A drill is a common cutting tool that is used not only to produce through holes by drilling, but also to increase the size of existing ones.

Technically, the products are attachments for hand drills, hammer drills and various machines.

Drilling itself involves removing material through the rotational movement of a sharp cutting edge.

The instrument is divided into a huge number of types according to its shape and purpose.

Types of drills depending on the shape of the working body

The types of drills and their purpose are closely related. Based on the type of working body, the following types are distinguished:

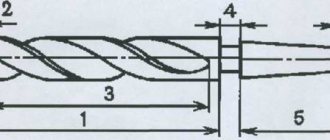

- Screw or spiral. This is one of the most widely used drill shapes. It is used to work with a variety of substances. Universal drills also have a spiral design. Their sizes range from tenths of a millimeter to tens of centimeters.

- Flat or feather. Used for holes in soft substances, wood, foam concrete. The working body is a sharpened blade, in the middle of which there is a sharp protrusion for centering.

- Deep drilling. Used if the hole depth is at least five times greater than the diameter. There are two screw cavities in the body of the drill, through which cutting fluid is supplied to the drilling zone

- Single sided cut. Used for high precision machining. They have a supporting plane and a pair of working edges located on one side of the longitudinal axis.

- Crown. The shape is a hollow cylinder; the cut is made with the lower edge. As a result, a ring is cut through the material, and a core is located inside it - a solid cylindrical piece of material. At the end of the operation, it must be shaken out of the crown.

- Centering. For preliminary drilling, mark the center.

- Stepped. It is a stepped cylindrical pyramid. A progressive type of equipment, used for sheet metal for large diameters. With a gradual increase in diameter, the sheet does not deform.

Feather drill

Core drill

Types of drills are also divided according to the shape of the resulting hole:

- conical types - the diameter gradually decreases with depth;

- stepped types - the diameter decreases in leaps and bounds;

- cylindrical types - the diameter is constant throughout the entire depth.

There are other types. They are used for highly specialized cases.

Types of holes in metal and methods of drilling them

Threaded holes require diameters to be determined with the tolerances established in GOST 16093–2004. For common hardware, the calculation is given in Table 5.

Table 5. The ratio of metric and inch threads, as well as the selection of hole size for drilling

| Metric thread | Inch thread | Pipe thread | |||||||

| Thread diameter | Thread pitch, mm | Threaded hole diameter | Thread diameter | Thread pitch, mm | Threaded hole diameter | Thread diameter | Threaded hole diameter | ||

| min. | Max. | min. | Max. | ||||||

| M1 | 0,25 | 0,75 | 0,8 | 3/16 | 1,058 | 3,6 | 3,7 | 1/8 | 8,8 |

| M1.4 | 0,3 | 1,1 | 1,15 | 1/4 | 1,270 | 5,0 | 5,1 | 1/4 | 11,7 |

| M1.7 | 0,35 | 1,3 | 1,4 | 5/16 | 1,411 | 6,4 | 6,5 | 3/8 | 15,2 |

| M2 | 0,4 | 1,5 | 1,6 | 3/8 | 1,588 | 7,7 | 7,9 | 1/2 | 18,6 |

| M2.6 | 0,4 | 2,1 | 2,2 | 7/16 | 1,814 | 9,1 | 9,25 | 3/4 | 24,3 |

| M3 | 0,5 | 2,4 | 2,5 | 1/2 | 2,117 | 10,25 | 10,5 | 1 | 30,5 |

| M3.5 | 0,6 | 2,8 | 2,9 | 9/16 | 2,117 | 11,75 | 12,0 | — | — |

| M4 | 0,7 | 3,2 | 3,4 | 5/8 | 2,309 | 13,25 | 13,5 | 11/4 | 39,2 |

| M5 | 0,8 | 4,1 | 4,2 | 3/4 | 2,540 | 16,25 | 16,5 | 13/8 | 41,6 |

| M6 | 1,0 | 4,8 | 5,0 | 7/8 | 2,822 | 19,00 | 19,25 | 11/2 | 45,1 |

| M8 | 1,25 | 6,5 | 6,7 | 1 | 3,175 | 21,75 | 22,0 | — | — |

| M10 | 1,5 | 8,2 | 8,4 | 11/8 | 3,629 | 24,5 | 24,75 | — | — |

| M12 | 1,75 | 9,9 | 10,0 | 11/4 | 3,629 | 27,5 | 27,75 | — | — |

| M14 | 2,0 | 11,5 | 11,75 | 13/8 | 4,233 | 30,5 | 30,5 | — | — |

| M16 | 2,0 | 13,5 | 13,75 | — | — | — | — | — | — |

| M18 | 2,5 | 15,0 | 15,25 | 11/2 | 4,333 | 33,0 | 33,5 | — | — |

| M20 | 2,5 | 17,0 | 17,25 | 15/8 | 6,080 | 35,0 | 35,5 | — | — |

| M22 | 2,6 | 19,0 | 19,25 | 13/4 | 5,080 | 33,5 | 39,0 | — | — |

| M24 | 3,0 | 20,5 | 20,75 | 17/8 | 5,644 | 41,0 | 41,5 | — | — |

Through holes

Through holes penetrate the workpiece completely, forming a passage through it. A special feature of the process is to protect the surface of the workbench or tabletop from the drill going beyond the workpiece, which can damage the drill itself, as well as provide the workpiece with a “burr” - a burr. To avoid this, use the following methods:

The latter method is required when drilling holes “in situ” so as not to damage nearby surfaces or parts.

Holes in thin sheet metal are cut with feather drills, since a twist drill will damage the edges of the workpiece.

Blind holes

Such holes are made to a certain depth and do not penetrate through the workpiece. There are two ways to measure depth:

Some machines are equipped with an automatic feeding system to a given depth, after which the mechanism stops. During the drilling process, you may need to stop work several times to remove chips.

Holes of complex shape

Holes located on the edge of the workpiece (half holes) can be made by connecting the edges and clamping two workpieces or a workpiece and a spacer with a vice and drilling a full hole. The spacer must be made of the same material as the workpiece being processed, otherwise the drill will “go” in the direction of least resistance.

A through hole in a corner (profiled metal) is made by fixing the workpiece in a vice and using a wooden spacer.

It is more difficult to drill a cylindrical workpiece tangentially. The process is divided into two operations: preparing a platform perpendicular to the hole (milling, countersinking) and the actual drilling. Drilling holes in surfaces located at an angle also begins with preparing the site, after which a wooden spacer is inserted between the planes, forming a triangle, and a hole is drilled through the corner.

Hollow parts are drilled, filling the cavity with wood plug.

Shouldered holes are produced using two techniques:

Shank types

By design, the drill is divided into a working part and a shank. The shank is clamped in the chuck of a machine tool or drill. They are:

- Cylindrical.

- Conical. Designed for fixation in special clamping devices.

- Faceted. They have 3, 4 or 6 edges. The latter are widely used in household screwdrivers and allow you to quickly change tools.

- Quick-release (type SDS and others) The shank has special depressions that are securely fixed by the protrusions of the chuck. Used in hammer drills.

Faceted shank

Types of products by purpose

The main differences between the components are the angle of sharpening, the shape and type of cutting edge. Many components have a limited area of application.

According to their purpose, they can be divided into several categories, including interaction with surfaces from:

- Wood

- Tiles and glass

- Metal

- Concrete, brick and stone

On wood

When working with wood, a standard spiral tool for metal structures is usually used. It is suitable for holes measuring 0.2-1.8 cm. But when processing wood, these capabilities are not enough.

Several special parts have been developed to expand the scope of action:

- Hole saws

- Spiral for wood

- Screw

- Ballerinas

- Feathers

- Forstner drills

Hole saws are elements with a standard drill located in the center and a hollow cylinder framing it, covered with teeth at the end. They are used to drill lining, plywood and boards. This is a good option for installing lamps, since the size of the recesses is quite wide (2-6 cm). Hole saws are also suitable for cutting into sockets if the base is made of foam concrete, wood or clay. In this case, you can sample the material using a chisel.

Spiral models are in many ways similar to similar nozzles for metal, but have a different shape of the cutting part. It looks like a trident. The central point is fixed in the required place with high precision and enters the wood without any problems.

Screw-type drills are equipped with an improved working component for removing chips. The long length of the products allows you to drill deep recesses. This tool is often chosen for logs and beams. The tip of the device is similar to a screw and penetrates well into the wood, pressing the cutting part against the fibers.

Expert opinion

Levin Dmitry Konstantinovich

Many varieties have a handle that allows you to do the work without using a rotator, hammer drill or machine.

Ballerina shoes - options with a key to adjust the gap between the incisors. They can create large diameter notches in MDF, chipboard, OSB and plywood. The design includes a cross with a spiral drill in the middle. The sharp cutters on the arms of the piece can easily cut through metal sheets.

Feathers are flat elements with a trident at the end. This variety gives a larger drilling width, but can be attached to a standard drill. It is often chosen for hand cranking.

Forstner drills consist of a pair of cutting components mounted on a cylinder-shaped shank. They are in demand in the manufacture of furniture. They create large recesses to accommodate cabinet door hinges.

For tiles and glass

Two types of parts are used for processing glass and ceramic surfaces:

- Crowned

- Feathers

Crown varieties are coated with diamond coating and reach a width of 1.3-8 cm. To perform the task well, you will need a high-quality machine or hammer drill.

The feather parts are made in the form of a standard metal rod with a sharp spear-shaped tip. They create recesses with a diameter from 3 to 13 mm. The cutting edge of the pen is made of pobedite.

To work with glass and ceramics, a selection of high-quality consumables is required. Insufficient sharpening of the cutting element or its unevenness can cause cracks.

For metal

Such drills are mainly used for working with a metal base, but are also used when drilling wood or plastic.

Products may have different designs:

- Conical

- Stepped

- Spiral

- Crowned

Conical models are most often installed in machines. The cone-shaped working part has a pointed top that cuts into the metal. The result of drilling is a thin and neat hole. It expands as the thicker housing component penetrates into the material.

Components with a stepped are among the most modern options. The cone shape has a stepped structure that allows the recess to be gradually expanded.

Spiral – classic components of a standard shape. They include the shank, working part and cutting edge. The latter has a sharp edge that passes well through the metal base. The working element is made in the form of a spiral that frees the hole from accumulating chips. The tail zone is fixed in the machine niche or drill chuck. In the production of such items, high-speed steel grades H6M5, P18, HSS are used.

Crown varieties consist of an empty cylinder with sharp serrations at the border of the lower end. They process metal sheets with a thickness of no more than 10 mm. They are made from HSS steel. Some options are equipped with carbide brazing or diamond coating. Crown-shaped nozzles perform well when interacting with metal and concrete.

For concrete, brick and stone

Consumables for processing stone, concrete and brick bases have soldering tips for cutting through solid structures, which are made from artificial diamonds or pobedite sheets.

They can be produced in three forms:

- Spiral

- Crowned

- Screw

Spiral elements are inserted into the hammer drill. They are very similar to parts for processing metal structures, but are additionally equipped with soldering. These components are capable of creating holes up to 80-100 mm deep.

Crown-shaped attachments are similar to similar attachments for wood. In the middle there is a drill in the form of a spiral, which cuts well into the surface. But the main drilling process takes place with the participation of a crown equipped with soldering.

Screw components are also equipped with soldering. They are longer than spiral models. Such devices are suitable for creating deep recesses.

Wood drills

Small diameter holes (up to 15 mm) in wood, plywood, OSB can be easily made with a metal drill. If increased precision and surface smoothness are required, special carbon steel drills are used, which have special structural elements and are not suitable for processing metal parts. The following types are distinguished:

- Spiral. They have a specific sharpening that allows you to obtain the best surface quality.

- Screw. They have a sharp cutting edge and are made in the form of a screw. This makes it easier to remove chips from deep holes.

- Feathers. Allows you to work on large diameters - up to 50 mm. Cheap and simple in design. The surface quality and dimensional accuracy are lower than those of screw ones.

- Crowned. They look like a crown. The diameter reaches 150 mm.

Wood drills

Drills for glass, tiles

Glass is processed in only two types - either crown or feather. The core tool has a diamond coating on the edge, which ensures a neat cut. With its help, holes from 13 to 80 mm are made. The feather drill has the shape of a spear (a rod inserted into the machine and a pointed tip). It is used for small holes.

Drills for stone materials

Regular drill bits are not suitable for drilling into concrete, brick or stone. They quickly become dull on grains of sand and stone particles that have abrasive properties. In addition, a compacted layer of tiny particles of material is created in front of the drill. This layer is sintered by frictional heating. Therefore, both the drill itself and the drilling technology have their own characteristics. A reciprocating motion is added to the rotation of the tool, crushing the material. This is how a hammer drill, a more powerful hammer drill, and a boring drill work. A slightly larger diameter plate made of a particularly hard alloy (for example, Pobedit) is fused into the head of the tool. For larger diameters and depths, a crown with carbide teeth or with embedded industrial diamonds is used.

Concrete drill

Let's look at the pros and cons of the tool

| Purpose | Form | pros | Minuses |

| For metal | Conical | Allows you to carry out work in one stage | Not suitable for low power drills |

| Stepped | Suitable for creating recesses of different widths. One pass drilling is enough | Used only for sheet metal having a thickness of no more than 2 mm | |

| Spiral | Reliable, retains sharpness well | Requires the use of products of different thicknesses to create the desired hole diameter | |

| Crowned | Suitable for creating large recesses over 30mm wide | Not compatible with conventional drills | |

| On wood | Hole saws | Can be used for PVC lining, expanded polystyrene and cellular polycarbonate | Installing socket boxes in surfaces made of OSB or lining requires finishing the hole with a jigsaw |

| Spiral for wood | Allows you to obtain high-quality recesses without torn fibers | Limited scope | |

| Screw | Provides a neat and clean cut, even on damp wood | ||

| Ballerinas | Allows you to adjust the diameter of the future hole | ||

| Feathers | Produces clean edges without torn wood fibers | When creating a hole of small depth, a groove from the tip remains in its central part. The tool only works at low speeds | |

| Forstner drills | Allows you to create recesses with neat edges and a flat bottom | ||

| For concrete, brick and stone | Spiral | Works well with concrete and brick | |

| Crowned | Do quality work | Requires hammer drilling and is therefore not suitable for standard drills | |

| Screw | The design provides good dust removal | ||

| For tiles and glass | Crowned | Large diameter range | Requires a smooth touch to the surface, without runout or uneven pressure |

| Feathers | Strength of alloys in construction | Small selection of drilling diameters |

Recommendations for selection

To select the right tool for the best performance and surface quality, you need to consider:

- characteristics of the part material;

- diameter;

- depth.

The most important drill parameters are:

- diameter;

- length;

- design features;

- type and sharpness of sharpening;

- working part material;

- working surface color;

- balance;

- appointment;

- compatible equipment.

Thus, an SDS shank will require an appropriate chuck, and large-diameter drilling in metal workpieces requires a powerful, low-speed machine or high-torque drill.

Drills for stone, concrete, brick

Tools for such materials are distinguished by the presence of soldering. It is with the help of it that such hard material is broken through. • Spiral type. Similar to the spiral type for metal, only with soldering. The drilling depth with this tool can reach up to 100 mm. • Screw. A long tool that allows you to make a very deep hole. Its working part removes chips and dust well, so you can work almost continuously. • Crowned. They are similar to the crown type of wood tool with one difference: instead of teeth, there are solders on the cylinder.

Drill surface color

The color of the surface can tell a lot about the material from which the instrument is made.

- Grey. It's just steel, and inexpensive. This type of drill is not subjected to additional processing to improve cutting or strength properties. It makes sense to use them only when you need to drill a couple of holes every two weeks.

- Black. This is the result of hardening by superheated steam. Decent, durable enough mass-produced tools for household use. Maintain affordability

- Light golden. Such tools have undergone tempering heat treatment, which significantly increases strength and relieves internal stress. They are noticeably more expensive, but they justify their price due to their long service life.

- Bright golden. Titanium is added to the alloy. This is the best type of drill available for home use. Titanium reduces friction and therefore heat. This allows for excellent service life. But the price rises accordingly. The purchase is economically justified for large volumes of work.

Types of drills by surface color

The general pattern is that more expensive drills have to be changed less often. If the volume of upcoming work is significant, then it is better not to save money and then not buy dozens of cheap drills. In addition to saving money, invaluable time will be saved and the risk of material damage if the drill breaks is significantly reduced.

Drill characteristics

The main characteristic of any drill is its strength, which should exceed this indicator for the material being processed.

The tool, depending on the conditions of use, has different sizes and shapes.

The sharpening angle of the cutting part, color, etc. also differ.

Each product has a shank, the type of which must match the chuck of a drill, screwdriver or machine.

Material

For the manufacture of drills, alloys with different characteristics are used.

In this case, the so-called “high-speed” steel grades P18, P9, P9K15 are used.

If the diameter of the drill exceeds 8 mm, a welding method is used in its manufacture, for example: carbon steel for the shank, high-speed steel for the working part.

For materials with high hardness (mainly metal), cobalt drills are usually used.

Their peculiarity is that the working part is made from high-speed steel R6M5K5, VK6M with the addition of cobalt.

NOTE

After the letter “K” in the marking there is always a number that indicates the amount of cobalt in the parts.

Carbide Pobedit drills are used for drilling concrete, stone and brick.

The tip of such a tool is tipped with pobedite, an alloy of tungsten (90%) and cobalt (10%), developed in the USSR. There are more than ten modern modifications of this alloy.

IMPORTANT!

The pobedite tip does not cut the material, but crumbles it, so it is not suitable for working with metal, plastic and wood.

In addition to tungsten and cobalt, chromium, molybdenum, and vanadium are found in the alloys, and their percentage is indicated in the marking.

Coating

To extend the life of drills, their body has one of the following coatings:

• Oxide film – significantly increases resistance to overheating from friction.

Also protects the product from rust.

The service life naturally increases.

• Diamond coating is the most durable coating available.

It is mainly used on those products that are used when working with extremely hard materials, including stone and porcelain stoneware.

• Titanium coating is a general name indicating that the material contains a chemical compound of titanium - TiN (titanium nitride), TiAIN (titanium aluminum nitride), TiCN (titanium carbonitride).

Coloring

The color of the drill is very important.

It indicates the coating used or processing method:

• Gray is the native color of steel.

Indicates the absence of any processing.

The cheapest and most short-lived products are gray in color.

• Black is the color of steel that has been exposed to superheated steam during finishing.

Black products are much more durable than the previous option.

• Yellow is the color of steel that has been tempered (processing of metal to relieve its internal stress).

It speaks of the high hardness of steel, and its brittleness is greatly reduced by tempering.

• Golden – the color of titanium nitride. Bright golden tools are very durable, and they also have reduced friction against the workpiece.

Dimensions and weight

Manufacturers of cutting tools offer an impressive range of drills of every possible “caliber”, depending on the design and purpose.

Let's look at the most common spiral products according to GOST:

- Short: 20 – 131 mm in length, 0.3 – 20 mm in diameter (GOST 4010-77);

- Extended: 19 – 205 mm in length, 0.3 – 20 mm in diameter (GOST 10902-77);

- Long: 56 – 254 mm in length, 1 – 20 mm in diameter (GOST 886-77).

As for the exact weight, it depends not only on the design of the products, their sizes, but also on the material of manufacture.

The weight of ordinary twist drills usually ranges from several units to several tens of grams.

Processing accuracy

For twist drills there is such a characteristic as accuracy class:

- A - increased accuracy (10 - 13 qualifications);

- B1 – normal accuracy (up to 14 qualifications);

- B – normal accuracy (up to 15 qualifications).

Quality is a characteristic of accuracy that determines the tolerance values.

Classification by size

There are a wide variety of sizes available on the market, both in diameter and drilling depth. In accordance with GOSTs 4010-77, 10902-77, 886-77 there are:

- short total length from 20 to 130 mm, diameter from 0.2 to 20;

- extended - from 19 to 205 mm;

- long - 56 to 255 mm, diameter - 1-20 mm

Foreign manufacturers use their own systems for classifying tools by size; correspondence tables can be obtained by contacting regional representatives.

How to store and care

The durability of parts is influenced by the characteristics of operation and the condition of the products themselves:

- Cutting speed

- Innings

- Roughness of cutting element coating

- Processing quality

- Application of cooling compounds

The lifespan of a drill is also largely influenced by the features of its storage and care. Wooden stands, pencil cases and plexiglass containers are used for storage.

Any storage option should provide protection for the tool from the adhesion of debris and dust, chipping of cutting parts, their wear and dullness. The devices should also have easy access and the ability to periodically clean them from dirt.

As a result, the features of components for a hammer drill come down to the following:

- Their main characteristics are influenced by the type of alloys, coating, color, weight and size.

- Products vary in purpose and design shape.

- High-quality components should be purchased from trusted companies that have been on the market for a long time.

- When choosing, you must take into account the manufacturer, main characteristics, cost and compatibility of models with the existing tool.

- To extend the life of attachments, proper storage of equipment, regular maintenance, and compliance with operating rules are required.

How to understand the markings

Markings can tell everything about the size, type and material from which the drill is made. For small diameters (up to 2 millimeters), markings are not applied to the instrument itself; the boxes in which it is stored are marked.

Drills from 2 to 3 mm have a diameter designation on the shank accurate to tenths and the grade of the alloy from which they are made

Drills thicker than 3 mm are marked with diameter, material designation and manufacturer’s logo.

Explanation of NHD drill markings

Additional characters may be added to the inscription:

- P are high-speed tool alloys;

- M - molybdenum additives;

- K - cobalt additives;

- etc.

Many foreign manufacturers put more detailed information on the shank:

- country of origin;

- manufacturer's label;

- grade of tool alloy;

- diameter;

- the maximum accuracy class achievable by this tool;

- list of materials recommended for drilling.

Popular brands of instruments from foreign manufacturers

To choose the right imported drill for your materials, you should understand their designation system. The most common types of designation are:

HSS-R and HSS-G

They can drill:

- steel castings, carbon and low-alloy alloys;

- non-ferrous alloys;

- cast iron parts.

HSS-G Co 5

For medium strength steels:

- high carbon;

- stainless steel;

- thermally strengthened;

- resistant to aggressive environments;

- highly alloyed.

HSS-G TiAN/TiN

Drills with titanium coating and additives of aluminum and nitrogen compounds. They are characterized by high wear resistance and corrosion protection.

Drills brand HSS-G TiAN

Recommended for working with high-strength materials

- cast irons with carbon in spherical form;

- high-strength bronze and brass;

- injection moldings

There are other types of tool steel. They serve for industrial and highly specialized applications

Drilling according to markings, templates and jigs

You can drill holes according to the markings made or without it - using a template or jig.

The marking is done with a center punch. With a hammer blow, a place is marked for the tip of the drill. You can also mark the place with a felt-tip pen, but the hole is also needed so that the point does not move from the intended point. The work is carried out in two stages: preliminary drilling, hole control, final drilling. If the drill has “moved away” from the intended center, notches (grooves) are made with a narrow chisel, directing the tip to the specified location.

To determine the center of a cylindrical workpiece, use a square piece of sheet metal, bent at 90° so that the height of one arm is approximately one radius. Applying a corner from different sides of the workpiece, draw a pencil along the edge. As a result, you have an area around the center. You can find the center using the theorem - by the intersection of perpendiculars from two chords.

A template is needed when making a series of similar parts with several holes. It is convenient to use for a pack of thin-sheet workpieces connected with a clamp. This way you can get several drilled workpieces at the same time. Instead of a template, a drawing or diagram is sometimes used, for example, in the manufacture of parts for radio equipment.

The jig is used when precision in maintaining the distances between holes and strict perpendicularity of the channel is very important. When drilling deep holes or when working with thin-walled tubes, in addition to the jig, guides can be used to fix the position of the drill relative to the metal surface.

The best manufacturers

The reputation of the manufacturer is a very important criterion when selecting a drill. Many companies are proud of a hundred and two hundred year history of impeccable quality.

Bosch drills

Many technologists agree that the best price/performance ratio on the market today is:

- Enterprises of the CIS countries. Their products have traditionally, since the times of the USSR, been distinguished by their strength and durability at a low price. Unfortunately, they are gradually leaving the market

- At an affordable price, Ruko provides decent quality and a wide range of designs, coatings, diameters, lengths and sharpenings.

- Bosh. It costs more, but has a significantly greater resource. Beneficial for large volumes of work.

- Bison A worthy attempt to revive the glory of Soviet instrumentalists. Combines high quality and reliability with reasonable prices.