Drills are special tools that allow you to quickly make holes in materials. To fix them, a chuck located on a drill or screwdriver is used. For the manufacture of such special tools, grades of hard steel are used. Thanks to this, they can be actively used when working with materials such as metal, stone, concrete, brick, wood.

Almost every person in the workshop has a set of drills (usually for working with metal). However, in some cases, the user may only use thin drills to perform a variety of jobs. For example, if you need to make a large hole in a sheet of metal, but there are no large-diameter tools available. There are a large number of different tricks, the use of which will allow you to use thin drills more effectively when performing a variety of jobs.

Drill with three drills at once to create a large diameter hole

Situations arise when a craftsman needs to make a hole of a large diameter, and there are tools at hand that allow him to do such work. In this case, you can use several small diameter drills.

To do this, you need to use three thin drills and fasten them together using regular electrical tape. It is worth noting that their diameter should not differ much from each other. To get the most even hole possible, the drills must be aligned with each other while twisting. If at least one drill from the common bundle protrudes slightly forward, it will become the so-called axis of rotation of the entire structure. As a result, the diameter of the hole made will be slightly larger than the originally planned size.

Then the entire bunch must be fixed in the chuck of an electric drill. It must be positioned in such a way as to ensure reliable grip of the entire structure in the chuck. At the same time, we should not forget that the length of the tools used must be sufficient to make through holes in the material.

If the ligament is poorly fixed in the chuck, the drill bits will begin to move apart and break during rotation. For repeated use of such a tool, it must be correctly and securely fixed in the chuck of the power tool.

When using a bundle, it is necessary to set a low rotation speed of the electric drill chuck. During work, it is necessary to periodically stop and remove all accumulated debris from the hole being made. This method, which involves the use of a binder, is best suited for making large-diameter holes in wood and soft metals (copper, aluminum).

Drills for small work 0.5 0.8 1.5 2.0 mm. Minor repair of a remote control machine

I ordered these drills without any particular purpose - in case someday I need to drill something small. I was so undemanding and inattentive to the purchase that I didn’t even notice that the set included not one drill of each diameter, but 10. Well, I divided my expectations from the drills by 10. So they lay there until they arrived hands to repair a radio-controlled car, which I once reviewed, and during the review I dug into the wall so that the pin connecting the wheel and steering rack broke off. At the same time, I decided to take pictures of the drills and conduct a couple of primitive tests. Let's go over the drill bits first. As I already said, the set includes drills of four diameters: 0.5 mm 0.8 mm 1.5 mm 2.0 mm, 10 pieces of each. The seller states that they are suitable for drilling wood, plastic, and aluminum. Each diameter is placed in its own bag.

My compass is very simple and not suitable for precise measurements. But taking into account its error, the declared diameters can be considered correct.

Drill length

Drills close up. I’m not an expert in this, so anyone in the know, write in the comments what’s going on with sharpening, etc. by appearance.

0.5 mm

0.8 mm

1.5 mm

2.0 mm

Now let's check how they drill. For mounting in the engraver, I also used a set of collets purchased in reserve for drills of 0.5 mm, 1.0 mm, 1.5 mm, 2.5 mm, 3.0 mm.

Or rather, three of them. The 1.5 mm collet turned out to be actually 2 mm, and I tested the 1.5 drill by inserting it into a screwdriver. I tested the two smallest drills on a board from a dead flying ball with blades.

The recording of the drilling process has been slightly sped up, the real time is displayed on the timer.

0.5 mm

While watching the video, I noticed that I was drilling at an angle. I read that such thin drills usually break because of this, but it held up.

0.8 mm was normally fixed in the collet at 1 mm.

1.5 mm, as I already said, had to be installed in a screwdriver. I started with textolite, recording speed 1:1

Then I thought that we were promised aluminum drilling. I didn’t find anything aluminum that I wouldn’t mind, so I took a bottle cap.

Rejoiced, I decided to give the task a more difficult one and tried to drill a 1 mm thick steel ruler. Not too fast, but the drill did the job. It seems to me that the result is quite good.

2 mm. I didn’t even try it on PCB. Of course, it drills through tin lids.

But there was a puncture with the ruler. I tried two drills, with an engraver and a screwdriver, the result was the same, within 30 seconds they went a little deeper into the metal and didn’t go any further.

Now about practical application. For quite some time now I have had a 1/14 scale RC car lying around with a broken steering wheel. When she collided with a wall, the pin that connects the steering rack and the wheel itself broke off. Fortunately, I managed to find the pin itself after the accident.

Just gluing it on is not the answer. Therefore, I decided to put it on a metal pin for reinforcement. An ordinary paper clip acted as a pin. Diameter 0.7 mm.

I straightened the paperclip and bent one end with thin pliers.

Next, using a 0.8 mm drill, you need to make holes in the pin and the car wheel mount. He acted a little barbarically. Since it was already a little late, my wife was putting my daughter to bed, I didn’t want to buzz the engraver on the balcony. Therefore, I attached a collet holder to a drill with a diameter of 2.5 mm and installed it in a screwdriver. It doesn't even hit the eye.

I drilled a hole in the wheel mount, inserted a paper clip, heated it with a lighter and melted it into the plastic.

I drilled a pin, threaded it onto a paperclip, and “polished” everything with superglue.

After installing the part in the car and checking it, I had to remove some of the remaining glue with a file. After all procedures, the steering functionality is completely restored.

How to drill in the right place

To drill in the right place, you need to use a special device called a core. It is made of durable steel grades, has a cylindrical shape and has a small point at its end. Before performing work, you need to take a core, place its tip on the surface, and hit its opposite end with a hammer. As a result, a recess is formed on the surface of the material in which it is necessary to drill.

How to avoid dulling drills

During use, a metal drill may become dull if it begins to get very hot when rotating. As a result of such heating, the strength of such a tool is lost. It is worth noting that the heating process occurs due to friction, therefore, the faster the amplitude of rotation of the drill chuck, the stronger the heating will be.

Therefore, in order to prevent such a tool from overheating during work, it is recommended to make holes in metal surfaces at low speeds (no more than 1 thousand revolutions per minute). If it is necessary to drill a thick workpiece, then it is recommended to use a special lubricant or paste that will provide additional cooling of the tool. Lubricant can be added directly to the place where drilling is carried out. You can also dip the drills themselves in lubricants or pastes. If you don’t have special lubricants at hand, then you can use ordinary machine oil.

Carbide drills from 0.3 to 1.2 mm in a set.

To expand the functionality of the DREMEL 4000-4/65 mini-drill (engraver), we purchased carbide drills in a set from 0.3 to 1.2 mm. Similar reviews are here and here. The drills came in a regular envelope, wrapped in a thin bubble wrap. The drills themselves differ from those on the seller’s page for the better because they have a landing limiter and a convenient storage box. There are no identification marks on the box, but it is exactly the same as in other reviews. I suppose you can put on a label that was made in Japan, or you can leave it off. Drill sizes: from 0.3mm to 1.2mm in increments of 0.1mm. shank diameter 3.15mm. Fits a 3.2mm collet or chuck. Analysis of the colors of the restrictive rings suggested that this was Chinese ancient wisdom and I could not understand it. On the shank there are secret marks indicating the diameter of the drill, the length of the drill itself and probably something else, on each drill it looks like they were done differently in different places. The experiments carried out showed excellent drilling of both ordinary steel and stainless steel. I did not experiment with drilling a file for fear that my hand would tremble and the drill would break; I drilled it manually. In the future I plan to drill using a Dremel Workstation 220. This is what it looks like already installed. Pros. Externally they look great. Nice storage box made of soft transparent plastic. A range of sizes to suit every taste. There is a limiter on the collet for ease of installation. They drill perfectly. (probably this should be the first ) Cons We don’t have it on sale, and if a drill breaks, you’ll have to look for it online.

Well, how would it be without a cat? And it’s Spring in our yard. Planning to buy +78 Add to favorites Liked review +44 +89 mysku.ru

How to drill thick workpieces

To process workpieces that are too thick, it is recommended to use tools of different diameters in combination. For example, if you need to make a large hole in a thick piece, then you can use a thin drill first. Once a small hole has been punched in the workpiece, it can be gradually expanded using thicker drill bits. That is, in this case, to drill one hole in a thick workpiece, tools of different diameters are used alternately. During operation, the user gradually increases their diameter to the required size.

Lubricating the area to be drilled

In order to successfully drill through any material made of metal (stainless steel, steel, cast iron) in a short period of time, it is recommended to use special lubricants. The area in which drilling will be carried out is treated with lubricant before performing work. Thanks to this, the drill used glides better and does not heat up too much. For example, to process stainless steel, you can make your own special lubricant from machine oil and colloidal sulfur. To do this, you need to take pieces of sulfur, grind them and mix them with oil. In this case, during material processing, lubricant must be supplied to the drilling area on a constant basis.

There are many different ways to use fine drill bits to make large holes in thick, strong materials. During their use, it is recommended to set low speed on the electric drill. Also, when using power tools, when carrying out such work, safety precautions should be observed. It is necessary to use safety glasses or a mask, and wear gloves to avoid accidental injury.

Homemade drilling machine for thin drills

Homemade drilling machine for thin drills

Nikolay wrote:

I'm interested in a drilling machine... what brand is it and how much does it cost? I would very much like to see in the future an article dedicated separately to this machine, or rather to its detailed description and manufacturing process.

Responding to Nikolai’s request, I decided to describe the design of my drilling machine. Unfortunately, this machine is not a budget solution, since quite expensive components were used in its manufacture. https://oldoctober.com

The drilling machine in question was made many years ago in order to drill thin holes with a diameter of up to 0.3mm.

Once upon a time, in the era of matrix printers, when repairing matrix heads, it was necessary to drill fairly precise holes of small diameters.

When drilling printed circuit boards, of course, such thin holes are not needed, but drills with a diameter of 0.5 - 0.7 mm are also quite gentle and this machine can extend their life.

The highlight of this machine is the ADP-1262 asynchronous AC motor with a “squirrel wheel” rotor. The rotor of this motor is a hollow aluminum glass with a wall thickness of about 0.5 mm. The stator occupies the rest of the space. The stator has a narrow cylindrical slot in which the rotor rotates with a gap of a few tenths of a millimeter.

I do not recommend disassembling such an engine without sufficient experience in working with precision mechanics. One careless movement and the glass will be deformed, after which you can say goodbye to the engine. https://oldoctober.com

Naturally, the weight of such a rotor is so small that its inertia can be neglected, especially considering the mass of the clamping chuck.

In addition, the engine has a very smooth characteristic. As the engine speed decreases, the torque on the shaft also decreases. All this ensures the safety of thin drills when jammed and when the permissible torque on the cutting edge is exceeded.

A 6B10 three-jaw chuck is used as a drill holder, which allows clamping drills with a diameter of up to 6 mm.

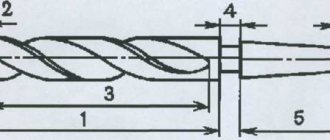

The bed is assembled from two parts. The stand pos. 1 and the rack and pinion mechanism pos. 2 are borrowed from the MBS-1 microscope. The base of item 3 is cut from a steel sheet 10 mm thick.

The engine is secured with a clamp, which in turn is attached to the feed mechanism with four screws. The screws are indicated by arrows in the figure. The holes are located at the vertices of the square, so the engine can be positioned not only vertically, but also horizontally.

The cartridge is secured using a shaped bushing, on the outside of which a No. 1 cone is machined, and inside there is a hole machined for a transitional fit equal to the diameter of the engine shaft (6mm).

The bushing is turned on a lathe in one step. That is, during the turning of the cone and the turning of the hole (not drilling), the workpiece was fixed in the machine and only then cut off.

For reliable fixation and selection of possible misalignment, the bushing has six M3 threaded holes for locking screws. There are six recesses made in the motor shaft, into which these locking screws fit. The holes are staggered, which allows you to select misalignment even if it arises as a result of wear of the mating surfaces. The screws are secured with locking paint.

A flange with a slot is attached to the upper extension of the engine shaft, which, together with a bar fixed to the engine body, represents a locking mechanism. This mechanism allows you to tighten the cartridge without using a key (by hand).

The use of a key asymmetricizes the chuck clamping mechanism and leads to uneven wear of the latter, which can cause the drill to run out. When using thin drills with thick shanks, this can cause noticeable eccentricity of the working surface of the drill.

At the upper end of the engine there is a duralumin casing (marked with an arrow), inside of which there is a phase-shifting capacitor and an engine switch.

To control the torque on the motor shaft, LATR is used.

The motor allows the rated supply voltage to be doubled, which allows the use of drills up to 8 mm, with shanks machined up to 6 mm, when drilling thin sheet plastic, fiberglass and other materials, the drilling of which does not require large moments on the working edge of the drill.

Attention! The twofold excess was taken not from passport data, but from practice.

October 15, 2010 (22:12) in Do it yourself

oldoctober.com