17.03.2020

- Tool Options

- Basic angles of metal turning tools and their purpose

- Measuring the sharpening angles of a turning tool

- Machining planes

- Types of turning cutters and their purpose

- Main rules for choosing a tool

- When sharpening is required

- How to attach a cutter to a machine

One of the main parts of the machine deserves detailed consideration. Therefore, the focus is on the geometry of the turning tool: the main elements and angles, surfaces and other characteristics. You will also learn how its different types differ from each other, for example, what is the difference between threading and boring, and you will be able to choose one or more of them, depending on your production or domestic needs.

Let us immediately note the importance of the role of those indicators discussed below. They, in fact, determine not only the functional purpose, but also the reliability of the edges, and therefore the duration of operation of the device. They also determine the productivity and accuracy of technological operations, and, finally, orientation in space when solving a problem.

Tool Options

Any of them consists of two structural elements. This is a holder responsible for high-quality fixation in the machine, and a working head that directly removes excess layers of material.

And each of them has three turning tool surfaces:

- the front one is responsible for chip collection;

- main (primary) and auxiliary (secondary) rear ones, facing the workpiece.

- The intersections form the edge and form the apex, that is, the sharpest point experiencing maximum loads. To prevent it from chipping, it is slightly rounded to improve durability (introducing the concept of radius into the technical documentation) or, alternatively, a straight transition is made.

But there are also parameters whose role is even more important, because they determine the relative position of all three planes. These are angles, the calculated values of which depend on a number of factors, and in the list of key ones:

- operating conditions and intensity;

- instrument material;

- hardness, viscosity and other quality characteristics of the workpiece.

They need detailed consideration.

The main surfaces of a turning cutter and its geometric parameters

A turning cutter was chosen as a representative of cutting tools, as it is the simplest.

The definitions of the geometric parameters of a turning cutter remain valid for other types of cutting tools, taking into account the peculiarities of their kinematic cutter patterns.

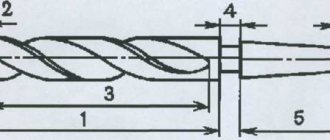

A turning cutter consists of a working part and a holder (Fig. 1.2).

The working part contains cutting blades and is formed during the process of sharpening (grinding) the cutter.

The holder is used to secure the cutter in the tool holder of the machine.

The rake surface is the surface along which chips flow.

The main rear surface faces the workpiece surface to be machined.

The auxiliary rear surface faces the machined surface of the workpiece.

The main cutting edge is formed by the intersection of the front and main back surfaces.

The auxiliary cutting edge is formed by the intersection of the front and auxiliary back surfaces.

Rice. 1.2. Turning cutter:

1 – front surface; 2 – main rear surface; 3 – auxiliary rear surface; 4 – main cutting edge; 5 – auxiliary cutting edge; 6 – tip of the cutter

The tip of the cutter is the junction of the main and minor edges along a radius or chamfer.

According to GOST 25762–83, static and kinematic angles of a turning tool are distinguished.

Static angles are used when developing a tool drawing, when sharpening and inspecting it.

The kinematic angles of the cutter are formed during the cutting process and depend on the parameters of the cutting mode (mainly on the feed rate).

Static angles of a turning tool are measured in a static coordinate system, and kinematic angles are measured in a kinematic coordinate system. Both static and kinematic coordinate systems are related to the kinematics of the cutter.

The static coordinate system is a rectangular coordinate system with the origin at the considered point of the cutting edge, oriented relative to the direction of the velocity V of the main movement (Fig. 1.3a). For a cutter installed along the center axis, the z axis is directed vertically upward, the x and y axes are located in the horizontal plane (Fig. 1.3a); The y axis is directed along the axis of the cutter holder, the x axis is directed along the feed direction of the cutter.

To measure the static angles of a turning tool (sharpening angles), the following static coordinate planes are used: the main plane, the cutting plane and the working plane (Fig. 1.3a).

The main plane is a plane drawn through the point of interest on the cutting edge perpendicular to the vector V of the speed of the main movement (plane OXY).

The cutting plane is a plane tangent to the cutting edge at the point under consideration and perpendicular to the main plane.

The working plane is a plane passing through the vectors V of the main movement speed and Vs of the feed movement speed (OXZ plane).

Rice. 1.3. Static (a) and kinematic (b) coordinate systems (η – cutting speed angle)

Figure 1.4 shows the static angles of a turning tool.

The main cutting plane is a plane perpendicular to the projection of the main cutting edge onto the main plane.

Auxiliary cutting plane is a plane perpendicular to the projection of the auxiliary cutting edge onto the main plane.

In the main cutting plane there are:

· main rake angle γ – the angle between the front surface and the main plane. Depending on the position of the front surface relative to the main plane, a positive or negative front angle is distinguished (Fig. 1.4). If the front surface coincides with the main plane, then the front angle is zero. Figure 1.4 shows a positive rake angle;

· main rear angle α – the angle between the main rear surface and the cutting plane;

· sharpening angle β – the angle between the main rear and front surfaces of the cutter.

From Figure 1.4 it follows:

γ + β + α = 900 (1.1)

Typically, angles γ and α are specified, and angle β is calculated using formula (1.1).

In the auxiliary cutting plane, the auxiliary clearance angle α1 - this is the angle between the auxiliary clearance surface and the plane passing through the auxiliary cutting edge perpendicular to the main plane.

In the main plane, plan angles are measured:

· main plan angle φ – the angle between the projection of the main cutting edge onto the main plane and the working plane;

· auxiliary plan angle φ1 – the angle between the projection of the auxiliary cutting edge onto the main plane and the working plane;

· vertex angle in plan ε – the angle between the projections of the main and auxiliary cutting edges onto the main plane.

Rice. 1.4. Static turning tool angles:

NN – main cutting plane; N1-N1 – auxiliary cutting plane

From Figure 1.4 it follows:

φ + φ1 + ε = 180º. (1.2)

Usually the angles φ and φ1 are assigned, and the angle ε is determined by formula (1.2).

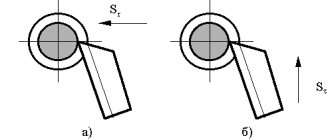

The inclination angle of the main cutting edge λ is the angle located in the cutting plane between the main cutting edge and the main plane. The angle λ can be positive, zero or negative. The angle λ is zero if the main cutting edge is in the main plane. Figure 1.5b shows a negative angle of inclination of the main cutting edge.

Rice. 1.5. Inclination angle of the main cutting edge λ of a turning cutter [ 3]: a)λ>0, b)λ<0, c)λ = 0

The kinematic angles of a turning tool are formed during the cutting process and depend on the parameters of the cutting mode (mainly on the feed rate).

The kinematic coordinate system is a rectangular coordinate system with the origin at the considered point of the cutting edge, oriented relative to the speed Ve of the resulting cutting movement (Fig. 1.3b).

From Figure 1.3b it follows that the kinematic coordinate system is rotated relative to the static one by an angle η (cutting speed angle). Moreover, the rotation is carried out relative to the y-axis (on the OXZ plane).

Thus, the kinematic and static angles of a turning tool differ only in the position of the coordinate planes of their reference. The definitions of angles are the same; only instead of the word “static” the word “kinematic” is used.

Below are some of the most important definitions.

The kinematic main plane is the plane perpendicular to the velocity vector Ve of the resulting cutting motion.

Kinematic cutting plane is a plane tangent to the main cutting edge and perpendicular to the kinematic main plane.

Kinematic perpendicular angle γк – the angle in the kinematic main cutting plane between the front surface and the kinematic main plane.

Kinematic rear rake angle αk is the angle in the kinematic main cutting plane between the main rear surface and the kinematic cutting plane.

During the cutting process, the kinematic rake angle increases, and the kinematic rear angle decreases compared to static angles (γк < γ; αk < α). Other kinematic angles (angles in plan, angle of inclination of the main cutting edge) will change slightly. These changes in cutting angles are usually not taken into account. The greatest change in kinematic angles occurs for the persistent cutter. So, at Y = 90º, λ = 0º

γк = γ + η1, αк = α – η1(1.3)

where η is the kinematic component equal to the cutting speed angle:

η = arctan = arctan , (1.4)

where Vs is the feed speed, So is the feed per revolution, D is the diameter of the cutting edge point under consideration. At V? The Vs kinematic component can be assumed to be zero. In this case

γк γ, αк α. (1.5)

Changes in kinematic angles compared to static ones must be taken into account if the feed speed Vs is comparable to the speed of the main movement V. A change in the kinematic rear angle is especially dangerous, because it can become zero or even negative, which is unacceptable. So, for example, when cutting threads with large pitches or when drilling small-diameter holes, the clearance corner must be sharpened taking into account the kinematic component.

Sharpening angles of pass-through cutters; static cutter angles are also called sharpening angles, because all angles can be set on the limbs of the three rotary vices of the sharpening machine. The sharpening angles of cutters depend on the properties of the technological system, mainly on rigidity and vibration resistance. Thus, the average value of the front angle γ is 10º. However, if the cutting edge is not cut out, this angle can be increased to 15-20º. To harden the cutting edge, sharpen a hardening chamfer f, with a width approximately equal to the thickness of the cut layer a, at an angle γf = 0 - –5º. A hole is often sharpened on the front surface to ensure curling of the chips. The rear angle α lies within 8-12º.

Smaller values are used for roughing, larger values for finishing. The main plan angle φ varies within 30-90º. Lower values are used in conditions of increased rigidity of the technological system. Angle φ = 90º is recommended for processing non-rigid workpieces. This leads to a decrease in the radial cutting force Py and an increase in machining accuracy. The auxiliary angle φ1 affects the quality of the machined surface.

With high requirements for surface quality, this angle is reduced to 5-10º, and sometimes made zero (for cutters with cleaning cutting edges). The inclination angle of the cutting edge λ affects the direction of chip flow and the strength of the cutting wedge. The angle λ varies within ±5º. At positive angles λ, the chips flow towards the machined surface. For negative λ – in the direction towards the treated surface.

A turning cutter was chosen as a representative of cutting tools, as it is the simplest.

The definitions of the geometric parameters of a turning cutter remain valid for other types of cutting tools, taking into account the peculiarities of their kinematic cutter patterns.

A turning cutter consists of a working part and a holder (Fig. 1.2).

The working part contains cutting blades and is formed during the process of sharpening (grinding) the cutter.

The holder is used to secure the cutter in the tool holder of the machine.

The rake surface is the surface along which chips flow.

The main rear surface faces the workpiece surface to be machined.

The auxiliary rear surface faces the machined surface of the workpiece.

The main cutting edge is formed by the intersection of the front and main back surfaces.

The auxiliary cutting edge is formed by the intersection of the front and auxiliary back surfaces.

Rice. 1.2. Turning cutter:

1 – front surface; 2 – main rear surface; 3 – auxiliary rear surface; 4 – main cutting edge; 5 – auxiliary cutting edge; 6 – tip of the cutter

The tip of the cutter is the junction of the main and minor edges along a radius or chamfer.

According to GOST 25762–83, static and kinematic angles of a turning tool are distinguished.

Static angles are used when developing a tool drawing, when sharpening and inspecting it.

The kinematic angles of the cutter are formed during the cutting process and depend on the parameters of the cutting mode (mainly on the feed rate).

Static angles of a turning tool are measured in a static coordinate system, and kinematic angles are measured in a kinematic coordinate system. Both static and kinematic coordinate systems are related to the kinematics of the cutter.

The static coordinate system is a rectangular coordinate system with the origin at the considered point of the cutting edge, oriented relative to the direction of the velocity V of the main movement (Fig. 1.3a). For a cutter installed along the center axis, the z axis is directed vertically upward, the x and y axes are located in the horizontal plane (Fig. 1.3a); The y axis is directed along the axis of the cutter holder, the x axis is directed along the feed direction of the cutter.

To measure the static angles of a turning tool (sharpening angles), the following static coordinate planes are used: the main plane, the cutting plane and the working plane (Fig. 1.3a).

The main plane is a plane drawn through the point of interest on the cutting edge perpendicular to the vector V of the speed of the main movement (plane OXY).

The cutting plane is a plane tangent to the cutting edge at the point under consideration and perpendicular to the main plane.

The working plane is a plane passing through the vectors V of the main movement speed and Vs of the feed movement speed (OXZ plane).

Rice. 1.3. Static (a) and kinematic (b) coordinate systems (η – cutting speed angle)

Figure 1.4 shows the static angles of a turning tool.

The main cutting plane is a plane perpendicular to the projection of the main cutting edge onto the main plane.

Auxiliary cutting plane is a plane perpendicular to the projection of the auxiliary cutting edge onto the main plane.

In the main cutting plane there are:

· main rake angle γ – the angle between the front surface and the main plane. Depending on the position of the front surface relative to the main plane, a positive or negative front angle is distinguished (Fig. 1.4). If the front surface coincides with the main plane, then the front angle is zero. Figure 1.4 shows a positive rake angle;

· main rear angle α – the angle between the main rear surface and the cutting plane;

· sharpening angle β – the angle between the main rear and front surfaces of the cutter.

From Figure 1.4 it follows:

γ + β + α = 900 (1.1)

Typically, angles γ and α are specified, and angle β is calculated using formula (1.1).

In the auxiliary cutting plane, the auxiliary clearance angle α1 - this is the angle between the auxiliary clearance surface and the plane passing through the auxiliary cutting edge perpendicular to the main plane.

In the main plane, plan angles are measured:

· main plan angle φ – the angle between the projection of the main cutting edge onto the main plane and the working plane;

· auxiliary plan angle φ1 – the angle between the projection of the auxiliary cutting edge onto the main plane and the working plane;

· vertex angle in plan ε – the angle between the projections of the main and auxiliary cutting edges onto the main plane.

Rice. 1.4. Static turning tool angles:

NN – main cutting plane; N1-N1 – auxiliary cutting plane

From Figure 1.4 it follows:

φ + φ1 + ε = 180º. (1.2)

Usually the angles φ and φ1 are assigned, and the angle ε is determined by formula (1.2).

The inclination angle of the main cutting edge λ is the angle located in the cutting plane between the main cutting edge and the main plane. The angle λ can be positive, zero or negative. The angle λ is zero if the main cutting edge is in the main plane. Figure 1.5b shows a negative angle of inclination of the main cutting edge.

Rice. 1.5. Inclination angle of the main cutting edge λ of a turning cutter [ 3]: a)λ>0, b)λ<0, c)λ = 0

The kinematic angles of a turning tool are formed during the cutting process and depend on the parameters of the cutting mode (mainly on the feed rate).

The kinematic coordinate system is a rectangular coordinate system with the origin at the considered point of the cutting edge, oriented relative to the speed Ve of the resulting cutting movement (Fig. 1.3b).

From Figure 1.3b it follows that the kinematic coordinate system is rotated relative to the static one by an angle η (cutting speed angle). Moreover, the rotation is carried out relative to the y-axis (on the OXZ plane).

Thus, the kinematic and static angles of a turning tool differ only in the position of the coordinate planes of their reference. The definitions of angles are the same; only instead of the word “static” the word “kinematic” is used.

Below are some of the most important definitions.

The kinematic main plane is the plane perpendicular to the velocity vector Ve of the resulting cutting motion.

Kinematic cutting plane is a plane tangent to the main cutting edge and perpendicular to the kinematic main plane.

Kinematic perpendicular angle γк – the angle in the kinematic main cutting plane between the front surface and the kinematic main plane.

Kinematic rear rake angle αk is the angle in the kinematic main cutting plane between the main rear surface and the kinematic cutting plane.

During the cutting process, the kinematic rake angle increases, and the kinematic rear angle decreases compared to static angles (γк < γ; αk < α). Other kinematic angles (angles in plan, angle of inclination of the main cutting edge) will change slightly. These changes in cutting angles are usually not taken into account. The greatest change in kinematic angles occurs for the persistent cutter. So, at Y = 90º, λ = 0º

γк = γ + η1, αк = α – η1(1.3)

where η is the kinematic component equal to the cutting speed angle:

η = arctan = arctan , (1.4)

where Vs is the feed speed, So is the feed per revolution, D is the diameter of the cutting edge point under consideration. At V? The Vs kinematic component can be assumed to be zero. In this case

γк γ, αк α. (1.5)

Changes in kinematic angles compared to static ones must be taken into account if the feed speed Vs is comparable to the speed of the main movement V. A change in the kinematic rear angle is especially dangerous, because it can become zero or even negative, which is unacceptable. So, for example, when cutting threads with large pitches or when drilling small-diameter holes, the clearance corner must be sharpened taking into account the kinematic component.

Sharpening angles of pass-through cutters; static cutter angles are also called sharpening angles, because all angles can be set on the limbs of the three rotary vices of the sharpening machine. The sharpening angles of cutters depend on the properties of the technological system, mainly on rigidity and vibration resistance. Thus, the average value of the front angle γ is 10º. However, if the cutting edge is not cut out, this angle can be increased to 15-20º. To harden the cutting edge, sharpen a hardening chamfer f, with a width approximately equal to the thickness of the cut layer a, at an angle γf = 0 - –5º. A hole is often sharpened on the front surface to ensure curling of the chips. The rear angle α lies within 8-12º.

Smaller values are used for roughing, larger values for finishing. The main plan angle φ varies within 30-90º. Lower values are used in conditions of increased rigidity of the technological system. Angle φ = 90º is recommended for processing non-rigid workpieces. This leads to a decrease in the radial cutting force Py and an increase in machining accuracy. The auxiliary angle φ1 affects the quality of the machined surface.

With high requirements for surface quality, this angle is reduced to 5-10º, and sometimes made zero (for cutters with cleaning cutting edges). The inclination angle of the cutting edge λ affects the direction of chip flow and the strength of the cutting wedge. The angle λ varies within ±5º. At positive angles λ, the chips flow towards the machined surface. For negative λ – in the direction towards the treated surface.

Basic angles of metal turning tools and their purpose

Their accuracy must be ensured down to one or two degrees. To do this, you need to clearly monitor the relationships between the mutual inclinations of the three surfaces already considered.

Main rear

It is marked (α), its role is to reduce friction in the zone of mechanical interaction, and should not be “floating”. You need to understand that its expansion entails a serious reduction in the strength of the tool - at some point, with excessive force, it may simply break - and even worsens the fixation of the shank in the holder, which reduces overall labor safety; in addition, it provokes the appearance of beating and increases the frequency of vibrations, increasing their amplitude, and therefore accelerates wear. And vice versa, its narrowing increases the contact area, as a result of which the accuracy of the technological operation decreases.

Main front

It is written down on the drawings (γ), and it determines both the geometric parameters of the turning cutter and the final dimensions of the part, since it is responsible for reducing the deformation of the layers being removed. If it is narrow, the material is removed quickly, but in a targeted manner. Accordingly, as it expands, the captured space becomes larger, but the force of impact is weakened, which negatively affects overall performance. Also, the thickness of the blade decreases, which is fraught with deterioration in strength and heat dissipation, and more frequent chipping.

It may even be negative - for tools used for stripping under shock load; they are in demand because they absorb pressure with their entire front part, and not just the edge.

cutting

It is designated (δ) and determines the ease and depth of penetration of the device into the thickness of the workpiece material.

Equal to the sum of α and β (which is next in line). In the vast majority of cases, it is performed within 60-100 degrees.

Points

It's labeled on the drawings (β), and it talks about the shape of the top. The duller (wider), the stronger the blade is under conditions of intensive use.

Basic angle of turning tool

It is written as (φ), and it determines both the speed of the technological operation and the physical strength of the tool, which are higher the narrower it is. But it should not be too small, as this is fraught with the occurrence of vibrations due to excess radial forces.

Located between the edge projection and the workpiece feed vector.

Secondary in plan

It is designated (φ1) and has a significant influence on the cleanliness of the part: the wider it is, the more roughness the workpiece has; but remember that as its value decreases, heating increases.

Rear auxiliary

It is marked (α1) and it helps eliminate friction at the point of contact of the blade with the part, preventing an increase in temperature in this area, and therefore protecting against premature wear. As it increases, the strength of the device decreases, and if it goes beyond the recommended limits, this provokes a breakdown.

Apex between cutter edge and flank auxiliary surface

Already from the subtitle it is clear at what intersection point it is measured. And the sharper it is, the better the material is removed, but the faster the contact zone heats up, and the worse the resistance to mechanical damage, and therefore the lower the service life.

Tilt

Denoted by (λ), can be positive, zero or negative. Its indicator determines in which direction the metal (wood, plastic) shavings will flow when performing a technological operation.

For example, if λ < 0, that is, negative, the waste falls in the same direction in which the movement occurs.

Cutting speed, feed rate and depth of cut

Determination of cutting speed, feed rate and chip thickness

The cutting speed of any operation consisting of removing chips or cutting metal is expressed in meters per minute or millimeters per second. For lathes, the cutting speed is equal to the length traversed by the cylindrical (with cylindrical turning) or end (with frontal turning) surface of the product per unit time along the cutter blade. If one could accurately measure the length of chips removed by a cutter in a minute (or second), it would represent the cutting speed.

The feed rate or simply feed (feed) during turning is the amount of movement of the cutter along the workpiece per one revolution of the latter. If, for example, when turning a shaft, the feed is 0.5 mm, this means that when the product makes 100 revolutions, the caliper will move by 0.5 x 100 = 50 mm. The expressions often used are: “large” or “large” feed, “small” or “thin” feed. These expressions make sense only when talking about machines of approximately the same power. It is clear that the same feed can be “small” for a large machine and “large” for a low-power machine.

The cutting depth is the thickness of the metal layer removed by the cutter; This is sometimes also the name for the thickness of the chips removed, although these values are not quite the same due to the deformation of the metal during cutting. Let us assume, for example, that a steel blank with a diameter of 50 mm needs to be turned on a lathe to a diameter of 47 mm in one pass. It is clear that the cutting depth should be (50 - 47) /2 = 1.5 mm.

Time Element

One of the main factors that determines the productivity of a machine or workshop is time. The time at which the metal is removed from the product depends on the time it takes to completely process it. The amount of chips removed depends, in turn, on three elements - depth of cut, feed rate and cutting speed. Let's take turning as an example.

- Let's assume that it is necessary to reduce the diameter of the product from 50 mm to 47 mm, i.e. The cutting depth should be 1.5 mm. If the cutter can take such chips in one pass, then there is no point in making two passes, removing 0.75 mm chips, since turning would require twice as much time. Therefore, the first productivity factor is the depth of cut.

- If, with one revolution of the product, the cutter is fed by 0.4 mm, while it could be given a feed of 0.8 mm, then to pass a certain length, twice the number of revolutions of the product will be required, in other words, all other things being equal, twice as long. Thus, the feed rate is the second factor affecting the processing speed.

- Let the diameter of the product be 50 mm and its rotation speed 65 per minute. The cutting speed is obviously: π ✖ 0.050 ✖ 65 = 10 meters per minute. If the cutter can operate (without abnormally frequent regrinding) at a cutting speed of 20 meters/min, then it is uneconomical to give the machine spindle only 65 rpm. Therefore, the third productivity factor is cutting speed.

The task of productive and economical workshop operation therefore comes down to the skillful selection of cutting speed, feed rate and depth of cut for each job and the selection of the appropriate machine. Successful selection of these elements requires a lot of experience. It’s easier to find them by counting using known formulas.

Measuring the sharpening angles of a turning tool

For maximum accuracy of the result, it must be performed only with specialized manual equipment. It consists of the following parts:

- base - all other elements are attached to it;

- movable template for the stand, adjustable to a convenient position;

- graduated scale making it possible to read readings;

- a locking screw that allows you to mark and store the direction of value changes.

The algorithm for recording the results is as follows:

- place the tool;

- apply its edge;

- look how much it shows - the found figure will be the actual degree.

The method is easy to implement and quite accurate. By the way, taking into account possible differences in the geometry of turning tools, it is recommended to determine the entering angles using equipment equipped with a vernier.

Machining planes

The following types are distinguished:

- the main one – goes parallel to the feed vector, be it longitudinal or transverse;

- cutting - it is formed by the blade (directly) and the area on which it acts (tangentially).

Plus, there are a couple of secants - the main one and the additional one. The direction of the first is through the free point of the tip perpendicular to the projection, the second is created in a similar way and also at a right angle, only through the auxiliary edge.

All obtained values should be recorded, thus maintaining technical documentation, which, if necessary, will help calculate the accuracy, speed, quality of material removal and the approximate service life of the tool, taking into account the intensity of its use.

Types of turning cutters and their purpose

The entire set of devices existing today can be conditionally classified according to a number of characteristics:

- nature of execution - prefabricated (from soldered carbide plates) or solid (made from a monolithic bar);

- technological role – general (for standard operations) and special (for complex profiles);

- blade configuration - straight or curved (for parts with hard-to-reach places), the latter - with a wide variety of curvature shapes;

- processing class – rough (rough, for peeling) and finishing (fine, for finishing);

- feeding feature - to a stationary workpiece (planing) or to a rotating one.

To facilitate classification, the design of a turning tool or its key differences is often reflected in its name. For example, it is immediately clear from a diamond that it is intended for removing layers of superhard materials. The main part of the spring resembles a spiral and slightly cushions under load. We think it’s clear what shape the blade is, what the nature of the impact of the slotting machine seems to be clear without further ado.

Now let’s take a closer look at those popular groups of tools that are used regularly today.

Passing

The most common and more than in demand for external processing of cylindrical parts. Divided into three categories:

- straight - their blade runs strictly parallel to the axis of rotation of the machine equipment;

- bent - their edge is located with a deviation to the left or right (relative to the holder), which makes it possible to significantly facilitate the longitudinal feed;

- persistent - already with two bends, as a result of which the head of the device acquires a ϟ-shaped shape that supports the part and prevents it from bending; This makes them suitable for removing material from non-rigid or long objects.

The differences between the elements and angles of a turning cutter are clearly visible in the diagram below. We will add that all 3 varieties are produced and used on a truly massive scale. Therefore, in order to make reasonable savings without compromising quality, they are most often made non-separable and made from tool grades of steel.

Scoring

Needed to create ledges and trim rotating objects. They are good for their ability to support each of the feeding directions - this allows you to easily form any ledges you want. They are usually prefabricated, since they are not subject to strict reliability requirements.

Cut-off

They belong to the group of groove blades and are distinguished by a specific blade configuration: the main edge of any of them is supplemented by a pair of auxiliary ones (one on each side), which also affect the side planes at the point of contact. It is also made trapezoidal, tapering towards the holder, in order to reduce friction. But the head is strengthened and, if bent upward, is called a cockerel head.

It is important to position such a tool directly opposite the axis of rotation and as close to the chuck as possible, placing the body perpendicular to the part, if necessary, using fluid for lubrication and cooling.

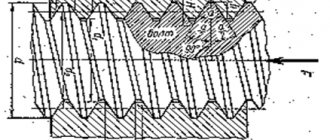

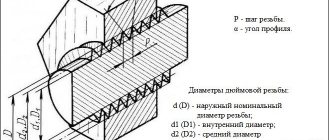

Threading

Maintain high accuracy of alignment of the machine shaft with the workpiece area. Due to the maximum matching of profiles, the reliability of the final result is ensured. Depending on the surface being processed, they are divided into 2 types:

- internal ones are bent, they need to be inserted into a hollow workpiece;

- external ones are straight, with the most convenient access.

In each case, it is important to synchronize the feed with the spindle speed.

Boring

Needed to ensure alignment: such a device is inserted into a cylindrical part and removes excess material until it fits perfectly onto the shaft.

It is worth considering that the operation is performed under conditions of high heat and difficult removal of chips and the use of coolant, so it must be performed at low speeds and without going too deep.

Divided into 2 types:

- persistent - for dead-end holes;

- pass-through - for through.

Their holders can also be of different sizes.

Prefabricated

Here, the structure of a turning cutter consists of an all-metal profile and a removable plate, either soldered (welded) or mechanically attached. In the second case, fixation is carried out using clamps, a threaded connection or eccentrics - the main thing is that it is sufficiently reliable.

To create a durable blade, it is also important to choose the right material. This can be either “classic” tool steel or even harder alloys or, alternatively, powder composites.

Turning cutters. Basics of the metal cutting process

Conditions for high productivity of mechanical cutting tools

The action of cutting tools used on metal machines, in particular turning tools, depends on three main conditions: 1) on the stability of the workpiece, i.e. on the strength of its material and the method of fixing it on the machine; 2) on the strength of the tool, in other words, on its size and method of fastening; 3) on the shape of the cutting part of the tool.

Proper stability and strength of the machine is also, of course, necessary.

The person working on the machine usually has to sharpen and install the cutters required for the job himself, and therefore he must be well acquainted with the requirements for them.

Turning cutters

Forged turning tools

- The scoring cutter (on the right in the figure) is used for end (frontal) turning. Has side and front clearance. The cutting edge is sharpened at such an angle that the cutter does not touch the rear center of the machine when approaching the center of the surface being ground. The cutter has only a transverse slope. There is no longitudinal slope.

- The sharp-nosed incisor (right in the figure) is now rarely used, as it has been replaced by “normal” Taylor incisors.

- Curved, sharp-nosed incisor (left in the picture). The ends of most types of incisors often bend to the right or left. For some jobs, eg when processing shoulders, this is convenient.

- Normal through cutter. This type of cutter was developed by Taylor as a result of many years of experience, which showed that this form of cutter is the most advantageous for turning. The average longitudinal slope is 8°, the average transverse slope is 14°. In what follows, for brevity, this incisor is called “normal.”

- Cut-off cutter. Discussed in detail in §§ 147 and 148.

- Round-nosed incisor. The cutting edge is rounded to an arbitrary radius, which distinguishes it from a normal cutter. Used for cutting semicircular grooves, fillets (fillets), shoulders, etc.

- Brass cutter. It is sharpened like a type 6 cutter, the tip of which is rounded to a small radius. It has neither longitudinal nor transverse slope, in order to avoid cutting the cutter into soft brass.

- Wide finishing cutter. Very useful for aligning front centers and turning short tapers. It is often used with large feeds to remove the finest finishing chips from cast iron. It has no longitudinal slope.

- Spring cutter. For turning wide shoulders and other shaped work where it is necessary to remove wide chips, as well as for finishing cast iron and steel (with water). When this cutter springs, its cutting edge moves away from the surface being processed.

- Flat (blunt-nosed) incisor. Very convenient for frontal turning of large diameter ends when a lot of metal needs to be removed. Feed from the circumference to the center. It is also used for finishing steel, with large feeds and small depths of cut (“thin chips”). For the cleanest finish, cool with water and soda. It has only a longitudinal slope, no transverse one. Lateral clearance - on both sides, therefore, can work as a right-handed or left-handed cutter.

- Centering cutter (cutter-drill). It is sharpened at an angle of 120°—corresponding to the angle of the tip of the twist drill. Works similar to the perk. The gap of both cutting ribs is directed in opposite directions. Used to mark the center of holes to be drilled with a twist drill.

- Cutter for cutting screw threads. Its toe is sharpened exactly according to the thread profile. For details, see chap. 16,

- Boring cutter. See § 162.

A lathe is used for a wide variety of work - turning, threading, boring holes, etc., and each operation requires specially shaped cutters. In fig. 62 shows various types of forged turning tools. However, recently they are gradually being replaced by more economical cutters of small sizes, inserted into special holders (see Fig. 66).

The basic principles underlying the choice of cutter sharpening angles, clearance angles, etc., set out in further paragraphs, are common to all metal cutting tools. Anyone who knows why a turning cutter is sharpened this way and not another, knows why certain bevel angles are chosen, etc., and knows how to hold the cutter on a grinding wheel while sharpening, will quickly learn how to properly sharpen other tools and understand which they must have a form.

The material from which the cutters are made must be sufficiently hard and tough to withstand the forces exerted on the cutter during cutting. Therefore, metal cutting tools are made of steel, hardened and then tempered.

Cutter point angle

The action of each cutting tool is similar to the action of a wedge, which pushes the particles of material apart. In relation to the cutters, the angle of the wedge formed by its edges is called the point angle of the cutter or, in short, the angle of the cutter (see Fig. 63).

The harder the material being processed, the stronger the cutter blade should be, i.e. the greater the angle of its sharpening should be. The angle of the cutter, suitable for wood, is not suitable for processing iron or steel, since its value will soon change due to the fact that the cutting edge will round off (“give in”) under the influence of the high cutting resistance of the metal. For metal cutters, the sharpening angle is made from 60° to 80°, depending on the hardness of the metal being processed.

Clearance angles

The action of a cutter removing shavings from metal is similar to the action of a knife used to peel an apple. The chips being removed rub against one of the faces forming the wedge, while the other face should not touch the product and therefore makes a certain small angle with it, the so-called. side clearance angle (Fig. 63). This angle should not, generally speaking, be more than 6°, since as it increases, the angle of the cutter decreases, therefore, the cutter will have to be sharpened more often.

The action of the cutting resistance force on the turning cutter is directed tangentially to the circumference of the workpiece being turned at the point of contact of the cutter with the workpiece (see Fig. 64). Since the top is the so-called. the toe of the cutter is usually installed at the height of the center line or slightly above it, then in order to avoid friction between the product and the front edge of the cutter, this face is given some slope. The angle between the rake face and the cutting direction is called the rake clearance angle or, in short, the clearance angle. Its usual value is about 10°. However, it depends on the height of the cutter in the support.

Cutting edge slope angles

In order to obtain the required sharpening angle, it is necessary to grind off the upper (cutting) edge of the cutter so that it has both a longitudinal slope - from the cutting edge back - and a lateral slope - from the cutting edge in the direction opposite to the feed. Otherwise, the sharpening angle of the cutter will not be sharp enough. The slope from the toe of the cutter back is called the longitudinal slope angle of the cutting edge, and the lateral slope is called its transverse slope angle (Fig. 65). The magnitude of these angles depends, naturally, on what sharpening angle is required, since the greater the slope, the smaller the angle of the cutter, i.e. the sharper the cutting wedge formed by its edges. For turning cast iron and tool carbon steel, the cutter angle should average about 70°, for mild semi-finished steel - 60°. When sharpening a cutter, first remove the clearance angle, then the slope angles, in such a way as to obtain the sharpening angle required for processing the material.

Compared to steel, brass is a soft metal and therefore, to process it, it would not be necessary to give the cutter the same large sharpening angle as a cutter for steel. However, in reality, bevel angles are usually not sharpened on brass cutters, since sharp cutters tend to “eat in”, i.e. delve into soft material.

Tool holders

High speed steel cutters are approximately twice as productive as carbon tool steel cutters. Therefore, recently turning cutters, as well as other cutting tools for metal processing, have been made mainly from high-speed steel. Since it is much more expensive than carbon steel, various holders have become widespread, in which a small piece of high-speed steel, sharpened accordingly, is securely fixed. This results in savings not only on the cost of steel, but also on the costs of forging cutters.

In fig. Figure 66 shows several common types of tool holders. In fig. 67 are shown on the right - inserted turning cutters (plates) made of high-speed steel, sharpened for various jobs, on the left - the operation of these cutters mounted in holders.

Sharpening cutters

A properly sharpened cutter, when used under normal conditions, remains sharp for quite a long time. As soon as it shows signs of dullness, it is necessary to immediately resharpen it, otherwise not only the cutter will suffer, but also the product being processed by it. A dull cutter does not so much cut metal as tear out particles of it, so the surface being processed cannot be smooth. One of the main factors in the productive operation of the machine is a sharply sharpened cutter.

It must be remembered that improper sharpening of cutters places a heavy burden on the cost of products simply by the cost of excessively worn material of cutters and grinding wheels. Where should the cutter be sharpened - from above, from the front, from the side, or from all sides a little? It is impossible to give definite rules in this regard, and when sharpening a cutter you should proceed from the work for which it is intended. The method of sharpening largely depends on how long the cutter should work without regrinding and how long it should last in total.

When sharpening a carbon steel cutter, you should not press it too hard against the grinding wheel, otherwise the cutting edge will heat up (usually it turns blue) and release, i.e. its hardening will be lost. It is preferable to use a wet sharpener. High-speed steel cutters do not lose their hardening so easily, but sometimes, if there is not enough water, cracks appear on their surface. Therefore, firstly, you should not spare water, and secondly, you should not press too hard on the cutter while sharpening.

Do not keep the cutter in one place, move it so that it is pressed against different places on the cylindrical surface of the circle. In this case, the cutter must be gradually rotated, as shown in Fig. 68, i.e., so that it takes sequential positions a, b, c.

Small cutters should not be sharpened in holders, because, firstly, it is inconvenient, and secondly, the end of the holder can be ground down at the same time. In fig. 69 shows how to hold such cutters while sharpening.

It is recommended for a beginner to practice first on small pieces of simple ornamental steel of a suitable shape and only then proceed to sharpening high-speed steel insert cutters. At first, obtaining the correct clearance angle on such a cutter by sharpening presents some difficulties, since for work the cutter is inserted into the holder at a known angle. Therefore, at first, while there is no skill, it is best to use a template. In cases where it is necessary to obtain a relief angle of 10°, it is convenient to use a template for turning centers (see Fig. 85), the angle of which is 60°, since in most holders the cutter is fixed so that its upper edge is 20° with the horizontal (Fig. 70). If the cutter angle is other than 60°, it is not difficult to cut a corresponding template from a piece of sheet metal.

What not to do when sharpening a cutter

- Don't sharpen the cutter at random; be aware of where and how much metal needs to be removed.

- Hold the cutter firmly and confidently.

- Do not press the cutter to the circle with your left hand; hold it properly, that's the easiest thing.

- Don't skimp on water.

- Do not keep the cutter in one place on the grinding wheel all the time, otherwise you will cut a groove on it.

- If possible, do not use a circle that has lost its correct cylindrical shape or whose surface is heavily chipped.

- Do not sharpen a cutter on the end surface of a circle unless necessary: when you need to sharpen on the end, its surface will no longer be flat, but scratched by you or someone else.

- Do not rest the insert cutters on the tool rest: hold them in your left hand and rest your hand on the tool rest.

- Do not move the tool rest further than 1.5-2 mm from the grinding wheel.

- Do not round the tip of a thread cutter or turn a round nose cutter into a thread cutter: this is a waste of material and time.

Main rules for choosing a tool

- Decide in advance why it is needed and in what modes you plan to use it.

- Consider the production purpose - the capabilities of something that is great for one-time or rare use in a garage or personal workshop are unlikely to be enough for industry, with its mass production.

- Focus not on the price (too low a cost should even scare you away), but on durability, which you can see in the table of turning tools.

- Pay attention to whether the blade can be edited - if it lasts comparatively longer, but cannot be re-sharpened and must be replaced after the first dullness, you will end up spending more.

When sharpening is required

There are two cases in which it is necessary:

- the edge has worn out and lost its useful qualities;

- a new tool is released.

In both cases, it must be carried out, otherwise you simply will not be able to process the part with the required accuracy and ensure the required surface quality. Plus, during the process, the workpiece will probably additionally suffer from beating and vibration.

So be sure to do it when it is required, that is, regularly and in a timely manner; Thus, you will provide the blade with the necessary sharpness and reliability, which will have a positive impact on the overall level of safety of technological operations on the machine.

Rules for sharpening

- use only a suitable abrasive wheel;

- work with gloves and a mask (goggles), do not forget about protection;

- clean all the main parts and elements of the turning cutter from dust and dirt and fix it in the tool rest, adjusting the position;

- first of all, remove the rear corners and only after measuring and checking them, proceed to the front ones;

- do not neglect fine-tuning - it is needed in every area where even the smallest irregularities are observed.

Tools used

The base in this case is a pair of grinding wheels: one is made of green silicon carbide, the other is made of electrocorundum. The first is suitable for materials with a high degree of hardness, the second for softer tool steels.

You will also need a grinding machine for finishing operations. Since the latter are considered thin, the equipment must operate at low speeds with the lowest possible level of runout. A diamond or CBN surface is suitable as an abrasive.

Turning tool geometry

Every turner should know the geometry of a turning tool and the ability to sharpen it. A lot depends on the geometry and sharpening of the cutter, for example, the quality of the manufactured product, the durability of the cutter from the moment of sharpening until the next resharpening, chip formation and much more.

The cutter consists of:

Heads

— (carbide plate or high-speed working (cutting) part of the cutter).

Body or rod

— (ordinary steel is often used), intended for fastening the cutter.

Support surface

– serves for fastening the cutter in the cutter holder and in a horizontal position.

Front surface

– serves to collect chips. The rake surface can be negative (the tip of the cutter looks up) and positive (the tip of the cutter looks down, that is, the tip is below the main cutting edge of the cutter) depending on the type of processing.

Main cutting edge

– used for cutting material.

Secondary cutting edge

– with the intersection of the main cutting edge they form the tip of the cutter.

Blade top

- this is the point of contact between the material being processed and the cutting tool.

Main back surface

– serves to support the plate (cutter head). The wear resistance of the cutter depends on the angle of the main flank surface.

Auxiliary back surface

– designed for free movement of the cutting tool along the surface being processed.

Cutter geometry

And so, having figured out what the cutter consists of, we move directly to the geometry of the cutter.

Along the front surface of the blade

Aγ chips come off.

Main rear surface of the blade

Aα faces the workpiece surface being processed.

Main and auxiliary cutting edges

formed by the intersection of the front surface with the back.

Main plane

Рυ is a coordinate plane drawn through the point of interest on the cutting edge perpendicular to the direction of the speed of the main cutting movement at this point.

Cutting plane

Pn is a coordinate plane tangent to the cutting edge at the point under consideration and perpendicular to the main plane.

Main cutting plane

Рτ coordinate plane perpendicular to the line of intersection of the main plane and the cutting plane.

Rake cutting angle

γ is the angle in the cutting plane between the front surface of the blade and the main plane.

The main rake angle

γ will be the angle in the main cutting plane. The size of the rake angle determines the flow of chips.

Back angle

α is the angle in the cutting plane between the back surface of the blade and the cutting plane, and in the main cutting plane this angle

is called the main relief angle

. An increase in the clearance angle leads to a decrease in the sharpening angle β, and consequently to a weakening of the cutting edge, chipping and premature failure of the tool.

How to attach a cutter to a machine

It is installed on the caliper carriage (moving element) and fixed with a holder, which can be either single- or multi-position. Attention, its position must be adjusted with maximum accuracy: it must be placed parallel and perpendicular at the same time. The edge is strictly opposite the shaft axis, take time to adjust the height. Steel plates will help with centering.

Also, gaps or backlash should not be allowed, which can lead to the tool becoming loose (over time and under loads), and therefore to a decrease in the accuracy of machining parts. Therefore, the fasteners must be rigid.

We explained in detail what parts a turning cutter consists of, what angles it has and why they are needed. Now you probably understand how important it is to maintain its profile geometry in the recommended condition and, if necessary, you can sharpen it. Well, you will always find a machine for this in the Izhevsk catalog - contact us and buy high-quality equipment.