The profession of a turner is gaining increasing popularity among working specialties.

The invention of computer-controlled machines turned the process into a unique art of engineering.

There are more and more young specialists who are ready to expand their theoretical knowledge and master the practical side of turning production.

Basics for Beginners

Turning specialists produce parts for various machines and mechanisms. Their work involves processing workpieces using the cutting method, during which a layer of material of a certain thickness is removed in the form of chips.

All work is carried out on machines that process various parts using cutters and other tools. When starting a task, the turner clearly sees the sequence of work, the method of manufacturing and processing.

In this case, the specialist must consider the possibility of a certain type of fixation of the workpiece, select devices and tools, and also select a cutting mode. This set of measures is reflected in the content of the production technology process.

Evolution

Oddly enough, humanity has moved along the path of modernizing lathes very slowly. Only by the middle of the 16th century did machines for processing metal with a foot drive appear, and a little later - with a water drive. But the master's rapidly weakening hand still held the cutter . The real problem was solving the following problems:

- production of metal parts of complex geometric shapes;

- applying threads, both external and especially internal;

- creation of gear wheels, so necessary in those days in a variety of industries.

The industrial and technological revolution that occurred in Europe (mainly in Great Britain) in the second half of the 18th century led to a real breakthrough in the evolution of metal turning. More and more metal parts for a wide variety of purposes were required, the demand for them increased exponentially, and the industry developed at an accelerated pace.

It was then that much more advanced machines were created , where the cutting tool could move mechanically, regardless of the physical capabilities of the operator. And the invention of the steam engine made it possible to create lathes capable of processing large parts and quickly removing thick layers of material from the body of the workpiece, making deep grooves, cutting threads with different pitches and depths.

The first prototype of a modern lathe, containing all the components that we are accustomed to seeing in it today, was finally finalized by its inventor, the Englishman Henry Maudsley, exactly in 1800. After which the Americans got down to business, achieving complete mechanization of the turning process and significantly modernizing the design of the machine, making it universal for various types of work.

Lathe cutting tool

A cutting tool is a piece of equipment that is used to shape surfaces by separating excess material from a workpiece.

- Cutter . Blade for processing with rotational and translational movements, while movement can be carried out in several directions. Cutters can be boring, threading, scoring, shaping, cutting and grooving.

- Milling cutter A tool with a blade that produces rotational movements without changing the radius. Provides one feed movement with a direction that does not coincide with the axis of rotation.

- Axial tool . Performs rotation and feed movement that occurs along the axis. Axial tools include drill, countersink, reamer, countersink, counterbore, tap and die.

- Broach. A multi-blade tool designed to form a part using rotary and translational movements without feed.

- Hacksaw blade . A strip with many blade teeth used for cutting and cutting grooves.

- Shever . A device for finishing wheels with teeth. There are worm and rack shavers.

Depending on the method of fastening, tools can be mounted or tail-mounted. According to their shape, they are divided into disk, conical, cylindrical and lamellar.

Basic principles of turning

For beginners, turning seems like a dark forest full of incomprehensible terms. Although in fact the essence of the turning process is quite simple. The main tool of a lathe is a machine in which the clamped part rotates at high speed, and the cutting element carries out processing processes on wood, metal or plastic.

A wide variety of materials can be processed. The most popular material in turning is undoubtedly steel.

But historically, everything began with wood processing; 12 still operating lathes of Peter the Great are still preserved in the Hermitage collection. The Russian Tsar was fond of crafts, but turning wooden and metal parts was his favorite pastime.

Modern machines, of course, are much more complex than the first wooden models. But the basic principle remains the same, despite the advent of an electric motor instead of a manual drive and a multiple increase in size.

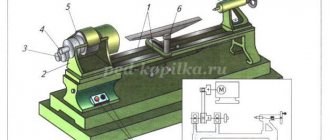

A lathe consists of several basic elements:

- the frame on which all other elements are attached;

- headstock with motor and spindle for fixing the part;

- a caliper moving along guides in the frame, with a cutter located on it;

- tailstock with locking dimensional parts.

The part is clamped, the drive imparts rotation to it and, by adjusting the position of the cutting or milling tool, the material is processed.

Lathe device

Standard turning operations that are used in both metalworking and woodworking are:

- turning of spheres, conical and cylindrical workpieces;

- trimming;

- cutting grooves inside and outside parts;

- cutting;

- alignment;

- drilling;

- thread cutting, external and internal;

- countersinking.

Each operation requires a special tool, which is selected in accordance with the material, the required processing accuracy and the design features of the machine.

Types of equipment for metal work

Any type of lathe involves cutting, but some devices may have additional functions and capabilities.

Screw-cutting lathe - used for turning profiles, producing grooves and recesses, drilling holes and making threads in various ways.

Turning and milling machine - used for turning a workpiece in a continuous way, as well as producing threads, chamfering, cutting straight and curved grooves.

Vertical lathe - it is used to process large diameter workpieces.

Turret lathe - used to produce parts from calibrated rods.

A CNC machine is equipment that performs many operations specified by the program. The specialist’s job is to observe, adjust and remove finished products.

Equipment classification

The types of this equipment are divided based on several parameters, which include:

- The maximum diameter of this part.

- The maximum length of a part that can be processed on this equipment.

- Weight of equipment.

The length of the part that is processed on this equipment of one model or another completely depends on the distance between its centers. When considering the diameter of the workpiece that a certain type of lathe can process, this parameter ranges from 100 to 4 thousand millimeters. It is also necessary to take into account the fact that equipment models that can process elements of the same diameter may have different lengths of the processed workpiece.

Universal lathes can have different weights. According to this parameter, equipment is divided into the following categories:

- Lightweight machines. Their weight does not exceed 0.5 tons. It processes elements with a diameter of 100-200 millimeters.

- The weight of the equipment does not exceed 4 tons. The permissible diameter of processing elements is 250−500 millimeters.

- Equipment weight up to 15 tons. The diameter of the processed elements ranges from 600-1250 millimeters.

- The machines are heavy. Their weight can reach 400 tons. The diameter of the processed elements is 1600-4000 millimeters.

Turner ranks

In the process of professional growth, a turner can receive a higher rank, which requires knowledge, improvement of work technique and tool proficiency.

- 1st category - given to a student who does not have professional skills;

- 2nd category - acquired by a specialist who has experience in processing parts of 12–14 qualifications on universal machines;

- 3rd category - the employee is able to process parts on machines with 8–11 qualifications and has confirmed knowledge of setting up equipment, sharpening tools and designing a plasma torch;

- 4th category - a turner who has knowledge of special devices, heat treatment rules, calibration of profiles and preparation of cutting tools for operation;

- 5th category - a specialist who has the skills to process complex parts up to 6–7 qualifications, the correct sequence of checking lathes and adjusting tools;

- 6th category is the highest mark, reflecting the professional training of the employee, his knowledge and practical skills in working, servicing and setting up machines.

To obtain the next rank, a turner must undergo training and pass the appropriate exam.

Technological instructions for working on a machine - Machine tools, welding, metalworking

The workplace at a lathe is a high-risk place. Workpieces and machine parts rotating at enormous speed, flying chips, and a voltage of 380 Volts pose a threat to human life and health. Therefore, safety rules when working on wood and metal are the first thing a worker should know.

Download safety instructions when working on lathes

General provisions

- Adults who have studied the necessary instructions and received instructions: introductory and on-the-job are allowed to perform turning work.

- The turner must be provided with special clothing: a robe or suit, boots, glasses.

- The worker must perform only those tasks assigned by the master.

- Work should be carried out in clean, repaired overalls on serviceable machines that have access to them.

- The workplace must be clean and orderly.

- It is prohibited to block passages.

- Eating and smoking are permitted in specially designated areas at certain times.

- It is prohibited to perform work under the influence of drugs that reduce the reaction rate (alcohol, drugs, medicines).

- The turner must observe the rules of personal hygiene.

Safety precautions before starting work

Before operating the lathe, you must adhere to the following safety rules:

Turner overalls:

- Clothes must be fully buttoned, with no hanging parts. Particular attention should be paid to sleeves, the cuffs of which should fit snugly to the limbs;

- shoes should be tight-fitting, closed and have a hard sole;

- the headdress should cover the hair tightly and have no hanging ends;

- Glasses must be the required size, transparent, with clear, undamaged lenses.

- Machine readiness:

- availability of grounding, protective shields, fences, casings;

- availability of the necessary tools, as well as hooks for removing chips, tubes and hoses for supplying coolant, shields to reflect emulsion splashes;

- absence of anything in the chuck, trough or on the machine (chips, blanks, emulsions).

- adjust the lighting on the machine.

- Test run:

- make sure that the launch does not threaten anyone's safety;

- at idle speed, check the functionality of all unit controls, lubrication and cooling systems.

- Constant control:

- each start-up of the machine should not threaten anyone’s safety;

- Avoid splashing of oil and coolant;

- control that all handles and switches are in the neutral position.

TB during turning work

When working on a lathe, you must follow the following safety rules:

- Monitor the reliable fastening of the workpiece, cutting tool and the location of the socket wrench in a specially designated place.

- Workpieces weighing more than 16 kg for men and workpieces weighing more than 10 kg for women are allowed to be installed using special lifting devices.

- Monitor the timely removal of chips from the cutting zone using chip breakers, special hooks, and brushes.

- Monitor the drainage of coolant from the machine trough.

- Make sure the center of the tailstock is lubricated.

- Prohibited:

- transmit something through a working machine;

- remove chips by hand or with a jet of air;

- support and catch the workpiece being cut with your hands;

- stop the cartridge using hands or objects;

- clean a working machine;

- put any objects on the machine;

- work in mittens or gloves;

- lean against the machine;

- measure a rotating part;

- lubricate parts and centers with a rag;

- move away from the working machine.

- Necessary:

- use tailstock centers if the length of the part exceeds 2 workpiece diameters or when working at high speeds;

- use steady rests if the length of the part exceeds twelve times the diameter of the workpiece or when working at high speeds;

- use special sharpened cutters when processing viscous metals;

- use chip guards when cutting brittle metals;

- Use only special shims for an appropriately sized cutter.

How to become a professional

Turning can be studied throughout your life, since in addition to the theoretical part, a specialist must understand modern technology.

Progress does not stand still, which means there will always be an object of study. In addition, new samples of composite and polymer compounds are appearing among the materials being processed.

To master a profession, there are educational institutions and courses where highly qualified specialists pass on their experience to young students.

Information can also be gleaned from the Internet, where a variety of literature on turning is openly available.

The work requires good physical training, since very often turners suffer from a number of diseases. We can say that excellent health, advanced training courses and the ability to set up equipment will help you achieve the desired heights in your career.