tightly clog the grooves of the cutter. The tool fails.

In order to eliminate the likelihood of such situations occurring, the following is required:

- perform work with the “correct” cutters, with the required number of teeth and grooves;

- use coolant;

- correctly select the required milling modes.

All this is achieved, first of all, by strictly following the recommendations of manufacturers of machines and cutters.

One more feature. By default, the definition of “aluminum” is collective. It applies to all alloys produced on the basis of this metal. The specifics of their processing can vary quite significantly.

Example. “Soft” AMG and duralumin require their own processing modes. The latter are selected taking into account existing requirements for the finishing quality of the manufactured part and machine parameters.

Where to order and buy?

CNC milling machines can be purchased throughout the country through specialized online stores that provide a fairly wide range of models. It is possible to purchase the device you are interested in directly from the manufacturers:

- Bagus-Technology.

- Vladimir Machine Tool Plant.

- Vitebsk Machine Tool Plant.

- Reckermann and others.

The most popular method of processing aluminum and other metals is milling. CNC machines are most often used for milling, since their use can guarantee high quality material processing. Thus, it is always possible to give the metal a predetermined shape and achieve the desired size in the manufacture of the part.