Physically, an electrical cable is an assembly consisting of one or more conductors with their own insulation, additional shielding, assembly protection, and an overall protective covering. A conductor (core) is a material that can transmit electricity through itself. The most commonly used conductors in cables are copper and aluminum. These metals are characterized by good electrical conductivity and long service life. Another advantage of these conductors is that they are recyclable. That’s why today the question of where to scrap a cable in Moscow is so popular. End-of-life electrical cables and wires can bring material income to those who collect and sell them, as well as reduce the cost of energy consumption in the production of primary conductor metals.

Prices for cable reception

| Cable type | Price per kg, rub. |

| Copper cable 1.5-4 square | 70-150 gross or up to 320 for contents. |

| Copper cable from 6 square | 300-330 copper yield |

| Internet cable (twisted pair, utp), telephone cable in plastic | 80-140 gross or up to 320 for contents. |

| Coaxial cable (corrugated feeder, thin ones are not accepted) | 300-360 copper yield |

| Power cable (contact) | 305-370 for copper yield |

| Copper cable with lead sheath | 120-160 gross |

| Aluminum cable with lead sheath | 45-55 gross |

| Aluminum cable (power) | 60-80 for aluminum yield |

How does the electrical conductivity of different metals differ?

The electronic theory of electrical conductivity of metals was developed in the research of Paul Drude. He was able to discover such a property as resistance, which is observed when electric current passes through a conductor. In the future, this will make it possible to classify different substances according to their conductivity level. From the results obtained, it is easy to understand which metal is suitable for the manufacture of a particular cable. This is a very important point, since incorrectly selected material can cause a fire as a result of overheating from the passage of excess voltage current.

Insulators

Insulators are synthetic materials that are used to insulate electrical wires and perform the following protective functions:

- from electric shock;

- from mechanical damage;

- from moisture;

- against the harmful effects of various substances.

The insulation in the cables has its own marking, thanks to which you can immediately determine what type of material we are dealing with. Most often used for insulation:

- regular tires G;

- silicone gum Gs;

- Halogen-free material N or H;

- cross-linked polyethylene XS;

- organofluorine plastic Zb;

- multivitamin coating Y;

- heat-resistant polyvinyl coating Yc.

Cables subject to high mechanical loads that can destroy the insulation are additionally protected and reinforced with metal armor. Armor can be made of galvanized steel, bronze or aluminum. It is used both for screen (signal insulation of power cables) and for internal or external insulation.

Classical theory of electrical conductivity of metals

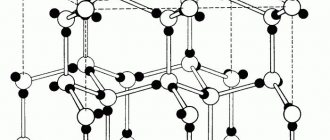

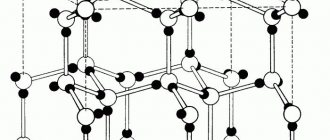

The basic principles of the theory of electrical conductivity of metals contain six points. First: a high level of electrical conductivity is associated with the presence of a large number of free electrons. Second: electric current arises through external influence on the metal, during which electrons move from random motion to ordered motion.

Third: the strength of the current passing through a metal conductor is calculated according to Ohm's law. Fourth: different numbers of elementary particles in the crystal lattice lead to unequal resistance of metals. Fifth: electric current in the circuit arises instantly after the start of exposure to electrons. Sixth: as the internal temperature of the metal increases, the level of its resistance also increases.

The nature of the electrical conductivity of metals is explained by the second point of the provisions. In a quiet state, all free electrons rotate chaotically around the nucleus. At this moment, the metal is not able to independently reproduce electrical charges. But as soon as you connect an external source of influence, the electrons instantly line up in a structured sequence and become carriers of electric current. With increasing temperature, the electrical conductivity of metals decreases.

This is due to the fact that the molecular bonds in the crystal lattice weaken, elementary particles begin to rotate in an even more chaotic order, so the formation of electrons in a chain becomes more complicated. Therefore, it is necessary to take measures to prevent overheating of the conductors, as this negatively affects their performance properties. The mechanism of electrical conductivity of metals cannot be changed due to the current laws of physics. But it is possible to neutralize negative external and internal influences that interfere with the normal course of the process.

Metals with high electrical conductivity

The electrical conductivity of alkali metals is at a high level, since their electrons are weakly attached to the nucleus and easily line up in the desired sequence. But this group is characterized by low melting points and enormous chemical activity, which in most cases does not allow their use for the manufacture of wires.

Metals with high electrical conductivity when opened are very dangerous for humans. Touching a bare wire will result in an electrical burn and a powerful discharge to all internal organs. This often results in instant death. Therefore, special insulating materials are used for the safety of people.

Depending on the application, they can be solid, liquid or gaseous. But all types are designed to do one thing—isolating electrical current within a circuit so that it cannot affect the outside world. The electrical conductivity of metals is used in almost all areas of modern human life, so ensuring safety is a top priority.

Cables with aluminum core

Although copper has high throughput, flexibility, and low creep resistance, aluminum has some important advantages. This metal has 61% of the conductivity of copper, while it is 30% lighter than its competitor - this means that a bare aluminum wire will weigh half as much as copper with a similar electrical resistance. Aluminum is a cheaper conductor than copper, and when using aluminum cables there is no current fluctuation that usually occurs due to conductor resistance. Due to their light weight, aluminum wires are often used when installing high-voltage overhead power lines, as they require fewer support towers.

In addition to the above conductors, other metals such as gold, silver, tungsten and alloys can be used in the production of cables. Each of them has its own advantages and disadvantages and is used depending on the purpose of the cable.

Physical meaning of conductivity

The use of metal conductors has a long history. Scientists and engineers working in fields of science and technology that use electricity have long decided on materials for wires, terminals, contacts, printed circuit boards, etc. A physical quantity called electrical conductivity helps determine the most electrically conductive metal in the world.

The concept of conductivity is the inverse of electrical resistance. The quantification of conductivity is related to the unit of resistance, which is measured in Ohms in the International System of Units (SI). The SI unit of electrical conductivity is siemens. The Russian designation for this unit is Cm, the international designation is S. An electrical conductivity of 1 Cm has a section of an electrical network with a resistance of 1 Ohm.

Conductivity

The measure of a substance's ability to conduct electric current is called electrical conductivity. The most electrically conductive metal has the highest similar indicator. This characteristic can be determined for any substance or environment instrumentally and has a numerical expression. The specific electrical conductivity of a cylindrical conductor of unit length and unit cross-sectional area is related to the resistivity of this conductor.

The system unit for conductivity is siemens per meter – S/m. To find out which metal is the most electrically conductive metal in the world, it is enough to compare their experimentally determined conductivities. You can determine the resistivity using a special device - a microohmmeter. These characteristics are inversely dependent.

Conductivity of metals

The very concept of electric current as a directed flow of charged particles seems more harmonious for substances based on crystal lattices characteristic of metals. Charge carriers when an electric current occurs in metals are free electrons, and not ions, as is the case in liquid media. It has been experimentally established that when a current occurs in metals, there is no transfer of particles of matter between the conductors.

Metallic substances differ from others by having looser bonds at the atomic level. The internal structure of metals is characterized by the presence of a large number of “lonely” electrons. which, at the slightest influence of electromagnetic forces, form a directed flow. Therefore, it is not for nothing that metals are the best conductors of electric current, and it is precisely such molecular interactions that distinguish the most electrically conductive metal. Another specific property of metals—high thermal conductivity—is based on the structural features of the crystal lattice of metals.

The best guide

The best conductor - silver (Table 5.7) has a high degree of migration of atoms over the surface of the substrate and is quickly covered with a film of sulfur compounds.

[1] The best conductors of heat and electric current are silver, copper, gold and aluminum. [2]

The best conductor is silver, followed by copper. [3]

The best conductors are those metals that offer the least resistance to the passage of electric current. [4]

The best conductors of electricity are silver, copper, gold and aluminum. These metals are the most thermally conductive. [5]

The best conductor of electricity is silver, followed by copper, gold, aluminum, and iron. Along with copper, aluminum electrical wires are also produced. [6]

The best conductors of heat are metals, in which I varies from 3 to 418 W/m-deg. The thermal conductivity coefficients of pure metals, with the exception of aluminum, decrease with increasing temperature. [7]

The best conductor of electricity is silver, followed by copper, gold, aluminum, and iron. Along with copper, aluminum electrical wires are also produced. [8]

One of the best conductors of electricity, copper, cannot be converted into a superconducting state. [9]

One of the best conductors of electricity, copper, cannot be converted into a superconducting state. [10]

Silver is the best conductor of electricity and heat. In products it is used in the form of an alloy with other metals, mainly copper, which increases their hardness. The silver content in alloys is indicated by breakdown. [eleven]

Refractory metals are the best conductors of electric current, but their characteristics are much worse than fusible metals, since their melting point is high. For example, the melting point of copper is 1080 C, and that of silver is 960 C. Fuse-links made of copper and silver have a small cross-section and high breaking capacity. [12]

A lower chloride compound of a metal is a better conductor of current than a higher chloride compound of the same metal. [13]

After silver and copper, aluminum metal is the best conductor of electricity and heat. [14]

If the pipe is water (water is usually a better conductor than soil), then this effect will be detected inside the pipe. Welded pipes greatly reduce the hassle of making connections, and welding is now often used for gas lines. [15]

Top best conductors - metals

4 metals that are of practical importance for their use as electrical conductors are distributed in the following order relative to the value of specific conductivity, measured in S/m:

- Silver - 62,500,000.

- Copper – 59,500,000.

- Gold – 45,500,000.

- Aluminum - 38,000,000.

It can be seen that the most electrically conductive metal is silver. But like gold, it is used to organize the electrical network only in special specific cases. The reason is high cost.

But copper and aluminum are the most common option for electrical appliances and cable products due to their low resistance to electric current and affordability. Other metals are rarely used as conductors.

Properties of electrical conductors

Electrical conductors have mobile electrically charged particles, which in metals are called "electrons". The moment an electric charge interacts with a metal, its electrons begin to move and transmit electricity. Metals with high electron mobility are good conductors, while metals with low electron mobility are used as insulators. Various conductors are used in electrical wiring and in the manufacture of electrical cables, but copper and aluminum continue to be the most common. These can be used to produce:

- Single-core cables, which, as the name suggests, have one conductor or strand that carries the electric current, as well as an insulating layer that protects against short circuits and electric shocks.

- Stranded is a combination of several single-core electrical wires that have one insulating and protective layer.

Copper conductors: copper is one of the oldest metals mastered by mankind. Copper was used by Ben Franklin and Michael Faraday in their experiments with electricity, and was first used in inventions such as the telegraph, telephone and electric motor.

With the exception of silver, copper is considered the most common conductive metal and became an international standard, which was adopted in the 13th century. The international standard was created for the purpose of comparing other copper conductors. According to it, annealed pure copper has 101% IACS conductivity.

In addition to excellent conductivity, this metal has characteristics such as tensile strength, thermal conductivity and lack of thermal expansion. Advantages of copper cables:

- Low resistance.

- Excellent ductility – elongation of molar alloy from 20 to 40%.

- High strength at high temperature stresses.

- The flexibility of copper is 1.8 times higher than aluminum - this suggests that cables with a copper core are more resistant to bending.

- Good stability and corrosion resistance.

- High current carrying capacity: Due to its low resistivity, copper cable has a cross-section that is approximately 30% larger than the permissible current carrying capacity of aluminum cable.

- Low voltage loss.

- Low power consumption: Since the resistance of copper cable is lower than aluminum cable, its power loss is also lower.

- Resistance to creep - deformation of a metal under the influence of a changing load. Copper is resistant to expansion and contraction, so its connections do not weaken and therefore do not overheat or spark.

Factors affecting the conductivity of metals

Even the most electrically conductive metal reduces its conductivity if it contains other additives and impurities. Alloys have a different crystal lattice structure than “pure” metals. It is characterized by a violation of symmetry, cracks and other defects. Conductivity also decreases with increasing ambient temperature.

The increased resistance inherent in alloys is used in heating elements. It is no coincidence that nichrome, fechral and other alloys are used to manufacture working elements of electric furnaces and heaters.

The most electrically conductive metal is precious silver, mostly used by jewelers, for minting coins, etc. But its special chemical and physical properties are also widely used in technology and instrument making. For example, in addition to being used in components and assemblies with reduced resistance, silver plating protects contact groups from oxidation. The unique properties of silver and alloys based on it often make its use justified, despite its high cost.