Design

The insides of the part are not hidden, so it is more convenient to adjust the tension. The body is made by casting, forging or welding . And the holes for the screws are milled, they regulate the force. For difficult weather conditions, a closed type lanyard is used, which consists of three parts:

- Frame.

- Two screws (left and right thread).

- Screw heads (hook, fork and ring).

Each part of the device is precisely calibrated and will perform a specific function that meets the standards. International documents regulating the technical characteristics and production of lanyards - DIN 1480, DIN 1478. In the territory of the former USSR - GOST 9690-71.

PTR 7-1 lanyards (as these devices were previously called) helped keep steel ropes and cables under constant tension. But they did not have such a large number of heads, unlike modern models. There were oblong loops at the ends. The load for which the lanyard is designed was indicated in the name, based on the ton-force indicator. New models are designated by the parameter in kN. T 30-01, withstands 3 tf or 30 kN.

Design and production features

The design of this device is quite simple and consists of only two parts, but its reliability can only be envied. So, its main elements are two screws with threads in opposite directions and a ring bracket. The end of one rod fastening element has the form of a hook, and the second - a ring, which greatly simplifies the process of working with it and expands the scope of application. True, there are other types, such as ring-ring lanyard or hook-hook, but this is a separate article.

Turnbuckles are mainly used to tension a chain, cable or rope. This process is carried out quite simply, you just need to rotate the brackets of the ring, then the screws, due to the opposite direction of the thread, will begin to move towards each other, i.e., twist, thereby reducing the distance between the hook and the ring and, accordingly, the total length of the entire product. So, as you can see, it will be difficult to come up with a simpler mechanism. Moreover, such simplicity is one of the main advantages, because then the part is not only easier to repair if it breaks down, but the likelihood of breakdowns itself is significantly reduced.

In principle, the manufacture of these parts is not anything overly complicated. The coupling is produced in three ways: casting, stamping or forging. It looks like an elongated rectangle, the corners of which are beveled. From the end in the middle of this part a thread is applied, as mentioned above, on one side right and on the other left.

The material used is low-carbon steel, the carbon content of which does not exceed 0.25%. With an increase in the amount of carbon, the strength characteristics improve and the hardness also increases. True, such changes will negatively affect the ductility of the material. But these steels themselves cannot provide the necessary wear resistance and resistance against such destructive corrosion, so a layer of zinc must also be applied to the surface of the finished part.

This process is called galvanizing and involves forming a protective film on the metal of the product. It prevents the penetration of oxygen and thereby prevents the oxidation process. There are several ways to apply zinc. One of them is galvanic, which refers to the electrochemical deposition of zinc while the part is in a special solution. If protection is created through powder processing, then this type is called diffusion galvanizing. You can also apply a special solution to the part using methods that are applicable for simple painting. In general, the method is not so important, the main thing is the end result - the product has improved characteristics.

Lanyard selection

Selecting a tool based on the expected load is a guarantee that it will not deform during operation.

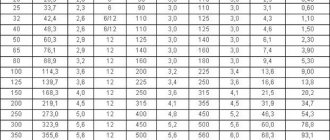

The tables that the seller has will help you do this, where the manufacturer indicates which model is designed for what. But the choice depends not only on the weight of the load, but also on the function. The first parameter you need to pay attention to is thread diameter . Screw fasteners for M10, M8, M12, M20, M16 have different threads. The number following the letter “M” indicates the thread diameter in millimeters, M12 is a 12 mm thread. Marking T 10-01, T 30-01 indicates the load at which the part begins to collapse.

Lanyards are most often used when working outdoors, where they are exposed to moisture and temperature changes. Modern parts are not supplied without protection from such exposure; most often this is galvanizing.

TEST METHODS

4.1. Measurement of lanyards should be carried out using a universal measuring tool, templates and gauges.

4.2. The material of lanyard parts must be verified according to certificates or laboratory analysis data.

4.3. Lanyards are tested for tension with double the permissible load. The holding time under load must be at least 5 minutes.

4.4. Before testing and after testing according to clause 4.3, turnbuckles must be inspected, as well as checked for ease of rotation of the threaded connection.

4.5. Head samples of lanyards must be tested at four times the permissible load, and they must not be destroyed. Elongation of parts is not considered destruction.

4.6. Lanyards and their parts tested according to clause 4.5 are not subject to further use.

4.7. The quality of welds is checked according to GOST 3242-69.

4.8. The quality of lanyard coatings is checked according to GOST 3002-70.

4.9. Testing of material samples of forged parts of lanyards must be carried out by the manufacturer in accordance with GOST 8479-70 (IV group). During serial production, it is allowed to carry out tests in accordance with GOST 8479-70 (II group).

GOST 9690-71

According to GOST 9690-71, there are the following types of lanyards:

- OS - with open coupling;

- OZ - with a closed coupling;

- ОШ - with a stamped coupling.

Types of lanyards:

- VU - fork-eye;

- BB - fork-fork;

- UU - ear-ear.

Lanyards manufactured in accordance with GOST 9690-71 are used on ships and other floating craft. OSH parts are made of carbon steel, in the following versions:

- VU - fork-eye;

- BB - fork-fork;

- УУ - ear-ear;

- VG - hook fork;

- GG - gak-kak;

- GU - gak-ear.

Lanyard OS are made of magnetic and carbon steels and come in the following versions:

- BB - fork-fork;

- УУ - ear-ear;

- VU - fork-eye.

ZS lanyard is made of steel with a high carbon content and in two types:

- BB - fork-fork;

- VG - fork-hook.

To protect against friction, graphite lubricant is applied . According to GOST, nuts are used to fix the position of the ears (forks). The main purpose of the part is to enhance linear tension. Do not use for lifting loads. When engaging the turnbuckle, there should be no loose turns on the coupling.

Production technology

Ring-to-ring lanyards, hook-to-ring lanyards, fork-to-fork lanyards, and hook-to-hook lanyards operate in harsh operating conditions. This is due to the fact that when a load occurs, all parts work in tension, sometimes accompanied by bending.

It is also important that the force sometimes changes over time, so the strength and durability of the device also depends on the fatigue limit of the material

Standard sizes of ring-to-ring lanyard according to DIN 1480

The critical element of the drawing is the coupling. As a tensioner, it works under alternating loads. Moreover, the frame structure of many standard couplings used for connections already contains stress concentrators at the transition points from the side posts to the threaded base. Therefore, these transitions in the drawings are designed in the form of radius curves, their diameter is set by the overall dimensions of the lanyard assembly.

Ring-ring lanyard, hook-ring lanyard, fork-fork lanyard are never manufactured in welded versions. Moreover, it is very undesirable to make couplings by casting, even if from high-quality structural steels (for example, from casting grade 45L according to GOST 977). The possibility of the presence of internal empty spaces and cavities in the casting is preserved with any technological production option, which terribly weakens the cross-section, especially in the fastening areas. The performance indicators of the milled options are also not very successful. During the mechanical processing of parts included in this assembly, the fibers of the metal macrostructure are cut, which reduces durability.

The optimal production option for parts included in the design is considered to be hot stamping: during this process, plastic redistribution of the volumes of deformed metal occurs, while the fibers bend along the contour, maintaining the strength of the forging. During cold die forging, even hardening of the metal occurs, which makes it possible to make devices from much affordable grades with a low carbon content (for example, from steel 20).

After stamping, the parts are subjected to thermal treatment - normalization at 820...860 °C, with further cooling in air. Quenching is carried out at the same temperatures of heating into oil. Residual hardness should be in the range of 190…220 HB. For anti-corrosion protection, a galvanized lanyard is used.

DIN 1480

A simple lanyard design (photo) - rings and an oblong cylinder and threads, with different directions of twisting. At the end of the screw there is a place for fixing the steel cable. It could be a hook, a ring, a fork .

The cylindrical body design can be open or closed. In the first version, the threaded ends of the screws converge towards the center, when tensioned, in the second, this does not happen. A closed lanyard is used in areas where there is a risk of moisture and debris getting into the threads.

The head, made in the form of a fork, must be sized to fit the hole or bolt to which it will be attached. When using rope, it is easily made into a loop that is fixed to the fork. Everything must be attached end to end, without reserve.

The hook is fixed to a ring or other device that will provide reliable retention when tensioned. And if your head ends in a ring, then you need a chain or other part that will not fly out during operation.

Ratchet is a chain lanyard that uses a ratchet and is different in appearance from others. The scope of application is bringing together distant objects; it is not used anywhere else. Large dimensions significantly limit it.

Design and principle of operation of the lanyard

The device in question consists of four parts:

- A cast or stamped coupling equipped with two threaded holes. The coupling can be in the form of a rectangular frame or an ellipse.

- Pairs of hooks or other load-handling elements (slings) with threads on the opposite part.

- Washers that distribute the load more evenly.

- Locking nuts that prevent spontaneous rotation of the grips.

A separate group consists of chain lanyards (ratchets), in which the tension occurs not due to the gradual screwing of the grips into the coupling, but due to the twisting of the tension chain located between the load grips. Chain lanyards are used when securing long loads on platforms. It consists of:

- Chains (cable tensioner).

- Two slings.

- The tension mechanism, which, in turn, includes a ratchet and a shaft on which the ratchet wheel is mounted.

In simple designs of chain lanyards, instead of a ratchet, a lever is provided, the rocking movement of which removes slack in the chain tension.

The necessary fixing force is created due to the rotation of the slings. At the same time, the distance between them is reduced, the gaps are selected, and the tension of the held object between the lanyards is ensured.

Coupling turnbuckles are mainly used in pairs, which allows the tension force to be evenly distributed in the branches of the slings. The chain lanyard can be one-sided. The opposite end of such a lanyard is rigidly fixed to the supporting part of the platform. However, in this case, only the axial component of the tension force is perceived, which is why the ratchet cannot be used for lifting loads or holding objects in a vertical position.