Do-it-yourself belt sander from a drill + photo and video

Most amateur craftsmen for small amounts of grinding (which is required from time to time) use grinding machines that they make with their own hands.

As an abrasive tool, such devices usually use discs and belts made of fabric, as well as sanding paper. This can be explained by the fact that they are inexpensive and can be easily changed if you need to sand at a different grit level.

In addition to grinding metals, wood and plastic, such homemade products can quite successfully sharpen plumbing/carpentry tools, as well as improve drills and turning cutters.

Making a belt sander with your own hands

Making a belt sander yourself is not at all difficult; you need to complete the following steps:

- select suitable materials and parts;

- create

a reliable basis for securing the tool; - install a suitable tabletop;

- secure the vertical posts with tensioner and drum;

- mount the motor and drums;

- secure with sanding tape.

To process fairly large parts and elements, it is necessary to make a large copy of a serial grinder. For example, if you take an electric motor with a power of 2 kW or more powerful with a rotor speed of 1500 rpm, then you don’t need to install a gearbox. The power of such an engine is quite enough to rotate a drum about 20 cm in diameter and process parts of about 2 m.

You can also use an electric motor from an old washing machine. In this case, the frame is made from a thick sheet of iron, preparing a place for installing the motor and carefully securing it with bolts to eliminate vibration. The design of such a machine consists of 2 drums, one of which is fixed, and the second can be tensioned and rotates on bearings around an axis. It is advisable to make the base for the machine from metal or several sheets of thick plywood. The drums are made on a lathe from chipboard. The tape is cut from sandpaper sheets about 20 cm wide and secured to the frame. The larger the table size, the larger the parts can be stacked and processed in the future. Drawings of finished products can be found online.

Features of the use of machines

Working with a drill while holding the tool only with your hands significantly limits its capabilities. The weight of the tool and vibration do not allow the drill to be firmly fixed in the desired position. But if you think through and design a special frame where it will be firmly attached, then an ordinary hand drill will turn into professional, almost industrial equipment.

From a drill you can make the following types of machines yourself:

- drilling;

- turning;

- milling;

- grinding.

Moreover, after replacing the working or cutting element, the machines become interchangeable. They provide a two-in-one function, for example, a drilling and milling machine, a lathe and a grinder. It all depends on the installation conditions and the needs of the owner.

The power of the machines and their capabilities will depend on the type of drill (the power of its electric motor), the method of fastening, since in this case it is the main working part of the equipment.

How to make a grinder from a drill

There are various devices for manual and mechanized grinding. All of them can be divided into two main types.

- Tools that directly perform the processing of the part are hand-held devices, which include sanding blocks (pads, whetstones) and grinding attachments for a drill

or grinder, which are all kinds of support plates and drums. - Devices that ensure the required position of the grinding tool relative to the part - guides, supporting surfaces, etc.

A separate type includes devices for dust removal, which, due to the abundance and harmfulness of grinding dust, should also not be neglected.

Preparing for work

Preparation for work is important, since it is at this stage that the full composition of the required tools, mechanisms, materials, fittings and fasteners is determined. It is at this stage that you need to make sure that you have everything you need so as not to interrupt or stop the work. Therefore, before starting, we recommend that you review the material in full and make sure that everything is available.

Tools

During the work you will need some hand and power tools, let's check the list:

- Tool for straight sawing: Circular saw or sawing machine.

- Jigsaw.

- Screwdriver.

- Additional hand tools: hammer, clamps, square, screwdriver, marking pencil, etc.

Materials, fittings and fasteners

To make a drill-based grinding machine you will need:

- Plywood 15 mm thick. Chipboard can also be used.

- Wing nut – 2 pcs.;

- M6 bolt and self-tapping screws.

Main structural elements

The main structural elements of the grinding machine are:

- Base:

- Frame;

- Spindle box;

- Sanding table;

- Drill (or screwdriver);

Making a grinder from a grinder

Many may say that the “grinder” is the same as an angle grinder

, however, there are some subtleties hidden here.

It should be borne in mind that the angle grinder has very high speeds and often quite a decent weight. To polish a surface with a grinder, you need to have considerable experience in this matter and use special polishing discs and circles. The grinder has much lower engine speed and weight.

To operate a factory grinding machine, no specific experience or skill is required. READ How to Unscrew a Drill Without a Key Video

Do it yourself

You can make a good grinder from a grinder, which is not inferior in its parameters to the factory machine, only by modifying its electrical circuit, by installing the regulator at lower speeds and by using special grinding attachments.

Original idea

This design is very versatile, since its basic part (base and spindle box) is the working part of several other devices described in the following articles:

- DIY wood lathe. Description, drawing, video.

- Do-it-yourself thicknesser machine: drawings, photos and videos.

- Homemade grinding machine from a drill (screwdriver). Description, drawings, video.

These articles contain photos and videos of do-it-yourself machines.

| Turning | Thicknesser | Grinding |

Thus, part of the structure of the described machine can be used for the manufacture and subsequent assembly of three more additional devices. If necessary, having all the components, you can assemble the devices you need at the moment at your own discretion.

The basic structure of a grinding machine

Without thorough knowledge of the design of grinding machines, it is impossible to assemble a high-quality device with your own hands. Before moving on to the structure, let's get acquainted with the most common types of grinders:

- Corner. Simply put, Bulgarian. Consumables are discs. Grinding wheels are designed for surface grinding. Pressure adjustment is carried out manually.

- Tape. Surface treatment is carried out with a sanding belt. Suitable for working on flat surfaces only.

- Delta sander. For processing products with a curved structure.

- Vibrating. Ideal for finishing smooth surfaces.

In addition to the above, there are several more devices that are less common:

Regardless of whether the device is factory-made or self-assembled, the main design elements are:

- Drive unit. The performance of the device depends on its power. Do-it-yourself devices use an electric drive, but there are pneumatic homemade ones powered by a compressor.

- Gearbox. Transmits torque from the drive to the working tool. The basic part of the gearbox is the spindle.

The gearbox is an integral part of tools such as a grinder or drill

. Some models, especially those assembled with your own hands, can do without it.

- Working platform. An abrasive material is attached to it. For this you can use circles, tapes, disks.

- Frame. Protects the structure from mechanical damage and dust, which is why many factory models are equipped with dust collection systems. The materials used to make a device with your own hands, as a rule, are not able to compete with high-quality polymers that are used in the production of professional tools.

- Control system. Includes turning off the power, as well as adjusting the abrasive speed.

Homemade grinder from a computer hard drive

From an old hard drive you can assemble a small grinding device, the main advantage of which will be the complete absence of investments, with the exception of the cost of abrasive wheels. The DIY manufacturing process is as follows:

Useful homemade attachment for DRILL and SCREWDRIVERS with your own hands

- Open the case and remove all elements located next to the magnetic disk.

- According to the size of the upper part of the drive, cut out a circle of sandpaper of the desired grit.

- Using double-sided tape, secure the paper to the surface of the disk.

- We make a casing that protects from dust or abrasive grain.

- To start the design, the hard drive must be connected to the computer's power supply.

This DIY device will allow you to do small jobs, such as grinding contacts, sharpening files or tweezers. The rotation speed depends on the factory settings. The average value is 7200 rpm.

A homemade sander will not have the attractive appearance of a factory tool, but good performance and low assembly costs compensate for this disadvantage.

Have you tried assembling a grinding machine with your own hands? What did you use as a drive? Share your invention experience in the comments.

When work with a wooden surface comes to an end, the final sanding stage begins. To perform grinding without burrs, scratches, and to beautifully round sharp corners of any part, you need to use a wood sander. This tool will help you perform professional grinding even for a beginner who picks up the machine for the first time. If you wish, you can do it

grinding machine yourself, using only available tools.

Do-it-yourself grinder from an angle grinder

As the name suggests, the grinder is designed for grinding. Cleaning discs successfully cope with rough work: removing old paint, removing metal deposits or traces of corrosion. For finer cleaning, special attachments made from sanding sheets of various grain sizes are sold.

Models for domestic use operate in one mode, and the number of revolutions reaches 15 thousand per minute with an average of 11 thousand. This speed is great for sawing materials, but it is too high for sanding work.

The grinder's motor has excess power. For polishing, 300–400 W will be enough.

A grinder made from an angle grinder will have more weight compared to a factory tool, but it is possible to adapt a homemade one for yourself, which will increase comfort when grinding.

READ How to Disassemble Makita 2450 Rotary Hammer Video

For an angle grinder, you can make a simple attachment that will turn the device into a miniature belt grinder. In this case, work is carried out without a protective casing.

If you do not want to use devices, you can adjust the number of engine revolutions. Independent modernization of the circuit will require specialized knowledge in electrical engineering.

On professional devices, you can set the number of revolutions manually, however, their cost starts from $200.

Design

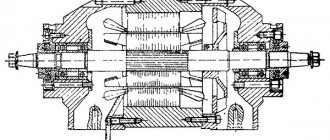

There is nothing particularly complicated in the design of a belt grinder. The device consists of a motor, drive and guide rollers. A sanding or roughing belt of the required grain size is passed through them.

When the engine is turned on, the drive roller mounted on its shaft begins to rotate, and through the tensioned working belt, the rotation is transmitted to the guide rollers. By pressing the part to be processed in the working area against the belt, the operator performs the required operation, changing the position of the workpiece relative to the surface of the belt if necessary.

By adjusting the distance between the guide rollers, it is possible to process surfaces with defects of different depths. During prolonged use, the sanding belt may not stretch much. To compensate for possible slack, a tension mechanism is provided in the design on one of the rollers. Typically, such a function is assigned to a roller located at the same distance between the leader and the slave.

The grinding machine is supplied with a support table, which also serves as a surface for fixing the workpiece. As a rule, such a table should be able to rotate 90 degrees about one axis. In this case, it is possible to process two perpendicularly located planes without reinstalling the part on the support table.

Of course, a grinder control panel is required! For safety reasons, it is recommended to mount it on the machine frame in close proximity to the operator’s working area. Portable machines are equipped with a stand made of durable steel with mounting holes on the base, allowing you to fix the unit on a wooden surface.

If you look at the design details, you can immediately notice some visual instability of the assembled grinding device. The overhang of the side dimensions of the installed rollers significantly exceeds the supporting surface on the base. In addition, the absence of a support table makes it difficult to effectively process relatively large surfaces, and holding the part in a canopy is inconvenient and quite dangerous.

An increased length of the working belt leads to additional losses due to friction. It is necessary to use a higher power power unit in the drive, and this increases energy costs. The tension unit is simple and functional. Adjusting the tension is a matter of seconds. The machine comes with replaceable sanding attachments, which can be used for sanding even on internal surfaces. Despite this, the cost is 100 thousand rubles. makes me think.

Option for manufacturing a band press

To assemble a belt-type grinding machine, you will need an electric motor, a durable frame and rollers on which the belt will rotate. Be sure to have a drawing or detailed diagram on hand indicating all components and dimensions. We offer an example of a diagram of a machine with a wooden bed in the photo.

The following photo shows the finished design of the machine. In this embodiment, the arrangement of the three working shafts is designed so that the moving belt forms a vertical grinding plane. A belt drive is used as a drive.

The machine design can use four rollers. One of them is the leading one and is mounted directly on the electric motor shaft. The photo shows an example of such a design. Installing four rollers allows you to get two grinding planes: horizontal and vertical.

The wooden frame smoothes out the vibration of a running electric motor, however, wood is short-lived. It is optimal to cut a workpiece measuring 50x18 cm from steel 2 cm thick. One edge of the frame is made perfectly flat in order to attach a platform for the electric motor to it. For the next part, you will need steel 1 cm thick. The area is cut out 18x16 cm in size, and then secured to the frame with a bolted connection.

A large electric motor power is not needed for such a machine. A motor from an old washing machine will do. If greater productivity of the grinding machine is required, then it is advisable to find an electric motor with a shaft speed of 1500 rpm with a power of 2.5 to 3 kW. High-quality grinding can be achieved by moving the sanding belt at a speed of 20 m/s. To achieve such parameters, drums with a diameter of 20 cm are used. If you do

thinner rollers, you will have to reduce the speed of the motor shaft using a gearbox, which is extremely inconvenient.

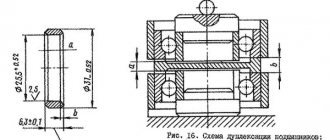

The drive drum can be mounted on the motor shaft. If this option is not suitable, a separate unit is made. The drive shaft with bearings is fixed to the frame. A belt drive pulley is installed at this end, and a drive drum is installed at the other end. Then a pulley is also mounted on the electric motor shaft and a V-belt is put on. The driven rollers rotate freely on bearings.

Belt drive pulleys will have to be turned on a lathe, but rollers can be made

from square pieces of chipboard measuring 20x20 cm. The plates are stacked on top of each other until a total thickness of 24 cm is obtained. A hole is drilled in the center of the square plates, a threaded pin is inserted and the plates are tightened tightly on both sides with nuts. The square blank is machined to form a drum with a diameter of 20 cm.

When grooving the roller, a thickening is provided in its central part. In relation to the edges of the drum, the difference should be 3 mm. Due to the thickening, the belt will not move off the rollers. The surface of the wooden drum is covered with rubber. An old bicycle tube will do. Rubber will prevent the belt from slipping on rollers.

To make a sanding belt, cloth-based sandpaper is suitable. You can cut a solid strip of the required length, the edges of which are glued end-to-end. If there is no long strip of sandpaper, cut a strip of durable fabric and sew it into a ring. The sandpaper is cut into rectangles and then glued onto a strip of fabric. When making a sanding belt, it is important to choose high-quality glue so that the sandpaper does not peel off.

Characteristics that a belt for a sanding unit must meet

Selecting an abrasive strip is an important step when assembling a mini-grinder with your own hands. First of all, you need to decide on the length of the tape and its width. The geometric parameters of the strip are influenced by two main factors:

- grinder dimensions;

- purpose of the unit.

Fabric base withstands surface tension better

Endless abrasive strips are also classified into grit types. The length of the sanding strips can be different (from 610 to 1830 mm). Such tapes have a width of 50 or 100 mm. The first option is most often found in units assembled by hand at home.

A high-quality abrasive strip must have an elastic fabric base. When choosing the right tool, you also need to pay attention to how many revolutions the strip can withstand. It is recommended to purchase products that can operate at 1500 rpm. This option is best suited for making a belt grinder with your own hands. The drawing drawn up earlier must contain information about the dimensions of the abrasive strip and its other characteristics.

A good tape must have high abrasive resistance. The wear resistance of the tape depends on this indicator. For homemade machines, it is recommended to use belts whose length is no more than 123 cm. The abrasive strip must not only be resistant to wear, but also have good resistance to high temperatures generated during friction against the workpiece during operation.

It is worth noting that short length tapes are much more susceptible to wear than longer length products. Experts advise paying attention to pictures depicting finished products. Photos of the machines allow us to answer the question of how to make a grinder with your own hands. The design of the device can be significantly simplified if ready-made elements purchased separately are used in its assembly.

The speed and quality of product processing depends on the choice of tape.

And finally, special attention must be paid to the place where the abrasive tape is glued. The junction of the two ends of the strip should be as neat as possible, without any defects or protrusions.

How to glue the tape for the sanding unit yourself

Belt grinders contain a spring, which performs a very important function: it tensions the belt that has sagged due to wear. The belt is changed several times even when processing a small workpiece. This should be remembered.

When assembling a grinder with your own hands from plywood or metal, you can make an abrasive strip yourself. Gluing such tape is a complex undertaking that does not tolerate mistakes. There is a lot of advice on the Internet on how to properly glue tape, but many of them are incorrect.

The gluing process is as follows. First you need to select a fabric-based sanding material. Then you should prepare both ends of the abrasive strip. To do this, they are cleaned. The seam on the strip is made exclusively using the butt method. Experts definitely recommend reinforcing the glued tape from the inside with a thick strip of fabric, which is fixed with a special adhesive composition.

Gluing tape is a complex process that does not tolerate mistakes.

Note! Under no circumstances should you use Moment glue to glue the tape.

In order to connect the ends of the abrasive strip, you need to purchase a special adhesive composition. The best option is to use elastic glue. There is no point in saving money, since cheap products, as a rule, are not of good quality.

Before gluing, it is necessary to prepare a strip for sanding tape. A do-it-yourself grinder (from scrap materials) needs a reliable abrasive strip, which is difficult to do at home. The process is carried out using a glue stick, which is installed on hot-melt guns. First, the composition is heated. To do this, you can use a regular hairdryer, which is found in every home.

Manufacturing of disc grinding machine

The disk machine is considered the easiest to manufacture. The principle of its operation resembles an ordinary electric emery. Assembly of the grinding machine is provided with step-by-step instructions.

- The working disk is cut out of plywood 1.5 cm thick. Two identical blanks are glued together. The result is a disk 3 cm thick. A hole is drilled strictly in the center, the diameter of which is equal to the thickness of the electric motor shaft.

- To assemble the frame, it is better to use an edged board, and the guides and work table are cut out of 1.5 cm thick plywood. Wood is better suited for making the machine than metal. Wood dampens engine vibrations.

- The working disc can be used for grinding and even sharpening. It is important to choose the right abrasive materials. They must be Velcro and fit for their purpose. If you need to grind a product made of stone or granite, stick a “Turtle” diamond wheel onto the working disc.

- To sand a wooden workpiece, glue a circle of sandpaper to the working disk.

- There are similar Velcro circles for metal. This disc can be used to sharpen knives, axes and other tools.

READ Which is Better: Drill Or Hammer?

When designing a disc sander, it is important to consider safety. The rotating working disk is covered with a protective arch on top. An adjustable heel is provided on the work table, which serves as a stop for the workpiece.

The table top of the machine should not be varnished or painted. Over time, an unevenly worn coating will create difficulties in moving the workpiece being processed.

Manufacturing algorithm

Considering that home machines will be interchangeable in terms of the type of processing, and the decisive role will be played by the attachment installed in the drill, we will consider two main options for home-made units - horizontal and vertical.

The procedure for assembling a vertical machine is as follows.

- Cut a square base 50 by 50 cm from a piece of metal or wood, with a thickness of 10 to 20 mm.

- Drill a hole in it exactly in the center at a distance of 1-2 cm from the edge for mounting the stand. The diameter of the stand must be at least 5 cm.

- Install the stand, center it using a level and weld it with a welding electrode. If you are making a wooden machine and the stand will be wooden, then firmly fix it with self-tapping screws.

- Using metal clamps, secure the drill to a movable element that will be put on the stand, forming a lowering/raising spindle.

Place the spring on the strut. Its length must be at least 2/3 of the rack. Having placed the drill on the stand, mark the place where the drill will hit when lowering the spindle. According to this place, cut two through hollows in the frame crosswise. A table is installed in the groove on the threaded pin on which the workpiece will be mounted. A nut is screwed onto the pin from the bottom side; it will fix the table in the desired position.

You can also attach the table to the pin from the outside with a nut, recessing it into the surface of the table so that it does not interfere with the placement of workpieces. It is important that after securing with a nut, the length of the outer part of the pin is flush with the top surface of the table.

The assembly algorithm for a horizontal machine looks like this.

- Cut a rectangular frame - dimensions are determined individually.

- At one edge, secure a seat for a drill with a hollow in the upper part corresponding to the size of the tool.

- Secure the drill to it with a clamp.

- Cut a through groove for the pin along the frame, and install two metal corners along the edges along which the pressure sleeve will move.

- The width of the pressure sleeve must exactly match the distance between the guide angles (runners). A threaded pin is screwed into it from below, which will move in the hollow.

- By moving the sleeve close to the drill chuck, determine the place where the special headstock will be installed for fixing the workpieces.

- Attach the headstock to the bushing with a metal cone-shaped pin placed in the center.

- The sleeve is fixed in the desired position (for clamping the workpiece) with a nut screwed onto the pin from below.

In both options, it is necessary to provide special adjustable legs for the frame.

If the bed rests flat on a workbench or table, it will become impossible to adjust and fix the clamping sleeve on a horizontal machine or the workpiece table on a vertical one.

Making a grinder from a drill

To transform a regular, household electric drill

The grinding machine must be equipped with a special attachment - a working drum or a special support plate, depending on the task at hand.

The support or sanding pad is a plastic or rubber base with sandpaper glued on and a shank for clamping into the drill chuck. Discs with a flexible shaft are suitable for working with a loose drill, while those with a rigid shaft are best used only for a well-secured drill.

Sanding drums for a household drill are structurally a regular cylinder, a shank and sandpaper glued to the cylinder. When using drums, the working surface of the grinder is parallel to the axis of rotation.

Making a belt sander with your own hands

Do

Using a belt sander yourself is not at all difficult, you need to complete the following steps:

- select suitable materials and parts;

- create

a reliable basis for securing the tool; - install a suitable tabletop;

- secure the vertical posts with tensioner and drum;

- mount the motor and drums;

- secure with sanding tape.

To process fairly large parts and elements, it is necessary to make a large copy of a serial grinder. For example, if you take an electric motor with a power of 2 kW or more powerful with a rotor speed of 1500 rpm, then you don’t need to install a gearbox. The power of such an engine is quite enough to rotate a drum about 20 cm in diameter and process parts of about 2 m.

You can also use an electric motor from an old washing machine. In this case, the frame is made from a thick sheet of iron, preparing a place for installing the motor and carefully securing it with bolts to eliminate vibration. The design of such a machine consists of 2 drums, one of which is fixed, and the second can be tensioned and rotates on bearings around an axis. It is advisable to make the base for the machine from metal or several sheets of thick plywood. The drums are made on a lathe from chipboard. The tape is cut from sandpaper sheets about 20 cm wide and secured to the frame. The larger the table size, the larger the parts can be stacked and processed in the future. Drawings of finished products can be found online.

Existing types of grinding machines

The industry produces several types of machines, differing both in design and purpose. Here are the main ones:

- Eccentric or orbital, in this case the base of the tool simultaneously rotates around its axis and along a certain orbit. It turns out that each time it passes in a slightly different place, so scratches and burrs are rubbed out more and more with each pass.

- Vibration model. Here the working sole carries out reciprocating movements with a frequency of about 20,000 movements per minute. It is through these movements that grinding occurs.

- An angle grinder, which is popularly called a “grinder”. Using this tool, rough processing of parts, large logs, etc. is carried out. Abrasive wheels of the required grain size are used for processing.

- Belt sander

, which is usually used for work on large surfaces. Structurally, it consists of rollers driven by an electric motor, on which sanding tape is worn.

Safety precautions when working on a sanding grinder

Like any other work on any other machines, grinding on a homemade belt sanding machine is subject to fairly strict safety rules that must be strictly adhered to.

The principle of operation of the grinder.

These rules are as follows:

- It is strictly forbidden to touch anything that moves with your hands while the machine and working surface are operating.

- Wear safety glasses while working to protect against hot abrasive particles.

- Carefully check that the connections and fastenings of all moving parts of the grinder are tight.

- Monitor the condition of the braiding of electrical wires.

- A protective casing is a must, even though it slightly narrows the viewing angle.