The service life of a pipeline is determined by the rate of corrosion. Destruction due to corrosive wear of utility networks entails financial losses and poses a threat to the environment, labor safety, and deteriorates the quality of the transported product. Critical elements of systems are susceptible to corrosion: control and shut-off devices.

The causes of pipeline corrosion are external and internal. The following types of negative impacts are considered environmental factors:

- Atmospheric;

- Soil-ground;

- Biocorrosion;

- Stray currents;

- Induced alternating currents.

Internal corrosion is caused by the chemical properties of the transferred substances, airing, and dynamic loads. The formation of sediment accelerates the process of changing the structure of the metal.

Corrosive destruction of equipment costs billions of rubles annually: inefficient operation, reduction in transported volumes, repair and maintenance costs, accidents. Pipeline corrosion control is carried out based on the standards of the Unified System of Protection against Corrosion and Aging (USZKS). The main regulatory document for underground structures is GOST 9.602-2016.

Types of pipeline corrosion

Iron reacts actively with oxygen only at a temperature of +260 Co. Such ranges are not supported in main lines, but an oxidative reaction can be triggered by moisture condensation in the insulating layer and microcracks of welds. This damage occurs when installation technologies are not followed and the service life is long.

Highways are characterized by electrochemical destruction mechanisms. In the chemical type, the metal interacts with the oxidizing agent without access to moisture. With electrochemical, moisture is present, and water, with salts dissolved in it, serves as an electrolyte.

It is customary to distinguish between two types of corrosion damage:

- General: distributed evenly, calculated during design;

- Local: appear under the influence of the active environment and tensile loads.

Types of local destruction:

- Ulcerative: grooves on the outside, usually shallow in depth.

- Pitting: point lesions with great depth;

- Slotted: appear in the connecting gaps of parts, develop quickly;

- Cracks: grow slowly until they reach a critical value, then quickly lead to an accident.

For oil and gas industry lines, microbial contamination poses an additional threat. The most dangerous are sulfate-reducing bacteria that produce sulfates, sulfites and large amounts of hydrogen sulfide. The formation of biofilms leads to peeling of protective coatings.

Pipeline corrosion - causes and consequences. Part 1. Main pipelines

Pipeline transport is the most common method of delivering liquid and gaseous media in the world. Small internal pipelines are present in every modern home; networks of above-ground and underground distribution pipelines have been built in populated areas; all regions of our country are connected by a system of main pipeline transport. Pipelines transport water, oil and petroleum products, gas, etc. Our country even built a unique ammonia transport pipeline. The majority of domestic pipelines in use are metal, the main reason for their destruction is corrosion, and there are many types of corrosion. In this review, we will briefly look at the main types of pipeline corrosion depending on their purpose, and also talk a little about the consequences of corrosion accidents.

The causes of corrosion are always determined by the properties of the corrosive environment with which the internal and external surfaces of the pipeline come into contact. Corrosion of the internal surface of pipelines occurs mainly when pumping aqueous media, especially if corrosive substances are dissolved in them: salts, acids, alkalis, etc. This situation occurs in all water pipelines, in particular in heating and hot water supply systems, oil collection systems (remember that in the Russian Federation, oil extracted from wells contains up to 99% water!), and wastewater from industrial enterprises. The most dangerous last case. Corrosion of the outer surface depends on the method of laying the pipeline and the design solutions used. For example, when laying using the “pipe-in-pipe” method, corrosion of the outer surface does not occur. When laying a pipeline in air, atmospheric corrosion occurs, which practically does not lead to a violation of the integrity of the pipeline (the formation of through defects). We have already devoted a separate review , so we will not return to this issue in this article. The main danger of corrosion destruction of the outer surface of pipelines occurs during underground installation, and the purpose of the pipeline in this case is not very important. With few exceptions, all types of underground pipelines corrode equally. A separate issue is underwater corrosion of pipelines laid along the bottom without being buried in the ground. True, this very specific type of corrosion concerns only a few objects in the Russian Federation - offshore gas pipelines, for example, Blue Stream and Nord Stream, as well as several field pipelines in the Caspian, Black and Northern seas. Due to the extremely narrow circle of interested parties and the specificity of the processes, marine corrosion of the outer surface of pipelines will also not be addressed in this review.

So here we go. In this review, divided into several parts, we will separately and in detail consider the possible corrosion mechanisms of the following types of pipelines, classified according to their functional purpose:

- main pipelines;

- field pipelines of oil and gas fields;

- pipelines of heating systems, hot and cold water supply;

- industrial waste water pipelines.

Let's start with, perhaps, the most simple objects from a corrosion point of view - main pipelines for transporting oil, gas, ammonia, petroleum products, etc.

Corrosion of main pipelines

Perhaps this is the most well studied and systematized type of pipeline corrosion. At least, main pipelines are the only type of pipelines whose corrosion protection is regulated by a separate national standard GOST R 51164-98* “Main steel pipelines. General requirements for corrosion protection." Of course, GOST R 51164-98* is mainly devoted to methods of anti-corrosion protection, and not to mechanisms of corrosion destruction, however, upon careful study it is possible to identify a certain systematization of the danger of corrosion of main pipelines depending on its mechanism. It should be immediately noted that main pipelines are used for transporting prepared corrosive-inert products, therefore only external corrosion poses a danger to them, and in areas of overhead installation only relatively harmless atmospheric corrosion

. Further, our review will focus only on sections of underground main pipelines.

So, GOST identifies 3 types of sections of main pipelines that are subject to special corrosion hazards: areas of high corrosion hazard, areas of increased corrosion hazard and corrosion-hazardous areas. Among the GOST criteria relating to corrosion mechanisms and allowing some sections of pipelines to be classified as particularly dangerous areas, the following criteria for areas of increased corrosion hazard can be identified:

- stray currents from direct current sources;

- microbiological corrosion;

- stress corrosion cracking.

Additionally, GOST classifies as areas of increased corrosion hazard the areas where main pipelines are laid, where the risk of ordinary soil corrosion can sharply increase:

- pipeline sections in saline soils of any region of the country (salt soils, solonetzes, solods, sors, etc.);

- sections of pipelines in areas of industrial and domestic wastewater, garbage and slag dumps;

- sections of pipelines with the temperature of the transported product above 303 K (30 °C).

Summarizing the above, as well as many years of experience in operation and diagnostics, we can summarize that the following types of corrosion destruction are mainly realized on underground main pipelines:

- soil electrochemical corrosion;

- corrosion by stray currents from direct current sources;

- corrosion by stray currents from alternating current sources (in areas of intersections and, less often, approaches to overhead lines of 110 kV and above);

- stress corrosion cracking (typical mainly of main gas pipelines);

- microbiological corrosion (in areas where the soil around the pipeline is contaminated with microorganisms).

Soil electrochemical corrosion

Corrosion of underground pipelines proceeds through an electrochemical mechanism, based on the occurrence of a potential difference between different sections of the pipeline, and, as a consequence, the occurrence of a corrosion current. As a result of the flow of corrosion current, sections of metal in the anodic zones dissolve and pass into the soil, where they subsequently interact with the soil electrolyte, forming rust.

Mechanism of electrochemical corrosion

One of the most important features of pipelines from a corrosion point of view is their large length. Given their great length, underground lines pass through soils of different composition and structure, different humidity and aeration. All this creates the possibility of significant potential differences occurring between individual parts of the underground line. Since pipelines have high conductivity, corrosive galvanic couples are easily formed on them, sometimes extending for tens or even hundreds of meters.

Since this often creates high current densities in the anodic areas, this greatly increases the corrosion rate. It is also important for the development of corrosion that underground lines are laid at such a depth where some moisture is always retained, ensuring the occurrence of corrosion processes. At the depth of pipelines, the temperature rarely drops below 00C and this also promotes corrosion. The development of corrosion on underground pipelines is also facilitated by the presence of mill scale on the surface of the pipes, which is not always removed during cleaning.

It was established that there is a direct relationship between the area exposed to corrosion and the depth of corrosion destruction. This is explained by the fact that on a larger metal surface there is a greater possibility of creating more severe corrosive conditions. In particular, this explains that other steel underground structures, in addition to pipelines, ceteris paribus, are destroyed by electrochemical corrosion more slowly.

The corrosive aggressiveness of the soils themselves is determined by their structure, granulometric composition, electrical resistivity, humidity, air permeability, pH, etc. Typically, the corrosive aggressiveness of the soil in relation to carbon steels is assessed by the electrical resistivity of the soil, the average density of the cathode current when the electrode potential is shifted by 100 mV more negative than the corrosion potential of steel, the gradient of natural free corrosion potentials along the pipeline section.

Corrosion by stray currents from DC sources

Stray currents are currents of anthropogenic origin that flow in the ground and in underground metal structures. Such currents arise due to leakage into the ground of the currents of operated devices and structures operating on direct current, in particular direct current railways, electric welding machines, cathodic protection systems of third-party objects, etc., etc. As is known, electric current always tends to move along the path of least resistance, therefore, if there are long underground metal pipelines in the distribution zone of stray currents in the ground, the electrical conductivity of which is several times greater than the electrical conductivity of the soil, the stray current will flow precisely through them. In the most favorable place (from the point of view of the same principle of least resistance), the stray current will flow from the pipeline back into the ground and return to its source. In this case, the section of the pipeline from which the stray current enters the ground is the anode, and the part of the pipeline where the stray current enters it is the cathode. In the anode sections, stray currents of increased density cause significant corrosion damage to pipelines; the corrosion rate on them is practically unlimited and can reach gigantic values of 10-20 mm/year.

Corrosion by stray currents from AC sources

This type of corrosion occurs in places where overhead lines with a voltage of 110 kV and higher and main pipelines come together and run in parallel. This phenomenon has already been covered in detail on our website in a special review.

and will not be considered further in this article.

Stress corrosion cracking (SCC) or stress corrosion

Stress corrosion cracking in main pipelines (mainly gas pipelines) develops as a result of simultaneous exposure of the metal to a corrosive environment and tensile stresses. Thanks to the research carried out, a hydrogen-corrosion theory of the development of SCC in pipelines has now been formed.

The formation and development of microcracks in metal occurs as a result of hydrogenation of pipe steel in places of dislocations and vacancies of the crystal lattice and an increase in internal pressure in them to values exceeding the equivalent binding energy of lattice atoms. Hydrogenation itself occurs as a result of the ongoing processes of diffusion of protons (H+), formed as a result of the hydrolysis of water at increased cathodic protection potentials, the dissociation of a number of inorganic compounds, such as bicarbonates, hydrosulfides and sulfides, nitrates, ammonates, phosphates, etc., and the vital activity of sulfate-reducing organisms .

After cracks open on the surface of the pipe in places where the insulating coating of the pipeline is damaged, crack formation accelerates due to the corrosive effect of the soil electrolyte penetrating into the cracks.

The final stage of destruction (including the extent of cracks) is controlled by the conditions of mechanical load on the pipeline, the stress-strain state of the pipe steel, as well as its strength characteristics.

Microbiological corrosion

Microbiological corrosion (or biocorrosion) is metal corrosion that occurs as a result of the activity of microorganisms. Soils and natural surface waters contain a huge number of microorganisms - bacteria, fungi, algae, protozoa, etc. It has now been established that in most cases, metal corrosion is initiated by bacteria due to their high rate of reproduction and activity in chemical transformations of the environment. For the process of microbiological corrosion to occur, the bacteria that cause it must be in a moist or aqueous environment; they also need nitrogen, mineral salts and a number of other elements. It is necessary to have certain external conditions under which they begin to actively multiply near the pipeline, such as:

- temperature;

- pressure;

- illumination;

- hydrogen ion concentration;

- oxygen concentration.

Microorganisms can cause corrosion by producing substances that cause corrosion (for example, acids), creating conditions on the metal surface that cause the appearance of a potential difference on the metal surface and the formation of additional anodic and cathodic zones, with the further occurrence of the corrosion process according to the electrochemical mechanism.

In the case of main pipelines, the most common microbiological corrosion is initiated by sulfate-reducing bacteria. Under the influence of these bacteria, individual cavities form on the pipes. Corrosion products are black in color and smell of hydrogen sulfide. They contain about 40% ferrous iron and 5% sulfur in the form of sulfides. Sulfate-reducing bacteria are present in almost all soils, but significant corrosion occurs only when relatively large numbers of them are present.

So, in this article we briefly outlined the types and mechanisms of corrosion of main pipelines. Read the continuation of the topic dedicated to plumbing systems here .

Protection of main pipelines from corrosion

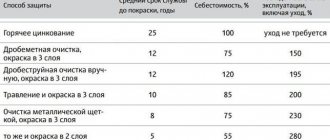

To increase the service life of highway elements, a set of measures is provided that corresponds to various types of negative impacts. During installation, drainage is provided and connections are insulated depending on the grade of steel. Active methods of protecting pipelines from corrosion are constantly being developed: reducing the aggressiveness of the environment, treating gas and oil pipelines with bactericides, and introducing inhibitor substances.

Protective coatings for pipelines against corrosion play an important role. Treatment with chemical compounds reduces the electrochemical effect and prevents the formation of point processes in microcracks. In addition, the internal surface and reinforcement remain smooth and prevent the formation of sediment. Industrial industry standards regulate the properties of coatings depending on the characteristics of the transported medium.

Types of protection

The following methods are used to clean damaged surfaces:

- stray current;

- cleaning the walls;

- purification of liquids with special substances;

- anodic;

- cathode.

All methods of cleaning heating pipelines are based on the general principle of treating metal with special substances and mixtures. As a result of their influence, a strong protective film appears on the surface of the structure.

Liquid handling

Cleaning pipelines from the inside from destruction is a rather complex technical process.

Corrosion on the inner walls of pipes occurs as a result of exposure to the constituent elements of the flowing liquid - carbonate, bicarbonate and oxygen.

The goal of cleaning interior walls is to transform the liquid from an aggressive to a weakly reactive medium.

The process is to add baking soda, calcium or sodium carbonate to the liquid itself.

Sometimes polyphosphates are used if water passes through individual points of the pipe.

To protect galvanized pipes, it is enough to use phosphates, silicates and polycarbonates. As a result of this finishing, a protective film appears on the pipe walls.

Wall treatment

The walls of the pipe must be finished from the outside and inside.

Thanks to galvanization, a protective film appears on the inner and outer surfaces, penetrates deeply into the metal layer and preserves the material for many years.

To protect against damage, a method of applying metal to metal is suitable, for example, zinc, which does not lend itself to rust. In addition to zinc, it is also effective to apply paintwork materials and enamel.

The most popular way to protect a metal exterior from rust is galvanizing or applying magnesium to the material.

Stray current

To combat damage to metal surfaces through which current passes, it is necessary to carry out electrical drainage.

In the case of electrolysis (the passage of electric current from the cathode to the anode), the walls of the material react and can destroy the metallic exterior, which contributes to the occurrence of corrosion.

Induced current

Cathodic protection is based on the supply of constant electrical voltage, which prevents the protective film of the metal from being destroyed.

To do this you will need a low resistance electrical cable, well insulated.

In this case, the pipeline acts as a cathode, which means safety from damage.

General provisions

Corrosion processes are the oxidation of a metal, in which its atoms change from a free state, losing their electrons, to an ionic state . An underground pipeline is subject to two types of corrosion, the nature of which is worth understanding before starting to deal with them. Therefore, I will pay a little attention to their description:

Soil

Diagram showing the effects of soil corrosion on a metal pipeline

As you probably guessed from the name and the accompanying diagram, soil corrosion occurs due to contact of steel with soil. In turn, it is divided into the following subspecies:

- Chemical _ Appears as a result of exposure to iron by gases and non-electrolytes of the liquid type. It is noteworthy that with it the material is destroyed evenly, and the formation of through holes is almost impossible, which makes this type of corrosion process the least dangerous for a highway laid underground;

- Electrochemical . The metal acts as an electrode, and groundwater, of which there is an incredible amount in our climate zone, acts as an electrolyte. The ongoing process is very similar to the work of a galvanic couple and provokes the destruction of point areas on the surface of the pipes, which ultimately leads to their emergency condition;

The result of damage to the wall of a steel pipe by electromechanical corrosion

- Electric . It occurs due to the impact of stray currents on steel, which can “drain” from rails, substations and other electrified devices that fill modern cities. It is the most dangerous and destructive corrosion process.

We recommend: 16 ways to get rid of mold in an apartment or house

Internal corrosion

Diagram showing the effects of internal corrosion on a metal pipeline

If the transported liquid has a low hydrogen index, but its content of oxygen, sulfates and chlorides, on the contrary, is high, then internal corrosion processes cannot be avoided, as a result of which:

- The level of roughness of the inner surface of the wall increases , which leads to a decrease in water permeability;

The inside of the pipeline becomes rougher due to the effects of internal corrosion

- The quality of the transported liquid deteriorates as rust gets into it;

- Over time, a through hole may appear , which can cause a pipeline rupture.

2.1. Causes of corrosion on the outer surface of metal

2.1.1. Corrosion of the outer surface of the metal of pipelines occurs when moisture is present directly on the surface of the metal. The intensity of this corrosion is determined by the following:

temperature (the corrosion rate increases with increasing temperature to 70 - 80 ° C);

composition of insulating materials, including thermal insulation;

presence of stray currents*;

salt composition, total acidity, alkalinity, pH value of soil-ground electrolyte and composition of soil-ground air*;

specific electrical resistivity of soils and soils*

* These factors play a significant role in ductless installation of heat pipelines, as well as in areas of duct installation prone to flooding or silting.

the level of local mechanical stresses in the metal;

participation of microorganisms (biocorrosion).

2.1.2. The most dangerous is corrosion by stray currents (electrocorrosion), which occurs in the case of a positive or alternating potential difference between the heating network pipeline and the ground. Sources of stray currents are:

rails of DC-electrified trams, railways, subways, and mine transport;

anodic grounding of electrochemical protection installations on adjacent underground structures;

pipelines with electrochemical protection;

grounding of DC power lines using the “wire-ground” system;

galvanic baths and welding installations with current leakage into the ground;

electrical interference from power cables when laying communications in a common manifold.

3.3. Typical cases of internal surface corrosion

In connection with the localization of internal surface corrosion, typical cases of its manifestation can be identified.

3.3.1. Ulcers or fistulas on pipelines (Figure 4), not associated with construction and installation work during new construction and repairs, the occurrence of which is determined by the heterogeneity of oxide films on the metal and the metal itself.

3.3.2. Corrosion in the slot of technological lack of penetration of the weld. Basically, lack of penetration occurs at installation joints, but sometimes also on straight-seam pipes of small diameter (DN = 150 mm) in factory joints made by contact welding.

Figure 6 — View of the pipeline wall during the formation of a fistula from internal corrosion and the subsequent development of external corrosion

- fistula

- humidification zone

3.3.3 Corrosion pits and grooves in the heat-affected zone of factory and installation welds (Figure 7). This is due to the formation of an iron oxide film on the metal surface near the seam, which has a structure different from the film on the rest of the surface.

3.3.4 Corrosion pits and grooves on the lower generatrix of the pipe (Figure 8). Associated with sludge corrosion due to high aggressiveness of supply water.

3.3.5 Corrosive destruction of the metal of repair patches in conical transitions from one diameter to another made on the installation site. Corrosion is associated with differences in the composition of the carbon steels used and mechanical stresses.

3.3.6 Corrosion pits and grooves in the place where the supports are welded to the pipe (Figure 9). Corrosion is associated with heating of the inner surface of the pipe metal during welding of supports and high mechanical stresses.

3.3.7 Complete destruction in the form of a field of ulcers merging with one another. It is typical for places with low fluid velocity (bypasses, bends, fittings), and sometimes also for the head sections of main pipelines.

Figure 7 — Groove in the metal from internal corrosion near the factory seam

Figure 8 — View of the corrosion groove along the lower generatrix of the pipeline DN = 1000 mm

Figure 9 — Destruction of the pipe metal from internal corrosion at the welding site of the support (pipe DN = 200 mm)

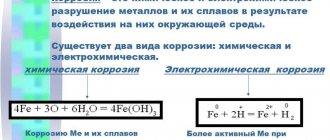

Chemical corrosion

Chemical corrosion is possible due to the thermodynamic instability of metals. Gas corrosion, having its own definition, is a type of chemical corrosion. The latter have the ability to independently transform into a much more stable state at the end of the reaction: metal + oxidizing agent → reaction product.

The most common example of chemical corrosion of a metal is a reaction with oxygen:

Me+0.5O2→MeO

4Fe+3O2→2Fe2O3

Decarburization of steel as gas corrosion:

Fe3C+2H2→3FeCH4